Perfectly right. Perfectly flexible. FPSO with KSB

advertisement

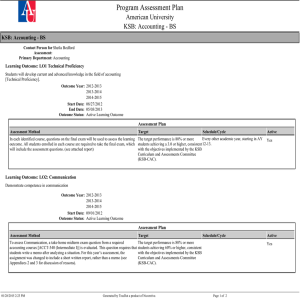

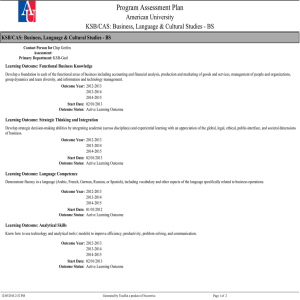

Our technology. Your success. Pumps Valves Service n n Perfectly right. Perfectly flexible. FPSO with KSB 02 Introduction Quality, reliability and safety combined – FPSO with KSB products For the demanding FPSO applications, KSB has a unique range of products and services on offer, which ensure maximum safety and reliability. Our holistic solutions and expertise from years of working in this field allow us to provide high-quality and comprehensive equipment for FPSO applications. KSB products used in FPSO need to function even under the toughest conditions typically found in the rough environment of these production vessels. KSB tackles the related challenges with technically mature products designed to the respective standards. Your benefits at a glance: In addition, KSB offers mechanical seals which ensure smooth interaction of the seal and API pump. With our comprehensive ■■ range of services, we support you during the products' entire life cycle. Special expertise is required to provide services on oil ships, equipping FPSO units ■■ so KSB Service staff undergo demanding training and obtain all certificates required for these challenging applications. We can also trust in pumps, valves and seals from the same manufacturer, or simply trust in KSB. Profound knowledge of the related requirements ■■ rely on a worldwide service network to be on your site quickly. When it comes to FPSO applications, trust in a reliable partner, Many years of experience with Solutions for the most demanding of challenges ■■ Pumps, valves, seals and service from a single source Service 03 Always there for you: KSB Service When it comes to maintain maximum ■■ With more than 2,600 service specialists in 160 service centres worldwide plant availability and safety as well as ■■ Spare parts for all brands and pump types reliability, our customer service is there ■■ More than 350,000 orders per year for you: ■■ Service throughout the life cycle, from A to Z Retrofits: good can be made Efficient, affordable and No compromises: even better SCCP-certified KSB original spare parts New framework conditions do With unique manufacturer know- With KSB original spare parts not always require new pumps how, knowledge of specific you‘re on the safe side as regards or new valves: KSB retrofit is regulations and ongoing training, the usual operating reliability of the alternative to buying a new our employees are perfectly your pumps and valves. product and comprises measures equipped to carry out all agreed for hydraulic and mechanical jobs on your pumps and valves. modifications or changes to the materials. 04 FPSO applications The flexible comprehensive range for all FPSO applications KSB offers the best solution for any FPSO application. See for yourself: the table gives an overview of KSB‘s products and the different applications in which they can be employed. Fluids containing abrasive solids, corrosive, explosive and viscous liquids, high pressures, extreme temperatures and rough climate: such conditions call for flexible products that reliably and safely deliver high performance. API pumps, valves and seals by KSB have proven for decades what they are capable of on offshore platforms, in refineries and similarly exacting surroundings. Process circuit Fire fighting Seawater lifting Injection Seawater transport Process water Auxiliary pumps, non-API Cooling water circuit Ballast Water Treatment Crude oil Drainage 05 Application Description Products Injection KSB pumps deliver a maximum pressure of 400 bar for water injection. KSB pumps and valves with super duplex casing, short delivery period (less than 50 weeks): CHTR (API-BB5), TRIODIS, DANAÏS, ECOLINE GTL, IVC Process Water For process water transport and treatment. RPH, RPHb, RPH V, TRIODIS, DANAÏS, ISORIA, ECOLINE GTL, IVC Process circuit For the safe, reliable and efficient transport of well liquid to separation and contemporary storage units. RPH (API-OH2), RPHb (API-BB2), YNKR (API-BB2), RPH-V (API-VS4), WKTR (API-VS6), API-685 series (API-OH3), TRIODIS, DANAÏS, ECOLINE GTL/GLT, IVC Crude oil For the transport and treatment of crude oil, KSB offers pumps with high flow rates and favourable consumption rates. CHTR (API-BB5), RPH (API-OH2), RPHb (API-BB2), UPA, UPV, B series (4-pole), TRIODIS, DANAÏS, ECOLINE GTL/GLT, IVC Cooling water circuit Where large amounts of cooling water need to be moved in the most diverse of applications, e.g. process water treatment and power generation. RPH (API-OH2), MegaCPK (ISO-5199), RDLO (non-API), DANAÏS, ISORIA, ECOLINE GTL/GLT, IVC Seawater transport For transporting seawater, KSB offers reliable pumps with duplex or super duplex casings for maximum corrosion resistance, and submersible borehole pumps. Optional hypochlorite injection system mounted outside to prevent biofouling. RDL/RDL-V, RDL O/RDL O-V (non-API), Omega/Omega V, submersible motor pumps, DANAÏS, ISORIA, ECOLINE GTL/GLT, IVC Drainage For draining caissons and headers, KSB has available particularly space-saving pumps to API standard. RPH-V (API-VS4) and UPA (non-API), DANAÏS, ECOLINE GTL, IVC Fire fighting Safety and reliability are a top priority: in addition to special fire-fighting water pumps, that can even be submersible, KSB offers complete fire­fighting systems to different country-specific standards with autonomous power supply. CPK / Megachem / MegaCPK (ISO-5199), RDL/RDL-V, RDL O/RDL O-V (Non-API), Omega/Omega V, submersible motor pumps, KSB ITUR to NFPA20, DANAÏS, ISORIA, BOAX-B, ECOLINE GTL/GLT, IVC Seawater lifting Lifting of untreated seawater for further processing. Submersible motor pumps and valves, UPA, UPV, B series (4-pole), DANAÏS, ISORIA, ECOLINE GTL/GLT, IVC Ballast Water Treatment An environment-friendly, flexible method for an energy-efficient ballast water treatment. A combination of filtration and low pressure ultraviolet radiation removes particles and microorganisms efficiently from ballast water. ISORIA, Actuators & Systems Auxiliary pumps, non-API But KSB not only has products for safety- and security-related applications. Our range also includes pumps for different auxiliary processes, e.g. boiler feed packages, optimally matched to every individual application. MegaCPK, RDLO, TRIODIS, DANAÏS, ECOLINE GTL/GLT, IVC KSB products got the type approval of the major classified societies such as BV, LR, DNV, ABS, KR, NK 06 Pumps / Mechanical seals KSB API pumps for hydrocarbon production and non-API pumps for auxiliary processes KSB manufactures, installs and maintains all pumps applying also offers safe, proven and flexible solutions for nearly all high flexibility, short delivery periods and fast service. The pumps other applications where liquids need to be pumped, transported cover all FPSO applications and can be used offshore for the and distributed on FPSO platforms – from pumps to complete production, storage and loading of crude oil. What is more: KSB fire-fighting systems. CHTR RPH® RPHb BB5 high-pressure pump to API 610 OH2 process pump to API 610 BB2 process pump to API 610 Horizontal high-pressure barrel-type pumps with radial impellers, single-entry and double-entry, multistage, with flanges or weld end nozzles to DIN, API 610, type BB5, and ANSI Horizontal radially split volute casing pump in back pull-out design, to API 610, type OH2, ISO 13709 (heavy-duty), with radial impeller, single-entry, single-stage, centreline pump feet; with inducer, if required. ATEX-compliant version available Horizontal radially split volute casing pump to API 610, and/or VDMA 24 297, type BB2, class A (heavy-duty), with radial impeller, single-entry, two-stage, back-to-back impeller arrangement, centreline pump feet For handling the large variety of crude oil products in refineries as well as in the chemical and petrochemical industries For use in FPSO, refineries, as well as the petrochemical and chemical industries For use in FPSO, refineries and the petrochemical industry DN Q [m3/h] H [m] p [bar] T [°C] 50 – 300 1450 max. 4000 max. 400 max. – 60 to + 450 DN Q [m3/h] H [m] p [bar] T [°C] 25 – 400 4150 max. 270 max. 110 max. – 70 to + 450 DN Q [m3/h] H [m] p [bar] T [°C] 80 – 200 790 max. 430 max. 100 max. – 80 to + 450 YNKR RPH-V BB2 process pump to API 610 VS4 process pump to API 610 Horizontal radially split, single-stage, double-entry pump with single or double cast steel volute casing to API 610 Horizontal radially split submersible pump in back pull-out design to API 610, type VS4, and/or VDMA 24 297, class A (heavy-duty), with radial impeller, single-entry, two-stage, back-to-back impeller arrangement, centreline pump feet For use in FPSO, refineries, in the petrochemical industry and steam generation DN Q [m3/h] H [m] p [bar] T [°C] 250 and 350 3800 max. 390 max. 60 max. + 400 max. Other values on request All data for 50 Hz operation For use in FPSO, refineries, the petrochemical and chemical industries, or as sump and tank pump DN Q [m3/h] H [m] p [bar] T [°C] 25 – 80 110 max. 170 max. 35 max. – 30 to + 230 max. 07 WKTR MegaCPK API-685 series* VS6 heavy duty process pump to API 610 Standardised chemical pump with two bearing bracket variants (Nikkiso-KSB)* refinery pumps Vertical can-type, ring section multistage pump with radial single entry impellers and first stage suction impeller. ATEX compliant version available. For handling of condensate and similar NPSH critical products in FPSO and other industrial applications, particularly refineries and petrochemical plants. DN Q [m3/h] H [m] p [bar] T [°C] 40 – 150 400 max. 500 max. 50 max. – 45 to + 200 Horizontal radially split volute casing pump in back pull-out design, with radial impeller, single-entry, single-stage, to ISO 2858 / ISO 5199; also available as a variant with wet shaft and conical seal chamber. ATEX-compliant version available Horizontal or vertical canned motor pump to API 685, single-stage, with centreline pump feet; with inducer, if required For use in FPSO, for handling aggressive liquids in the chemical and petrochemical industries, and in refineries Applications: HNP: for clean liquids HTP: for hot fluids HSP / HMP: for contaminated or polymerising fluids HRP: for liquids with steep vapour pressure curve, e.g. liquefied gases DN Q [m3/h] H [m] p [bar] T [°C] DN Q [m3/h] H [m] p [bar] T [°C] 25 – 250 1160 max. 162 max. 25 max. + 400 max. 40 – 150 360 max. 220 max. 40 max. +450 max. *Only available in Europe, Russia, the Middle East and Africa RDLO UPA, B series (4-pole) Axially split volute casing pump DN 350-700 UPA, B series (4-pole), submersible borehole pump Single-stage axially split volute casing pump for horizontal or vertical installation, with double-entry radial impeller, mating flanges to DIN, EN or ASME Single-stage or multistage single-entry centrifugal pump in ring-section design for vertical or horizontal installation. Optionally available with lift check valve or connection branch For use in FPSO for handling water with low solids content, e.g. in irrigation and drainage pumping stations, in desalination plants for extraction, in power stations, fire-fighting systems, and shipbuilding DN Q [m3/h] H [m] p [bar] T [°C] 350 – 700 10000 max. 240 max. 25 max. + 80 max. Other values on request 4KSBM6S AND 4KSBM6 – Mechanical Seals acc. API 682 Pressure Temperature Diameter Speed All data for 50 Hz operation Up to 42 bar –10 to 176° C Up to 110 mm Up to 23 m/s For use in FPSO, for handling clean or slightly contaminated water in general water supply, and in pressure booster, fire-fighting and emergency water supply systems, etc. DN Q [m3/h] H [m] p [bar] T [°C] 200 – 450 2800 max. 480 max. 57 max. + 50 max. 08 Valves KSB API valves for FPSO applications From a single source: KSB valves to API standards are perfectly matched to KSB‘s pumps and their respective application. They are easy to install, very maintenance-friendly, and feature a robust, highly wear-resistant design. ISORIA Centred-disc butterfly valve Tight shut-off for virtually every fluid. Our extensive range of materials for this butterfly valve reflects the multitude of fluids to be handled: a large number of disc materials and elastomer liners make for increased corrosion and wear resistance, resulting in optimum adaptation of the material combination to the fluid. The valve can be combined with manual, pneumatic, hydraulic and electric actuators – with safety function, too. Material: cast steel, nodular and grey cast iron, stainless steel,aluminium bronze, hard rubber coating, Halar® coating. Large elastomers variet DN 32 to 1000 p [bar] Up to 25 T [°C] – 10 to + 200 DANAÏS 150 & 300 Double-offset butterfly valve High performance butterfly valves by KSB. Our AMRI valve types DANAÏS satisfies the most exacting demands in terms of safety, service life and tight shut-off in both flow directions. This space-saving butterfly valve delivers excellent performance in everyday operation. Extremely reliable for all requirements of modern industrial plants. Very low weight, simple installation, extremely service-friendly. Long service life. Fire-safe and and fugitives emissions tested and approved. Material: Aluminium Bronze, Carbon steel, Stainless steel, Duplex, Hastelloy Flanges, Lug, Wafer as standard and butt weld ends DN 50 to 1200 p [bar] Up to 50 T [°C] – 200 to + 420 TRIODIS Triple-offset butterfly valve TRIODIS is a bidirectional high-performance maintenance free butterfly valve with triple-offset technology for high-pressure (up to 100 bar) and severe applications. Extremely reliable with high shut-off performance, TRIODIS is suitable for highly demanding applications and continious operations . Wide range of body types. Large number of body and disc materials. Fire-safe and fugitives emissions tested and approved. Material: carbon steel and stainless steel, flanges, wafer, and butt weld ends DN 150 to 1500 p [bar] 150 max. T [°C] – 196 to + 500 09 SICCA ANSI high-pressure valves High Pressure Gate, Globe and Check Valve SICCA gate, globe and non-return valves are made of cast or forged steel to API 602, ASME B16.34 and BS 5352. With socket weld or threaded ends, external thread rotating stem. Bolted cover (Class 800) or welded cover (Class 1500 and 2500). Material: Cast steel, stainless steel DN p [bar] T [°C] 1/2“ to 24“ Class 800 to 2500 0 to + 593 SISTO Diaphragm Valves An optimized long-term operation with a Position indicator with integrated stem protection to prevent ingress of contamination. A low maintenance design as all moving parts are located outside the fluid. An absolutely reliable sealing to atmosphere as the diaphragm provides hermetic sealing and a perfectly tight shut-off. Material: grey cast iron, nodular cast iron, stainless steel DN – 20 to 200 T [°C] – 30 to + 160 DIN PN16, ISO PN20 Eco Line ANSI low-pressure valves 2-piece ball valve Gate and globe valves, strainers and non-return valves to API 600, ASME B16.34 and BS. High wear allowance on the sealing surfaces for high wear and corrosion resistance. The stainless steel/graphite gasket is fully confined to provide maximum sealing to atmosphere. The valve is available in a wide range of materials and variants. Material: Various steels and stainless steels DN p [bar] T [°C] 2“ – 36“ Class 150, 300, 600, 800 – 29 to + 593 IVC VET Trunnion Ball Valves API 6D, ASME B16,5 / B16.10 / B16.25 Material: Various steels and stainless steels DN 2“ – 48“ p [bar] Class 150 and 2500 T [°C] – 101 to + 600 Hydraulic actuators 10 KSB Actuators MR - Manual gearbox For the actuation of any kind of ¼ turn valves. Ductile iron casing, cover and hand wheel - Standardized force: operating force according to EN 12570 standard - Factory lubricated for life = No maintenance Equipped with Adjustable end stops in open and close position - Worm wheel kinematics non-reversible in any position equipped with interchangeable insert. Can be used with extension and cardan join or motorized with electric actuators. T [°C] Output Torque [Nm] Enclosure Flange – 50 to + 80 Up to 16000 IP68 ISO5211 Hydraulic actuators (double-acting and single acting with mechanical springs) Designed for the operation of any type of 1/4 turn valve, Hydraulic actuators offer output torque values up to 32 000 N.m at max. working pressure 160 bar (16MPa). The range consist in 3 kinematics; ■■ ■■ ■■ Rack and pinion kinematics Scotch yoke kinematics Yoke slide kinematics The rack and pinion kinematics of actuators offers the following advantages; ■■ ■■ ■■ ■■ ■■ Accurate and reliable operation Constant output torque High performances with minimum overall dimensions Reliable, long life performance Suitable for submerged service The yoke slide kinematics offers an extra additional torque during the stroke to cover potential hydrodynamic torque from the valve T [°C] – 50 to + 120 Output Torque [Nm] Up to 32500 p [bar] Up to 160 ENNACTO Single-acting hydraulic actuator with gas cartridge Patented AMRI yoke kinematics from 2000 Nm which offer an extra additional torque during the stroke to cover potential hydrodynamic torque from the valve. Equipped with adjustable end stops for precise valve position adjustment (open & close). Valve monitoring with any kind of signalization box thanks to VDI/VDE 3845 top plate interface. Compact design single acting actuator as Gas cartridge reduces considerably the dimensions compare to spring. Highly reliable single acting actuator for ESD system. Easy maintenance thanks to integrated manometer. Manual emergency control thanks to hydraulic quick coupling for manual and hand pump. T [°C] – 20 to + 65 Output Torque [Nm] Up to 125000 p [bar] Up to 120 Enclosure IP68 Flange ISO5211 AMTROBOX R, HEAVY-DUTY SIGNALIZATION BOX A compact and robust signalization box designed for harsh environment made of Grey Iron with cataphoresis and black epoxy painting. Position indication can be made through limit switches / proximity detector or / feed-back 4-20 mA. Double Sealed Protection: Instrumentation components are separated from the conduit entry by a sealed terminal block. Visualization of valve position can be made by local pointer or by flag indicator. Easy access to internal instrumentation by a screwable cover. T [°C] – 20 to + 70 Tightness IP68 – (72h, 30 m), fully submersible version on option The scotch yoke kinematics of actuators offers the following advantages; ■■ ■■ ■■ ■■ ■■ Accurate and reliable operation Suitable for hi-torque service Symmetric output torque for ball & plug valves Reliable, long life performance Also suitable for submerged service VRC system 11 KSB VRC system VRCS (VALVE REMOTE CONTROL SYSTEM) Hydraulic system to operate all valves. Including hydraulic power pack, control panel and solenoid valve rack ■■ Valves are installed in different places on a ship to control the flow of fluid ■■ The actual position of the valves is indicated by way of remote telemetry ■■ These data are normally displayed on a mimic panel, or via the vessel‘s computerised equipment monitoring and data acquisition systems ■■ Products: ISORIA, DANAIS, ACTUATOR & SYSTEMS Safety Area Valve & Actuator Solenoid Valve Rack Interface Panel Automation System Hazardous Area Control Console & Mimic Panel Valve & Actuator Deck Box Hydraulic Power Pack The KSB Newsletter – don‘t miss out, sign up now: www.ksb.com/ksb-en/ newsletter Your local KSB representative: KSB Aktiengesellschaft Johann-Klein-Straße 9 67227 Frankenthal (Germany) www.ksb.com 0555.02-EN / 06.15 / © KSB Aktiengesellschaft 2015 · Subject to technical modification without prior notice. Technology that makes its mark