Steel Stud Solutions Catalog

advertisement

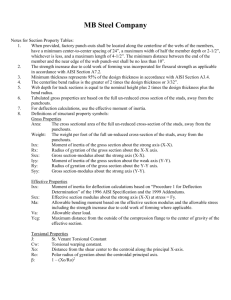

Steel Stud Solutions Product Catalog Table of Contents 1 3 5 7 - 2 - 4 - 6 - 14 Table of Contents, Product Line Product Notes Specifications Drywall & Structural Properties Steel Values The thicknesses used in this catalog are the standard minimum thicknesses specified by AISI with respect to ASTM standards. This catalog is based upon design thicknesses for a conservative approach. Calculations used in this brochure have been based upon the 1996 AISI “Specification for the Design of Cold Formed Steel Structural Members”. Gauges and thicknesses used are as follows: Thickness – Steel Components Gauge No. Design Thickness (in) Minimum Thickness (mils) Color Reference 25 ga .0179 18 mil natural 22 ga .0269 27 mil black 20 ga Drywall .0312 30 mil pink 20 ga Structural .0329 33 mil white 18 ga .0428 43 mil yellow 16 ga .0538 54 mil green 14 ga .0677 68 mil orange Contact Information Steel Stud Solutions 4165 Spartan Industrial Drive Grandville, MI 49418 Ph: 616-531-8600 Fx: 616-531-7555 1 Drywall Studs and Accessories Drywall Studs and Track (DWS – DWT) Available Web Size in: 1 5/8”, 2 1/2”, 3 5/8”, 4” and 6” Gauge: 25ga, 22ga, 20ga Standard and Custom Lengths available. Drywall Furring Channel (DWC) Available in 7/8" and 1 1/2" Gauge: 25ga, 22ga, 20ga Lengths: Standard Stock 12' and 10' (Other Lengths Available upon Request) Cold Rolled Channel (CRC) Available in 1 1/2” and 3/4” Gauge: 16ga Lengths: Standard Stock 16' Product Gauge Wt / Ft 7/8” DWC 25 .275 7/8” DWC 20 .477 1 1/2” DWC 25 .345 1 1/2” DWC 20 .599 300 pcs / skid Product Gauge Wt / Ft 1 1/2” CRC 16 .440 300 pcs / skid Resilient Furring Channel (RC) Product Gauge Wt / Ft RC-1: Single Leg RC-2: Double Leg Gauge: 25ga, 22ga, 20ga Lengths: Standard Stock 12' RC-1 25 .170 RC-2 25 .220 Rolled Angles (RA) Size Length Gauge 1.5 x 1.5 10’ 25, 20, 18, 16, 14 2x2 10’ 25, 20, 18, 16, 14 3x3 10’ 25, 20, 18, 16, 14 Available in Stock Sizes and Gauges (see table). Custom Sizes available upon request. 1000 pcs / skid 300 pcs / skid Drywall Corner Bead Made of quality Galvanized Steel to provide durable protection for Drywall external corners. Cement adheres readily to the knurled flanges. Exposed nose provides a straight, clean corner definition and guards against impact damage. Size 6’ 9” Pcs / Ctn 75 8’ 63 9’ 56 10’ 50 12’ 42 Strapping (FS) Bridge Clips (BC) Available in Stock Widths: 2", 3", 4", 6", 8" Gauge 25ga - 12ga Lengths: Standard 10' Custom widths and lengths available. Available in 1 1/2" x 1 1/2", 2" x 2", 3" x 3" Standard Gauge: 16ga Standard Length 3 3/8" Custom widths and lengths available. 2 Product & Notes CWS = 1 3/8” Flange (S137) CSJ = 1 5/8” Flange (S162) JW = 2” Flange (S200) JWE = 2 ½” Flange (S250) Flange Return Web TSB = 1 ¼” Leg (T125) TSB2” = 2” Leg (T200) Custom Sizes Available (T***) Universal Designator System for Light Gauge Steel Framing Members Member Depth. Style Flange Width Material Thickness All member depths are taken in 1/100 inches. For all “T” sections member depth is the inside dimension. Characters utilized by the system are: S = Stud or Joist Sections T = Track Sections U = Channel U Sections F = Furring Channel Section All Flange widths are taken in 1/100 inches Material thickness is the minimum base metal thickness represents 95% of the design thickness 600 S 162 - 54 Steel Stud SolutionsUniversal Code Examples 600S162-54 = 6” CSJ 16 gauge (stud) 362T125-43 = 3 5/8” TSB 18 gauge (track) 3 The Right STUF Universal Designator System for Light Gauge Steel Framing Members The Logic The dimensions of the webs and flanges in the designators are used because they convey an intuitive picture of the shape, like a "2 x 4" describes a wood stud. The web depth was put first instead of the flange width (the "2" in "2 x 4") because with steel the strength-to weight ratio is usually optimized by increasing web depth instead of flange width, all else being equal. The web depth and flange width are expressed in 1/100th or 1/1000th inches because fractions are messy, and with such a variety of depths and widths available, rounding to the nearest fraction of an inch is not sufficiently descriptive. Also, the metric system is expected to become universal, in which case the depths and widths would be expressed in millimeters, resulting in the same 3-digit format. Lastly, the logic behind the alpha designators (S for Stud, T for Track, etc.) should be obvious. Minimum Base Metal Thicknesses The minimum allowable base metal thickness designators are those used in Prescriptive Standards that are currently in CABO and the upcoming IBC and IRC, and correspond to ICBO's minimum prescribed thicknesses (expressed in mils). These minimum thicknesses are Gauge Thickness Color 25 0.018 None 22 0.027 Black 20-Drywall 0.030 Pink 20-Structural 0.033 White 18 0.043 Yellow 16 0.054 Green 14 0.068 Orange 12 0.097 Brown Stiffening Lips on C- Sections The dimension of the stiffening lip by flange width and material thickness are as follows: Material Thickness Flange Width Stiffening Lip .0179” to .0329” 1 -1/4” 3/16” All Thicknesses 1-3/8” 3/8” All Thicknesses 1 5/8” 1/2” All Thicknesses 2” 5/8” The Purpose With the universal designator system for steel framing members and accepted minimum base metal thicknesses and stiffening lip dimensions, the section properties and load-carrying abilities of any given profile can be calculated and implemented. Regardless of the manufacturer, not only will the designation be identical for a standard steel framing member, but the section properties and load-carrying abilities of that standard member will be uniform throughout the country. In addition to helping eliminate the confusion in the market stemming from the widely varying properties and loads published by manufacturers making essentially identical shapes, these standards should greatly facilitate submittals for plan check, code approvals, prescriptive standards, software development, etc. The intent is to make the products easier to use in existing markets and to accelerate their acceptance in new markets 4 I – General Related Work: specified elsewhere by the A/E of record. Workmanship & Quality Assurance: specified elsewhere by the A/E of record. Submittals: specified elsewhere by the A/E of record. II - Material · All studs, joists, tracks and other framing materials shall be of type, size and gage as shown on the project drawings and as manufactured by Steel Stud Solutions · All galvanized steel shall comply with ASTM A653. AII structural members in gages 22, 20 and 18 shall be SQ Grade 33, i.e., with Fy=33 Ksi and all members in gages of 16, 14 and 12 shall be SQ Grade 50, i.e., with Fy=50 Ksi. Tracks in all gages shall be SQ Grade 33, i.e., with Fy=33 Ksi. · All studs, joists, tracks and other framing materials shall be made with steel having a G-60 galvanized coating meeting ASTM A653 and C955. · Physical and structural properties listed in Steel Stud Solution's catalog shall be considered as the minimum permitted for all the member sizes specified by the Architect or Engineer of record. Thicknesses, cross-sectional areas, moments of inertia and resisting moments shall be met as per AISI limitations. III - Fabrication · Fabrication may be done on site using elemental components as manufactured by Steel Stud Solutions, or such components may be assembled at a central manufacturing facility using panelization as approved by the A/E of record. Accordingly, all fabrication procedures should be backed up by working drawings approved by the A/E of record. · All framing components shall be cut squarely or at the desired angle for a proper square or angular fit. Components shall be held in position with adequate means until properly fastened. IV – Execution and Erection · Tracks shall be securely anchored to the supporting foundation or structure as per project and/or working drawings. Abutting pieces of track shall be securely anchored to common structural elements or they shall be butt-welded or spliced together. Uniform and level bearing surface shall be provided under the tracks. · Studs shall be plumbed, aligned and securely attached to the flanges and/or webs of both upper and lower tracks. Studs carrying axial loads shall be installed in a manner which assures a minimum gap between the stud ends and the track webs. Temporary bracing shall be provided during erection of wall panels. · Handling and lifting of prefabricated panels or of panels assembled on site shall be done in a manner to prevent distortion of any member or of the panel assembly. · Jack or cripple studs shall be installed under window sills, above door and window lintels and elsewhere as required to furnish support and they shall be securely attached to supporting members. · Bridging for a series of studs shall be attached in a manner that will prevent stud rotation or sympathetic buckling. Wall studs shall be braced at a maximum spacing of 48 inches o/c. · Provision for vertical movement of studs shall be made with the help of vertical slide clips or deflection tracks as approved by the A/E of record. · Stud walls that act as shear walls shall be adequately cross braced, as per project and/or working drawings approved by the A/E of record. Additional studs shall be provided to resist vertical components of the forces in the cross-bracing. · No splices shall be permitted in axially loaded members · Joists shall be supported directly over load-bearing studs and joist bracing shall be provided as per project and/or working drawings. Where indicated in the drawings web stiffeners as specified shall be provided and end blocking shall be provided where joist ends are not adequately restrained against rotation. · Insulation as provided elsewhere shall be provided in all doubled header and other members that will not be accessible to the insulation contractor. Components shall be held in position with adequate. 5 Table Notes General Notes for All Tables 1. The strength increase due to cold work of forming was incorporated for flexural strength as applicable per AISI A7.2. 2. The moment of inertia for deflection is calculated at a stress which resulrts in an effective section modulus such that the stress times that section modulus is equal to the allowable moment. This follows Procedure 1 of the AISI Specification. 3. The yield stress (33 ksi or 50 ksi) used to calculate the tabulated values are indicated in the tables. 4. When provided, factory punch-outs will be located along the centerline of the webs of the members and will have a minimum centerto-center spacing of 24”. Punch-outs will have a maximum width = half the member depth (d/2) or 2 ½”, whichever is less, and a maximum length = 4 ½”. The minimum distance between the end of the member and the near edge of the web punch-out = 10”. 5. For those steels that have both 33 and 50 ksi listings, if the design is based upon 50 ksi, the 50 ksi steel needs to be specified by the contractor/buyer (e.g., 362S137-54 (50 ksi).) Notes for Individual Tables 1. Section Properties 1.1. The centerline bend radius is the greater of 2 times the design thickness, or 3/32”. 1.2. Web depth for track sections is equal to the nominal height plus 2 times the design thickness plus the bend radius. 1.3. Effective properties incorporate the strength increase from the cold work of forming as applicable per AISI A7.2. 1.4. Tabulated gross properties are based on the full unreduced cross section of the studs, away from the punch-outs. 1.5. For deflection calculations, use the effective moment of inertia. 1.6. For those steels that have both 33 and 50 ksi listings, if the design is based upon 50 ksi, the 50 ksi steel needs to be specified by the contractor/buyer (e.g., 362S137-54 (50ksi).) 2. Height Limitations 2.1. Lateral loads multiplied by 0.75 for strength determination per AISI A5.1.3 2.2. Check end reactions for web crippling. 2.3. Limiting height based on continuous support of each flange over the full length of the stud. 2.4. Heights based on steel properties only. 2.5. Values based on Fy = 33 ksi. 3. Axial Loads 3.1. Allowable loads based on weak axis and torsional bracing at 48” o.c. maximum for axial load calculation and continuous support of each flange for flexural calculation. 3.2. Lateral and axial load multiplied by 0.75 for strength determination per AISI A5.1.3. 3.3. Check lateral end reactions for web crippling. 3.4. Allowable axial load in kips/stud (1 kip = 1000 lbs.) 4. Joist Span 4.1. Web punch-outs were not considered for shear or web crippling. 4.2. Spans are based on continuous lateral support of the compression flange. 4.3. Joists must be braced against rotation at all supports by track or blocking. 4.4. Joist spans are based on 50 ksi for the 54, 68, and 97 mil thicknesses, and 33 ksi for the thinner members. Definitions of Physical Property Symbols Ixx: Moment of inertia of the gross section about the X-X axis, used for deflection Sx: Section Modulus about the X-X axis, used for stress and loads Rx: Radius of Gyration about the X-X axis, used for axial loads Iy: Moment of inertia about the Y-Y axis Sy: Section Modulus about the Y-Y axis Ry: Radius of Gyration about the Y-Y axis Xo: Distance from the shear center to the centroid along the principle X-axis Jx: St. Venant Torsional Constant Cw: Torsional warping constant Ro: Polar Radius of gyration about the centroidal principle axis L/120 L/240 L/360 Length (height) of stud, in inches, divided by 120 Length (height) of stud, in inches, divided by 240 Length (height) of stud, in inches, divided by 360 6 Design Section Designation GROSS PROPERTIES EFFECTIVE PROPERTIES 33ksi EFFECTIVE PROPERTIES 50ksi TORSIONAL PROPERTIES Cw Xo Ro β in in6 in in in 309 0.010 0.011 -1.082 1.361 0.367 516 0.033 0.016 -1.071 1.348 0.369 1.31 566 0.044 0.017 -1.067 1.344 0.369 0.045 1.28 249 0.012 0.027 -0.952 1.464 0.577 0.101 0.076 2.00 700 0.039 0.039 -0.941 1.452 0.580 0.162 0.116 0.090 2.28 851 0.053 0.042 -0.938 1.448 0.581 0.437 0.227 0.100 0.050 1.98 167 0.014 0.061 -0.830 1.696 0.760 0.034 0.432 0.349 0.168 0.086 3.32 572 0.048 0.088 -0.820 1.685 0.763 1.406 0.037 0.431 0.384 0.191 0.102 3.78 768 0.064 0.096 -0.817 1.682 0.764 0.151 1.542 0.024 0.431 0.283 0.110 0.051 2.18 150 0.015 0.076 -0.797 1.788 0.801 0.449 0.225 1.536 0.035 0.426 0.440 0.193 0.088 3.82 515 0.051 0.110 -0.787 1.777 0.804 0.71 0.493 0.246 1.534 0.038 0.424 0.484 0.220 0.104 4.34 691 0.068 0.120 -0.784 1.774 0.805 0.165 0.56 0.798 0.266 2.200 0.026 0.399 0.720 0.164 0.053 3.24 98 0.019 0.190 -0.660 2.331 0.920 0.0283 0.247 0.84 1.188 0.396 2.193 0.038 0.394 1.172 0.304 0.095 6.02 336 0.066 0.277 -0.650 2.321 0.921 600S125-30 0.0312 0.272 0.93 1.305 0.435 2.191 0.042 0.392 1.287 0.368 0.113 7.26 451 0.088 0.303 -0.648 2.318 0.922 Section Designation Thickness Area Wt/Ft Ix Sx rx Iy ry Ix Sx 4 3 in 4 in 4 3 Thickness Area 2 Wt/Ft Ix Sx 4 3 rx Iy in 4 ry Ix Sx in 4 3 A 2 Ma in. in Lb/Ft in in 162S125-18 0.0188 0.083 0.28 0.039 0.048 0.684 0.018 0.461 0.036 0.037 0.038 0.73 162S125-27 0.0283 0.123 0.42 0.057 0.070 0.680 0.026 0.456 0.056 0.057 0.061 1.14 162S125-30 0.0312 0.135 0.46 0.062 0.077 0.679 0.028 0.455 0.061 0.066 0.071 250S125-18 0.0188 0.099 0.34 0.102 0.082 1.015 0.020 0.454 0.095 0.065 250S125-27 0.0283 0.148 0.50 0.151 0.121 1.010 0.030 0.449 0.148 250S125-30 0.0312 0.163 0.55 0.165 0.132 1.009 0.033 0.448 362S125-18 0.0188 0.120 0.41 0.240 0.133 1.413 0.023 362S125-27 0.0283 0.180 0.61 0.356 0.197 1.408 362S125-30 0.0312 0.198 0.67 0.391 0.216 400S125-18 0.0188 0.127 0.43 0.303 400S125-27 0.0283 0.190 0.65 400S125-30 0.0312 0.209 600S125-18 0.0188 600S125-27 in in in in k-in Va Ix Sx lbs 4 3 in in A 2 in Ma k-in Va lbs Jx1000 4 PHYSICAL AND STRUCTURAL PROPERTIES FOR DRYWALL (S) STUDS Design GROSS PROPERTIES EFFECTIVE PROPERTIES 33ksi EFFECTIVE PROPERTIES 50ksi TORSIONAL PROPERTIES Cw Xo Ro β in in6 in in in 309 0.009 0.007 -0.876 1.216 0.481 572 0.031 0.011 -0.871 1.214 0.485 1.01 631 0.042 0.012 -0.869 1.213 0.487 0.037 0.89 236 0.011 0.018 -0.767 1.364 0.684 0.080 0.075 1.58 700 0.038 0.027 -0.762 1.363 0.687 0.148 0.091 0.089 1.80 851 0.051 0.030 -0.761 1.362 0.688 0.380 0.190 0.065 0.037 1.28 161 0.014 0.042 -0.664 1.630 0.834 0.025 0.378 0.304 0.136 0.077 2.69 548 0.046 0.063 -0.660 1.630 0.836 1.442 0.027 0.378 0.343 0.154 0.092 3.04 734 0.062 0.069 -0.659 1.630 0.837 0.145 1.564 0.017 0.374 0.242 0.071 0.037 1.41 145 0.014 0.052 -0.636 1.729 0.865 0.451 0.217 1.566 0.025 0.372 0.383 0.158 0.078 3.11 495 0.049 0.078 -0.632 1.729 0.866 0.69 0.498 0.239 1.566 0.028 0.371 0.431 0.178 0.093 3.52 664 0.066 0.086 -0.631 1.729 0.867 0.083 0.28 0.039 0.048 0.684 0.018 0.461 0.036 0.037 0.038 0.73 309 0.010 0.011 -1.082 1.361 0.367 0.0283 0.123 0.42 0.057 0.070 0.680 0.026 0.456 0.056 0.057 0.061 1.14 516 0.033 0.016 -1.071 1.348 0.369 0.0312 0.135 0.46 0.062 0.077 0.679 0.028 0.455 0.061 0.066 0.071 1.31 566 0.044 0.017 -1.067 1.344 0.369 2 A 2 Ma in. in Lb/Ft in in 162T125-18 0.0188 0.078 0.26 0.042 0.048 0.737 0.013 0.411 0.030 0.026 0.035 0.50 162T125-27 0.0283 0.117 0.40 0.064 0.072 0.740 0.020 0.409 0.051 0.045 0.071 0.88 162T125-30 0.0312 0.129 0.44 0.071 0.079 0.741 0.022 0.409 0.059 0.051 0.084 250T125-18 0.0188 0.094 0.32 0.105 0.080 1.055 0.015 0.399 0.079 0.045 250T125-27 0.0283 0.142 0.48 0.158 0.119 1.057 0.022 0.398 0.130 250T125-30 0.0312 0.156 0.53 0.175 0.131 1.058 0.025 0.397 362T125-18 0.0188 0.115 0.39 0.239 0.127 1.440 0.017 362T125-27 0.0283 0.173 0.59 0.360 0.191 1.442 362T125-30 0.0312 0.191 0.65 0.397 0.210 400T125-18 0.0188 0.122 0.42 0.299 400T125-27 0.0283 0.184 0.63 400T125-30 0.0312 0.203 162S125-18 0.0188 162S125-27 162S125-30 in in in in k-in Va Ix Sx lbs 4 3 in in A 2 in Ma k-in Va lbs Jx1000 4 PHYSICAL AND STRUCTURAL PROPERTIES FOR DRYWALL (T) TRACK 7 Design Section Designation Thickness GROSS PROPERTIES Area 2 Wt/Ft Ix Sx 4 3 EFFECTIVE PROPERTIES 33ksi rx Iy in 4 ry Ix Sx in 4 3 A 2 Ma TORSIONAL PROPERTIES Cw Xo Ro β in in6 in in in 1025 0.078 0.076 -1.140 1.610 0.498 1323 0.172 0.096 -1.128 1.596 0.501 0.336 0.115 -1.114 1.582 0.504 Ix Sx lbs 4 3 A 2 Ma 4 Lb/Ft in 250S137-33 0.0346 0.196 0.67 0.202 0.161 1.014 0.052 0.514 0.202 0.156 0.128 3.07 250S137-43 0.0451 0.253 0.86 0.258 0.206 1.009 0.066 0.509 0.258 0.206 0.181 4.08 250S137-54 0.0566 0.315 1.07 0.317 0.253 1.003 0.080 0.503 0.317 0.250 0.230 4.94 1643 0.317 0.247 0.214 250S137-68 0.0713 0.392 1.33 0.388 0.311 0.996 0.096 0.496 0.388 0.264 0.285 5.22 2042 0.388 0.300 0.285 8.97 3094 0.664 0.138 -1.097 1.563 0.507 250S137-97 0.1017 0.544 1.85 0.523 0.419 0.981 0.126 0.481 0.523 0.418 0.391 8.27 2831 0.523 0.418 0.391 12.53 4290 1.874 0.176 -1.061 1.523 0.515 250S162-33 0.0346 0.222 0.76 0.234 0.187 1.025 0.086 0.623 0.234 0.178 0.151 3.51 1025 0.089 0.146 -1.469 1.897 0.400 250S162-43 0.0451 0.287 0.98 0.299 0.239 1.021 0.110 0.618 0.299 0.239 0.215 4.73 1323 0.195 0.184 -1.456 1.883 0.402 250S162-54 0.0566 0.357 1.22 0.368 0.295 1.015 0.134 0.613 0.368 0.295 0.272 5.82 1643 0.368 0.287 0.254 8.60 2490 0.382 0.223 -1.443 1.867 0.403 250S162-68 0.0713 0.445 1.52 0.453 0.362 1.009 0.163 0.606 0.453 0.362 0.338 7.16 2042 0.453 0.350 0.338 10.49 3094 0.754 0.268 -1.425 1.848 0.405 250S162-97 0.1017 0.620 2.11 0.613 0.490 0.995 0.217 0.592 0.613 0.490 0.467 9.69 2831 0.613 0.490 0.467 14.68 4290 2.137 0.346 -1.389 1.808 0.410 362S137-33 0.0346 0.235 0.80 0.476 0.262 1.422 0.059 0.500 0.476 0.253 0.143 5.00 1046 0.094 0.165 -1.002 1.810 0.694 362S137-43 0.0451 0.304 1.04 0.611 0.337 1.417 0.074 0.495 0.610 0.337 0.206 6.65 1777 0.206 0.208 -0.990 1.798 0.697 362S137-54 0.0566 0.379 1.29 0.753 0.416 1.410 0.091 0.489 0.753 0.415 0.269 8.21 2484 0.753 0.404 0.247 12.10 3446 0.404 0.251 -0.977 1.784 0.700 362S137-68 0.0713 0.472 1.61 0.928 0.512 1.402 0.110 0.482 0.928 0.512 0.352 10.12 3101 0.928 0.512 0.337 15.33 4699 0.800 0.302 -0.960 1.767 0.705 362S162-33 0.0346 0.261 0.89 0.548 0.302 1.449 0.099 0.614 0.548 0.288 0.166 5.69 1046 0.104 0.297 -1.307 2.046 0.592 362S162-43 0.0451 0.338 1.15 0.704 0.388 1.443 0.126 0.609 0.704 0.388 0.240 7.68 1777 0.229 0.376 -1.295 2.033 0.594 362S162-54 0.0566 0.421 1.43 0.870 0.480 1.437 0.154 0.604 0.870 0.480 0.312 9.48 2484 0.870 0.466 0.286 13.96 3446 0.450 0.457 -1.282 2.019 0.597 362S162-68 0.0713 0.525 1.79 1.074 0.593 1.430 0.187 0.597 1.074 0.593 0.405 11.71 3101 1.074 0.593 0.390 17.74 4699 0.890 0.552 -1.265 2.000 0.600 362S162-97 0.1017 0.734 2.50 1.469 0.811 1.415 0.249 0.582 1.469 0.702 0.582 13.87 4342 1.469 0.806 0.580 24.14 6578 2.531 0.723 -1.230 1.963 0.607 362S200-33 0.0346 0.287 0.98 0.631 0.348 1.483 0.162 0.750 0.631 0.304 0.171 6.00 1046 0.115 0.480 -1.647 2.340 0.504 362S200-43 0.0451 0.372 1.27 0.812 0.448 1.478 0.207 0.745 0.812 0.395 0.232 7.81 1777 0.252 0.610 -1.635 2.327 0.506 362S200-54 0.0566 0.464 1.58 1.005 0.555 1.473 0.254 0.740 1.005 0.535 0.335 10.58 2484 1.005 0.466 0.274 13.97 3446 0.495 0.744 -1.621 2.312 0.508 362S200-68 0.0713 0.579 1.97 1.243 0.686 1.466 0.311 0.733 1.243 0.683 0.456 13.50 3101 1.243 0.647 0.407 19.37 4699 0.981 0.904 -1.604 2.293 0.511 362S200-97 0.1017 0.811 2.76 1.706 0.941 1.451 0.418 0.718 1.706 0.825 0.658 16.31 4342 1.706 0.934 0.653 27.97 6578 2.794 1.194 -1.568 2.254 0.516 362S250-43 0.0451 0.428 1.46 0.975 0.538 1.509 0.382 0.944 0.975 0.470 0.280 9.29 1777 0.290 1.230 -2.197 2.828 0.396 362S250-54 0.0566 0.534 1.82 1.207 0.666 1.503 0.471 0.939 1.207 0.601 0.370 11.88 2484 1.195 0.547 0.321 16.37 3446 0.571 1.506 -2.184 2.813 0.397 362S250-68 0.0713 0.668 2.28 1.496 0.825 1.497 0.580 0.932 1.496 0.799 0.518 15.78 3101 1.496 0.687 0.423 20.57 4699 1.132 1.837 -2.166 2.793 0.399 362S250-97 0.1017 0.938 3.20 2.061 1.137 1.483 0.790 0.918 2.061 1.012 0.785 20.01 4342 2.061 1.089 0.731 32.60 6578 3.233 2.452 -2.129 2.752 0.401 362S300-43 0.0451 0.485 1.65 1.133 0.625 1.529 0.628 1.138 1.115 0.530 0.322 10.47 1777 0.329 2.229 -2.775 3.367 0.321 362S300-54 0.0566 0.605 2.06 1.406 0.776 1.524 0.777 1.133 1.405 0.681 0.423 13.46 2484 1.3553 362S300-68 0.0713 0.757 2.58 1.744 0.962 1.518 0.960 1.126 1.744 0.862 0.550 17.03 3101 1.733 0.793 362S300-97 0.1017 1.065 3.63 2.409 1.329 1.504 1.317 1.112 2.409 1.188 0.895 23.47 4342 2.409 1.212 400S137-33 0.0346 0.248 0.85 0.599 0.299 1.554 0.061 0.494 0.599 0.289 0.146 5.71 945 400S137-43 0.0451 0.321 1.09 0.769 0.385 1.548 0.077 0.489 0.769 0.385 0.212 7.60 1777 400S137-54 0.0566 0.400 1.36 0.950 0.475 1.541 0.093 0.483 0.950 0.475 0.278 9.38 2764 0.94972 0.46201 0.25401 13.83 400S137-68 0.0713 0.499 1.70 1.172 0.586 1.533 0.113 0.476 1.172 0.586 0.366 11.58 3454 1.17155 0.58578 0.34832 17.54 400S162-33 0.0346 0.274 0.93 0.688 0.344 1.585 0.102 0.610 0.688 0.328 0.169 6.48 945 400S162-43 0.0451 0.355 1.21 0.885 0.443 1.579 0.130 0.605 0.885 0.442 0.246 8.74 1777 0.241 0.460 -1.250 2.103 0.647 400S162-54 0.0566 0.442 1.51 1.094 0.547 1.573 0.159 0.599 1.094 0.547 0.320 10.81 2764 1.094 0.532 0.293 15.92 3446 0.472 0.560 -1.237 2.089 0.649 400S162-68 0.0713 0.552 1.88 1.353 0.676 1.565 0.193 0.592 1.353 0.676 0.420 13.36 3454 1.353 0.676 0.402 20.25 5233 0.935 0.677 -1.220 2.071 0.653 400S162-97 0.1017 0.772 2.63 1.855 0.927 1.550 0.257 0.577 1.854 0.865 0.620 17.09 4845 1.854 0.927 0.605 27.76 7341 2.663 0.889 -1.186 2.035 0.660 400S200-33 0.0346 0.300 1.02 0.790 0.395 1.623 0.167 0.747 0.790 0.346 0.174 6.83 945 0.120 0.587 -1.596 2.396 0.556 400S200-43 0.0451 0.389 1.32 1.017 0.509 1.618 0.214 0.742 1.017 0.450 0.238 8.88 1777 0.264 0.746 -1.584 2.382 0.558 400S200-54 0.0566 0.485 1.65 1.260 0.630 1.612 0.263 0.736 1.259 0.608 0.344 12.01 2764 1.259 0.532 0.281 15.92 3446 0.518 0.911 -1.570 2.368 0.560 400S200-68 0.0713 0.606 2.06 1.559 0.780 1.605 0.322 0.729 1.559 0.777 0.471 15.35 3454 1.559 0.735 0.419 22.02 5233 1.026 1.108 -1.553 2.349 0.563 400S200-97 0.1017 0.849 2.89 2.144 1.072 1.590 0.433 0.714 2.144 1.006 0.696 19.87 4845 2.144 1.068 0.677 31.99 7341 2.926 1.468 -1.518 2.311 0.569 400S250-43 0.0451 0.445 1.52 1.217 0.608 1.653 0.396 0.943 1.217 0.533 0.285 10.54 1777 0.302 1.486 -2.137 2.862 0.442 400S250-54 0.0566 0.555 1.89 1.509 0.754 1.648 0.488 0.937 1.509 0.681 0.379 13.46 2764 1.491 0.621 0.328 18.60 3446 0.593 1.821 -2.124 2.847 0.444 400S250-68 0.0713 0.695 2.37 1.871 0.936 1.641 0.601 0.931 1.871 0.904 0.533 17.87 3454 1.871 0.781 0.434 23.38 5233 1.177 2.225 -2.106 2.828 0.445 400S250-97 0.1017 0.976 3.33 2.583 1.292 1.627 0.819 0.916 2.583 1.220 0.823 24.11 4845 2.583 1.236 0.756 37.00 7341 3.364 2.978 -2.070 2.788 0.449 400S300-43 0.0451 0.502 1.71 1.413 0.706 1.678 0.651 1.139 1.390 0.601 0.328 11.87 1777 0.340 2.661 -2.708 3.384 0.359 400S300-54 0.0566 0.626 2.13 1.753 0.877 1.673 0.805 1.134 1.753 0.772 0.432 15.25 2764 1.689 0.695 0.369 20.81 3446 0.669 3.269 -2.694 3.368 0.360 400S300-68 0.0713 0.784 2.67 2.177 1.089 1.667 0.996 1.127 2.177 0.975 0.564 19.28 3454 2.162 0.899 0.499 26.92 5233 1.328 4.007 -2.677 3.348 0.361 400S300-97 0.1017 1.103 3.76 3.013 1.507 1.653 1.366 1.113 3.013 1.420 0.933 28.06 4845 3.013 1.373 0.823 41.11 7341 3.802 5.398 -2.640 3.308 0.363 550S137-33 0.0346 0.300 1.02 1.276 0.464 2.062 0.066 0.470 1.275 0.449 0.155 8.87 674 0.120 0.411 -0.839 2.275 0.864 550S137-43 0.0451 0.389 1.32 1.642 0.597 2.055 0.084 0.465 1.642 0.597 0.227 11.80 1500 0.264 0.520 -0.829 2.264 0.866 550S137-54 0.0566 0.485 1.65 2.033 0.739 2.048 0.102 0.459 2.032 0.739 0.302 14.60 2799 2.032 0.720 0.273 21.57 2977 0.518 0.632 -0.817 2.252 0.868 550S137-68 0.0713 0.606 2.06 2.516 0.915 2.039 0.124 0.452 2.516 0.915 0.407 18.08 4442 2.516 0.915 0.380 27.39 5468 1.026 0.764 -0.802 2.237 0.872 550S162-33 0.0346 0.326 1.11 1.451 0.528 2.110 0.113 0.588 1.451 0.505 0.178 9.99 674 0.130 0.713 -1.113 2.456 0.795 550S162-43 0.0451 0.423 1.44 1.870 0.680 2.104 0.143 0.582 1.870 0.680 0.261 13.44 1500 0.287 0.905 -1.101 2.445 0.797 550S162-54 0.0566 0.527 1.80 2.318 0.843 2.097 0.175 0.577 2.318 0.843 0.345 16.65 2799 2.318 0.820 0.312 24.54 2977 0.563 1.105 -1.089 2.432 0.800 550S162-68 0.0713 0.659 2.25 2.874 1.045 2.088 0.214 0.570 2.874 1.045 0.460 20.65 4442 2.874 1.045 0.434 31.29 5468 1.117 1.342 -1.073 2.416 0.803 550S162-97 0.1017 0.925 3.15 3.965 1.442 2.071 0.285 0.555 3.964 1.442 0.717 28.49 6859 3.964 1.442 0.675 43.16 10392 3.189 1.775 -1.041 2.383 0.809 550S200-33 0.0346 0.352 1.20 1.645 0.598 2.162 0.186 0.726 1.644 0.530 0.182 10.47 674 0.140 1.153 -1.423 2.688 0.720 550S200-43 0.0451 0.456 1.56 2.122 0.772 2.156 0.237 0.721 2.121 0.689 0.253 13.61 1500 0.309 1.470 -1.412 2.676 0.722 550S200-54 0.0566 0.570 1.94 2.633 0.957 2.150 0.291 0.715 2.632 0.925 0.368 18.27 2799 2.632 0.821 0.301 24.57 2977 0.608 1.799 -1.399 2.663 0.724 550S200-68 0.0713 0.712 2.43 3.268 1.188 2.142 0.357 0.708 3.268 1.184 0.511 23.39 4442 3.268 1.124 0.451 33.64 5468 1.207 2.196 -1.382 2.646 0.727 550S200-97 0.1017 1.001 3.41 4.521 1.644 2.125 0.481 0.693 4.520 1.644 0.794 32.48 6859 4.520 1.638 0.747 49.05 10392 3.452 2.931 -1.348 2.610 0.733 550S250-43 0.0451 0.513 1.75 2.511 0.913 2.213 0.442 0.928 2.511 0.809 0.300 15.98 1500 0.348 2.837 -1.931 3.080 0.607 550S250-54 0.0566 0.640 2.18 3.120 1.134 2.207 0.545 0.923 3.119 1.030 0.403 20.35 2799 3.076 0.948 0.348 28.38 2977 0.684 3.486 -1.918 3.066 0.609 550S250-68 0.0713 0.802 2.73 3.879 1.411 2.200 0.672 0.916 3.878 1.362 0.573 26.92 4442 3.878 1.192 0.466 35.69 5468 1.358 4.274 -1.901 3.048 0.611 550S250-97 0.1017 1.128 3.85 5.384 1.958 2.184 0.915 0.901 5.383 1.957 0.921 38.68 6859 5.383 1.872 0.826 56.04 10392 3.890 5.761 -1.866 3.011 0.616 in in in in in in lbs Jx1000 in in k-in Va in. in k-in EFFECTIVE PROPERTIES 50ksi Va PHYSICAL AND STRUCTURAL PROPERTIES FOR STRUCTURAL (S) STUDS 8 7.38 2490 18.33 3446 0.646 2.736 -2.761 3.351 0.321 0.487 23.74 4699 1.283 3.349 -2.744 3.332 0.322 0.798 36.29 6578 3.671 4.501 -2.707 3.290 0.323 0.099 0.204 -0.964 1.894 0.741 0.218 0.257 -0.952 1.882 0.744 3446 0.427 0.311 -0.939 1.869 0.747 5233 0.845 0.375 -0.923 1.852 0.751 0.109 0.363 -1.262 2.116 0.644 0.61223 0.36197 Design Section Designation Thickness GROSS PROPERTIES Area 2 Wt/Ft Ix Sx 4 3 EFFECTIVE PROPERTIES 33ksi rx Iy 4 ry Ix Sx 4 3 A 2 Ma EFFECTIVE PROPERTIES 50ksi Va Ix Sx 4 3 A 2 Ma TORSIONAL PROPERTIES Va Jx1000 4 Cw Xo Ro β in6 in in in in. in Lb/Ft in in in in in in in in k-in lbs 550S300-43 0.0451 0.569 1.94 2.895 1.053 2.255 0.729 1.132 2.847 0.909 0.343 17.96 1500 550S300-54 0.0566 0.711 2.42 3.599 1.309 2.250 0.902 1.126 3.599 1.161 0.456 22.94 550S300-68 0.0713 0.891 3.04 4.480 1.629 2.243 1.116 1.119 4.479 1.465 0.605 550S300-97 0.1017 1.255 4.28 6.233 2.266 2.228 1.533 1.105 6.232 2.241 1.030 600S137-33 0.0346 0.317 1.08 1.573 0.524 2.227 0.068 0.463 1.573 0.508 0.157 10.03 616 0.127 0.500 -0.805 2.413 0.889 600S137-43 0.0451 0.411 1.40 2.027 0.676 2.220 0.086 0.457 2.026 0.675 0.230 13.35 1369 0.279 0.633 -0.795 2.402 0.890 600S137-54 0.0566 0.513 1.75 2.510 0.837 2.212 0.105 0.452 2.510 0.837 0.308 16.53 2716 2.510 0.816 0.278 24.43 2716 0.548 0.769 -0.783 2.390 0.893 600S137-68 0.0713 0.641 2.19 3.110 1.037 2.202 0.126 0.444 3.109 1.036 0.416 20.48 4442 3.109 1.036 0.388 31.03 5457 1.087 0.930 -0.769 2.375 0.895 600S162-33 0.0346 0.343 1.17 1.784 0.595 2.280 0.115 0.580 1.783 0.570 0.180 11.27 616 0.137 0.861 -1.071 2.585 0.828 600S162-43 0.0451 0.445 1.52 2.301 0.767 2.273 0.147 0.575 2.300 0.767 0.264 15.15 1369 0.302 1.095 -1.060 2.573 0.830 600S162-54 0.0566 0.555 1.89 2.853 0.951 2.266 0.180 0.569 2.853 0.951 0.350 18.79 2716 2.853 0.925 0.317 27.70 2716 0.593 1.337 -1.048 2.561 0.833 600S162-68 0.0713 0.695 2.37 3.540 1.180 2.258 0.219 0.562 3.539 1.180 0.469 23.31 4442 3.539 1.180 0.441 35.32 5457 1.177 1.626 -1.033 2.545 0.835 600S162-97 0.1017 0.976 3.33 4.892 1.631 2.239 0.292 0.547 4.891 1.630 0.738 32.21 7530 4.891 1.630 0.691 48.81 11124 3.364 2.153 -1.001 2.513 0.841 600S200-33 0.0346 0.369 1.26 2.015 0.672 2.336 0.190 0.718 2.014 0.586 0.184 11.58 616 0.147 1.394 -1.375 2.804 0.760 600S200-43 0.0451 0.479 1.63 2.600 0.867 2.330 0.244 0.713 2.600 0.776 0.256 15.34 1369 0.325 1.778 -1.363 2.792 0.762 600S200-54 0.0566 0.598 2.04 3.228 1.076 2.324 0.299 0.707 3.228 1.040 0.374 20.54 2716 3.228 0.927 0.305 27.75 2716 0.638 2.179 -1.351 2.779 0.764 600S200-68 0.0713 0.748 2.55 4.010 1.337 2.315 0.367 0.700 4.009 1.332 0.520 26.31 4442 4.009 1.265 0.458 37.88 5457 1.268 2.661 -1.335 2.762 0.767 600S200-97 0.1017 1.052 3.59 5.555 1.852 2.298 0.493 0.685 5.554 1.851 0.815 36.58 7530 5.554 1.845 0.764 55.25 11124 3.627 3.557 -1.301 2.728 0.772 600S250-43 0.0451 0.535 1.82 3.067 1.022 2.394 0.455 0.921 3.067 0.908 0.304 17.95 1369 0.363 3.411 -1.872 3.176 0.652 600S250-54 0.0566 0.669 2.28 3.812 1.271 2.388 0.561 0.916 3.811 1.156 0.409 22.83 2716 3.751 1.067 0.352 31.94 2716 0.714 4.194 -1.859 3.162 0.654 600S250-68 0.0713 0.837 2.85 4.743 1.581 2.380 0.691 0.909 4.742 1.527 0.583 30.18 4442 4.742 1.342 0.473 40.17 5457 1.419 5.145 -1.842 3.144 0.657 600S250-97 0.1017 1.179 4.02 6.591 2.197 2.364 0.942 0.894 6.590 2.197 0.942 43.40 7530 6.590 2.101 0.842 62.91 11124 4.065 6.947 -1.808 3.107 0.662 600S300-43 0.0451 0.592 2.02 3.527 1.176 2.442 0.751 1.127 3.469 1.020 0.346 20.15 1369 0.401 5.873 -2.405 3.608 0.556 600S300-54 0.0566 0.739 2.52 4.388 1.463 2.436 0.930 1.121 4.387 1.301 0.462 25.70 2716 4.219 1.185 0.393 35.49 2716 0.790 7.238 -2.392 3.593 0.557 600S300-68 0.0713 0.926 3.16 5.465 1.822 2.429 1.150 1.114 5.464 1.641 0.614 32.42 4442 5.408 1.527 0.538 45.71 5457 1.570 8.907 -2.375 3.575 0.559 600S300-97 0.1017 1.306 4.45 7.611 2.537 2.414 1.580 1.100 7.610 2.508 1.051 49.56 7530 7.610 2.317 0.910 69.36 11124 4.504 12.103 -2.339 3.537 0.563 800S137-33 0.0346 0.387 1.32 3.182 0.796 2.869 0.073 0.433 3.181 0.664 0.162 13.12 457 0.154 0.957 -0.695 2.984 0.946 800S137-43 0.0451 0.502 1.71 4.107 1.027 2.862 0.092 0.428 4.106 1.026 0.240 20.28 1014 0.340 1.214 -0.685 2.974 0.947 800S137-54 0.0566 0.626 2.13 5.098 1.274 2.853 0.112 0.422 5.096 1.274 0.324 25.17 2010 5.096 1.246 0.290 37.30 2010 0.669 1.478 -0.675 2.962 0.948 800S137-68 0.0713 0.784 2.67 6.331 1.583 2.842 0.135 0.415 6.329 1.582 0.442 31.27 4034 6.329 1.582 0.408 47.37 4034 1.328 1.789 -0.662 2.948 0.950 800S162-33 0.0346 0.412 1.41 3.567 0.892 2.941 0.124 0.549 3.566 0.749 0.185 14.80 457 0.165 1.630 -0.935 3.134 0.911 800S162-43 0.0451 0.535 1.82 4.607 1.152 2.933 0.158 0.544 4.605 1.151 0.273 22.75 1014 0.363 2.076 -0.925 3.123 0.912 800S162-54 0.0566 0.669 2.28 5.724 1.431 2.926 0.194 0.538 5.722 1.430 0.366 28.27 2010 5.722 1.395 0.329 41.75 2010 0.714 2.539 -0.914 3.112 0.914 800S162-68 0.0713 0.837 2.85 7.118 1.779 2.916 0.236 0.531 7.115 1.779 0.496 35.15 4034 7.115 1.779 0.461 53.26 4034 1.419 3.093 -0.899 3.097 0.916 800S162-97 0.1017 1.179 4.02 9.881 2.470 2.895 0.314 0.516 9.878 2.470 0.798 48.80 9037 9.878 2.470 0.737 73.94 11124 4.065 4.114 -0.870 3.066 0.919 800S200-33 0.0346 0.438 1.49 3.978 0.995 3.012 0.206 0.686 3.977 0.768 0.189 15.17 457 0.175 2.642 -1.213 3.319 0.866 800S200-43 0.0451 0.569 1.94 5.142 1.285 3.006 0.264 0.681 5.140 1.126 0.265 22.26 1014 0.386 3.375 -1.202 3.308 0.868 800S200-54 0.0566 0.711 2.42 6.393 1.598 2.998 0.324 0.675 6.392 1.548 0.389 30.59 2010 6.392 1.350 0.317 40.42 2010 0.759 4.142 -1.190 3.296 0.870 800S200-68 0.0713 0.891 3.04 7.958 1.990 2.989 0.397 0.668 7.956 1.982 0.547 39.17 4034 7.956 1.891 0.478 56.62 4034 1.509 5.069 -1.175 3.280 0.872 800S200-97 0.1017 1.255 4.28 11.071 2.768 2.970 0.534 0.652 11.068 2.767 0.875 54.68 9037 11.068 2.759 0.810 82.59 11124 4.328 6.807 -1.144 3.249 0.876 800S250-43 0.0451 0.626 2.13 5.989 1.497 3.094 0.496 0.891 5.987 1.303 0.313 25.75 1014 0.424 6.374 -1.673 3.629 0.787 800S250-54 0.0566 0.782 2.66 7.453 1.863 3.087 0.613 0.885 7.452 1.707 0.424 33.74 2010 7.359 1.525 0.364 45.66 2010 0.835 7.850 -1.661 3.616 0.789 800S250-68 0.0713 0.980 3.34 9.289 2.322 3.079 0.755 0.878 9.287 2.246 0.609 44.39 4034 9.287 2.001 0.494 59.92 4034 1.660 9.652 -1.645 3.599 0.791 800S250-97 0.1017 1.383 4.71 12.958 3.239 3.061 1.029 0.863 12.955 3.239 1.002 64.00 9037 12.955 3.105 0.888 92.96 11124 4.767 13.091 -1.612 3.566 0.796 800S300-43 0.0451 0.682 2.32 6.826 1.706 3.164 0.825 1.100 6.739 1.449 0.355 28.63 1014 0.462 10.781 -2.172 3.992 0.704 800S300-54 0.0566 0.853 2.91 8.501 2.125 3.158 1.021 1.094 8.500 1.908 0.477 37.71 2010 8.230 1.670 0.405 49.99 2010 0.910 13.309 -2.159 3.978 0.706 800S300-68 0.0713 1.069 3.64 10.605 2.651 3.150 1.263 1.087 10.603 2.404 0.640 47.51 4034 10.475 2.254 0.558 67.49 4034 1.811 16.415 -2.142 3.961 0.708 800S300-97 0.1017 1.510 5.15 14.823 3.706 3.133 1.736 1.072 14.820 3.663 1.111 72.38 9037 14.820 3.401 0.956 101.82 11124 5.205 22.406 -2.108 3.926 0.712 925S137-33 0.0346 0.430 1.46 4.572 0.989 3.262 0.075 0.417 4.529 0.760 0.164 15.03 393 0.171 1.330 -0.641 3.350 0.963 925S137-43 0.0451 0.558 1.90 5.905 1.277 3.253 0.095 0.412 5.903 1.171 0.243 23.14 873 0.378 1.688 -0.632 3.340 0.964 925S137-54 0.0566 0.697 2.38 7.337 1.586 3.244 0.115 0.406 7.334 1.586 0.330 31.33 1730 7.334 1.427 0.295 42.72 1730 0.744 2.055 -0.622 3.328 0.965 925S137-68 0.0713 0.873 2.97 9.123 1.972 3.233 0.139 0.399 9.119 1.972 0.453 38.96 3469 9.119 1.972 0.416 59.03 3469 1.479 2.491 -0.609 3.314 0.966 925S162-33 0.0346 0.456 1.55 5.091 1.101 3.342 0.129 0.531 5.034 0.859 0.187 16.98 393 0.182 2.258 -0.867 3.494 0.938 925S162-43 0.0451 0.592 2.02 6.581 1.423 3.335 0.164 0.526 6.578 1.318 0.277 26.05 873 0.401 2.877 -0.858 3.483 0.939 925S162-54 0.0566 0.739 2.52 8.183 1.769 3.327 0.200 0.520 8.180 1.769 0.372 34.95 1730 8.180 1.599 0.334 47.86 0.790 3.521 -0.847 3.472 0.940 925S162-68 0.0713 0.926 3.16 10.186 2.202 3.316 0.244 0.513 10.183 2.202 0.507 43.51 3469 10.183 2.202 0.470 65.92 3469 1.570 4.293 -0.833 3.457 0.942 925S162-97 0.1017 1.306 4.45 14.172 3.064 3.294 0.324 0.498 14.168 3.063 0.824 60.53 9037 14.168 3.063 0.756 91.72 10136 4.504 5.719 -0.806 3.427 0.945 925S200-33 0.0346 0.482 1.64 5.642 1.220 3.423 0.214 0.667 5.640 0.883 0.192 17.45 393 0.192 3.665 -1.131 3.666 0.905 925S200-43 0.0451 0.626 2.13 7.297 1.578 3.415 0.274 0.661 7.295 1.283 0.269 25.35 873 0.424 4.684 -1.121 3.655 0.906 925S200-54 0.0566 0.782 2.66 9.080 1.963 3.408 0.336 0.656 9.077 1.904 0.396 37.63 1730 9.077 1.539 0.322 0.835 5.751 -1.110 3.643 0.907 925S200-68 0.0713 0.980 3.34 11.312 2.446 3.398 0.412 0.648 11.309 2.437 0.558 48.16 3469 11.309 2.331 0.487 69.80 3469 1.660 7.045 -1.095 3.628 0.909 925S200-97 0.1017 1.383 4.71 15.768 3.409 3.377 0.554 0.633 15.764 3.408 0.900 67.35 9037 15.764 3.398 0.829 101.75 10136 4.767 9.477 -1.066 3.597 0.912 925S250-43 0.0451 0.682 2.32 8.439 1.825 3.518 0.517 0.871 8.436 1.491 0.317 29.46 873 0.462 8.801 -1.571 3.950 0.842 925S250-54 0.0566 0.853 2.91 10.509 2.272 3.511 0.638 0.865 10.506 2.091 0.431 41.32 1730 10.440 1.746 0.369 52.28 1730 0.910 10.847 -1.559 3.937 0.843 925S250-68 0.0713 1.069 3.64 13.108 2.834 3.502 0.786 0.858 13.105 2.745 0.620 54.24 3469 13.105 2.463 0.502 73.75 3469 1.811 13.349 -1.543 3.922 0.845 925S250-97 0.1017 1.510 5.15 18.316 3.960 3.483 1.071 0.842 18.311 3.959 1.027 78.23 9037 18.311 3.802 0.907 113.83 10136 5.205 18.137 -1.512 3.889 0.849 925S300-43 0.0451 0.738 2.52 9.569 2.069 3.600 0.862 1.081 9.504 1.665 0.359 32.90 873 0.501 14.795 -2.050 4.281 0.771 925S300-54 0.0566 0.923 3.15 11.924 2.578 3.594 1.067 1.075 11.922 2.327 0.484 45.99 1730 11.641 1.919 0.410 57.46 1730 0.986 18.277 -2.038 4.269 0.772 925S300-68 0.0713 1.158 3.95 14.886 3.219 3.585 1.320 1.068 14.883 2.931 0.651 57.93 3469 14.692 2.758 0.567 82.58 3469 1.962 22.561 -2.021 4.252 0.774 925S300-97 0.1017 1.637 5.58 20.838 4.505 3.568 1.813 1.053 20.833 4.454 1.136 88.02 9037 20.833 4.149 0.975 124.21 10136 5.643 30.851 -1.988 4.218 0.778 1000S137-33 0.0346 0.456 1.55 5.565 1.113 3.495 0.076 0.408 5.323 0.819 0.165 16.18 363 0.182 1.587 -0.613 3.571 0.971 1000S137-43 0.0451 0.592 2.02 7.191 1.438 3.486 0.096 0.403 7.188 1.253 0.245 24.75 805 0.401 2.014 -0.604 3.561 0.971 1000S137-54 0.0566 0.739 2.52 8.938 1.788 3.477 0.117 0.397 8.935 1.787 0.333 35.31 1596 8.935 1.526 0.297 45.68 1596 0.790 2.454 -0.594 3.549 0.972 1000S137-68 0.0713 0.926 3.16 11.121 2.224 3.465 0.141 0.390 11.116 2.223 0.459 43.93 3200 11.116 2.223 0.420 66.57 3200 1.570 2.975 -0.582 3.535 0.973 9 in in in k-in lbs in 0.386 4.919 -2.473 3.533 0.510 2799 3.462 1.055 0.388 31.59 2977 0.759 6.059 -2.460 3.519 0.511 28.95 4442 4.437 1.360 0.530 40.72 5468 1.509 7.451 -2.442 3.500 0.513 44.28 6859 6.232 2.067 0.893 61.90 10392 4.328 10.108 -2.407 3.461 0.516 46.07 1730 1730 Design Section Designation Thickness GROSS PROPERTIES Area 2 Wt/Ft Ix Sx 4 3 EFFECTIVE PROPERTIES 33ksi rx Iy 4 ry Ix Sx 4 3 A 2 Ma EFFECTIVE PROPERTIES 50ksi TORSIONAL PROPERTIES Cw Xo Ro β in in6 in in in 363 0.192 2.692 -0.831 3.712 0.950 805 0.424 3.430 -0.822 3.702 0.951 0.835 4.198 -0.812 3.691 0.952 Va Ix Sx 4 3 A 2 Ma 4 in Lb/Ft in in in in in in in in k-in lbs 1000S162-33 0.0346 0.482 1.64 6.175 1.235 3.580 0.131 0.521 5.927 0.926 0.188 18.31 1000S162-43 0.0451 0.626 2.13 7.984 1.597 3.573 0.166 0.516 7.981 1.412 0.279 27.91 1000S162-54 0.0566 0.782 2.66 9.932 1.986 3.564 0.204 0.510 9.929 1.986 0.376 39.24 1596 9.929 1.713 0.336 1000S162-68 0.0713 0.980 3.34 12.370 2.474 3.553 0.248 0.503 12.366 2.473 0.512 48.87 3200 12.366 2.473 0.474 74.05 3200 1.660 5.121 -0.799 3.676 0.953 1000S162-97 0.1017 1.383 4.71 17.231 3.446 3.530 0.330 0.488 17.225 3.445 0.836 68.07 9037 17.225 3.445 0.765 103.14 9345 4.767 6.827 -0.772 3.646 0.955 1000S200-33 0.0346 0.508 1.73 6.819 1.364 3.665 0.218 0.655 6.677 0.953 0.193 18.83 363 0.203 4.372 -1.088 3.879 0.921 1000S200-43 0.0451 0.659 2.25 8.822 1.764 3.658 0.279 0.650 8.819 1.378 0.271 27.24 805 0.447 5.589 -1.078 3.868 0.922 1000S200-54 0.0566 0.824 2.81 10.981 2.196 3.650 0.342 0.644 10.978 2.122 0.399 41.94 1596 10.978 1.653 0.325 0.880 6.865 -1.067 3.857 0.923 1000S200-68 0.0713 1.033 3.52 13.688 2.738 3.640 0.419 0.637 13.684 2.728 0.563 53.91 3200 13.684 2.613 0.491 78.24 3200 1.751 8.412 -1.053 3.842 0.925 1000S200-97 0.1017 1.459 4.97 19.099 3.820 3.618 0.564 0.622 19.093 3.819 0.912 75.46 9037 19.093 3.808 0.838 114.01 9345 5.030 11.324 -1.024 3.811 0.928 1000S250-43 0.0451 0.716 2.44 10.162 2.032 3.768 0.528 0.859 10.159 1.604 0.319 31.70 805 0.485 10.481 -1.516 4.151 0.867 1000S250-54 0.0566 0.895 3.05 12.659 2.532 3.761 0.651 0.853 12.656 2.274 0.434 44.94 1596 12.624 1.880 0.372 56.27 1596 0.956 12.922 -1.504 4.139 0.868 1000S250-68 0.0713 1.122 3.83 15.796 3.159 3.751 0.803 0.846 15.792 3.062 0.625 60.50 3200 15.792 2.659 0.506 79.61 3200 1.902 15.909 -1.489 4.124 0.870 1000S250-97 0.1017 1.586 5.41 22.091 4.418 3.732 1.094 0.830 22.085 4.417 1.039 87.28 9037 22.085 4.246 0.916 127.11 9345 5.468 21.632 -1.458 4.092 0.873 1000S300-43 0.0451 0.772 2.63 11.489 2.298 3.857 0.882 1.069 11.445 1.795 0.361 35.47 805 0.523 17.572 -1.984 4.468 0.803 1000S300-54 0.0566 0.966 3.29 14.321 2.864 3.851 1.091 1.063 14.318 2.513 0.487 49.66 1596 14.041 2.069 0.412 61.95 1596 1.031 21.714 -1.972 4.455 0.804 1000S300-68 0.0713 1.212 4.13 17.885 3.577 3.842 1.350 1.056 17.881 3.266 0.657 64.53 3200 17.712 2.961 0.571 88.65 3200 2.053 26.816 -1.956 4.439 0.806 1000S300-97 0.1017 1.713 5.84 25.055 5.011 3.824 1.855 1.040 25.049 4.955 1.149 97.91 9037 25.049 4.623 0.984 138.43 9345 5.906 36.699 -1.924 4.405 0.809 1125S137-33 0.0346 0.499 1.70 7.509 1.335 3.879 0.077 0.394 6.831 0.918 0.167 18.13 322 0.199 2.072 -0.571 3.941 0.979 1125S137-43 0.0451 0.648 2.21 9.708 1.726 3.870 0.098 0.389 9.704 1.392 0.248 27.51 714 0.439 2.630 -0.562 3.930 0.980 1125S137-54 0.0566 0.810 2.76 12.075 2.147 3.861 0.119 0.383 12.070 1.982 0.337 39.16 1414 12.070 1.695 0.301 50.76 1414 0.865 3.205 -0.553 3.919 0.980 1125S137-68 0.0713 1.016 3.46 15.037 2.673 3.848 0.144 0.376 15.031 2.672 0.466 52.80 2834 15.031 2.515 0.426 75.29 2834 1.721 3.887 -0.542 3.904 0.981 1125S162-33 0.0346 0.525 1.79 8.285 1.473 3.973 0.134 0.505 7.616 1.039 0.190 20.53 322 0.209 3.511 -0.778 4.080 0.964 1125S162-43 0.0451 0.682 2.32 10.719 1.906 3.965 0.170 0.500 10.715 1.573 0.282 31.08 714 0.462 4.475 -0.769 4.070 0.964 1125S162-54 0.0566 0.853 2.91 13.342 2.372 3.956 0.208 0.494 13.337 2.209 0.380 43.64 1414 13.337 1.906 0.340 57.07 1414 0.910 5.479 -0.760 4.058 0.965 1125S162-68 0.0713 1.069 3.64 16.631 2.957 3.944 0.254 0.487 16.625 2.956 0.519 58.40 2834 16.625 2.800 0.479 83.82 2834 1.811 6.687 -0.747 4.044 0.966 1125S162-97 0.1017 1.510 5.15 23.203 4.125 3.920 0.338 0.473 23.195 4.123 0.853 81.48 8269 23.195 4.123 0.778 123.46 8269 5.205 8.922 -0.721 4.014 0.968 1125S200-33 0.0346 0.551 1.88 9.101 1.618 4.065 0.224 0.637 8.562 1.069 0.194 21.13 322 0.220 5.710 -1.023 4.240 0.942 1125S200-43 0.0451 0.716 2.44 11.781 2.094 4.057 0.286 0.632 11.777 1.539 0.274 30.41 714 0.485 7.302 -1.013 4.229 0.943 1125S200-54 0.0566 0.895 3.05 14.672 2.608 4.049 0.351 0.626 14.667 2.343 0.403 46.29 1414 14.667 1.847 0.328 55.29 1414 0.956 8.972 -1.003 4.218 0.943 1125S200-68 0.0713 1.122 3.83 18.301 3.254 4.038 0.430 0.619 18.295 3.243 0.570 64.08 2834 18.295 2.896 0.496 86.70 2834 1.902 11.000 -0.989 4.203 0.945 1125S200-97 0.1017 1.586 5.41 25.573 4.546 4.016 0.579 0.604 25.565 4.545 0.929 89.81 8269 25.565 4.532 0.851 135.70 8269 5.468 14.823 -0.961 4.173 0.947 1125S250-43 0.0451 0.772 2.63 13.486 2.397 4.179 0.544 0.839 13.482 1.795 0.321 35.46 714 0.523 13.666 -1.433 4.497 0.898 1125S250-54 0.0566 0.966 3.29 16.808 2.988 4.172 0.671 0.833 16.803 2.525 0.438 49.89 1414 1.031 16.854 -1.422 4.485 0.900 1125S250-68 0.0713 1.212 4.13 20.986 3.731 4.162 0.827 0.826 20.980 3.620 0.632 71.53 2834 20.980 2.954 0.512 88.46 2834 2.053 20.762 -1.407 4.470 0.901 1125S250-97 0.1017 1.713 5.84 29.385 5.224 4.142 1.126 0.811 29.376 5.222 1.056 103.20 8269 29.376 5.028 0.929 150.53 8269 5.906 28.262 -1.377 4.439 0.904 1125S300-43 0.0451 0.828 2.82 15.176 2.698 4.280 0.911 1.048 15.172 2.013 0.364 39.77 714 0.562 22.836 -1.884 4.793 0.845 1125S300-54 0.0566 1.037 3.53 18.925 3.365 4.273 1.127 1.043 18.921 2.799 0.491 55.32 1414 18.627 2.320 0.416 69.46 1414 1.107 28.231 -1.872 4.780 0.847 1125S300-68 0.0713 1.301 4.43 23.648 4.204 4.264 1.394 1.035 23.642 3.853 0.664 76.14 2834 23.557 3.300 0.576 98.80 2834 2.204 34.884 -1.857 4.765 0.848 1125S300-97 0.1017 1.840 6.27 33.165 5.896 4.245 1.916 1.020 33.156 5.831 1.166 115.23 8269 33.156 5.458 0.997 163.40 8269 6.345 47.797 -1.825 4.732 0.851 1200S137-33 0.0346 0.525 1.79 8.860 1.477 4.108 0.078 0.386 7.848 0.977 0.167 19.31 301 0.209 2.398 -0.548 4.163 0.983 1200S137-43 0.0451 0.682 2.32 11.459 1.910 4.099 0.099 0.381 11.268 1.478 0.249 29.20 668 0.462 3.043 -0.540 4.152 0.983 1200S137-54 0.0566 0.853 2.91 14.258 2.376 4.089 0.120 0.376 14.252 2.090 0.340 41.29 1323 14.252 1.799 0.302 53.87 1323 0.910 3.709 -0.532 4.141 0.984 1200S137-68 0.0713 1.069 3.64 17.764 2.961 4.077 0.145 0.369 17.757 2.959 0.469 58.48 2652 17.757 2.649 0.429 79.30 2652 1.811 4.499 -0.520 4.126 0.984 1200S162-33 0.0346 0.551 1.88 9.747 1.624 4.206 0.135 0.496 8.751 1.107 0.190 21.87 301 0.220 4.061 -0.750 4.301 0.970 1200S162-43 0.0451 0.716 2.44 12.613 2.102 4.198 0.173 0.491 12.340 1.671 0.283 33.01 668 0.485 5.177 -0.741 4.291 0.970 1200S162-54 0.0566 0.895 3.05 15.705 2.618 4.189 0.211 0.485 15.699 2.333 0.382 46.10 1323 15.699 2.024 0.341 60.61 1323 0.956 6.340 -0.731 4.280 0.971 1200S162-68 0.0713 1.122 3.83 19.584 3.264 4.177 0.257 0.479 19.576 3.263 0.523 64.47 2652 19.576 2.955 0.482 88.46 2652 1.902 7.739 -0.719 4.265 0.972 1200S162-97 0.1017 1.586 5.41 27.347 4.558 4.152 0.342 0.464 27.336 4.556 0.861 90.03 7735 27.336 4.556 0.784 136.41 7735 5.468 10.331 -0.694 4.236 0.973 1200S200-33 0.0346 0.577 1.97 10.675 1.779 4.302 0.227 0.627 9.826 1.139 0.195 22.52 301 0.230 6.611 -0.988 4.458 0.951 1200S200-43 0.0451 0.750 2.55 13.822 2.304 4.294 0.290 0.622 13.817 1.636 0.275 32.33 668 0.508 8.455 -0.978 4.448 0.952 1200S200-54 0.0566 0.938 3.20 17.219 2.870 4.286 0.356 0.616 17.213 2.478 0.405 48.97 1323 17.213 1.964 0.330 58.80 1323 1.001 10.391 -0.968 4.437 0.952 1200S200-68 0.0713 1.176 4.01 21.486 3.581 4.275 0.436 0.609 21.479 3.569 0.574 70.53 2652 21.479 3.062 0.499 91.67 2652 1.993 12.743 -0.955 4.422 0.953 1200S200-97 0.1017 1.662 5.67 30.046 5.008 4.252 0.586 0.594 30.036 5.006 0.937 98.92 7735 30.036 4.993 0.857 149.48 7735 5.731 17.180 -0.928 4.392 0.955 1200S250-43 0.0451 0.806 2.75 15.767 2.628 4.423 0.552 0.828 15.762 1.910 0.323 37.73 668 0.546 15.812 -1.388 4.709 0.913 1200S250-54 0.0566 1.008 3.44 19.656 3.276 4.415 0.681 0.822 19.650 2.676 0.440 52.89 1323 19.650 2.239 0.377 67.03 1323 1.077 19.505 -1.377 4.697 0.914 1200S250-68 0.0713 1.265 4.31 24.550 4.092 4.405 0.839 0.815 24.542 3.973 0.636 78.50 2652 24.542 3.134 0.515 93.82 2652 2.144 24.034 -1.363 4.683 0.915 1200S250-97 0.1017 1.789 6.10 34.398 5.733 4.384 1.144 0.799 34.387 5.731 1.065 113.25 7735 34.387 5.523 0.936 165.35 7735 6.169 32.734 -1.333 4.652 0.918 1200S300-43 0.0451 0.862 2.94 17.696 2.949 4.530 0.926 1.036 17.692 2.144 0.365 42.36 668 0.585 26.386 -1.830 4.994 0.866 1200S300-54 0.0566 1.079 3.68 22.073 3.679 4.523 1.146 1.031 22.067 2.972 0.493 58.74 1323 21.909 2.471 0.417 73.99 1323 1.152 32.627 -1.818 4.982 0.867 1200S300-68 0.0713 1.354 4.62 27.589 4.598 4.514 1.418 1.023 27.582 4.206 0.668 83.11 2652 27.582 3.505 0.579 104.93 2652 2.295 40.327 -1.803 4.967 0.868 1200S300-97 0.1017 1.917 6.53 38.715 6.452 4.494 1.948 1.008 38.704 6.383 1.174 126.13 7735 38.704 5.984 1.003 179.16 7735 6.607 55.286 -1.772 4.935 0.871 1400S137-33 0.0346 0.594 2.02 13.205 1.886 4.714 0.080 0.367 10.971 1.138 0.169 22.49 257 0.237 3.393 -0.497 4.755 0.989 1400S137-43 0.0451 0.772 2.63 17.091 2.442 4.705 0.101 0.362 15.506 1.711 0.252 33.81 571 0.523 4.308 -0.489 4.744 0.989 1400S137-54 0.0566 0.966 3.29 21.284 3.041 4.694 0.123 0.357 21.275 2.390 0.344 47.23 1130 19.698 2.082 0.306 62.35 1130 1.031 5.251 -0.481 4.732 0.990 1400S137-68 0.0713 1.212 4.13 26.547 3.792 4.681 0.149 0.350 26.535 3.484 0.477 68.84 2264 26.535 3.024 0.435 90.55 2264 2.053 6.372 -0.471 4.718 0.990 1400S162-33 0.0346 0.620 2.11 14.421 2.060 4.823 0.139 0.474 12.230 1.289 0.192 25.48 257 0.247 5.748 -0.683 4.894 0.981 1400S162-43 0.0451 0.806 2.75 18.675 2.668 4.814 0.177 0.469 17.056 1.935 0.286 38.25 571 0.546 7.331 -0.675 4.883 0.981 1400S162-54 0.0566 1.008 3.44 23.269 3.324 4.804 0.217 0.464 23.260 2.675 0.387 52.86 1130 1.077 8.980 -0.666 4.872 0.981 1400S162-68 0.0713 1.265 4.31 29.044 4.149 4.791 0.264 0.457 29.031 3.844 0.531 75.95 2264 29.031 3.383 0.488 101.29 2264 2.144 10.966 -0.655 4.858 0.982 1400S162-97 0.1017 1.789 6.10 40.637 5.805 4.765 0.351 0.443 40.620 5.803 0.880 114.67 6598 40.620 5.803 0.798 173.74 6598 6.169 14.651 -0.632 4.827 0.983 1400S200-33 0.0346 0.646 2.20 15.686 2.241 4.928 0.234 0.601 13.700 1.328 0.196 26.23 257 0.258 9.380 -0.905 5.046 0.968 1400S200-43 0.0451 0.840 2.86 20.322 2.903 4.919 0.299 0.596 19.238 1.899 0.278 37.52 571 0.569 12.001 -0.896 5.036 0.968 1400S200-54 0.0566 1.051 3.58 25.333 3.619 4.910 0.367 0.591 25.323 2.847 0.410 56.26 1130 1.122 14.755 -0.887 5.024 0.969 10 16.803 21.630 24.485 in 2.103 2.345 2.280 in 0.375 0.345 0.333 51.27 49.50 62.98 70.20 68.26 lbs Jx1000 in. in k-in Va 1596 1596 1414 1130 1130 Design Section Designation Thickness GROSS PROPERTIES Area 2 Wt/Ft Ix Sx 4 3 EFFECTIVE PROPERTIES 33ksi rx Iy 4 ry Ix Sx 4 3 A 2 Ma Ix Sx lbs 4 3 A 2 Ma TORSIONAL PROPERTIES Va Cw Xo Ro β in6 in in in Lb/Ft in in in in in in in in 1400S200-68 0.0713 1.319 4.49 31.637 4.520 4.898 0.449 0.584 31.625 4.198 0.582 82.95 2264 31.625 3.516 0.505 105.27 2264 2.234 18.101 -0.874 5.010 0.970 1400S200-97 0.1017 1.866 6.36 44.320 6.331 4.874 0.604 0.569 44.303 6.329 0.956 125.06 6598 44.303 6.313 0.871 189.03 6598 6.432 24.428 -0.849 4.980 0.971 1400S250-43 0.0451 0.896 3.05 22.985 3.284 5.064 0.571 0.799 21.858 2.218 0.325 43.83 571 0.608 22.425 -1.282 5.285 0.941 1400S250-54 0.0566 1.121 3.82 28.670 4.096 5.056 0.705 0.793 28.660 3.087 0.445 61.00 1130 27.853 2.602 0.380 77.89 1130 1.198 27.675 -1.271 5.273 0.942 1400S250-68 0.0713 1.408 4.80 35.834 5.119 5.045 0.869 0.786 35.822 4.620 0.644 91.29 2264 35.822 3.618 0.521 108.34 2264 2.385 34.118 -1.257 5.259 0.943 1400S250-97 0.1017 1.993 6.79 50.285 7.184 5.023 1.183 0.771 50.268 7.181 1.083 141.90 6598 50.268 6.936 0.949 207.67 6598 6.870 46.520 -1.229 5.229 0.945 1400S300-43 0.0451 0.953 3.25 25.630 3.661 5.187 0.962 1.005 24.546 2.494 0.368 49.29 571 0.646 37.335 -1.699 5.550 0.906 1400S300-54 0.0566 1.192 4.06 31.985 4.569 5.180 1.191 1.000 31.975 3.438 0.498 67.93 1130 31.191 2.876 0.421 86.11 1130 1.273 46.187 -1.688 5.539 0.907 1400S300-68 0.0713 1.497 5.10 40.003 5.715 5.170 1.474 0.992 39.991 4.813 0.676 95.10 2264 39.991 4.055 0.585 121.41 2264 2.536 57.119 -1.674 5.524 0.908 1400S300-97 0.1017 2.120 7.22 56.209 8.030 5.149 2.024 0.977 56.192 7.947 1.192 157.04 6598 56.192 7.477 1.017 223.86 6598 7.309 78.400 -1.644 5.493 0.910 Section Designation Thickness Area Wt/Ft Ix Sx rx Iy ry Ix Sx A Ma Va Ix Sx A Ma Va Jx1000 Cw Xo Ro β in. in2 Lb/Ft in4 in3 in in4 in in4 in3 in2 k-in lbs in4 in3 in2 k-in lbs in4 in6 in in in 250T125-33 0.0346 0.173 0.59 0.194 0.146 1.059 0.027 0.397 0.168 0.104 0.107 2.06 1046 0.069 0.033 -0.759 1.362 0.689 250T125-43 0.0451 0.225 0.77 0.254 0.189 1.062 0.035 0.395 0.235 0.150 0.168 2.96 1432 0.153 0.043 -0.754 1.360 0.693 250T125-54 0.0566 0.282 0.96 0.320 0.236 1.065 0.043 0.392 0.312 0.204 0.244 4.04 1798 0.299 0.190 0.215 0.302 0.054 -0.748 1.359 0.697 250T125-68 0.0713 0.355 1.21 0.406 0.296 1.068 0.054 0.390 0.405 0.279 0.339 5.52 2265 0.399 0.260 0.313 7.78 3431 0.602 0.068 -0.741 1.357 0.702 250T125-97 0.1017 0.505 1.72 0.585 0.419 1.076 0.074 0.384 0.585 0.438 0.505 8.65 3230 0.585 0.416 0.504 12.47 4894 1.742 0.096 -0.726 1.354 0.712 250T200-33 0.0346 0.225 0.77 0.283 0.213 1.123 0.097 0.658 0.206 0.114 0.109 2.26 1046 0.090 0.120 -1.417 1.924 0.458 362T125-33 0.0346 0.212 0.72 0.441 0.233 1.443 0.030 0.377 0.389 0.176 0.111 3.47 1001 0.085 0.076 -0.657 1.630 0.837 362T125-43 0.0451 0.276 0.94 0.576 0.303 1.445 0.039 0.375 0.538 0.248 0.177 4.90 1777 0.187 0.099 -0.653 1.630 0.840 362T125-54 0.0566 0.346 1.18 0.725 0.379 1.448 0.048 0.373 0.708 0.334 0.262 6.60 2638 0.370 0.124 -0.648 1.629 0.842 362T125-68 0.0713 0.435 1.48 0.916 0.475 1.451 0.060 0.370 0.206 0.114 0.109 2.26 1046 0.194 0.106 0.093 3.17 1288 0.738 0.155 -0.641 1.629 0.845 362T125-97 0.1017 0.620 2.11 1.316 0.671 1.457 0.082 0.364 1.315 0.698 0.620 13.79 4740 1.315 0.668 0.597 20.00 7183 2.137 0.218 -0.628 1.628 0.851 362T200-33 0.0346 0.264 0.90 0.624 0.329 1.538 0.110 0.645 0.469 0.192 0.113 3.80 1001 0.105 0.272 -1.269 2.096 0.633 362T200-43 0.0451 0.344 1.17 0.816 0.428 1.541 0.142 0.643 0.659 0.274 0.182 5.42 1777 0.233 0.355 -1.264 2.094 0.636 362T200-54 0.0566 0.431 1.47 1.028 0.536 1.544 0.177 0.640 0.884 0.374 0.272 7.39 2638 0.837 0.347 0.233 10.40 3446 0.460 0.445 -1.258 2.092 0.638 362T200-68 0.0713 0.542 1.85 1.301 0.674 1.548 0.221 0.638 1.190 0.516 0.404 10.19 3323 1.128 0.477 0.350 14.27 5036 0.919 0.560 -1.251 2.090 0.642 362T200-97 0.1017 0.772 2.63 1.872 0.955 1.557 0.309 0.632 1.859 0.846 0.702 16.72 4740 1.781 0.782 0.638 23.40 7183 2.663 0.796 -1.235 2.086 0.649 362T300-33 0.0346 0.333 1.13 0.868 0.458 1.614 0.327 0.992 0.552 0.200 0.114 3.96 1001 0.133 0.819 -2.157 2.871 0.435 362T300-43 0.0451 0.434 1.48 1.135 0.596 1.618 0.425 0.990 0.779 0.294 0.185 5.81 1777 0.294 1.070 -2.151 2.868 0.437 362T300-54 0.0566 0.544 1.85 1.431 0.747 1.622 0.531 0.988 1.057 0.404 0.277 7.98 2638 0.991 0.373 0.236 11.17 3446 0.581 1.345 -2.145 2.865 0.439 362T300-68 0.0713 0.685 2.33 1.813 0.939 1.627 0.665 0.985 1.444 0.562 0.415 11.11 3323 1.352 0.515 0.357 15.43 5036 1.161 1.697 -2.137 2.860 0.442 362T300-97 0.1017 0.976 3.33 2.615 1.333 1.637 0.937 0.980 2.330 0.945 0.734 18.68 4740 2.190 0.860 0.659 25.76 7183 3.364 2.432 -2.120 2.852 0.448 400T125-33 0.0346 0.225 0.77 0.552 0.265 1.567 0.031 0.371 0.489 0.203 0.112 4.01 905 0.090 0.095 -0.630 1.729 0.867 400T125-43 0.0451 0.293 1.00 0.721 0.345 1.569 0.040 0.369 0.674 0.285 0.179 5.63 1777 0.199 0.124 -0.625 1.729 0.869 400T125-54 0.0566 0.367 1.25 0.907 0.431 1.571 0.049 0.366 0.886 0.383 0.265 7.56 2799 0.853 0.360 0.228 10.79 3446 0.392 0.154 -0.620 1.729 0.871 400T125-68 0.0713 0.462 1.58 1.146 0.541 1.574 0.061 0.364 1.145 0.515 0.390 10.17 3676 1.126 0.486 0.340 14.54 5468 0.783 0.193 -0.614 1.729 0.874 400T125-97 0.1017 0.658 2.24 1.643 0.765 1.580 0.084 0.358 1.642 0.794 0.657 15.69 5244 1.642 0.761 0.610 22.80 7945 2.268 0.271 -0.601 1.728 0.879 400T200-33 0.0346 0.277 0.94 0.773 0.372 1.672 0.113 0.639 0.587 0.222 0.114 4.39 905 0.110 0.340 -1.228 2.170 0.680 400T200-43 0.0451 0.361 1.23 1.011 0.483 1.674 0.146 0.637 0.822 0.315 0.184 6.22 1777 0.244 0.442 -1.222 2.169 0.682 400T200-54 0.0566 0.452 1.54 1.273 0.605 1.678 0.182 0.635 1.099 0.428 0.275 8.46 2799 1.042 0.399 0.235 11.94 3446 0.483 0.554 -1.217 2.167 0.685 400T200-68 0.0713 0.569 1.94 1.609 0.760 1.682 0.227 0.632 1.475 0.587 0.411 11.61 3676 1.401 0.545 0.354 16.31 5468 0.964 0.697 -1.209 2.165 0.688 400T200-97 0.1017 0.811 2.76 2.314 1.077 1.690 0.318 0.626 2.297 0.959 0.739 18.94 5244 2.203 0.888 0.652 26.59 7945 2.794 0.990 -1.194 2.162 0.695 400T300-33 0.0346 0.346 1.18 1.068 0.513 1.757 0.338 0.989 0.694 0.222 0.115 4.39 905 0.138 1.019 -2.102 2.912 0.479 400T300-43 0.0451 0.451 1.54 1.397 0.668 1.761 0.439 0.987 0.969 0.338 0.186 6.69 1777 0.306 1.329 -2.096 2.910 0.481 400T300-54 0.0566 0.565 1.93 1.760 0.837 1.764 0.548 0.985 1.309 0.462 0.280 9.14 2799 1.231 0.429 0.238 12.84 3446 0.604 1.670 -2.090 2.907 0.483 400T300-68 0.0713 0.712 2.43 2.228 1.052 1.769 0.686 0.982 1.783 0.640 0.422 12.66 3676 1.674 0.590 0.361 17.65 5468 1.206 2.107 -2.081 2.903 0.486 400T300-97 0.1017 1.014 3.46 3.209 1.494 1.779 0.967 0.977 2.864 1.070 0.771 21.14 5244 2.697 0.977 0.673 29.26 7945 3.496 3.013 -2.065 2.895 0.491 550T125-33 0.0346 0.277 0.94 1.164 0.411 2.050 0.033 0.346 1.049 0.317 0.114 6.26 654 0.110 0.196 -0.540 2.149 0.937 550T125-43 0.0451 0.361 1.23 1.518 0.534 2.052 0.043 0.344 1.430 0.455 0.183 8.99 1449 0.244 0.254 -0.536 2.149 0.938 550T125-54 0.0566 0.452 1.54 1.907 0.668 2.054 0.053 0.342 1.867 0.604 0.274 11.93 2799 1.806 0.574 0.234 17.19 2863 0.483 0.317 -0.532 2.149 0.939 550T125-68 0.0713 0.569 1.94 2.406 0.839 2.056 0.066 0.340 2.405 0.804 0.409 15.89 4442 2.368 0.765 0.353 22.91 5468 0.964 0.395 -0.527 2.149 0.940 550T125-97 0.1017 0.811 2.76 3.441 1.187 2.060 0.090 0.334 3.440 1.226 0.710 24.23 7258 3.440 1.183 0.645 35.41 10996 2.794 0.551 -0.515 2.150 0.943 550T200-33 0.0346 0.329 1.12 1.575 0.556 2.189 0.123 0.613 1.255 0.312 0.116 6.16 654 0.131 0.699 -1.087 2.520 0.814 550T200-43 0.0451 0.428 1.46 2.056 0.723 2.191 0.160 0.611 1.708 0.500 0.188 9.89 1449 0.290 0.909 -1.082 2.519 0.815 550T200-54 0.0566 0.537 1.83 2.585 0.906 2.194 0.199 0.609 2.262 0.671 0.284 13.26 2799 2.161 0.632 0.241 18.93 2863 0.574 1.137 -1.077 2.519 0.817 550T200-68 0.0713 0.676 2.30 3.264 1.138 2.197 0.248 0.606 3.010 0.909 0.430 17.97 4442 2.877 0.853 0.366 25.53 5468 1.146 1.426 -1.071 2.518 0.819 550T200-97 0.1017 0.963 3.28 4.678 1.614 2.204 0.347 0.600 4.641 1.456 0.792 28.78 7258 4.466 1.363 0.687 40.81 10996 3.320 2.018 -1.057 2.517 0.824 550T300-33 0.0346 0.398 1.36 2.123 0.750 2.310 0.374 0.969 1.475 0.308 0.117 6.08 654 0.159 2.082 -1.908 3.149 0.633 550T300-43 0.0451 0.518 1.77 2.773 0.976 2.313 0.485 0.967 2.006 0.519 0.191 10.25 1449 0.351 2.712 -1.903 3.147 0.634 550T300-54 0.0566 0.650 2.22 3.488 1.223 2.316 0.606 0.965 2.665 0.726 0.290 14.34 2799 2.535 0.667 0.244 19.97 2863 0.694 3.402 -1.897 3.146 0.636 550T300-68 0.0713 0.819 2.79 4.408 1.537 2.320 0.758 0.963 3.589 0.991 0.440 19.58 4442 3.396 0.923 0.373 27.64 5468 1.387 4.283 -1.890 3.143 0.639 550T300-97 0.1017 1.166 3.98 6.327 2.183 2.329 1.068 0.957 5.682 1.620 0.824 32.01 7258 5.381 1.497 0.708 44.82 10996 4.022 6.101 -1.874 3.139 0.644 600T125-33 0.0346 0.294 1.00 1.434 0.465 2.208 0.034 0.339 1.306 0.341 0.114 6.73 599 0.117 0.239 -0.516 2.293 0.949 600T125-43 0.0451 0.383 1.31 1.870 0.605 2.210 0.044 0.337 1.765 0.519 0.184 10.26 1326 0.260 0.310 -0.512 2.293 0.950 600T125-54 0.0566 0.480 1.64 2.349 0.757 2.211 0.054 0.335 2.300 0.687 0.276 13.57 2621 2.229 0.655 0.236 19.61 2621 0.513 0.385 -0.508 2.293 0.951 600T125-68 0.0713 0.605 2.06 2.962 0.950 2.213 0.067 0.332 2.961 0.912 0.413 18.03 4442 2.917 0.870 0.355 26.06 5239 1.025 0.480 -0.503 2.294 0.952 600T125-97 0.1017 0.861 2.94 4.234 1.345 2.217 0.092 0.327 4.233 1.387 0.722 27.41 7929 4.233 1.340 0.653 40.12 11124 2.970 0.670 -0.492 2.295 0.954 600T200-33 0.0346 0.346 1.18 1.921 0.623 2.356 0.126 0.604 1.552 0.339 0.116 6.70 599 0.138 0.852 -1.048 2.649 0.844 600T200-43 0.0451 0.451 1.54 2.508 0.811 2.359 0.163 0.602 2.096 0.570 0.189 11.26 1326 0.306 1.108 -1.043 2.648 0.845 GROSS PROPERTIES in EFFECTIVE PROPERTIES 33ksi in lbs 4 in in k-in Jx1000 in. Design k-in EFFECTIVE PROPERTIES 50ksi Va in EFFECTIVE PROPERTIES 50ksi TORSIONAL PROPERTIES PHYSICAL AND STRUCTURAL PROPERTIES FOR STRUCTURAL (T) TRACK 11 0.681 0.314 0.226 5.68 9.39 2724 3446 Design Section Designation GROSS PROPERTIES EFFECTIVE PROPERTIES 33ksi EFFECTIVE PROPERTIES 50ksi TORSIONAL PROPERTIES Cw Xo Ro β in. in Lb/Ft in in in in in in in in k-in lbs in in in k-in lbs in in6 in in in 600T200-54 0.0566 0.565 1.93 3.152 1.016 2.361 0.204 0.600 2.769 0.762 0.286 15.06 2621 2.651 0.720 0.242 21.56 2621 0.604 1.385 -1.038 2.648 0.846 600T200-68 0.0713 0.712 2.43 3.979 1.276 2.364 0.254 0.597 3.677 1.029 0.434 20.33 4442 3.520 0.968 0.369 28.97 5239 1.206 1.738 -1.032 2.648 0.848 600T200-97 0.1017 1.014 3.46 5.698 1.810 2.371 0.355 0.591 5.652 1.640 0.804 32.40 7929 5.445 1.539 0.695 46.06 11124 3.496 2.456 -1.018 2.647 0.852 600T300-33 0.0346 0.415 1.41 2.571 0.834 2.488 0.384 0.961 1.819 0.336 0.118 6.65 599 0.166 2.536 -1.853 3.248 0.675 600T300-43 0.0451 0.541 1.84 3.357 1.086 2.491 0.498 0.959 2.469 0.565 0.192 11.17 1326 0.367 3.303 -1.847 3.247 0.676 600T300-54 0.0566 0.679 2.31 4.223 1.361 2.495 0.622 0.957 3.251 0.824 0.292 16.28 2621 3.119 0.727 0.246 21.75 2621 0.725 4.142 -1.842 3.245 0.678 600T300-68 0.0713 0.854 2.91 5.334 1.710 2.499 0.778 0.955 4.365 1.120 0.444 22.14 4442 4.139 1.048 0.376 31.36 5239 1.448 5.213 -1.834 3.243 0.680 600T300-97 0.1017 1.217 4.15 7.650 2.430 2.507 1.096 0.949 6.884 1.821 0.836 35.99 7929 6.530 1.688 0.716 50.55 11124 4.197 7.418 -1.819 3.239 0.685 800T125-33 0.0346 0.363 1.24 2.904 0.711 2.827 0.036 0.313 2.719 0.440 0.115 8.69 447 0.145 0.459 -0.439 2.878 0.977 800T125-43 0.0451 0.473 1.61 3.786 0.925 2.828 0.046 0.311 3.621 0.751 0.187 14.84 990 0.321 0.593 -0.435 2.878 0.977 800T125-54 0.0566 0.594 2.02 4.753 1.158 2.829 0.057 0.309 4.664 1.067 0.282 21.09 1958 4.558 0.967 0.239 28.95 1958 0.634 0.737 -0.432 2.879 0.978 800T125-68 0.0713 0.747 2.55 5.989 1.454 2.831 0.070 0.307 5.987 1.405 0.424 27.77 3914 5.904 1.351 0.362 40.44 3914 1.267 0.917 -0.427 2.879 0.978 800T125-97 0.1017 1.065 3.63 8.550 2.061 2.834 0.097 0.301 8.546 2.115 0.754 41.80 9037 8.546 2.054 0.674 61.51 11124 3.671 1.275 -0.418 2.880 0.979 800T200-33 0.0346 0.415 1.41 3.761 0.921 3.010 0.135 0.571 3.171 0.448 0.118 8.85 447 0.166 1.646 -0.917 3.198 0.918 800T200-43 0.0451 0.541 1.84 4.906 1.199 3.012 0.175 0.569 4.257 0.753 0.192 14.88 990 0.367 2.137 -0.913 3.198 0.919 800T200-54 0.0566 0.679 2.31 6.163 1.502 3.014 0.218 0.567 5.489 1.174 0.292 23.19 1958 5.366 0.968 0.246 28.97 1958 0.725 2.670 -0.908 3.198 0.919 800T200-68 0.0713 0.854 2.91 7.772 1.887 3.016 0.272 0.564 7.236 1.567 0.445 30.97 3914 6.967 1.488 0.376 44.56 3914 1.448 3.344 -0.902 3.198 0.920 800T200-97 0.1017 1.217 4.15 11.111 2.678 3.021 0.379 0.558 11.019 2.458 0.836 48.57 9037 10.656 2.327 0.716 69.67 11124 4.197 4.713 -0.891 3.199 0.922 800T300-33 0.0346 0.484 1.65 4.904 1.202 3.182 0.416 0.927 3.474 0.451 0.119 8.90 447 0.193 4.896 -1.661 3.707 0.799 800T300-43 0.0451 0.631 2.15 6.400 1.564 3.184 0.540 0.925 4.957 0.750 0.195 14.81 990 0.428 6.371 -1.656 3.707 0.800 800T300-54 0.0566 0.792 2.70 8.043 1.960 3.187 0.675 0.923 6.412 1.185 0.297 23.41 1958 6.253 0.962 0.249 28.81 1958 0.846 7.980 -1.651 3.706 0.802 800T300-68 0.0713 0.997 3.40 10.149 2.464 3.191 0.844 0.920 8.459 1.702 0.455 33.63 3914 8.126 1.536 0.383 46.00 3914 1.689 10.029 -1.644 3.705 0.803 800T300-97 0.1017 1.421 4.84 14.526 3.502 3.198 1.188 0.914 13.170 2.715 0.868 53.65 9037 12.565 2.543 0.737 76.15 11124 4.898 14.233 -1.631 3.704 0.806 925T125-33 0.0346 0.406 1.39 4.183 0.889 3.208 0.036 0.299 3.962 0.504 0.116 9.97 386 0.162 0.636 -0.401 3.247 0.985 925T125-43 0.0451 0.530 1.81 5.453 1.156 3.209 0.047 0.297 5.272 0.846 0.188 16.72 855 0.359 0.821 -0.398 3.247 0.985 925T125-54 0.0566 0.664 2.26 6.844 1.447 3.209 0.058 0.296 6.723 1.343 0.284 26.54 1691 6.634 1.087 0.241 32.54 1691 0.710 1.021 -0.395 3.247 0.985 925T125-68 0.0713 0.837 2.85 8.623 1.818 3.211 0.072 0.293 8.619 1.762 0.428 34.81 3379 8.507 1.699 0.365 50.88 3379 1.418 1.269 -0.391 3.248 0.986 925T125-97 0.1017 1.192 4.06 12.303 2.577 3.213 0.099 0.288 12.298 2.639 0.767 52.16 9037 12.298 2.570 0.683 76.94 9807 4.109 1.762 -0.382 3.248 0.986 925T200-33 0.0346 0.458 1.56 5.324 1.131 3.408 0.139 0.551 4.359 0.516 0.118 10.21 386 0.183 2.295 -0.851 3.556 0.943 925T200-43 0.0451 0.597 2.04 6.944 1.472 3.410 0.180 0.550 6.135 0.861 0.193 17.01 855 0.405 2.978 -0.847 3.556 0.943 925T200-54 0.0566 0.749 2.55 8.720 1.844 3.411 0.225 0.547 7.876 1.371 0.294 27.08 1691 0.800 3.719 -0.843 3.556 0.944 925T200-68 0.0713 0.943 3.22 10.993 2.318 3.413 0.280 0.545 10.276 1.953 0.449 38.59 3379 9.964 1.780 0.379 53.28 3379 1.599 4.655 -0.838 3.557 0.945 925T200-97 0.1017 1.344 4.58 15.705 3.290 3.418 0.391 0.539 15.575 3.038 0.849 60.04 9037 15.093 2.889 0.724 86.51 9807 4.635 6.552 -0.827 3.558 0.946 925T300-33 0.0346 0.528 1.80 6.845 1.454 3.602 0.432 0.905 4.649 0.522 0.119 10.32 386 0.211 6.836 -1.562 4.029 0.850 925T300-43 0.0451 0.688 2.34 8.931 1.893 3.604 0.561 0.903 7.090 0.865 0.196 17.09 855 0.466 8.891 -1.558 4.029 0.851 925T300-54 0.0566 0.863 2.94 11.220 2.373 3.607 0.700 0.901 9.155 1.356 0.299 26.80 1691 8.938 1.110 0.251 33.22 1691 0.921 11.133 -1.553 4.029 0.851 925T300-68 0.0713 1.086 3.70 14.153 2.984 3.610 0.877 0.898 11.914 2.116 0.460 41.81 3379 11.596 1.757 0.386 52.60 3379 1.840 13.983 -1.546 4.029 0.853 925T300-97 0.1017 1.548 5.28 20.242 4.240 3.616 1.233 0.893 18.431 3.344 0.881 66.09 9037 17.637 3.149 0.745 94.28 9807 5.336 19.822 -1.533 4.028 0.855 1000T125-33 0.0346 0.432 1.47 5.101 1.004 3.434 0.037 0.292 4.724 0.544 0.116 10.74 357 0.173 0.757 -0.382 3.468 0.988 1000T125-43 0.0451 0.563 1.92 6.649 1.306 3.435 0.047 0.290 6.461 0.905 0.189 17.89 791 0.382 0.978 -0.379 3.468 0.988 1000T125-54 0.0566 0.707 2.41 8.345 1.635 3.436 0.059 0.288 8.226 1.450 0.285 28.65 1563 8.129 1.162 0.241 34.79 1563 0.755 1.215 -0.376 3.468 0.988 1000T125-68 0.0713 0.890 3.03 10.512 2.054 3.437 0.073 0.286 10.508 1.993 0.430 39.39 3124 10.389 1.884 0.367 56.40 3124 1.508 1.510 -0.372 3.469 0.989 1000T125-97 0.1017 1.268 4.32 14.996 2.913 3.439 0.100 0.281 14.989 2.979 0.773 58.87 9037 14.989 2.904 0.687 86.96 9065 4.372 2.095 -0.364 3.469 0.989 1000T200-33 0.0346 0.484 1.65 6.432 1.266 3.644 0.142 0.541 5.074 0.558 0.118 11.03 357 0.193 2.743 -0.816 3.773 0.953 1000T200-43 0.0451 0.631 2.15 8.387 1.647 3.645 0.183 0.539 7.478 0.926 0.194 18.30 791 0.428 3.558 -0.813 3.774 0.954 1000T200-54 0.0566 0.792 2.70 10.531 2.064 3.647 0.228 0.537 9.596 1.464 0.295 28.92 1563 9.419 1.188 0.248 35.58 1563 0.846 4.443 -0.809 3.774 0.954 1000T200-68 0.0713 0.997 3.40 13.275 2.594 3.649 0.284 0.534 12.437 2.202 0.451 43.52 3124 12.138 1.898 0.381 56.83 3124 1.689 5.559 -0.803 3.774 0.955 1000T200-97 0.1017 1.421 4.84 18.960 3.683 3.653 0.397 0.529 18.804 3.412 0.855 67.43 9037 18.242 3.252 0.728 97.38 9065 4.898 7.819 -0.793 3.775 0.956 1000T300-33 0.0346 0.554 1.89 8.206 1.615 3.850 0.441 0.892 5.447 0.565 0.120 11.17 357 0.221 8.179 -1.509 4.230 0.873 1000T300-43 0.0451 0.721 2.46 10.705 2.102 3.852 0.572 0.890 8.606 0.934 0.196 18.46 791 0.489 10.637 -1.504 4.230 0.874 1000T300-54 0.0566 0.905 3.08 13.447 2.635 3.855 0.714 0.888 11.104 1.460 0.300 28.84 1563 10.847 1.198 0.252 35.88 1563 0.966 13.316 -1.499 4.230 0.874 1000T300-68 0.0713 1.140 3.88 16.959 3.313 3.858 0.894 0.885 14.368 2.361 0.462 46.66 3124 14.060 1.890 0.388 56.58 3124 1.931 16.720 -1.493 4.230 0.875 1000T300-97 0.1017 1.624 5.53 24.246 4.709 3.864 1.257 0.880 22.130 3.748 0.887 74.07 9037 21.211 3.539 0.749 105.95 9065 5.599 23.689 -1.480 4.230 0.878 1125T125-33 0.0346 0.476 1.62 6.904 1.210 3.810 0.037 0.280 6.729 0.650 0.117 12.84 297 0.190 0.985 -0.353 3.836 0.992 1125T125-43 0.0451 0.620 2.11 8.999 1.574 3.810 0.048 0.279 10.444 1.069 0.190 21.13 658 0.420 1.272 -0.351 3.837 0.992 1125T125-54 0.0566 0.778 2.65 11.293 1.971 3.811 0.060 0.277 13.283 1.670 0.287 33.01 1300 13.134 1.370 0.243 41.02 1300 0.830 1.579 -0.348 3.837 0.992 1125T125-68 0.0713 0.979 3.34 14.225 2.477 3.812 0.074 0.275 16.808 2.677 0.435 52.89 2599 16.768 2.161 0.370 64.72 2599 1.659 1.963 -0.344 3.837 0.992 1125T125-97 0.1017 1.395 4.76 20.287 3.514 3.813 0.102 0.270 23.968 3.979 0.786 78.62 7542 23.968 3.890 0.695 116.46 7542 4.810 2.720 -0.336 3.837 0.992 1125T200-33 0.0346 0.528 1.80 8.584 1.504 4.034 0.145 0.524 7.343 0.669 0.119 13.23 297 0.211 3.588 -0.765 4.139 0.966 1125T200-43 0.0451 0.688 2.34 11.193 1.958 4.035 0.187 0.522 11.942 1.103 0.195 21.80 658 0.466 4.654 -0.761 4.139 0.966 1125T200-54 0.0566 0.863 2.94 14.052 2.453 4.036 0.233 0.520 15.302 1.718 0.297 33.96 1300 15.033 1.414 0.250 42.34 1300 0.921 5.808 -0.757 4.139 0.967 1125T200-68 0.0713 1.086 3.70 17.709 3.084 4.038 0.291 0.517 19.649 2.780 0.456 54.93 2599 19.346 2.224 0.383 66.57 2599 1.840 7.265 -0.752 4.140 0.967 1125T200-97 0.1017 1.548 5.28 25.283 4.379 4.042 0.405 0.512 29.413 4.503 0.868 88.99 7542 28.608 4.314 0.737 129.17 7542 5.336 10.210 -0.742 4.141 0.968 1125T300-33 0.0346 0.597 2.03 10.824 1.897 4.259 0.453 0.871 7.932 0.680 0.120 13.44 297 0.238 10.728 -1.428 4.575 0.903 1125T300-43 0.0451 0.778 2.65 14.118 2.469 4.261 0.588 0.870 12.649 1.121 0.198 22.14 658 0.527 13.948 -1.423 4.575 0.903 1125T300-54 0.0566 0.976 3.33 17.730 3.095 4.263 0.734 0.867 17.519 1.737 0.303 34.33 1300 16.179 1.437 0.253 43.01 1300 1.042 17.455 -1.419 4.576 0.904 1125T300-68 0.0713 1.229 4.19 22.355 3.892 4.265 0.919 0.865 22.638 2.768 0.466 54.70 2599 22.167 2.246 0.391 67.25 2599 2.082 21.909 -1.413 4.576 0.905 1125T300-97 0.1017 1.751 5.97 31.945 5.533 4.271 1.292 0.859 34.171 4.920 0.900 97.22 7542 32.876 4.673 0.758 139.91 7542 6.038 31.016 -1.401 4.576 0.906 1200T125-33 0.0346 0.502 1.71 8.163 1.342 4.034 0.038 0.274 6.729 0.650 0.117 12.84 297 0.200 1.137 -0.338 4.057 0.993 1200T125-43 0.0451 0.654 2.23 10.639 1.746 4.034 0.049 0.272 10.444 1.069 0.190 21.13 658 0.443 1.468 -0.336 4.057 0.993 1200T125-54 0.0566 0.820 2.79 13.351 2.187 4.035 0.060 0.271 13.283 1.670 0.287 33.01 1300 13.134 1.370 0.243 41.02 1300 0.876 1.823 -0.333 4.058 0.993 1200T125-68 0.0713 1.033 3.52 16.816 2.749 4.035 0.074 0.268 16.808 2.677 0.435 52.89 2599 16.768 2.161 0.370 64.72 2599 1.750 2.264 -0.329 4.058 0.993 1200T125-97 0.1017 1.472 5.02 23.980 3.900 4.037 0.102 0.264 23.968 3.979 0.786 78.62 7542 23.968 3.890 0.695 116.46 7542 5.073 3.137 -0.322 4.058 0.994 1200T200-33 0.0346 0.554 1.89 10.071 1.656 4.265 0.146 0.514 7.343 0.669 0.119 13.23 297 0.221 4.156 -0.737 4.359 0.971 Thickness Area 2 Wt/Ft Ix Sx 4 3 rx Iy 4 ry Ix Sx 4 3 A 2 12 Ma Va Ix Sx 4 3 7.729 1.105 A 2 0.247 Ma 33.08 Va 1691 Jx1000 4 Design Section Designation Thickness GROSS PROPERTIES Area 2 Wt/Ft Ix Sx 4 3 EFFECTIVE PROPERTIES 33ksi rx Iy 4 ry Ix Sx 4 3 A Ma 2 EFFECTIVE PROPERTIES 50ksi Va Ix Sx lbs 4 3 A 2 Ma TORSIONAL PROPERTIES Va Jx1000 4 Cw Xo Ro β in6 in in in in. in Lb/Ft in in in in in in in in k-in 1200T200-43 0.0451 0.721 2.46 13.131 2.156 4.267 0.189 0.512 11.942 1.103 0.195 21.80 658 1200T200-54 0.0566 0.905 3.08 16.484 2.701 4.268 0.236 0.510 15.302 1.718 0.297 33.96 1200T200-68 0.0713 1.140 3.88 20.773 3.395 4.270 0.294 0.508 19.649 2.780 0.456 1200T200-97 0.1017 1.624 5.53 29.652 4.823 4.273 0.410 0.502 29.413 4.503 0.868 1200T300-33 0.0346 0.623 2.12 12.616 2.075 4.501 0.460 0.859 7.932 0.680 0.120 13.44 297 0.249 12.447 -1.383 4.787 0.916 1200T300-43 0.0451 0.812 2.77 16.454 2.701 4.503 0.597 0.857 12.649 1.121 0.198 22.14 658 0.550 16.180 -1.379 4.787 0.917 1200T300-54 0.0566 1.018 3.47 20.662 3.385 4.505 0.745 0.855 17.519 1.737 0.303 34.33 1300 16.179 1.437 0.253 43.01 1300 1.087 20.246 -1.375 4.787 0.918 1200T300-68 0.0713 1.282 4.37 26.049 4.258 4.507 0.932 0.853 22.638 2.768 0.466 54.70 2599 22.167 2.246 0.391 67.25 2599 2.173 25.407 -1.369 4.787 0.918 1200T300-97 0.1017 1.828 6.23 37.215 6.053 4.513 1.311 0.847 34.171 4.920 0.900 97.22 7542 32.876 4.673 0.758 139.91 7542 6.301 35.953 -1.357 4.788 0.920 1400T125-33 0.0346 0.571 1.95 12.229 1.727 4.628 0.038 0.259 9.280 0.758 0.117 14.97 254 0.228 1.600 -0.304 4.646 0.996 1400T125-43 0.0451 0.744 2.54 15.938 2.247 4.629 0.049 0.258 14.779 1.239 0.191 24.48 563 0.504 2.065 -0.302 4.646 0.996 1400T125-54 0.0566 0.933 3.18 19.999 2.815 4.629 0.061 0.256 19.988 1.909 0.289 37.73 1113 18.908 1.586 0.244 47.49 1113 0.997 2.563 -0.299 4.646 0.996 1400T125-68 0.0713 1.175 4.01 25.187 3.538 4.629 0.076 0.254 25.174 3.040 0.438 60.08 2225 25.174 2.465 0.372 73.82 2225 1.991 3.182 -0.296 4.646 0.996 1400T125-97 0.1017 1.675 5.71 35.909 5.023 4.630 0.104 0.249 35.890 5.114 0.795 101.05 6457 35.890 5.011 0.701 150.03 6457 5.775 4.404 -0.289 4.646 0.996 1400T200-33 0.0346 0.623 2.12 14.819 2.093 4.878 0.150 0.491 10.136 0.781 0.119 15.44 254 0.249 5.896 -0.672 4.949 0.982 1400T200-43 0.0451 0.812 2.77 19.319 2.724 4.879 0.194 0.489 16.059 1.283 0.196 25.35 563 0.550 7.643 -0.669 4.949 0.982 1400T200-54 0.0566 1.018 3.47 24.248 3.414 4.880 0.242 0.487 22.819 1.982 0.299 39.16 1113 1.087 9.534 -0.665 4.949 0.982 1400T200-68 0.0713 1.282 4.37 30.552 4.292 4.881 0.301 0.485 29.282 3.147 0.459 62.19 2225 28.837 2.561 0.386 76.68 2225 2.173 11.917 -0.661 4.950 0.982 1400T200-97 0.1017 1.828 6.23 43.594 6.098 4.884 0.420 0.480 43.254 5.730 0.877 113.23 6457 42.263 5.331 0.743 159.62 6457 6.301 16.724 -0.652 4.951 0.983 1400T300-33 0.0346 0.692 2.36 18.272 2.580 5.139 0.475 0.829 10.947 0.795 0.120 15.72 254 0.276 17.743 -1.278 5.360 0.943 1400T300-43 0.0451 0.902 3.07 23.827 3.360 5.140 0.616 0.827 17.215 1.308 0.198 25.85 563 0.611 23.058 -1.275 5.360 0.943 1400T300-54 0.0566 1.131 3.86 29.915 4.211 5.142 0.769 0.825 25.893 2.018 0.304 39.88 1113 1.208 28.842 -1.270 5.360 0.944 1400T300-68 0.0713 1.425 4.86 37.705 5.297 5.144 0.963 0.822 33.414 3.182 0.469 62.88 2225 32.747 2.607 0.393 78.07 2225 2.414 36.179 -1.265 5.361 0.944 1400T300-97 0.1017 2.031 6.92 53.841 7.532 5.149 1.354 0.816 49.698 6.229 0.909 123.09 6457 48.463 5.333 0.764 159.67 6457 7.002 51.152 -1.254 5.362 0.945 Design Gross Properties Section Designation Thickness Area Wt/Ft Ix Sx Ma Ix Sx Ma Ix Sx Ma in. in2 Lb/Ft in4 in3 lb-ft in4 in3 lb-ft in4 in3 lb-ft Effective Properties Tension at bottom effective in in in k-in lbs in 0.489 5.389 -0.733 4.359 0.972 1300 15.033 1.414 0.250 42.34 1300 0.966 6.725 -0.730 4.360 0.972 54.93 2599 19.346 2.224 0.383 66.57 2599 1.931 8.410 -0.725 4.360 0.972 88.99 7542 28.608 4.314 0.737 129.17 7542 5.599 11.814 -0.715 4.361 0.973 Tension at top effective PHYSICAL AND STRUCTURAL PROPERTIES FOR (HAT) FURRING (F) CHANNELS 087F137-18 0.0188 0.081 0.27 0.008 0.017 28.4 0.010 0.021 35.32 0.008 0.017 28.38 087F137-27 0.0283 0.121 0.41 0.012 0.027 44.1 0.014 0.031 51.83 0.012 0.027 44.09 087F137-30 0.0312 0.133 0.45 0.013 0.029 48.0 0.015 0.034 56.69 0.013 0.029 47.98 087F137-33 0.0346 0.147 0.50 0.014 0.032 52.4 0.017 0.038 62.29 0.014 0.032 52.39 150F137-18 0.0188 0.104 0.35 0.032 0.040 65.7 0.034 0.045 73.81 0.032 0.040 65.68 150F137-27 0.0283 0.156 0.53 0.048 0.064 104.9 0.051 0.066 109.46 0.048 0.064 104.90 150F137-30 0.0312 0.172 0.59 0.052 0.070 114.9 0.056 0.073 120.12 0.052 0.070 114.88 150F137-33 0.0346 0.191 0.65 0.058 0.077 126.4 0.062 0.080 132.49 0.058 0.077 126.40 150F137-43 0.0451 0.247 0.84 0.073 0.098 160.8 0.079 0.103 169.83 0.073 0.098 160.77 notes: 1. Effective properties are given as the minimum value for either positive of negative bending 2. Fy = 33 ksi Design Section Designation Gross Properties Effective Properties Tension at bottom effective Tension at top effective Thickness Area Wt/Ft Ix Sx Ma Ix Sx Ma Ix Sx Ma in. in2 Lb/Ft in4 in3 lb-ft in4 in3 lb-ft in4 in3 lb-ft PHYSICAL AND STRUCTURAL PROPERTIES FOR RC1 & RC2 FURRING CHANNELS RC1 0.0188 0.049 0.17 RC2 0.0188 0.064 0.22 0.002 0.006 9.9 0.002 0.010 0.19 0.002 0.006 0.12 0.002 0.010 0.19 0.002 0.006 0.12 notes: 1. Effective properties are given as the minimum value for either positive of negative bending 2. Fy = 33 ksi GROSS PROPERTIES Design Section Designation EFFECTIVE Thickness Area Wt/Ft Ix Sx rx Iy ry Ix Sx Ma in. in2 Lb/Ft in4 in3 in in4 in in4 in3 k-in PHYSICAL AND STRUCTURAL PROPERTIES FOR U-Channel (U) Sections 075U50-54 0.0566 0.087 0.30 0.007 0.019 0.288 0.002 0.156 0.007 0.019 0.38 150U50-54 0.0566 0.129 0.44 0.039 0.052 0.548 0.003 0.145 0.039 0.052 1.03 notes: 1. Effective properties based on 33 ksi 13 20.523 21.968 1.644 1.676 0.251 0.254 49.22 50.19 1113 1113 Notes: 14