Development of a Novel Cam-based Infinitely Variable Transmission

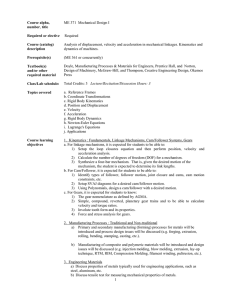

advertisement