CY3B/3R

4/18/02 6:53 PM

Page 1

CAT.ES20-172 A

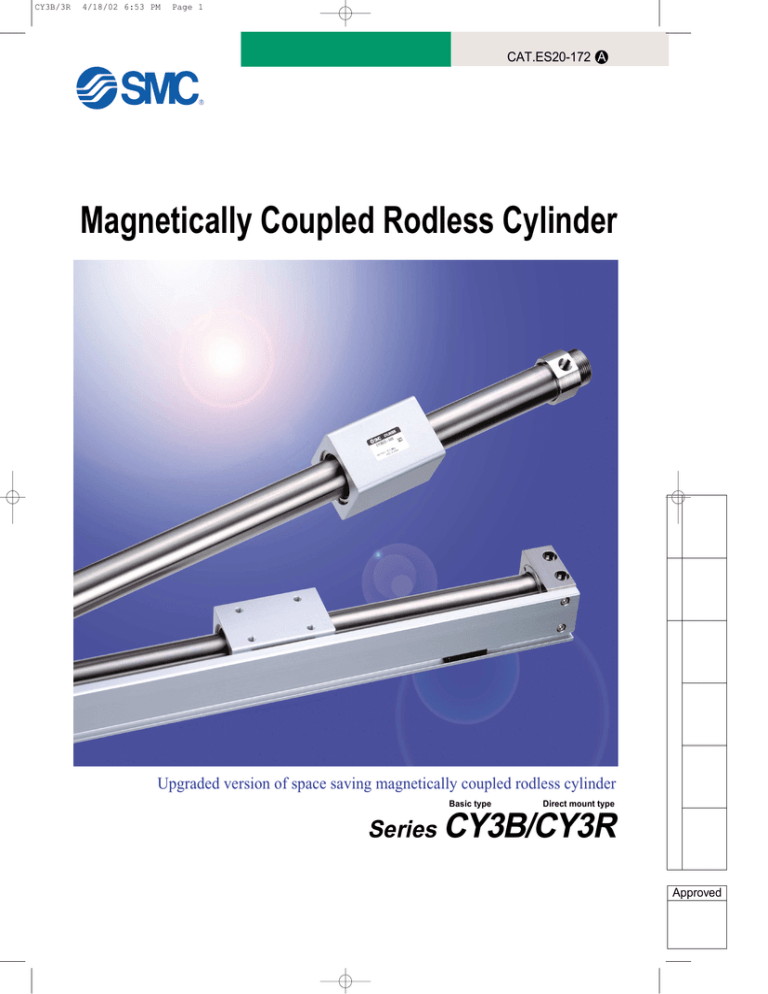

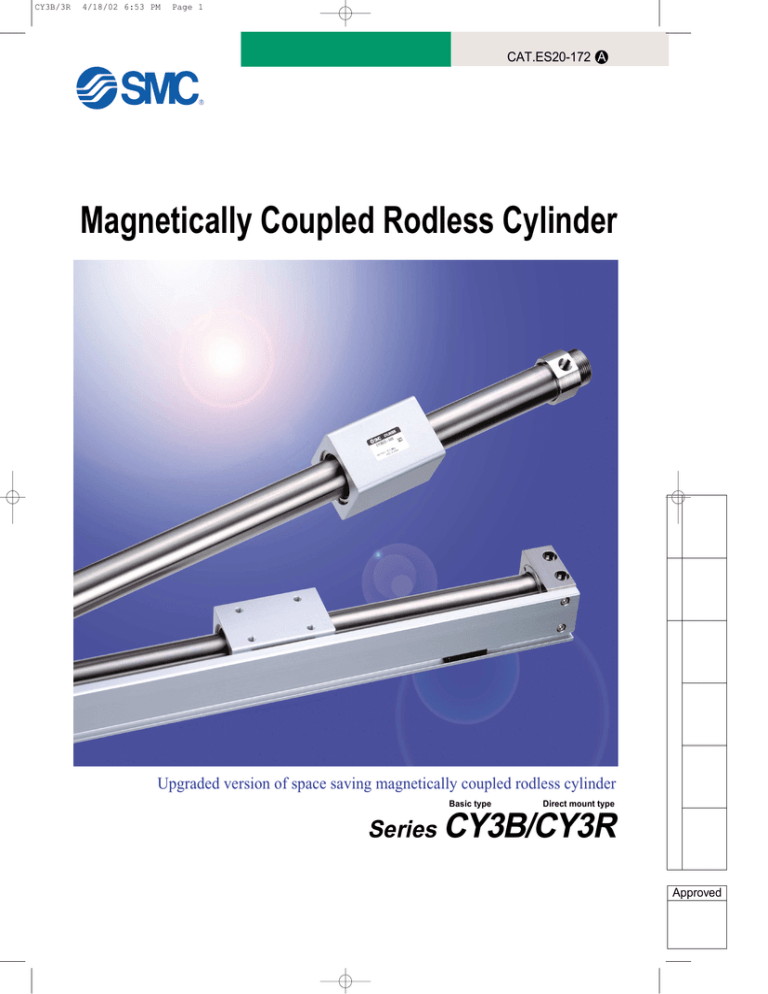

Magnetically Coupled Rodless Cylinder

Upgraded version of space saving magnetically coupled rodless cylinder

Basic type

Direct mount type

Series CY3B/CY3R

Approved

CY3B/3R

4/18/02 6:53 PM

Page 2

Magnetically

Coupled

Rodless

Cylinder

Basic type

Direct mount type

Series CY3B/CY3R

Improved durability

Improved bearing performance

Improved lubrication by using a soft wiper

A 70% longer wear ring length achieving an improvement in bearing

performance compared to the CY1B.

A special resin soft wiper is installed on the

dust seal to achieve a ideal lubrication on

the external surface of the cylinder tube.

Direct mount type Series

Basic type Series

CY3B

NPT and G thread are standardized.

Variety of piping port thread expanded to 3 types

Cylinders with a bore ¿20 or larger, are now available

with 3 types of piping port threads.

series

(Refer to "How to Order": CY3B

CY3R series

CY3R

Mounting dimensions are identical with those of series CY1.

Series CY3B

NN

Page 7

Page 11

)

S + Stroke

ZZ + Stroke

Bore size (mm)

15

Thread type

The mounting dimensions (in the drawing on the left) are

identical with those

of existing series

CY1B/CY1R, allowing easy replacement.

Series CY3R

M thread

Rc thread

20, 25, 32, 40

Features 1

NPT thread

S + Stroke

G thread

Z + Stroke

QW

Approved

CY3B/3R

4/18/02 6:53 PM

Page 3

Upgraded version of saving

magnetically rodless cylinder!

Wear ring A

Soft wiper

(special resin)

Reduction of sliding resistance

Wear ring B

Minimum operating pressure reduced by 30%

By using a soft wiper the

minimum operating pressure is reduced by 30%.

(comparing CY3B40 and CY1B40)

Series CY3B

Series variations

Bore size

Series

¿20

¿25

¿32

¿40

¿15

¿20

CY3R

150

100

¿15

CY3B

Standard stroke (mm)

50

¿25

¿32

¿40

250

200

350

300

450

400

Individual made to order products

600

500

800

700

1000

900

Note) The mark indicates the available combination of bore size and

standard stroke.

Long stroke (2001mm and up)

Low speed specifications (7 to 50mm/s)

Hydro specifications

Axial ports

High speed specifications

Helical insert thread specifications

Added mounting tap positions for slider

Oil-free exterior specifications

Outside of cylinder tube with hard chrome plating

Oil-free exterior specifications (with dust seal)

With floating joint

(XB11)

(XB13)

(X116)

(X132)

(X160)

(X168)

(X206)

(X210)

(X322)

(X324)

(XC57)

Availability of made to order products varies with the series

(CY3B/R) and the bore size. For more information please

refer page 20.

Features 2

Approved

CY3B/3R

4/18/02 6:53 PM

Page 4

Series CY3B/CY3R

Model Selection Criteria

Recommended cylinder

Model selection point

Appearance

Features

Series CY3B

Size/ø15, ø20, ø25, ø32, ø40

When used with many different

A long stroke is possible.

When used with many different

types of guides.

When auto switches are added

to the basic type.

When used without a guide for a

light load. (Application Example 1)

When space is very limited.

Types with guide

types of guides.

When a long stroke is necessary.

Series CY3R

Size/ø15, ø20, ø25, ø32, ø40

Cylinder can be directly mounted.

Auto switches can be mounted, and

there is no lurching from cylinder.

Non-rotation machanism is available

within the allowable range.

Piping can be concentrated with the

centralized piping type.

External dimensions are compact.

Mounting can be performed on the top

body surface or on one side surface.

Application example

Transferring

Cutting

Approved

1

CY3B/3R

4/18/02 6:53 PM

Page 5

Series CY3B/CY3R

Model Selection Method

E: Kinetic energy of load (J)

(W + WB)

V 2

E=

x

2

1000

Es: Allowable kinetic energy for intermediate stop using

an air pressure circuit (J)

Fn: Allowable driving force (N)

MD: Maximum allowable moment (N⋅m) when a connection

bracket, etc. is carried directly

Ps: Operating pressure limit for intermediate stop using

an external stopper, etc. (MPa)

Pv: Maximum operating pressure for vertical operation (MPa)

WBmax: Maximum load weight (kg) when loaded directly

on the body

(

Operating conditions

W: Load weight (kg)

Switches

WB: Connection bracket weight (kg) P: Operating pressure (MPa)

µ: Guide’s coefficient of friction

V: Speed (mm/s)

Lo: Distance from cylinder

Stroke (mm)

shaft center to work piece point Mode of operation

)

of application (cm)

(horizontal, inclined, vertical)

L1: Distance from cylinder shaft center to connection fitting, etc.

Mode of

operation

Note 1)

Vertical operation

Inclined operation

Horizontal operation

Review of load weight

and operating pressure

W

Lo

Guide

First tentative bore size

determination

F1

øD 1.6 x

P

WB

First tentative bore size

determination

F2

øD 1.6 x

P

First tentative bore size

determination

F3

øD 1.6 x

P

θ˚ θ˚

Inclined operation

W + WB WV

W + WB WV

Determination

P PV

P PV

Allowable driving force table (Fn) (n=1,2,3)

Inclined

F1 = µ x (W + WB) x 9.8

F2 = (W + WB) x 9.8 x (µCOSθ + SINθ)

Vertical

F3 = (W + WB) x 9.8 x (µ + 1)

Horizontal

of allowable load

weight &

pressure

Refer to the allowable driving force table for the (Fn) of data K

A.

(Refer to page 5 for

(Refer to page 5 for the maximum

vertical operation.)

load weight when loaded directly

on the body and connection bracket.)

WB WBmax

Determination of

connection bracket

weight (WB)

Review of connection bracket

CY3B

CY3R

WB WBmax

Review of switch use and stroke

Equipped with

switch rail?

(Refer to data

K

A on pages 3

and 4.)

Yes

Equipped with

switches?

No

No

Second tentative determination of

bore size and magnet holding power

(H, L) using the graph of allowable

driving force (Fn) and distance from

cylinder shaft center (Lo)

Yes

Yes

(Refer to

standard stroke

NG table on page 12.)

Determination

of stroke with

switch

OK

Equipped

with external guide

system?

No

Yes

Stop with external stopper

Intermediate

stopping method

Note 1)

Intermediate

stop?

Note 3)

WB x L1 MD

No

Stop with air pressure circuit

WB x L1 MD

Refer to page 6 for

intermediate stops.)

E=

Determination of

pressure (P) when making

intermediate stop

P Ps

Review of larger bore size

Review of larger bore size

( )

V

(W + WB)

x

2

1000

P Ps

(Refer to page 6 for

intermediate stops.)

2

Determination of

load’s kinetic

energy (E)

E Es

E Es

(Refer to page 6 for body

non-rotating accuracy and

maximum allowable moment.)

Determination

of rotating

moment

Bore size determination

Note 3)

NG

(Refer to page 6 for body

non-rotating accuracy and

Determination maximum allowable moment.)

of allowable

stroke

Note 2)

Review of order made

products based on

operating conditions

(Refer to pages 20

through 24.)

Model determination

OK

Note 1) This cylinder cannot perform an intermediate stop

using an air pressure circuit in vertical operation. In this

case, an intermediate stop can be performed only by

using an external stopper, etc.

Note 2) Depending on the operating environment, etc., order

made products should also be reviewed.

Note 3) An external guide system should be installed when

over specifications.

2

Approved

CY3B/3R

4/18/02 6:53 PM

Page 6

Series CY3B/CY3R

Model Selection Method

Precautions on Design q

Selection procedure

Selection procedure

<Data K

A : Distance from cylinder shaft center

3. Select the bore size and type of magnet

holding force (types H, L) from Lo and Fn

based on data K

A.

Work

piece

Load

Fn

50

40

30

20

10

Useable range

5

1

0 1 2 3 4 5 6 7 8 9 10 11

Lo

Allowable driving capacity>

CY3B32

Allowable driving force Fn (N)

2. Find the distance Lo (cm) from the point of

the load where driving force is applied, to

the center of the cylinder shaft.

CY3B15

Allowable driving force Fn (N)

1. Find the drive resisting force Fn (N) when

moving the load horizontally.

400

300

200

100

50

40

30

20

Useable range

10

5

1

0 1 2 3 4 5 6 7 8 9 101112 13 14 15

Distance from cylinder shaft center Lo (cm)

Distance from cylinder shaft center Lo (cm)

CY3B40

CY3B20

200

500

100

300

200

50

10

5

Useable range

1

Allowable driving force Fn (N)

Given a load drive resisting force of Fn = 100 (N)

and a distance from the cylinder shaft center to

the load application point of Lo = 8cm, find the

intersection point by extending upward from the

horizontal axis of data K

A where the distance from

the shaft center is 8cm, and then extending to

the side, find the allowable driving force on the

vertical axis.

Models suitable to satisfy the requirement of 100

(N) are CY332 or CY340.

Allowable driving force Fn (N)

Selection example

100

50

40

30

20

Useable range

10

5

0 1 2 3 4 5 6 7 8 9 10 11 12 13

1

0 1 2 3 4 5 6 7 8 9 1011 1213 1415

Distance from cylinder shaft center Lo (cm)

Distance from cylinder shaft center Lo (cm)

CY3B25

Allowable driving force Fn (N)

500

300

200

100

50

40

30

20

10

Useable range

5

1

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Distance from cylinder shaft center Lo (cm)

3

Approved

4/18/02 6:53 PM

Page 7

Model Selection Method

Series

CY3B/CY3R

Precautions on Design q

<Data K

A : Distance from cylinder shaft center

10

Useable range

Allowable driving force Fn (N)

50

40

30

20

5

Allowable driving capacity>

CY3R32

400

300

200

100

50

40

30

20

Useable range

10

5

1

0 1 2 3 4 5 6 7 8 9 10 11

1

0 1 2 3 4 5 6 7 8 9 10 1112 13 14 15

Distance from cylinder shaft center Lo (cm)

Distance from cylinder shaft center Lo (cm)

CY3R20

CY3R40

200

500

100

300

200

50

30

10

5

Useable range

1

Allowable driving force Fn (N)

Allowable driving force Fn (N)

CY3R15

100

50

40

30

20

Useable range

10

5

0 1 2 3 4 5 6 7 8 9 10 11 12 13

1

0 1 2 3 4 5 6 7 8 9 10 1112 13 14 15

Distance from cylinder shaft center Lo (cm)

Distance from cylinder shaft center Lo (cm)

CY3R25

Allowable driving force Fn (N)

CY3B/3R

500

300

200

100

50

40

30

20

10

5

Useable range

1

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Approved

Distance from cylinder shaft center Lo (cm)

4

CY3B/3R

4/18/02 6:53 PM

Page 8

Series CY3B/CY3R

Model Selection Method

Precautions on Design w

Max. Weight of Connection

Bracket to the Body

Cylinder Dead Weight Deflection

When the cylinder is mounted horizontally,

deflection appears due to its own weight as

shown in the data, and the longer the stroke is,

the greater the amount of variation in the shaft

center. Therefore, a connection method should

be considered which can assimilate this

deflection.

Load platform

Guide shaft

Series CY3 is guided by an external axis (such

as a linear guide) without directly mounting the

load. When designing a metal bracket to

connect the load, see to it that its weight will

not exceed the value in the table below.

Basically, guide the CY3R direct mounting type

also with an external axis. (For connection

methods, refer to Instruction Manual.)

CY3B

CY3R

C

Model

Max. connection bracket weight (WBmax) (kg)

CY315

1.0

1.1

CY320

1.2

CY325

1.5

CY332

2.0

CY340

Consult SMC in case a bracket with weight

exceeding the above value is to be mounted.

(Note)

CY332,40

CY320,25

CY315

Clearance (Note)

(0.2 to 0.5mm)

Note 1) According to the dead weight deflection

in the figure on the right, provide

clearance so that the cylinder does not

touch the mounting surface or the

load, etc., and is able to operate smoothly within the minimum operating

pressure range for a full stroke. For

more information, refer to instruction

manual.

Note 2) In case of CY3R, install a stay, etc. to

eliminate clearance between the body

and the switch rail. For more information, refer to CY3R instruction manual.

Deflection (mm)

The above clearance amount is a reference value.

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

<CY3R>

CY340

Max. Load Weight when

Loaded Directly on Body

CY332

CY325

When the load is applied directly to the body, it

should be no greater than the maximum

values shown in the table below.

CY320

Max. load weight (WBmax) (kg)

1.0

1.1

1.2

1.5

2.0

Model

CY3R15

CY3R20

CY3R25

CY3R32

CY3R40

CY315

1000

2000

3000

4000

Loading direction

Load

mounting surface

Stroke (mm)

∗The above deflection data represent values at the time

when the external sliding part moves to the middle of the

stroke.

Loading direction

Vertical Operation

Load

mounting surface

Switch rail

The load should be guided by a ball type bearing (LM guide, etc.). If a slide bearing is used, sliding

resistance increases due to the load weight and load moment, which can cause malfunction.

Body

Load weight

(Slider bracket weight

+ Work piece weight)

Work

piece

W

Bore size

(mm)

15

20

25

32

40

Model

CY315

CY320

CY325

CY332

CY340

Wear ring C

Allowable load Max. operating

weight (Wv) pressure (Pv)

(MPa)

(kg)

7.0

11.0

18.5

30.0

47.0

0.65

0.65

0.65

0.65

0.65

∗Use caution, as there is a danger of breaking

the magnetic coupling if operated above the

maximum operating pressure.

Rodless cylinder

Approved

5

CY3B/3R

4/18/02 6:53 PM

Page 9

Model Selection Method

Series

CY3B/CY3R

Precautions on Design e

Intermediate stop

Stroke End Stopping Method

(1) Intermediate stopping of load

with an external stopper, etc.

When stopping a load having a large inertial force at the stroke end, tilting of the body and damage to

the bearings and cylinder tube may occur. (Refer to the left hand drawing below.)

As shown in the right hand drawing below, a shock absorber should be used together with the

stopper, and thrust should also be transmitted from the center of the body so that tilting will not occur.

When stopping a load in mid-stroke using an

external stopper, etc., operate within the

operating pressure limits shown in the table

below. Use caution, as operation at a pressure

exceeding these limits can result in breaking of

the magnetic coupling.

Bore size

(mm)

Model

Operating pressure limit for

intermediate stop (Ps) (MPa)

15

CY315

0.65

20

CY320

0.65

25

CY325

0.65

32

CY332

0.65

40

CY340

0.65

Load

Guide shaft

When performing an intermediate stop of a

load using an air pressure circuit, operate at or

below the kinetic energy shown in the table

below. Use caution, as operation when

exceeding the allowable value can result in

breaking of the magnetic coupling.

(Reference values)

Slide block

Cylinder tube

Body tilting

Cylinder tube

Stopper

Body

Thrust transmission area

Note) The drawing shows CY3B.

<CY3R>

Body Non-rotating Accuracy and Maximum Allowable Moment

(with Switch Rail) (Reference Values)

Reference values for non-rotating accuracy and maximum allowable moment at stroke end are

indicated below.

Bore size

(mm)

Model

15

CY315

0.13

20

CY320

0.24

15

4.5

0.15

200

25

CY325

0.45

20

3.7

0.20

300

32

CY332

0.88

25

3.7

0.25

300

40

CY340

1.53

32

3.1

0.40

400

40

2.8

0.62

400

Allowable kinetic energy for

intermediate stop (Es) (J)

Load

Guide shaft

Body

(2) Intermediate stopping of load

with an air pressure circuit

Shock absorber

Slide block

Note 2)

Bore size Non-rotating Max. allowable

moment (MD) Allowable stroke

(mm)

accuracy (ß)

(N⋅m)

(mm)

Non-rotating accuracy

Switch rail

Body

Wear ring C

Note 1) Avoid operations where rotational torque (moment) is applied. In such a case, the use of an

external guide is recommended.

Note 2) The above reference values will be satisfied within the allowable stroke ranges, but caution is

necessary, because as the stroke becomes longer, the inclination (rotation angle) within the

stroke can be expected to increase.

Note 3) When a load is applied directly to the body, the loaded weight should be no greater than the

allowable load weights on page 5.

Approved

6

CY3B/3R

4/18/02 6:53 PM

Magnetically

Coupled

Rodless

Cylinder

Page 10

CY3B

Basic Type

Series

How to Order

Basic type

CY3B 25

300

Basic type

Bore size

15

20

25

32

40

Standard stroke

15mm

Refer to the standard strokes table below.

20mm

25mm

32mm

40mm

Port thread type

Symbol

Nil

TN

TF

Type

M thread

Rc

NPT

G

Bore size

15

20, 25, 32, 40

Standard Stroke

Bore size

(mm)

50, 100, 150, 200, 250, 300, 350

400, 450, 500

15

20

25, 32

40

Maximum stroke Note 1)

availabe (mm)

Standard stroke (mm)

1000

1500

100, 150, 200, 250, 300, 350, 400, 450

500, 600, 700, 800

Note 2)

3000

100, 150, 200, 250, 300, 350, 400, 450

500, 600, 700, 800, 900, 1000

3000

Note 1) Contact SMC if the maximum stroke will be exceeded.

Note 2) Use series CY1B if the stroke exceeds 1500 mm with a tube inside diameter of 20 mm.

Magnetic Holding Force (N)

Bore size (mm)

15

20

25

32

40

Holding force (N)

137

231

363

588

922

Approved

7

4/18/02 6:53 PM

Page 11

Magnetically Coupled Rodless Cylinder

Basic Type

CY3B

Series

Specifications

Fluid

Air

Proof pressure

1.05MPa

Max. operating pressure

0.7MPa

Min. operating pressure

Refer to the minimum operating pressure table.

10 to 60C

Ambient and fluid temperature

Piston speed

50 to 400mm/s

Cushion

Rubber bumper at both ends

Lubrication

JIS symbol

Non-lube

+

1.0

0 to 250st:

, 251 to 1000st: +1.4, 1001st to: +1.8

Stroke length tolerance

0

0

0

Mounting orientation

Unrestricted

Mounting nut (2 pcs.)

Standard equipment (accessory)

When calculating the actual thr-

Ordeer Made to Order specifications

Mad (Refer to pages 20 through 24 for

Theoretical Cylinder Thrust

design should consider the

Caution ust,

minimum actuating pressure.

details.)

Symbol

Specifications

1200

-XB11 Long stroke (2001mm and up)

-XB13 Low speed specifications (7 to 50mm/s)

1100

ø4

0

-X116 Hydro specifications

-X132 Axial ports

1000

-X160 High speed specifications

-X168 Helical insert thread specifications

900

-X322 Outside of cylinder tube with hard chrome plating

-X324 Oil-free exterior specifications (with dust seal)

-XC57 With floating joint

Minimum Operating Pressure

800

2

ø3

700

B

bo

re

si

ze

-X210 Oil-free exterior specifications

Theoretical thrust (N)

-X206 Added mounting tap positions for slider

600

500

ø25

400

Minimum operating pressure

(MPa)

CY3B/3R

0.2

0.16 0.16

0.14

0.15

0.15

0.12

300

ø20

200

ø15

0.1

100

0.05

0

0

10

15

20

25

32

0.1

0.2

0.3

40

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Supply pressure (MPa)

Bore size (mm)

Main Material

Weights

kg

Description

Head cover

Material

Note

Aluminum alloy Electroless nickel plated

Cylinder tube Stainless steel

Body

Aluminum alloy

Magnet

Rare earth magnet

Hard anodized

Bore size (mm)

15

20

25

32

40

Basic weight

0.275

0.351

0.672

1.287

2.070

Additional weight per 50mm of stroke

0.015

0.02

0.023

0.033

0.04

Calculation method

/Example: CY3B32-500

Basic weight1.287kg

Additional weight0.033kg/50s 1.287 + 0.033 x 500 50 = 1.617kg

Cylinder stroke500st

}

8

Approved

CY3B/3R

4/18/02 6:53 PM

Series

Page 12

CY3B

Construction

Basic type

CY3B15

w !2 !4 !1 !8 !7 !6 !5 !0 i o q u y t

r

CY3B20 to 40

w

e !3 !2 !4 !1 !8 !6 !5 !7 !0 i q o u t y

r

Parts list

No.

9

Description

Material

Note

1

Body

Aluminum alloy

Hard anodized

2

Head cover

Aluminum alloy

Electroless Ni plated

3

End collar

Aluminum alloy

Chromate (ø15 is not available.)

4

Cylinder tube

Stainless steel

5

Piston

Aluminum alloy

6

Shaft

Stainless steel

7

Piston side yoke

Rolled steel

Zinc chromate

8

External slider side yoke

Rolled steel

Zinc chromate

9

Magnet A

Rare earth magnet

10

Magnet B

Rare earth magnet

11

Spacer

Aluminum alloy

12

Bumper

Urethane rubber

Carbon steel

13

Hexagon nut with flange

14

C type snap ring for hole

15

Wear ring A

Special resin

16

Wear ring B

Special resin

17

Piston seal

NBR

18

Soft wiper

Special resin

Carbon tool steel

Chromate

Chromate

Replacement parts: Seal kits

Zinc chromate

(ø15: not available. ø20: hexagon nut)

Nickel plated

Bore size (mm)

15

20

25

32

40

Kits no.

CY3B15-PS

CY3B20-PS

CY3B25-PS

CY3B32-PS

CY3B40-PS

∗Seal kits are sets consisting of numbers 15 through 18, and may be

ordered using the order number to each bore size.

Approved

4/18/02 6:53 PM

Page 13

Magnetically Coupled Rodless Cylinder

CY3B

Series

Basic Type

Dimensions

Basic type

CY3B15 to 40

B

4-MM

thread depth J

0

L 0.1

H

G

2-P (Piping port)

E

G

X

øD

NN

(I)

øR

Mounting nut

NA

N

K

W

N

F

S + Stroke

F

ZZ + Stroke

H

B

G

E

Mounting nut

NN

NA

F

N

CY3B15

Model

CY3B15

CY3B20

CY3B25

CY3B32

CY3B40

Model

CY3B15

CY3B20

CY3B25

CY3B32

CY3B40

B

35

36

46

60

70

D

16.6

21.6

26.4

33.6

41.6

Nil

M5 x 0.8

Rc 1/8

Rc 1/8

Rc 1/8

Rc 1/4

E

3

2

2

2

3

F

10

13

13

16

16

P (Piping port)

TN

—

NPT 1/8

NPT 1/8

NPT 1/8

NPT 1/4

G

5.5

7.5

7.5

8

11

H

13

20

20.5

22

29

TF

—

G 1/8

G 1/8

G 1/8

G 1/4

I

—

12

15

18

23

J

6

6

8

8

10

K

11

8

10

15

16

L

57

66

70

80

92

MM

M4 x 0.7

M4 x 0.7

M5 x 0.8

M6 x 1

M6 x 1

NA

17

24

30

36

46

N

11

18

18.5

20

26

NN

M10 x 1

M20 x 1.5

M26 x 1.5

M26 x 1.5

M32 x 2

R

—

28

34

40

50

S

83

106

111

124

150

W

35

50

50

50

60

X

19

25

30

40

40

(mm)

ZZ

103

132

137

156

182

Mounting nut / Included in the package (2 pcs).

b

C

CY3B/3R

H

B

Part No.

Applicable bore size (mm)

d

H

B

C

SNJ-016B

SN-020B

SN-032B

SN-040B

15

20

25, 32

40

M10 x 1.0

M20 x 1.5

M26 x 1.5

M32 x 2.0

4

8

8

10

14

26

32

41

16.2

30

37

47.3

Approved

10

4/18/02 6:53 PM

Page 14

Magnetically

Coupled

Rodless

Cylinder

CY3R

Direct Mount Type

Series

How to Order

CY3R

25

300

Y7BW

Number of auto switches

Direct mount type

Nil

2 pcs.

Piping type

S

1 ps,

Nil

Both sides piping type

n

"n" pcs.

G

Centralized piping type

Auto switch type

Bore size

15

15mm

20

20mm

25

25mm

32

32mm

40

40mm

Nil

Switch rail

Nil

Port thread type

Type

Symbol

Nil

TN

TF

M thread

Rc

NPT

G

Without auto switch

Note 1) In case of ø20 with switch rail but without switch,

the cylinder construction is for reed switch.

∗Refer to the table below for auto switch model numbers.

∗The auto switch is packed together when shipped

(unmounted).

With switch rail

N

Without switch rail

Note 1) A type with switch rail has built-in switch magnets.

Note 2) ø15 has built-in switch magnets even without switch rail.

Bore size

15

20, 25, 32, 40

Standard stroke

Refer to page 12 for standard stroke.

Applicable auto switches / The applicable auto switch is determined by the tube inside diameter. Refer to Best Pneumatics for the detailed specifications of auto

Solid state switch Reed switch

Type

Special

function

Electrical

entry

Grommet

No

Solid state switch Reed switch

No

Load voltage

Wiring

(output)

2-wire

3-wire

(NPN equiv.)

DC

24V

3-wire (NPN)

Grommet Yes

Diagnostic

indication

(2-color display)

Special

function

2-wire

3-wire (NPN)

24V

2-wire

No

Diagnostic

indication

(2-color display)

2-wire

24V

12V

3-wire (NPN)

A96

F9B

F9NW

F9PW

F9BW

AC

5V

Z76

12V

100V

Z73

12V

2-wire

A93

Auto

switch

models

24V

3-wire (PNP)

A90

F9P

5V, 12V

Z80

Y59A

5V, 12V

2-wire

Auto

switch

models

F9N

5V, 12V 100V or less

∗Lead wire length symbols: 0.5mNil (Example) Y59B

3m L (Example) Y59BL

5m Z (Example) Y59BZ

11

5V

DC

3-wire (PNP)

Grommet Yes

100V

Load voltage

Wiring

(output)

3-wire (NPN)

12V

12V

3-wire

Yes (NPN equiv.)

Grommet

5V, 12V 100V or less

5V, 12V

3-wire (PNP)

Electrical

entry

AC

5V, 12V

3-wire (PNP)

For ø25, ø32, ø40

Type

Indicator

light

switches. Refer to page 18 for auto switch circuit diagrams.

For ø15, ø20

Indicator

light

CY3B/3R

Y7P

Y59B

Y7NW

Y7PW

Lead wire length (m)∗

0.5

(Nil)

3

(L)

5 Applicable load

(Z)

IC circuit

IC circuit

Relay

PLC

IC circuit

Relay

PLC

IC circuit

Lead wire length (m)∗

Applicable load

0.5

(Nil)

3

(L)

5

(Z)

IC circuit

IC circuit

Relay

PLC

IC circuit

Relay

PLC

IC circuit

Y7BW

12V

∗∗Solid state switches marked "" are produced upon receipt of order.

Approved

4/18/02 6:53 PM

Page 15

Magnetically Coupled Rodless Cylinder

Direct Mount Type

Series

CY3B

Specifications

Fluid

Air

Proof pressure

1.05MPa

Max. operating pressure

0.7MPa

Min. operating pressure

Refer to the minimum operating pressure table.

10 to 60C

Ambient and fluid temperature

Piston speed

Note)

50 to 500mm/s

Cushion

Rubber bumper at both ends

Lubrication

Non-lube

0 to 250st: +01.0, 251 to 1000st: +01.4, 1001st to : +1.8

0

Stroke length tolerance

Mounting

Ordeer Made to Order specifications

Mad (Refer to pages 20 through 24 for

Symbol

Direct mount type

Note) When an auto switch is installed at an intermediate position of a type with auto switch, keep the

maximum piston speed at 300 mm/s or below to ensure operation of relays or other devices.

details.)

Standard Strokes

Specifications

—X116 Hydro specifications

—X160 High speed specifications

Bore size

(mm)

—X168 Helical insert thread specifications

—X322 Outside of cylinder tube with hard chrome plating

—XC57 With floating joint

Max. stroke Note 1) Max. stroke Note 1)

without switch (mm) with switch (mm)

Standard stroke (mm)

50, 100, 150, 200, 250, 300

350, 400, 450, 500

15

20

Minimum Operating Pressure

100, 150, 200, 250, 300, 350

400, 450, 500, 600, 700, 800

25

Minimum operating pressure

(MPa)

32

0.2

0.16 0.16

100, 150, 200, 250, 300, 350

400, 450, 500, 600, 700, 800

900, 1000

40

0.14

0.15

0.15

0.12

1000

750

1500

1000

1500

1200

2000

1500

2000

1500

0.1

Note 1) Contact SMC if the maximum stroke will be exceeded.

Note 2) When installing the cylinder, refer to Selection Method (page 31) to handle the

dead weight deflection.

0.05

Magnetic Holding Force (N)

0

10

15

20

25

32

40

Bore size (mm)

Bore size (mm)

15

20

25

32

40

Holding force (N)

137

231

363

588

922

Theoretical Cylinder Thrust

When calculating the actual thrust, design should

Caution consider the 12 minimum actuating pressure.

Weights

Unit: kg

Item

Bore size

(mm)

15

20

25

32

1200

40

ø4

1100

CY3R

CY3RG

0.272

0.421

0.622

1.217

1.980

(with switch rail)

CY3R

(at 0st) (without switch rail)

0.225

Additional weight per 50mm

0.04

of stroke (with switch rail)

Additional weight per 50mm

of stroke (without switch rail) 0.015

0.351

0.542

1.097

1.820

0.051

0.056

0.076

0.093

0.02

0.023

0.033

0.04

Calculation method

Basic weight0.622kg

/Example: CY3R25-500

(with switch rail) Additional weight0.056kg/50s

Cylinder stroke500st

0.622 + 0.056 x 500 50 = 1.182 (kg)

Theoretical thrust (holding force) (N)

Basic weight

CY3B/3R

0

1000

900

800

2

ø3

700

600

500

ø25

400

300

ø20

200

ø15

100

0

0.1 0.2

0.3 0.4

0.5

0.6

0.7 0.8

0.9 1.0

Approved

Supply pressure (MPa)

12

CY3B/3R

4/18/02 6:53 PM

Series

Page 16

CY3R

Construction

Both sides piping type

CY3R15 to 40

2a

!9

@0 !5 !6 !3 @4 @9 @6 !0 i q !1 !4 !2 y r

!8 @2

@0 @3 @5

t

@8 o u !7

3a

@7

CY3R15, 20

CY3R15

Parts list

No.

Description

1

Body

Aluminum alloy

Note

Hard anodized

2a

End cover A

Aluminum alloy

Electroless nickel plated

2b End cover C

Aluminum alloy

End cover B

Aluminum alloy

3b End cover D

Aluminum alloy

3a

Material

Description

Material

Note

21

Steel balls

Chromium steel

ø40: Hexagon socket head plug

ø20: None

Electroless nickel plated

22

Hexagon socket head screw

Chromium steel

Nickel plated

Electroless nickel plated

23

Hexagon socket head set screw

Chromium steel

Nickel plated

Electroless nickel plated

24∗

Cylinder tube

Gasket

4

Cylinder tube

5

Piston

6

Shaft

7

Piston side yoke

Rolled steel plate

Zinc chromated

8

External slider side yoke

Rolled steel plate

Zinc chromated

Stainless steel

ø15: Brass

ø15: Electroless nickel plated

ø20 to ø40: Aluminum alloy ø20 to ø40: Chromate

Stainless steel

9

Magnet A

Rare earth magnet

10

Magnet B

Rare earth magnet

11

Spacer

Aluminum alloy

12

Bumper

Urethane rubber

13

Piston nut

Carbon steel

ø20 to ø40

14

Snap ring

Carbon tool steel

Nickel plated

15

Attachment ring

Aluminum alloy

Chromate

16

C type snap ring for shaft

Hard steel wire

17

Magnetism shielding plate

Rolled steel plate

Chromated

18

Switch rail

Aluminum alloy

White anodized

19

Magnet

20

Hexagon socket head plug

25∗ Wear ring A

26∗ Wear ring B

27∗ Wear ring C

28∗ Piston seal

29∗ Soft wiper

30∗

Black anodized

Rare earth magnet

Chromium steel

No.

Nickel plated

NBR

Special resin

Special resin

Special resin

NBR

Special resin

Switch rail

Gasket

NBR

Both sides

piping type: None

∗Seal kits are sets consisting of numbers 24 through 30, and may be

ordered using the order number to each bore size.

Replacement parts: Seal kits

Bore size (mm)

15

20

25

32

40

Kits no.

CY3R15-PS

CY3R20-PS

CY3R25-PS

CY3R32-PS

Contents

Numbers

@44, @5, @6, @7, @8, @9, #0

above

CY3R40-PS

∗Seal kits are the same for both the both sides piping type and the

centralized piping type.

Approved

13

CY3B/3R

4/18/02 6:54 PM

Page 17

Magnetically Coupled Rodless Cylinder

Series

Direct Mount Type

CY3B

Dimensions

Centralized piping type

CY3RG15 to 40

!5 !6 !3 @4 @9 @6 !0 i q !1 !4 !2 y

2b

!9

!8 @2 @0 #0 @3 @5

t

@8 o u !7

r

3b

@7

CY3RG15, 20

CY3RG15

!9

!8

@2 @1

CY3RG15

Replacement parts: Seal kits

Bore size (mm)

15

20

25

32

40

Kits no.

CY3R15-PS

CY3R20-PS

Contents

CY3R25-PS

Numbers

@4,@5,@6,@7,@8,@9,#0

CY3R32-PS

at the left

CY3R40-PS

∗Seal kits are the same for both the both sides piping type and the

centralized piping type.

Switch Rail Accessory

Switch rail accessory kits

CYR 15 E

Stroke

20

Bore size

Kits no.

Contents

15

CYR15E-

Numbers Note 2)

!7,!8,@0,@2,@7 at the left

For reed switch

CYR20E-

CYR20EN-

Bore size (mm)

For solid state switch

25

32

40

CYR25E-

CYR32E-

Numbers

!7,!8,@0,@2,@7 at the left

CYR40E-

Note 1) indicates to the stroke.

Note 2) A magnet is aleady is already built in for ø15.

Approved

14

4/18/02 6:54 PM

Series

Page 18

CY3R

Dimensions

Both sides piping type: ø15 to ø40

N

X

HB

HC

HT

Note 1) This figure shows types with switch rail (no symbol).

2-plug

H

HA

CB

A

2-P (Piping port)

HP

W

T

K

4-counter bore dia. øB

Counter bore depth C

Y

0

L -0.1

T

7

CY3R15, 20

Model

CY3R15

CY3R20

CY3R25

CY3R32

CY3R40

Model

CY3R15

CY3R20

CY3R25

CY3R32

CY3R40

Model

CY3R15

CY3R20

CY3R25

CY3R32

CY3R40

G

2 x 4-MM

Thread depth M

Q + Stroke

Z + Stroke

PW

Switch rail

G

CY3R25, 32, 40

A

B

10.5

8

9

9.5

8.5

9.5

10.5 11

10

11

L

53

62

70

76

90

K

QW

X

4-øLD

GW

GP

CR

W

Plug

HS

HR

øD

F

TC

4-J x E

WP

CY3B/3R

LD

4.3

5.6

5.6

7

7

Nil

M5 x 0.8

Rc 1/8

Rc 1/8

Rc 1/8

Rc 1/4

C

4.2

5.2

5.2

6.5

6.5

M

5

5

6

7

8

CB

2

3

3

3

5

CR

0.5

1

1

1.5

2

MM

M4 x 0.7

M4 x 0.7

M5 x 0.8

M6 x 1

M6 x 1

P (Piping port)

TN

—

NPT 1/8

NPT 1/8

NPT 1/8

NPT 1/4

D

F

16.6

8

21.6

9

26.4 8.5

33.6 10.5

41.6 13

N

6

7

6.5

8.5

11

PW

32

38

43

54

64

G

5

6

6

7

7

GP

33

39

44

55

65

GW

31.5

37.5

42.5

53.5

63.5

H

32

39

44

55

67

HA

30

36

41

52

62

HB

17

21

23.5

29

36

HC

31

38

43

54

66

HP

17

24

23.5

29

36

HR

30

36

41

51

62

Q

84

95

105

116

134

QW

18

17

20

26

34

T

19

20.5

21.5

24

26

TC

17

20

22.5

28

33

W

25

40

40

50

60

WP

16

19

21.5

27

32

X

18

22

28

35

40

Y

54.5

64

72

79

93

Z

94

107

117

130

148

HS

8.5

7.5

6.5

7

8

HT

17

24

23.5

29

36

JxE

M5 x 0.8 x 7

M6 x 1 x 8

M6 x 1 x 8

M8 x 1.25 x 10

M8 x 1.25 x 10

(mm)

K

14

11

15

13

15

TF

—

G 1/8

G 1/8

G 1/8

G 1/4

Approved

15

4/18/02 6:54 PM

Page 19

Magnetically Coupled Rodless Cylinder

Direct Mount Type

Series

CY3B

Dimensions

N

X

HC

HB

Centralized piping type: ø15 to ø40

W

T

4-counter bore dia. øB

Counter bore depth C

Y

0

L -0.1

T

7

Plug

CY3RG15

HS

HR

CR

W

Plug

K

G

2 x 4-MM

Thread depth M

QW

PW

øD

X

4-øLD

GW

GP

WP

F

8

2-P

(Piping port)

2-P

(Piping port)

K

TC

22

H

HA

HT

HP

CB

4-J x E

12.5

19.5

CY3B/3R

Switch rail

G

Q + Stroke

Z + Stroke

CY3RG25, 32, 40

CY3RG20

Model

CY3RG15

CY3RG20

CY3RG25

CY3RG32

CY3RG40

B

8

9.5

9.5

11

11

C

4.2

5.2

5.2

6.5

6.5

CB

2

3

3

3

5

Model

CY3RG15

CY3RG20

CY3RG25

CY3RG32

CY3RG40

LD

4.3

5.6

5.6

7

7

M

5

5

6

7

8

MM

M4 x 0.7

M4 x 0.7

M5 x 0.8

M6 x 1

M6 x 1

Model

CY3RG15

CY3RG20

CY3RG25

CY3RG32

CY3RG40

Nil

M5 x 0.8

Rc 1/8

Rc 1/8

Rc 1/8

Rc 1/4

CR

0.5

1

1

1.5

2

P (Piping port)

TN

—

NPT 1/8

NPT 1/8

NPT 1/8

NPT 1/4

D

F

16.6

8

21.6

9

26.4

8.5

33.6 10.5

41.6 13

N

6

7

6.5

8.5

11

PW

32

38

43

54

64

G

5

6

6

7

7

GP

33

39

44

55

65

GW

31.5

37.5

42.5

53.5

63.5

H

32

39

44

55

67

HA

30

36

41

52

62

HB

17

21

23.5

29

36

HC

31

38

43

54

66

HP

—

11

14.5

20

25

HR

30

36

41

51

62

Q

84

95

105

116

134

QW

19

20.5

21.5

24

26

T

19

20.5

21.5

24

26

TC

17

20

22.5

28

33

W

25

40

40

50

60

WP

16

19

21.5

27

32

X

18

22

28

35

40

Y

54.5

64

72

79

93

Z

94

107

117

130

148

HS

8.5

7.5

6.5

7

8

HT

—

28

33.5

41

50

JxE

M5 x 0.8 x 7

M6 x 1 x 8

M6 x 1 x 8

M8 x 1.25 x 10

M8 x 1.25 x 10

K

14

11

15

13

15

(mm)

L

53

62

70

76

90

TF

—

G 1/8

G 1/8

G 1/8

G 1/4

Approved

16

CY3B/3R

4/18/02 6:54 PM

Series

Page 20

CY3R

Auto Switch Proper Mounting Position for Stroke End Detection

Auto Switch Operation Range

(Reference dimension)

Auto switch

model

D-A9

A

15

8

D-F9, D-F9W 5

D-Z7, Z80

D-Y59, Y7P

D-Y7W

B

C

Bore size (mm)

20

25

32

40

6

4

9

9

11

6

6

6

∗Switches cannot be mounted in some cases.

∗Operating ranges are standards including

hysteresis, and are not guaranteed. (variation

on the order of 30%)

Large variations may occur depending on the

surrounding environment.

D

ø15, ø20

(mm)

Applicable switch model

Bore size

(mm)

D-A9

D-F9, D-A9W

B

C

A

B

C

D

A

15

17.5

76.5

56.5

21.5

72.5

60.5

D

20

19.5

87.5

39.5

67.5

23.5

83.5

35.5

71.5

Note 1) Auto switches cannot be installed in Area C in the case of ø15.

Note 2) Only non-magnetic material is permitted as the mounting surface of a ø20 cylinder.

ø25, ø32, ø40

Bore size

(mm)

(mm)

Applicable switch model

D-Z7, Z80, Y59, D-Y7P, Y7W

A

B

C

D

25

18

99

43

74

32

21.5

108.5

46.5

83.5

40

23.5

124.5

48.5

99.5

Note 1) 50mm is the minimum stroke available with 2 auto switches mounted.

Note 2) The above dimensions are given as reference dimensions. Confirm installation with actual

equipment.

Auto Switch Mounting

When mounting auto switches, they

should be inserted into the cylinder's

switch groove from the direction

shown in the drawing on the right.

After setting in the mounting position,

use a flat head watchmakers screw

driver to tighten the mounting

screw which is included.

Note) When tightening the auto switch mounting screw, use a

watchmakers screw driver with a handle about 5 to 6mm in

diameter.

Furthermore, the tightening torque should be approximately 0.05

to 0.1N⋅m (0.51 to 1.02kgf⋅cm). As a rule, it can be turned about

90 past the point at which tightening can be felt.

Flat head watchmakers screw driver

ø5 to ø6

Auto switch

Switch mounting screw

(M2.5 x 4 l)

(included)

Auto Switch Specifications

(1) Switches (switch rail) can be added to the standard type (without switch rail). The switch rail

accessory type is mentioned on page 14, and can be ordered together with auto switches.

(2) Refer to the separate disassembly instructions for switch magnet installation procedures.

Approved

17

4/18/02 6:54 PM

Page 21

Magnetically Coupled Rodless Cylinder

Direct Mount Type

Series

CY3B

Contact

protection

box

CD-P11

CD-P12

Resistor

Zener

diode

Blue

OUT (+)

Brown

D-A96

D-Z76

LED

Reed switch

Reed switch

LED

OUT ()

Blue

Resistor

DC (+)

Brown

D-A90

D-Z80

DC power

Brown

D-A93

D-Z73

Load

Reverse OUT

current

prevention Black

diode

Reed switch

Reed Switch Internal Circuit

Contact

protection

box

CD-P11

CD-P12

OUT ()

Brown

OUT ( )

Blue

DC ()

Blue

Solid State Switch Internal Circuit

DC (+)

Brown

D-F9N

D-Y59A

OUT

Black

DC (+)

Brown

Main

switch circuit

Main

switch circuit

D-F9NW

D-Y7NW

OUT

Black

DC ()

Blue

DC ()

Blue

D-F9P

D-Y7P

DC (+)

Brown

DC (+)

Brown

Main

switch circuit

Main

switch circuit

D-F9PW

D-Y7PW

OUT

Black

OUT

Black

DC ()

Blue

DC ()

Blue

Indicator light

OFF

D-F9BW

D-Y7BW

Indicator

Red Green Red

Optimum

operating position

D-F9B

D-Y59B

OUT (+)

Brown

OUT (+)

Brown

Main

switch circuit

ON

Operating

range

Main

switch circuit

OUT ()

Blue

OUT ()

Blue

Contact Protection Box/CD-P11, CD-P12

Internal circuit

<Applicable switches>

D-A9, Z7, Z8

The above auto switches do not have built-in contact protection circuits.

CD-P11

1. The operating load is an induction load.

2. The length of wiring to the load is 5m or more.

3. The load voltage is 100VAC.

Surge

absorber

CD-P12

Choke

coil

Contact protection box specifications

Zener

diodes

Choke

coil

OUT (+)

Brown

OUT ()

Blue

Dimensions

CD-P12

24VDC

50mA

CD-P

VOLT

38

46

SWITCH

4.4

9

18

Part no.

CD-P11

Load voltage

100VAC or less

200VAC

Max. load current

25mA

12.5mA

∗Lead wire length Switch contacts side 0.5m

Load connection side 0.5m

OUT

Brown

OUT

Blue

A contact protection box should be used in any of the above conditions.

3.4

CY3B/3R

15.5

Connection

To connect a switch unit to a contact protection box, connect the lead wire

from the side of the contact protection box marked SWITCH to the lead wire

coming out of the switch unit. The switch unit should be kept as close as

possible to the contact protection box with a lead wire that is no more than 1

meter in length.

18

Approved

CY3B/3R

4/18/02 6:54 PM

Page 22

Auto Switch Connections and Examples

Basic Wiring

Solid state 3-wire, NPN

Brown

Load

Black

Main

switch

circuit

2-wire

<Solid state>

Solid state 3-wire, PNP

Brown

Load

Brown

Main

switch

circuit

Indicator

light,

protection

circuit,

etc.

Main

switch

circuit

Black

Load

Blue

2-wire

<Reed switch>

Blue

Blue

Blue

Brown

Load

(Power supplies for switch and load

are separate.)

Brown

Brown

Load

Black

Main

switch

circuit

Brown

Indicator

light,

protection

circuit,

etc.

Main

switch

circuit

Load

Blue

Blue

Load

Blue

Examples of Connection to PLC

Source input specifications

3-wire, PNP

Sink input specifications

3-wire, NPN

Black

Black

Input

Input

Brown

Brown

Switch

Connect according to the applicable

PLC input specifications, as the

connection method will vary depending on the PLC input specifications.

Switch

Blue

Blue

COM

COM

PLC internal circuit

2-wire

PLC internal circuit

2-wire

Input

Brown

Blue

Switch

Input

Switch

Blue

Brown

COM

COM

PLC internal circuit

PLC internal circuit

Connection Examples for AND (Series) and OR (Parallel)

3-wire

AND connection for NPN output

(using relays)

Switch 1

Switch 2

OR connection for NPN output

AND connection for NPN output

(performed with switches only)

Brown

Black

Relay

Blue

Load

Relay

contact

Brown

Black

Relay

Blue

Switch 1

Switch 2

Brown

Black

Load

Blue

Switch 1

Brown

Black

Blue

Switch 2

Brown

Black

Blue

Load

Brown

Black

Blue

The indicator lights will light up when

both switches are turned ON.

2-wire with 2 switch AND connection

Brown

Load

Switch 1

Blue

Brown

Switch 2

Blue

When two switches are

connected in series, a load

may malfunction because

the load voltage will decline

when in the ON state.

The indicator lights will light

up if both of the switches

are in the ON state.

Internal

Power supply

voltage x 2 pcs.

voltage

drop

= 24V 4V x 2 pcs.

= 16V

Example: Power supply is 24VDC

Internal voltage drop in switch is 4V

Load voltage at ON =

19

2-wire with 2 switch OR connection

Brown

Switch 1

Switch 2

Blue

Brown

Blue

Load

<Solid state>

When two switches

are connected in

parallel, malfunction

may occur because

the load voltage will

increase when in

the OFF state.

Leakage

Load

Load voltage at OFF = current x 2 pcs. x

impedance

= 1mA x 2 pcs. x 3kΩ

= 6V

Example: Load impedance is 3kΩ

Leakage current from switch is 1mA

<Reed switch>

Because there is no current

leakage, the load voltage will

not increase when turned

OFF. However, depending

on the number of switches in

the ON state, the indicator

lights may sometimes dim or

not light up, because of dispersion and reduction of the

current flowing to the

switches.

Approved

CY3B/3R

4/18/02 6:54 PM

Page 23

Series CY3B/CY3R

Made to Order Specifications

Contact SMC for detailed specifications, lead times and prices.

Symbol

Contents

Model

Bore size (mm)

15

25

32

40

CY3B

CY3R

CY3B

CY3R

CY3B

CY3R

-XB11

Long stroke (2001mm and up)

CY3B

-XB13

Low speed cylinder (7 to 50mm/s)

CY3B

-X116

Hydro specifications

-X132

Axial ports

-X160

High speed specifications

-X168

CY3B

Helical insert thread specifications

20

-X206

Added mounting tap positions for slider

CY3B

-X210

Oil-free exterior specifications

CY3B

Outside of cylinder tube with hard chrome

plating

CY3B

-X322

CY3R

CY3B

CY3B

CY3R

-X324

Oil-free exterior specifications (with dust seal)

-XC57

With floating joint

Approved

20

CY3B/3R

4/18/02 6:54 PM

Page 24

Series CY3B/CY3R

Made to Order Specifications 1

Contact SMC for detailed specifications, lead times and prices.

Symbol

1

Long stroke (2001mm and up )

CY3B Bore size Port thread type

-XB11

Stroke

XB11

4

Symbol

-X132

Axial ports

CY3B Bore size Port thread type

Stroke X132

Long stroke (2001mm to 3000mm)

The air supply port has been changed to an axial position on the head

cover.

Specifications

Applicable series

Bore size

Applicable stroke

Axial ports

CY3B

Specifications

ø25 to ø40

2001st to 3000st

Applicable series

Bore size

Note 1) If the stroke exceeds 3000 mm, use XB11 specification of series CY1B.

2

Symbol

CY3B

ø15 to ø40

2-port size

Low speed (7 to 50mm/s) specifications -XB13

CY3B Bore size Port thread type

Stroke XB13

The port size is the same as the standard type.

Very low speed (7 to 50mm/s) specifications

There is no sticking and slipping even at very low drive speeds of 7 to

50mm/s. Furthermore, there is no lurching at start up, allowing smooth

drive through the entire stroke.

5

Symbol

-X160

High speed specifications

Specifications

Applicable series

Bore size

Piston speed

CY3B

CY3B

Bore size Port thread type

CY3R

ø15 to ø40

7 to 50 mm/s

Stroke X160

High speed specifications

3

Symbol

-X116

Hydro specifications

Makes possible high speed piston drive of 1500mm/s (without load).

Specifications

Applicable series

CY3B

Bore size Port thread type

CY3R

Stroke

X116

Hydro specifications

Suitable for precision low speed feeding, intermediate stopping and skip

feeding of the cylinder.

Applicable series

Bore size

Fluid

Piston speed

ø20 to ø40

Piston speed (no load)

1500mm/s

Note 1) When operating this cylinder at high speed, a shock absorber

must be provided.

Note 2) Only piping on both sides is available with CY3R.

6

Specifications

CY3B/CY3R

Bore size

Symbol

Helical insert thread specifications

-X168

CY3B/CY3R

ø25 to ø40

CY3B Bore size Port thread type

CY3R

Turbine oil

15 to 300mm/s

Note 1) Only piping on both sides is available with CY3R.

Note 2) When performing intermediate stops with an air-hydro circuit, set

the kinetic energy of the load so that it does not exceed the

allowable value. (Regarding the allowable value, refer to the

section "Intermediate stops" for each series.)

Stroke X168

Helical insert thread specifications

The standard mounting threads have been changed to helical insert

thread specifications.

Specifications

Applicable series

Bore size

CY3B/CY3R

ø20 to ø40

Approved

21

CY3B/3R

4/18/02 6:54 PM

Page 25

Series CY3B/CY3R

Made to Order Specifications 2

Contact SMC for detailed specifications, lead times and prices.

7

Symbol

Added mounting tap positions for slider -X206

CY3B Bore size Port thread type

Stroke X206

Symbol

9

Outside of cylinder tube with hard chrome plating -X322

CY3B Bore size Port thread type

CY3R

Added mounting tap positions for slider

Mounting taps have been added on the surface opposite the standard

positions.

Specifications

Applicable series

CY3B

Outside of cylinder tube with hard chrome plating

The outside of the cylinder tube has been plated with hard chromium,

reducing wear on the bearings.

Specifications

ø15 to ø40

Bore size

Applicable series

Bore size

CY3B/CY3R

ø15 to ø40

∗Be sure to provide shock absorption measures at the stroke end.

Mounting taps

Additional positions

Stroke X322

Standard surface

Construction

CY3B

∗Dimensions are the same as the standard product.

8

CY3R

Tube external surface is

hard chromium electro

Tube external surface is

hard chromium electro

Symbol

Oil-free exterior specifications

CY3B Bore size Port thread type

-X210

Stroke

X210

Symbol

10

Oil-free exterior specifications (with dust seal) -X324

CY3B Bore size Port thread type

Stroke X324

Oil-free exterior specifications

Oil-free exterior specifications (with dust seal)

Suitable for environments where oils are not tolerated. A scraper is not

installed. A separate version -X324 (with felt) has been prepared for cases

in which dust, etc. is scattered throughout the environment.

This unit has oil-free exterior specifications, with a felt dust seal provided

on the cylinder body.

Specifications

Specifications

Applicable series

Bore size

CY3B

ø15 to ø40

Construction

CY3B

Applicable series

Bore size

CY3B

ø15 to ø40

Construction

Special bearing

CY3B

Dust seal

(felt)

Special bearing

Approved

22

CY3B/3R

4/18/02 6:54 PM

Page 26

Series CY3B/CY3R

Made to Order Specifications 3

Contact SMC for detailed specifications, lead times and prices.

Symbol

11

With floating joint (CY3B)

-XC57

CY3B Bore size Port thread type

XC57

Stroke

Specifications

Bore size

ø15, ø20, ø25, ø32, ø40

Note) Since the body of this cylinder is designed for connection with a

floating joint, and cannot be connected to the bodies of standard

products, contact SMC if necessary.

With floating joint

A special floating joint is added to the Series CY3B, and the number of

connections to the guide on the other axis (the load side) is reduced.

The attachment of the bolt to the floating joint and the load is not limited to

the top or bottom.

Dimensions

A

Attached from top

W

PA

Attached from

bottom: MD

HA

HB

R Note 2)

M

F Note 1)

MM

L

LA

C

Body

B

(mm)

Model

CY3B15

CY3B20

CY3B25

CY3B32

CY3B40

F Note 1)

HA

HB

L

LA

MM

MD

M

PA

R Note 2)

W

5.5

16.5

23

57

25

M4 x 0.7

M3

4

25

6

36

5.5

17

23.5

66

30

M4 x 0.7

M3

4

27

6

37

8.0

5.5

21

28.5

70

30

M5 x 0.8

M4

5

36

7

47

60

9.5

6.0

27.5

36

80

35

M6 x 1.0

M5

6

47

8

61

70

9.5

6.0

28.5

41

92

40

M6 x 1.0

M5

6

55

8

71

B

C

16

35

6.5

18

36

6.5

20

46

22.5

26

A

Note 1) Dimension F provides a clearance of 1mm between the body and the floating joint, but does not consider dead weight deflection of the cylinder

tube, etc. When put into operation, an appropriate value should be set which considers dead weight deflection and alignment variations with

respect to the other axis. (Refer to the dead weight deflection table on page 5.)

Note 2) Use caution when attached from the top and operated at or above dimension R, because the end of the screw will contact the body, and floating

cannot be maintained in some cases.

Approved

23

CY3B/3R

4/18/02 6:54 PM

Page 27

Series CY3B/CY3R

Made to Order Specifications 4

Contact SMC for detailed specifications, lead times and prices.

Symbol

12

With floating joint (CY3R)

-XC57

CY3R Bore size Port thread type

Specifications

XC57

Stroke

Bore size

ø15, ø20, ø25, ø32, ø40

Note) Since the body of this cylinder is designed for connection with a

floating joint, and cannot be connected to the bodies of standard

products, contact SMC if necessary.

With floating joint

A special floating joint is added to the Series CY3R, and the number of

connections to the guide on the other axis (the load side) is reduced.

The attachment of the bolt to the floating joint and the load is not limited to

the top or bottom.

Dimensions

ø15

D

HL

XA FH

Attached from bottom

with CAP bolt

Bolt size: MD

4-SS thread depth S

(Helical insert depth)

Attached from top

with bolt

X A FG

L

LA

4-øBA

4-recessed area diameter øBB

4-recessed area depth CC

A

LF

Body

FF

Note 1)

X A FG

XA FH

HL

HB Note 1)

Switch rail

D’

FE Note 1)

Floating block

Section D-D’

ø20, ø25, ø32, ø40

D

Attached from top

with CAP bolt

Attached from bottom

with CAP bolt

Bolt size: MD

2-SS

(Helical insert thread)

A

LF

Body

FF Note 1)

Note 2) R

Switch rail

Note 1) HB

HL

S

FG

Floating block

L

LA

XB

WF

XA

FC

D’

Section D-D’

(mm)

Model

A

BA

BB

CC

FC FE

FG

FH HB

CY3R15

CY3R20

CY3R25

CY3R32

CY3R40

18

4.5

8

4.4

—

4.5

6.5

7.5

14.5

16.5

—

—

—

6.5

—

6

4

20.5

—

—

—

8

—

7

21

—

—

—

9.5

—

25.5

—

—

—

9.5

—

Note1)

HL

L

LA

LF

MD R

Note2)

S

SS

WF

XA

XB

38.5

35.5

53

17

8.5

M4

—

4.5

M4 x 0.7

—

14

—

—

45

14

62

29

14.5

M3

7

4.5

M4 x 0.7

34

26

3

4

—

51

17

70

29

14.5

M4

8

5.5

M5 x 0.8

39

31

3

7.5

4.5

—

62.5

22

76

34

17

M5

10

6.5

M6 x 1

50

41

3

7.5

7.5

—

74.5

28

90

39

19.5

M5

10

6.5

M6 x 1

60

45

3

FF

Note1)

Note1)

Note 1) FE, FF and HB provide a clearance of 1mm between the body and the floating joint, but do not consider dead weight deflection of the cylinder tube,

etc. When put into operation, an appropriate value should be set which considers dead weight deflection an alignment variations with respect to the

other axis. (Refer to the dead weight deflection table on page 5.)

Note 2) Use caution when attached from the top and operated at or above dimension R, because the end of the screw will contact the body, and floating

cannot be maintained in some cases.

24

Approved

CY3B/3R

4/18/02 6:54 PM

Page 28

Series CY3B/CY3R

Safety Instructions

These safety instructions are intended to prevent a hazardous situation and/or

equipment damage. These instructions indicate the level of potential hazard by a

label of "Caution", "Warning" or "Danger". To ensure safety, be sure to

observe ISO 4414 Note 1), JIS B 8370 Note 2) and other safety practices.

Caution : Operator error could result in injury or equipment damage.

Warning :

Operator error could result in serious injury or loss of life.

Danger :

In extreme conditions, there is a possible result of serious injury or loss of life.

Note 1) ISO 4414 : Pneumatic fluid power -- Recommendations for the application of equipment to transmission and

control systems.

Note 2) JIS B 8370 : General Rules for Pneumatic Equipment.

Warning

1. The compatibility of pneumatic equipment is the responsibility of the person

who designs the pneumatic system or decides its specifications.

Since the products specified here are used in various operating conditions, their compatibility for the

specific pneumatic system must be based on specifications or after analysis and/or tests to meet your

specific requirements.

2. Only trained personnel should operate pneumatically operated machinery and

equipment.

Compressed air can be dangerous if handled incorrectly. Assembly, handling or repair of pneumatic

systems should be performed by trained and experienced operators.

3. Do not service machinery/equipment or attempt to remove components until

safety is confirmed.

1. Inspection and maintenance of machinery/equipment should only be performed after confirmation of

safe locked-out control positions.

2. When equipment is to be removed, confirm the safety process as mentioned above. Cut the supply

pressure for this equipment and exhaust all residual compressed air in the system.

3 .Before machinery/equipment is restarted, take measures to prevent shooting-out of cylinder piston

rod, etc. (Bleed air into the system gradually to create back-pressure.)

4. Contact SMC if the product is to be used in any of the following conditions:

1. Conditions and environments beyond the given specifications, or if product is used outdoors.

2. Installation on equipment in conjunction with atomic energy, railway, air navigation, vehicles, medical

equipment, food and beverages, recreation equipment, emergency stop circuits, press applications,

or safety equipment.

3. An application which has the possibility of having negative effects on people, property, or animals,

requiring special safety analysis.

Approved

25

CY3B/3R

4/18/02 6:54 PM

Page 29

CY3B/CY3R

Actuator Precautions 1

Series

Be sure to read before handling.

Precautions on Design

Warning

1. There is a danger of sudden action by air

cylinders if sliding parts of machinery are

twisted, etc., and changes in forces occur.

In such cases, human injury may occur; e.g., by catching hands or

feet in the machinery, or damage to the machinery itself may occur.

Therefore, the machine should be designed to avoid such dangers.

2. A protective cover is recommended to minimize the risk of personal injury.

If a stationary object and moving parts of a cylinder are in close

proximity, personal injury may occur. Design the structure to avoid

contact with the human body.

3. Securely tighten all mounting parts and connecting parts so that they will not become

loose.

Especially when a cylinder operates with high frequency or is

installed where there is a lot of vibration, ensure that all parts remain

secure.

4. A deceleration circuit or shock absorber, etc.,

may be required.

When a driven object is operated at high speed or the load is heavy,

a cylinder’s cushion will not be sufficient to absorb the impact. Install

a deceleration circuit to reduce the speed before cushioning, or

install an external shock absorber to relieve the shock. In this case,

the rigidity of the machinery should also be examined.

5. Consider a possible drop in operating pressure due to a power outage, etc.

When a cylinder is used in a clamping mechanism, there is a danger of work pieces dropping if there is a decrease in clamping force

due to a drop in circuit pressure caused by a power outage, etc.

Therefore, safety equipment should be installed to prevent damage

to machinery and/or human injury. Suspension mechanisms and lifting devices also require consideration for drop prevention.

6. Consider a possible loss of power source.

Selection

Warning

1. Confirm the specifications.

The products advertised in this catalog are designed according to

use in industrial compressed air systems. If the products are used

in conditions where pressure, temperature, etc., are out of specification, damage and/or malfunction may be caused. Do not use

in these conditions. (Refer to specifications.)

Consult SMC if you use a fluid other than compressed air.

2. Intermediate stops.

When intermediate stopping of a cylinder piston is performed with

a 3 position closed center type directional control valve, it is difficult to achieve stopping positions as accurate and minute as with

hydraulic pressure due to the compressibility of air.

Furthermore, since valves and cylinders, etc., are not guaranteed

for zero air leakage, it may not be possible to hold a stopped position for an extended period of time. Contact SMC in case it is necessary to hold a stopped position for an extended period.

Caution

1. Operate within the limits of the maximum

usable stroke.

Refer to the selection procedures for the type of air cylinder to be

used for the maximum usable stroke.

2. Operate the piston within a range such that

collision damage will not occur at the stroke

end.

Operate within a range such that damage will not occur when the

piston having inertial force stops by striking the cover at the stroke

end. Refer to the cylinder model selection procedure for the range

within which damage will not occur.

3. Use a speed controller to adjust the cylinder

drive speed, gradually increasing from a low

speed to the desired speed setting.

Measures should be taken to protect against human injury and

equipment damage in the event that there is a loss of power to

equipment controlled by air pressure, electricity or hydraulics, etc.

7. Design circuitry to prevent sudden lurching

of driven objects.

When a cylinder is driven by an exhaust center type directional control valve or when starting up after residual pressure is exhausted

from the circuit, etc., the piston and its driven object will lurch at

high speed if pressure is applied to one side of the cylinder because

of the absence of air pressure inside the cylinder. In such cases,