Electrical Insulating Gloves - Give Your Employees a Hand Injuries

advertisement

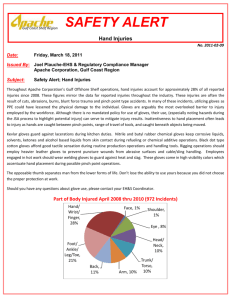

Electrical Insulating Gloves - Give Your Employees a Hand Injuries caused by electrical shock are one of the most severe that workers can experience on the job. According to the National Safety Council more than 1000 employees are killed and 30,000 injured each year from electrical shock. Many of these injuries involve the hands since they are the most common source of contact with an electrical current. Electrical current travels through the body causing damage to internal organs and possibly resulting in cardiac arrest. Such injuries from electrical shock can prove fatal. The best line of protection is to use electrical insulating gloves. It is important to know that electrical shock can result from contact with low voltage (under 600 volts) as well as high voltage lines (over 600 volts). The effects of this exposure depends on the amount of current (which is measured in milliamps or amps) flowing through the body, the amount of time it is in the body and the path of the current. Exposure to 100 milliamps flowing through the body for only 2 seconds can cause death by electrocution. This is not much current when you consider a hand-held electric drill draws 30 times that amount. OSHA requires that workers in high and low voltage applications wear electrical insulating gloves and that all insulating gloves be electrically tested every six months. There are several labs in the United States that perform this required testing. Rubber electrical insulating gloves are rated for their particular application. Workers should be trained to select gloves for the amount of protection needed against the circuits they are working with. For example, a Class 1 glove can be used for up to 7,500 volts AC, a Class 2 up to 17,000 volts AC, etc. It is also important to understand and recognize regulatory standards when it pertains to electrical safety awareness. These standards are easily accessed on OSHA's website, www.osha.gov. Finally, it is imperative that employers have in place an electrical safety program to ensure that all employees are aware of the potential electrical hazards in their locality. Both qualified and unqualified workers should be trained in avoiding the dangers of working on or near exposed and energized equipment.