1 GENERAL INTRODUCTION Polymers are

advertisement

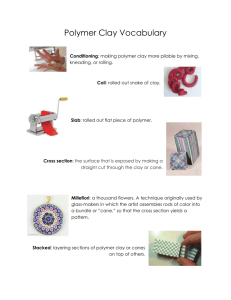

Introduction and aim of the thesis GENERAL INTRODUCTION Polymers are traditionally reinforced with inorganic fillers to improve their properties, such as stiffness, toughness, barrier properties, resistance to fire and ignition. The achievement of a significant improvement in the composite properties often requires incorporation of a large amount of the filler in the polymer materials which imparts drawbacks to the composite such as brittleness or opacity. To meet the rising demands of a wide variety of new applications, functional hybrids combining inorganic fillers and polymers are being continuously developed so as to better take benefit from their constituent’s properties or to induce new ones1. 1 Polymer nanocomposites Polymer nanocomposites are a new class of hybrid materials that are particle-filled polymers for which at least one dimension of the dispersed component is in the nanometer range. The reduction of particle size obtained in such materials increases the specific surface area of the filler, providing larger matrix/filler interface and so more mutual interactions. As a result, large reinforcing effect may be reached at much lower filler content when compared to classical microcomposites. Besides, the geometrical shape of the particles plays an important role in determining the properties of the composites2-4. One can distinguish three types of nanocomposites depending on how many dimensions of the dispersed filler are in the nanometer range (Figure 1). When all the three dimensions of the particles are in the order of nanometers, the inorganic fillers are equidimensional, such as spheres (like silica nanoparticles) or cubes (like calcium carbonate). Fillers with two dimensions in the nanometer scale and the third in the range of micrometers, forming an elongated structure, include carbon nanotubes and whiskers. The third type of nanocomposite is characterized by only one dimension in the nanometer range. In this case, the filler is present in the form of sheets of one to a few nanometer thick and hundreds to thousands nanometers long. Among the different types of sheet-like fillers, those based on layered silicates (alternatively referred to as clays), have attracted the most attention, notably because of the easy accessibility and low cost of the starting clay minerals. 1 Introduction and aim of the thesis Figure 1. Schematic, idealized representation of the three types of nanocomposites (left: equidimensional nanoparticles, middle: nanotubes, right: nanosheets) 2 Polymer/clay nanocomposites The preparation of polymer/clay nanocomposites is largely detailed and reviewed in the scientific literature5-12. The ongoing interest in this field is due to the remarkable properties improvement of polymer materials triggered by the dispersion of layered silicates nanofillers5,9,10,12,13. Among those properties, drastic increase in tensile modulus at filler contents sometimes as low as 1 wt% has drawn a lot of interest13-15. Thermal stability and fire retardancy through char formation are other interesting and widely searched properties displayed by nanocomposites16-18. Then, those new materials have also been studied and applied for their superior barrier properties against gas and vapor transmission19-21. These cited performances are closely linked to the high length/diameter ratio (aspect ratio), characteristic of individual layers (clay platelets)2,10,22. Thus, to really utilize all the potential advantages of polymer/clay nanocomposites, upon dispersion in the polymer matrix, the clay particles must be exfoliated to a large extent into individual platelets. However, this ideal structure is rarely achieved23. In fact, the complete and uniform dispersion of silicate layers in polymer is only one of the three main types of composites that can be obtained when a layered silicate is associated with a polymer (Figure 2a)5. We speak about intercalated structure (Figure 2b) when a single (and sometimes more than one) layer of extended polymer chains is intercalated between the silicate layers resulting in a well-ordered multilayer morphology. When the polymer is unable to intercalate between the silicate sheets, a phase separated microcomposite (Figure 2c) is obtained. Although these categorized structures are largely admitted, it was shown in practice that more complex structures are frequently obtained. Hence, four morphological entities, i.e. clay microparticles, intercalated clay stacks, individual layers and silicate network may be present 2 Introduction and aim of the thesis simultaneously in the composites24. Moreover, depending on the processing story of the materials and on polymer-clay and clay-clay interactions, specific clay re-organizations such as clay flocculation25 and exfoliated clay restacking26 can take place, creating original clay structures. Layered silicate a) Exfoliated (nanocomposite) Polymer c) Phase separated (microcomposite) b) Intercalated (nanocomposite) Figure 2. Schematic representation of different types of composites arising from interaction of layered silicate and polymer One of the main reasons for the non trivial preparation of exfoliated polymer/clay nanocomposites is the strong hydrophilic nature of clay. Therefore, the modification of clay surface is very widely used to render it more organophilic and hence more prone to induce clay delamination with non-polar polymers27. The most common method is the ionic exchange between the inorganic cations originally lying in the interlayer space of the clay and cationic surfactants such as ammonium cations bearing at least one long hydrocarbon chain (Figure 3)28. As a result of this ionic exchange, the surface energy of the clay platelets is decreased and the interlayer distance is increased (d’>d). Such organomodified clays are referred to as “organoclays” and their preparation is the object of the literature review (Part A) presented in this thesis. d Na+ Na+ Na+ Na+ Na+ Na+ + Br + + d’ Cationic surfactant Hydrophilic clay + + + + + NaBr + Organoclay Figure 3. Schematic representation of ionic exchange in layered silicate 3 Introduction and aim of the thesis 3 Potential impact of polymer/clay nanocomposites Nanocomposites technology is among the most widely watched technology areas within the plastics arena. A market research published by Frost & Sullivan in July 2007 details the key developments with respect to the usage of nanomaterials, namely nanoclays, carbon nanotubes and carbon nanofibers, in plastics29 (Table 1). They relate that the last few years have seen frantic activity in the world nanocomposites market with important technological breakthroughs. However, some major challenges faced by suppliers were identified, including: moving the industry away from the labs and into the market, timing capital expenditure and ensuring a good return on investment, achieving key technological breakthroughs through the nano-supply chain, creating testing and measurement standards for the industry and generating favorable public opinion towards nanotechnology. Table 1. Polymer nanocomposites market: market engineering measurements, base year 2006, world coverage29 Measurement name Measurement Trend Market size in revenues (nanoparticles) $33.7 million increasing Market size in volumes (nanocompounds) 33.0 kt increasing Base year market growth rate (revenue terms) 16.1% increasing Forecast period growth rate (revenue terms) 23.1% increasing Maximum future market size $144.6 million increasing Price sensitivity low/medium increasing Number of competitors in 2006 > 50 increasing Market saturation (current/potential users) very low increasing Market age/product life cycle introduction/growth increasing The main application segments of polymer/clay nanocomposites include: automotive30, sports goods, electric cable and packaging industry31. The automotive industry has been an early adaptor of the nanoclay technology and they are already being extensively used in polyolefin molded components. For example, the cargo bed of the 2005 General Motors Hummer has parts containing nanoclay composites. A new wave runner commercialized by Yamaha in 2008 incorporates nanoclay resin instead of heavy fillers, resulting in a 25 wt% reduction of weight. 4 Introduction and aim of the thesis The packaging sector is also emerging as a key end-user segment for nanoclay composites, where they provide increased gas barrier properties. Currently much of the applications for nanoclay composites have been based on nylon as the resin matrix. Examples include beer bottles commercialized by Honeywell and Durethan food packaging films from Bayer AG. Nevertheless, technical advancements are still needed with clay nanocomposites, especially with respect to their dispersion in polyolefins. Solutions are also searched for in other nonpolar matrices such as silicone-based and fluorinated polymers as well as in polyethylene terephthalate and in elastomers. 4 Supercritical carbon dioxide Supercritical carbon dioxide (scCO2) is an abundant, inexpensive, nontoxic and nonflammable solvent that has attracted extensive interest as a polymerization and processing medium since the 90’s, primarily driven by the need to replace conventional organic solvents with more environmentally benign and economically viable procedures32. The supercritical state of CO2 is reached above its critical temperature of 31.1°C and its critical pressure of 73.8 bar. In this state, the fluid has both liquid-like properties such as high density and gas-like properties, such as low viscosity and high diffusivity (Table 2). Table 2. Physical properties of supercritical fluids compared to liquids and gases33 Liquid Supercritical fluid Gas Density (g/cm³) 1 0.1-1 10-3 Viscosity (Pa.s) 10-3 10-4-10-5 10-5 Diffusivity (cm²/s) 10-5 10-3 10-1 The low viscosity, near-zero surface tension, relative chemical inertness and high diffusivity of supercritical carbon dioxide (scCO2) results in negligible competitive adsorption with guest molecules on the host surface and therefore facilitates solute transfer relative to classical solvents34. Furthermore, since CO2 is a gas at ambient conditions, the costly drying procedure associated with conventional liquid solvents is circumvented, and the product is free of residual solvent upon depressurization. 5 Introduction and aim of the thesis These unique properties of scCO2 have been exploited in various processes including extraction35, chromatography36, nanoparticles preparation37,38, polymer synthesis39 and foaming40. In the field of polymer/clay nanocomposites, three types of applications emerged recently in the scientific literature. One method is the use of scCO2 as a polymerization medium of various monomers in presence of organomodified montmorillonite clay for the in situ synthesis of nanocomposites41-48. A second technique is the injection of CO2 during the extrusion of a polymer/nanoclay mixture; it then acts as plasticizer to promote macromolecular chain diffusion between the clay galleries49-51. The third report is a pretreatment of organoclays in scCO2, followed by rapid gas depressurization52,53. After this process, the organoclay stacks are found to be disorganized, which favors their subsequent dispersion in polymer. 5 Solubility in supercritical carbon dioxide Solubility in scCO2 is comparable to hydrocarbons54. Indeed, small organic molecules and many monomers soluble in hexane are also soluble in compressed CO2. On the contrary, polar molecules and organometallic compounds are poorly soluble in this medium. As a rule, high molecular weight polymers are insoluble in scCO2 except for three families of polymers that can readily be dissolved under mild conditions of pressure and temperature (T°<100°C, P<1000 bar). These polymers are amorphous (or poorly crystalline) fluorinated polymers55, silicones56 and aliphatic poly(ether-co-carbonate)s57. Their solubility can be explained by specific interactions existing between CO2 quadrupolar moment and some polar functions (carbonyl, ether, siloxane or C-F bonds) of these polymers58. In the case of silicone and poly(ether-co-carbonate), the high chain flexibility also contributes to their solubility in scCO2. 6 Introduction and aim of the thesis SCOPE AND AIM OF THE THESIS The present research focuses on the preparation of new organoclays for polymer nanocomposites application. The organomodification of natural clays has been used for more than fifteen years to facilitate the dispersion of individual silicate platelets. The process generally employed for clay surface modification is an ionic exchange between the sodium ions of the clay and a cationic surfactant. This exchange has been largely studied in water due to the capacity of this solvent to swell the clay. However, it can only be applied to watersoluble surfactants, which strongly limits the range of organoclays available. This limitation is reflected in the structures of organomodifiers in commercially available organoclays: all are alkylammonium salts of similar structure. Now, the intense development of polymer/clay nanocomposites has raised two major needs for organoclays: the first is linked to the high processing temperature of several polymers. Indeed, commonly used temperatures in extrusion and injection molding (up to 250°C) can exceed the onset degradation temperature of alkylammonium salts (~180°C). As a consequence, there exists a strong demand for high temperature stable organoclays. Secondly, in parallel to the melt blending process, the development of in situ polymerization from the clay surface requires organomodifiers with specific functional groups. This method is suggested to facilitate the formation of an exfoliated structure, with functional organomodifiers increasing the compatibility between clay surface and polymer or even initiating the polymerization. To meet these new requirements, we propose the use of scCO2 as a medium for the ionic exchange. This solvent is chosen for its numerous advantages compared to classical solvents, like low environmental impact, non toxicity and tunable polarity and density. Compared to the water process, the two main advantages are the possibility to use non water-soluble surfactants and the recovery of a dry powder upon depressurization, which represents time and energy savings. The main objective of this thesis is to demonstrate the versatility of the scCO2 process, through the preparation of thermally stable organoclays and functional organoclays, and their evaluation as nanofillers in polymer matrices. To attain this objective, the adopted strategy involves four steps: 1) modification of natural clay in scCO2; 2) study of the organoclays properties in comparison with reference products; 3) qualitative and quantitative evaluation of organoclay platelets dispersion in a host polymer matrix; 4) characterization of the polymer/clay nanocomposites properties. 7 Introduction and aim of the thesis To study the versatility of the scCO2 process for clay organomodification, a large number of commercially available surfactants including ammonium, phosphonium and imidazolium salts, are first tested. The mechanism of ionic exchange in this medium is then analyzed, followed by the screening of some key experimental conditions. The possibility of preparation of organoclays in a pilot-scale reactor is investigated and the process is further extended to new functional organomodifiers. After the preparative step, organoclays characteristics are detailed. In particular, the interlayer distance is measured by X-ray diffraction while the organic content and exchange yield are determined by thermogravimetry. The latter technique also serves to assess the thermal stability of organoclays. For this purpose, phosphonium organoclays are compared with ammonium organoclays of exactly the same structure, both prepared in scCO2. The effect of the nature of the clay is also studied, by comparing two natural clays: montmorillonite and hectorite. In addition, surface coverage, mean particle size and surface energy of a selected phosphonium-montmorillonite prepared in scCO2 pilot reactor are calculated and compared with pristine (natural, purified) clay and a commonly used commercial organoclay. In the next step, the most promising organoclays are dispersed in selected matrices by two distinct methods. Thermally stable organoclays are melt blended with polymers at high temperature either by internal mixing or (mini)-extrusion. For this method, polyamide-6 (PA6) is chosen as reference matrix because it is processed at a temperature above the onset degradation of ammonium salts (230°C) and the largest extent of exfoliation, as depicted in the literature, was obtained in this polymer. Then, a second polyamide is used: poly(metaxylylene adipamide) (PA mXD-6), as specialty polymer processed at even higher temperature (250°). The second method is the in situ polymerization in scCO2 and is applied with functional organoclays. It involves mixing of the nanofiller with a liquid monomer in suitable conditions for polymerization. Methyl methacrylate is chosen as monomer because its polymerization in scCO2 is already mastered by our laboratory. In both cases, the extent of clay exfoliation is evaluated qualitatively by X-ray diffraction and transmission electron microscopy. Polyamide-6 nanocomposites are further analyzed by rheology and two distinct quantitative methods are used to assess the degree of exfoliation. 8 Introduction and aim of the thesis The last, but not least, step to validate the process is the evaluation of some key properties of nanocomposites prepared with scCO2 organoclays. Hence, the fire properties of PA-6 nanocomposites are evaluated quantitatively by cone calorimetry and the implication of onium stability on the results is discussed. Mechanical properties (Young modulus and yield stress) are also measured for the same polymer, with different types of organoclays and different extents of exfoliation, while oxygen barrier properties are determined for PA mXD-6 nanocomposites. THESIS OUTLINE The present thesis is divided in five chapters of experimental results. Preceding these chapters, a literature review is presented. It provides an outline of the patenting activity in the field of manufacturing organoclays through ionic exchange (Part A). The variety of organic modifiers and the diverse processing techniques are detailed, with the aim to extract the most relevant organoclays for successful nanocomposite formation at industrial scale. In Part B of the review, a survey of the state of the art concerning the use of thermally-stable organoclays is presented. Chapter 1 is dedicated to the process of clay organomodification in supercritical carbon dioxide. The preparation of ammonium-, phosphonium- and imidazolium-based organoclays is reported. In the second chapter, the thermal stability of phosphonium-modified clays (montmorillonite and hectorite) is compared with that of ammonium-modified clays. Nanocomposites are prepared by melt blending organoclays containing onium cations of identical structure with polyamide-6 as host matrix. Then, the morphology as well as the fire properties of the phosphonium and ammonium clay-based compounds are evaluated and compared. Chapter 3 relates the preparation of nanocomposites with the same matrix, PA-6, and focuses on the effect of clay modification on structure and mechanical properties. In this case, a phosphonium clay prepared in scCO2 is compared with pristine clay and a commercial organoclay. The same fillers are used in Chapter 4 but with a semi-aromatic polyamide (PA mXD-6). The study of the obtained nanocomposites is centered on the oxygen barrier properties. Chapter 5 is devoted to the preparation of functional organoclays and their application for the in situ polymerization of methyl methacrylate in scCO2. Finally, general conclusions are drawn and some comments are made on the potential of commercialization of organoclays prepared with the scCO2 process. 9 Introduction and aim of the thesis REFERENCES 1. Rothon, R. Particulate-Filled Polymer Composites; Longman: Harlow, 1995. 2. Fornes, T. D.; Paul, D. R. Polymer 2003, 44, 4993-5013. 3. Paul, D. R.; Robeson, L. M. Polymer 2008, 49, 3187-3204. 4. Móczó, J.; Pukánszky, B. J. Ind. Eng. Chem. 2008, 14, 535-563. 5. Alexandre, M.; Dubois, P. Mater. Sci. Eng., R 2000, 28, 1-63. 6. Ishida, H.; Campbell, S.; Blackwell, J. Chem. Mater. 2000, 12, 1260-1267. 7. Ray, S. S.; Okamoto, S. Progr. Polym. Sci. 2003, 28, 1539-1641. 8. Vaia, R. A.; Wagner, H. D. Mater. Today 2004, 7, 32-37. 9. Usuki, A.; Hasegawa, N.; Kato, M. Adv. Polym. Sci. 2005, 179, 135-195. 10. Mittal, V. Materials 2009, 2, 992-1057. 11. Tasdelen, M. A.; Kreutzer, J.; Yagci, Y. Macromol. Chem. Phys. 2010, 211, 279-285. 12. Pavlidou, S.; Papaspyrides, C. D. Progr. Polym. Sci. 2008, 33, 1119-1198. 13. LeBaron, P. C.; Wang, Z.; Pinnavaia, T. J. Appl. Clay Sci. 1999, 15, 11-29. 14. Kojima, Y.; Usuki, A.; Kawasumi, M.; Fukushima, Y.; Okada, A.; Kurauchi, T.; Kamigaito, O. J. Mater. Res. 1993, 8, 1185-1189. 15. Liu, L.; Qi, Z.; Zhu, X. J. Appl. Pol. Sci. 1999, 71, 1133-1138. 16. Leszczynska, A.; Njuguna, J.; Pielichowski, K.; Banerjee, J. R. Thermochim. Acta 2007, 453, 75-96. 17. Gilman, J. W. Appl. Clay Sci. 1999, 15, 31-49. 18. Morgan, A. B.; Wilkie, C. A. In Flame Retardant Polymer Nanocomposites; John Wiley & Sons: Hoboken, 2007; pp. 355-399. 19. Messersmith, P. B.; Giannelis, E. P. J. Polym. Sci., Part A: Polym. Chem. 1995, 33, 1047-1057. 20. Osman, M. A.; Mittal, V.; Morbidelli, M.; Suter, U. W. Macromolecules 2004, 37, 7250-7257. 21. Picard, E.; Vermogen, A.; Gérard, J. F.; Espuche, E. J. Membr. Sci. 2007, 292, 133144. 22. Lagaly, G. Appl. Clay Sci. 1999, 15, 1-9. 23. Százdi, L.; Pozsgay, A.; Pukánszky, B. Eur. Polym. J. 2007, 43, 345-359. 24. Százdi, L.; Ábrányi, Á.; Pukánszky, B., Jr.; Vancsó, G. J.; Pukánszky, B. Macromol. Mater. Eng. 2006, 291, 858-868. 25. Ray, S. S.; Okamoto, M. Macromol. Rapid Commun. 2003, 24, 815-840. 26. Alexandre, M.; Dubois, P.; Sun, T.; Garces, J. M.; Jérôme, R. Polymer 2002, 43, 2123-2132. 27. de Paiva, L. B.; Morales, A. R.; Valenzuela Díaz, F. R. Appl. Clay Sci. 2008, 42, 8-24. 10 Introduction and aim of the thesis 28. Vaia, R. A.; Ishii, H.; Giannelis, E. P. Chem. Mater. 1993, 5, 1694-1696. 29. Frost & Sullivan World Polymer Nanocomposites Markets, 2007. 30. Okada, A.; Usuki, A. Nanotechnology for Automotive Applications 2007, 49. 31. Azeredo, H. M. C. Food Res. Int. 2009, 42, 1240-1253. 32. Shaffer, K. Trends Polym. Sci. 1995, 3, 146-153. 33. Kemmere, M. F.; Meyer, T. Supercritical Carbon Dioxide; Wiley: Weinheim, 2005. 34. Zhao, Q.; Samulski, E. T. Macromolecules 2003, 36, 6967-6969. 35. Mukhopadhyay, M. J. Chem. Technol. Biotechnol. 2009, 84, 6-12. 36. Abbott, E.; Veenstra, T. D.; Isaaq, H. J. J. Sep. Sci. 2008, 31, 1223-1230. 37. Reverchon, E.; Adami, R. J. Supercrit. Fluids 2006, 37, 1-22. 38. Ye, X.; Wai, C. M. J. Chem. Educ. 2003, 80, 198-204. 39. Kendall, J. L.; Canelas, D. A.; Young, J. L.; DeSimone, J. M. Chem. Rev. 1999, 99, 543-564. 40. Park, C. B.; Behravesh, A. H.; Venter, R. D. Polym. Eng. Sci. 1998, 38, 1812-1823. 41. Zerda, A. S.; Caskey, T. C.; Lesser, A. J. Macromolecules 2003, 36, 1603-1608. 42. Zhao, Q.; Samulski, E. T. Macromolecules 2005, 38, 7967-7971. 43. Yan, C.; Ma, L.; Yang, J. J. Appl. Polym. Sci. 2005, 98, 22-28. 44. Li, J.; Xu, Q.; Peng, Q.; Pang, M.; Zhu, C. J. Appl. Polym. Sci. 2006, 100, 671-676. 45. Zhao, Q.; Samulski, E. T. Polymer 2006, 47, 663-671. 46. Sun, F.; Pan, Y.; Wang, J.; Wang, Z.; Hu, C.; Dong, Q. J. Macromol. Sci., Part A 2009, 46, 37-45. 47. Urbanczyk, L.; Calberg, C.; Stassin, F.; Alexandre, M.; Jérôme, R.; Jérôme, C.; Detrembleur, C. Polymer 2008, 49, 3979-3986. 48. Urbanczyk, L.; Ngoundjo, F.; Alexandre, M.; Jérôme, C.; Detrembleur, C.; Calberg, C. Eur. Polym. J. 2009, 45, 643-648. 49. Nguyen, Q. T.; Baird, D. G. Polymer 2007, 48, 6923-6933. 50. Zhao, Y.; Huang, H.-X. Polym. Test. 2008, 27, 129-134. 51. Treece, M. A.; Oberhauser, J. P. J. Appl. Pol. Sci. 2007, 103, 884-892. 52. Horsch, S.; Serhatkulu, G.; Gulari, E.; Kannan, R. M. Polymer 2006, 47, 7485-7496. 53. Manitiu, M.; Bellair, R. J.; Horsch, S.; Gulari, E.; Kannan, R. M. Macromolecules 2008, 41, 8038-8046. 54. Hyatt, J. A. J. Org. Chem. 1984, 49, 5097-5101. 55. DeSimone, J. M.; Guan, Z.; Elsbernd, C. S. Science 1992, 257, 945-947. 56. Hoefling, T. A.; Newman, D. A.; Enick, R. M.; Beckman, E. J. J. Supercrit. Fluids 1993, 6, 165-171. 57. Sarbu, T.; Styranec, T.; Beckman, E. J. Nature (London) 2000, 405, 165-168. 58. Fried, J. R.; Li, W. J. Appl. Polym. Sci. 1990, 41, 1123-1131. 11 Introduction and aim of the thesis 12