Lecture Set 1

advertisement

Lecture Set 1

Introduction to

Magnetic Circuits

S.D. Sudhoff

Spring 2016

1

Goals

• Review physical laws pertaining to analysis

of magnetic systems

• Introduce concept of magnetic circuit as

means to obtain an electric circuit

• Learn how to determine the flux-linkage

versus current characteristic because it

will be key to understanding

electromechanical energy conversion

2

Review of Symbols

•

•

•

•

•

•

•

•

•

•

•

•

Flux Density in Tesla: B (T)

Flux in Webers: Φ (Wb)

Flux Linkage in Volt-seconds: λ (Vs,Wb-t)

Current in Amperes: i (A)

Field Intensity in Ampere/meters: H (A/m)

Permeability in Henries/meter: µ (Η/m)

Magneto-Motive Force: F (A,A-t)

Permeance in Henries: P (H)

Reluctance in inverse Henries: R (1/H)

Inductance in Henries: L (H)

Current (fields) into page:

Current (fields) out of page:

3

Ampere’s Law, MMF, and Kirchoff’s

MMF Law for Magnetic Circuits

4

Consider a Closed Path …

5

Enclosed Current and MMF Sources

• Enclosed Current

ienc ,Γ = − N a ia + Nb ib − Nc ic

• MMF Sources

Fa = − N a ia

Fb = N b ib

Fc = − N c ic

• Conclusion

ienc , Γ =

∑F

s

s∈S Γ

SΓ = {' a ', ' b ', ' c '}

6

MMF Drops

• Going Around the Loop

∫ H ⋅ dl = ∫ H ⋅ dl + ∫ H ⋅ dl + ∫ H ⋅ dl + ∫ H ⋅ dl

lΓ

lα

lβ

lγ

lδ

• MMF Drop

Fy = ∫ Hidl

ly

• Thus

∫ Hidl = Fα + Fβ + Fγ + Fδ

lΤ

• Or

∫ H ⋅ dl = ∑ F

d

lΓ

d ∈DΓ

DΓ = {'α ', ' β ', ' γ ', ' δ '}

7

Ampere’s Law

• Ampere’s Law

∫ H ⋅ dl = i

enc , Γ

lΓ

• Recall

ienc , Γ =

∑ F ∫ H ⋅ dl = ∑ F

s

d

s∈S Γ

lΓ

• Thus

∑F

s

s∈SΓ

=

d ∈DΓ

∑F

d

d ∈DΓ

8

Kirchoff’s MMF Law

Kirchoff’s MagnetoMotive Force Law:

The Sum of the MMF Drops Around a

Closed Loop is Equal to the Sum of the

MMF Sources for That Loop

9

Example: MMF Sources

10 conductors, 3 A =

5 conductors, 2 A =

10

Example: MMF Drops

• A quick example on MMF drop:

11

Another Example: MMF Drops

• How about Fcb ?

12

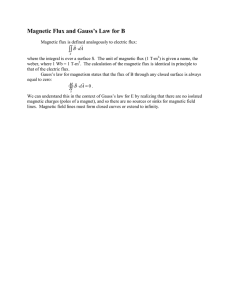

Magnetic Flux, Gauss’s Law, and

Kirchoff’s Flux Law for Magnetic Circuits

13

Magnetic Flux

Φm =

∫ B⋅dS

Sm

14

Example: Magnetic Flux

• Suppose there exist a uniform flux density field of

B=1.5ay T where ay is a unit vector in the direction

of the y-axis. We wish to calculate the flux through

open surface Sm with an area of 4 m2, whose

periphery is a coil of wire wound in the indicated

direction.

15

Example: Magnetic Flux

16

Example: Magnetic Flux

17

Kirchoff’s Flux Law

• Gauss’s Law

∫ B⋅dS = 0

SΓ

• Thus

∑ ∫ B ⋅ dS = 0

O Γ = {' α ', ' β ', ' γ ',⋯}

o∈ΟΓ So

• Or

∑Φ

o

=0

o∈Ο Γ

18

Kirchoff’s Flux Law

• Kirchoff’s Flux Law:

The Sum of the Flux Leaving A Node of a

Magnetic Circuit is Zero

19

Kirchoff’s Flux Law

• A quick example on Kirchoff’s Flux Law

20

Magnetically Conductive Materials and

Ohm’s Law for Magnetic Circuits

21

Ohm’s Law

• On Ohm’s Law Property for Electric Circuits

• On Ohm’s Law Property for Magnetic Circuits

22

Types of Magnetic Materials

• Interaction of Magnetic Materials with Magnetic

Fields

Magnetic Moment of Electron Spin

Magnetic Moment of Electron in Shell

• These Effects Lead to Six Material Types

Diamagnetic

Paramagnetic

Ferromagnetic

Antiferromagnetic

Ferrimagnetic

Superparamagnetic

23

Ferromagnetic Materials

• Iron

• Nickel

• Cobalt

24

Ferrimagnetic Materials

• Iron-oxide ferrite (Fe3O4)

• Nickel-zinc ferrite (Ni1/2Zn12Fe2O4)

• Nickel ferrite (NiFe2O4)

25

Behavior of Ferromagnetic and

Ferrimagnetic Materials

26

Behavior of Ferromagnetic and

Ferrimagnetic Materials

M19

MN80C

27

Modeling Magnetic Materials

• Free Space

B = µ0 H

• Magnetic Materials

B = µ0 ( H + M )

M = χH

B = µ0 H + M

M = µ0 χ H

• Either Way

B = µ0 (1 + χ ) H

B = µ0 µr H

µr = 1 + χ

• Or

B = µH

µ = µ0 µr

28

Modeling Magnetic Materials

B = µ H (H )H

B = µ B (B) H

29

Back to Ohm’s Law

30

Relationship Between MMF

Drop and Flux

Fa = Ra (ξ )Φ a

Φ a = Pa (ξ ) Fa

la

A µ (F / l )

a H a a

Ra (ξ ) =

la

Aa µB (Φ a / Aa )

Aa µ H ( Fa / la )

la

Pa (ξ ) =

Aa µ B (Φ a / Aa )

la

Form1: ξ = Fa

Form 2 : ξ = Φ a

Form1: ξ = Fa

Form 2 : ξ = Φ a

31

Derivation

32

Derivation

33

Construction of the Magnetic Equivalent

Circuit

34

Consider a UI Core Inductor

35

Inductor Applications

36

UI Core Inductor MEC

37

Reluctances

38

Reluctances

39

Reduced Equivalent Circuit

40

Example

• Let us consider a UI core inductor with the following

parameters: wi = 25.1 mm, wb = we = 25.3 mm, ws = 51.2

mm, ds = 31.7 mm, lc = 101.2 mm, g =1.00 mm, ww =

38.1 mm, and dw = 31.7 mm. The winding is composed of

35 turns. Suppose the magnetic core material has a

constant relative permeability of 7700, and that a current of

25.0 A is flowing. Compute the flux through the magnetic

circuit and the flux density in the I-core.

41

Example

42

Example

43

Solving the Nonlinear Case

Req (Φ) = Ric (Φ) + Rbuc (Φ) + 2Rluc (Φ) + 2Rg

Ni

Φ=

Req (Φ )

44

Translation of Magnetic Circuits to Electric

Circuits: Flux Linkage and Inductance

45

Flux Linkage

λx = N xΦ x

46

Inductance

Lx , abs =

λx

ix

∂λx

Linc =

∂ix

ix1 , λx1

ix1

47

Example

• Suppose

λ = 0.05(1 − e −0.2i ) + 0.03i

• Find the absolute and incremental

inductance at 5 A

48

Computing Inductance

Φx

+

N xix -

Rx

49

Computing Inductance

50

Nonlinear Flux Linkage Vs. Current

51

Nonlinear Flux Linkage Vs. Current

52

Nonlinear Flux Linkage Vs. Current

%

%

%

%

%

%

Computation of lambda-i curve

for UI core inductor

using a simple but nonlinear MEC

S.D. Sudhoff for ECE321

January 13, 2012

% clear work space

clear all

close all

% assign parameters

cm = 1e-2;

mm = 1e-3;

w=1*cm;

ws=5*cm;

ds=2*cm;

d=5*cm;

g=1*mm;

N=100;

mu0=4e-7*pi;

Bsat=1.3;

mur=1500;

Am=w*d;

%

%

%

%

%

%

air gap (m)

number of turns

perm of free space (H/m)

sat flux density (T)

init rel permeability

mag cross section (m^2)

% start with flux linkage

lambda=linspace(0,0.08,1000);

%

%

%

%

%

%

a centimeter

a millimiter

core width (m)

slot width (m)

slot depth (m)

depth (m)

% find flux and B and mu

phi=lambda/N;

B=phi/(w*d);

mu=mu0*(mur-1)./(exp(10*(B-Bsat)).^2+1)+mu0;

53

Nonlinear Flux Linkage Vs. Current

% Assign reluctances;

Ric=(ws+w)./(Am*mu);

Rbuc=(ws+w)./(Am*mu);

Rg=g/(Am*mu0);

Rluc=(ds+w/2)./(Am*mu);

% compute effective reluctances

Reff=Ric+Rbuc+2*Rluc+2*Rg;

% compute MMF and current

F=Reff.*phi;

i=F/N;

% find lambda-i characteristic

figure(1)

plot(i,lambda);

xlabel('i, A');

ylabel('\lambda, Vs');

grid on;

% show B-H characteristic

H=B./mu;

figure(2)

plot(H,B)

xlabel('H, A/m');

ylabel('B, T');

grid on;

54

Nonlinear Flux Linkage Vs. Current

55

Hardware Example – Our MEC

Non-Idealities: Fringing and

Leakage Flux

Log10 Energy Density J/m3

0.08

0.06

0.04

y,m

0.02

0

-0.02

-0.04

-0.06

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.1

x,m

57

Our MEC – With Leakage and Fringing

58

Faraday’s Law

• Faraday’s Law, voltage equation for

winding

v x = rx ix +

dλ x

dt

• If inductance is constant

λ x = Lx i x

• Combining above yields

v x = rx ix + Lx

di x

dt

59

Energy Stored in a Magnetically

Linear Inductor

• We can show

• Proof

1

E x = Lxi x2

2

60

Mutual Inductance

61

Mutual Inductance

62

Case Study: Lets Design a

UI Core Inductor

63

Architecture

Node 2

Node 1

Depth into

page = d

w

Node 3

g

Node 4

ds

Node 8

Node 7

N Turns

w

Node 6

w

Node 5

ws

w

64

Design Requirements

•

•

•

•

•

Current Level: 40 A

Inductance: 5 mH

Packing Factor: 0.7

Slot Shape ηdw: 1

Maximum Resistance: 0.1Ω

65

Information

•

•

•

•

•

•

Cost of Ferrite:

Density of Ferrite:

Saturation Flux Density:

Cost of Copper:

Density of Copper:

Resistivity of Copper:

230 k$/m3

4740 Kg/m3

0.5 T

556 $/m3

8960 Kg/m3

1.7e-8 Ωm

66

Step 1: Design Variables

Node 2

Node 1

Depth into

page = d

w

Node 3

g

Node 4

ds

Node 8

Node 7

N Turns

w

Node 6

w

Node 5

ws

w

67

Step 2: Design Constraints

• Constraint 1: Flux Density

68

Step 2: Design Constraints

• Constraint 2: Inductance

69

Step 2: Design Constraints

• Constraint 3: Slot Shape

70

Step 2: Design Constraints

• Constraint 4: Packing Factor

71

Step 2: Design Constraints

• Constraint 5: Resistance

72

Approach (1/6)

73

Approach (2/6)

74

Approach (3/6)

75

Approach (4/6)

76

Approach (5/6)

77

Approach (6/6)

78

Design Metrics

• Magnetic Material Volume

Node 2

Node 1

Depth into

page = d

w

Node 3

g

Node 4

ds

Node 8

Node 7

N Turns

w

Node 6

w

Node 5

ws

w

79

Design Metrics

• Wire Volume

80

Design Metrics

• Circumscribing Box

Node 2

Node 1

Depth into

page = d

w

Node 3

g

Node 4

ds

Node 8

Node 7

N Turns

w

Node 6

w

Node 5

ws

w

81

Design Metrics

• Material Cost

• Mass

82

Circumscribing Box Volume

83

Material Cost

84

Mass

85

Least Cost Design

•

•

•

•

•

•

•

•

•

•

•

•

N = 260 Turns

d = 8.4857 cm

g = 13.069 mm

w = 1.813 cm

aw = 21.5181 (mm)^2

ds = 8.94 cm

ws = 8.94 cm

Vmm = 0.00066173 m^3

Vcu = 0.0027237 m^3

Vbx = 0.0075582 m^3

Cost = 153.7112 $

Mass = 27.5408 Kg

86

Loss and Mass

87

Design Criticisms

88

Manual Design Approach

Flux Density B/m 2

0.08

Analysis

0.06

0.04

y,m

0.02

0

-0.02

Design

Equations

-0.04

-0.06

Design

Revisions

-0.08

-0.1

-0.05

0

x,m

0.05

0.1

Numerical

Analysis

Final

Design

89

Formal Design Optimization

Evolutionary

Environment

Detailed

Analysis

Fitness Function

90

Another Design Trade-Off

91

Lunar Rover Propulsion Drive

Pareto-Optimal Front

92