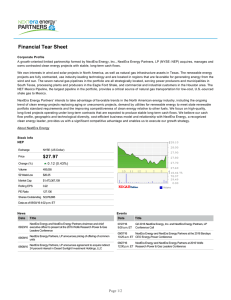

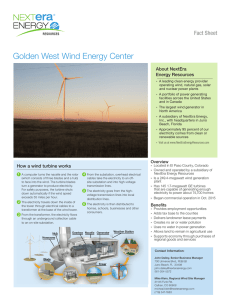

NextEra Energy Transmission, LLC

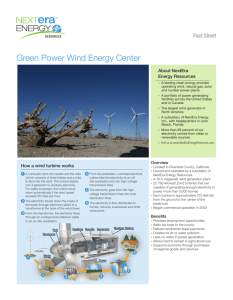

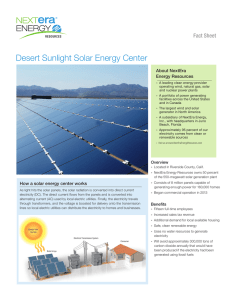

advertisement