candela 6300 - KLA

advertisement

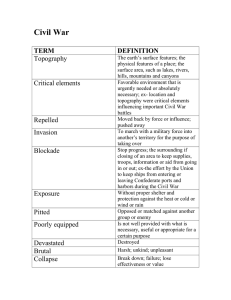

CANDELA 6300 SERIES Optical Surface Analyzer A new level of topography measurement and defect inspection capability METROLOGY & INSPECTION The Candela 6300 Series Offers As a leading provider of process control and yield management solutions for the data storage industry, KLA-Tencor offers a portfolio of products to help customers rapidly understand and resolve complex manufacturing problems, resulting in faster time to market and increased product yields. Growth in data storage is being driven by a wave of innovative consumer electronics with small form factors and immense storage capacities, such as MP3 players or video-capable cell phones. To make these devices possible, data storage manufacturers are currently embracing ultra-smooth glass media and perpendicular recording technologies. These technologies enable the creation of extremely small data bits in the magnetic media, and reduce the head-disk interface (HDI) for the flying of recording disk heads closer to the disk surface. KLA-Tencor’s Candela Series of Optical Surface Analyzers set the industry standard for magnetic disk media inspection. These highly versatile systems inspect metal or glass substrates, as well as finished disks — offering numerous metrology and defect inspection applications. • Industry’s widest spatial bandwidth and lowest noise floor • Circumferential, radial roughness and waviness metrology • Repeatable metrology which correlates to AFM measurements on metal and glass media • Fast and full-surface coverage on all disk form factors • High sensitivity for faint scratches, stains and particle inspection • Innovative Optical Surface Analysis (OSA) technology METROLOGY & INSPECTION Candela 6300 Series A New Approach The 6300 series harnesses patented multi-channel optics, combined with unique laser stability management technology, to deliver powerful measurement capabilities for edge roll-off and texture/polish uniformity, as well as scratch and particle inspection. The system’s leading-edge optical scanning technology enables full surface disk topography metrology in both radial and circumferential directions, and allows manufacturers to use a single tool to measure the entire spatial spectrum. Increased laser power, a lower noise floor and new optics design eliminate the need for sputtering glass substrates in order to detect defects and also allows for identification of roughness variations of less than 0.1 Angstroms. Ionic or Organic Contamination Carbon Overcoat (3 to 5nm) Ai rF Magnetic Head Slider Dust l ow Flying Height (10nm) Lubricant (1nm) Recording Layer Carbon Overcoat (3 to 5nm) Smaller form factors, glass substrates, higher areal densities and improved reliability are driving the needs for better control of the Head-Disk Interface (HDI). KLA-Tencor’s Candela™ 6300-series optical surface analyzer system addresses emerging requirements by delivering best-in-class metrology and inspection capabilities for data storage substrates and finished media. As data storage manufacturers strive to enhance device storage capacities by reducing head fly-heights even further, controlling disk surface roughness is becoming increasingly important. The 6300 series leverages the industry’s widest spatial bandwidth coverage (from 0.22 microns to 2,000 microns) and a noise floor below 0.5 Angstroms to satisfy requirements for comprehensive roughness and micro-waviness measurements. Compared with other systems such as scatterometers or laser Doppler vibrometry systems, the 6300 series is the best solution to provide radial and circumferential data, and fast, full-surface topography information on ultra-smooth substrate and media. The 6300 series provides full-disk, non-contact coverage at a much lower cost of measurement than stylus profilers or atomic force microscopy (AFM) technologies. Furthermore, the 6300 series offers excellent correlation to AFM — simultaneously reducing AFM dependence and making it a more efficient reference source at a lower cost of measurement. The Candela 6300 Series is the ideal solution for next-generation process control of disk topography on conventional metal or glass substrates and finished media. Radial Optical Path Two 50mW 405nm violet lasers Circumferential Optical Path Comparison of Spatial Wavelength Bandwidths Roughness AFM Waviness 0.10 Scatterometer 0.70 Stylus Profiler 8.2 1000 LDV 5.0 0.22 -1 10 1.8 0 10 Scatter Detector for Nano-Roughness New 0.50 Candela Technique Circumferential Detector for Radial Micro-Roughness and Waviness 100 2000 4.3 Radial Detector for Circumferential Micro-Roughness and Waviness 2000 1 10 2 10 3 10 Spatial Wavelength (µm) The 6300 system has the widest spatial bandwidth from 0.22 microns to 2,000 microns. The Candela Optical Surface Analyzer (OSA ) topography system. HDI Characterization The system enables characterization of head dynamics with true three dimensional disk topography and an understanding of the impact of radial topography to HDI issues. These graphs illustrate the importance of disk topography for flying-height. The graphs show good correlation between the 6300 series topography data and modeled flying-height for three different media suppliers. The disk with the least topography and flying-height variation would be the optimal choice.* Site A (RMS 2.55 Å) Site C (RMS 2.88 Å) Site B (RMS 2.84 Å) Site D (RMS 3.12 Å) The 6300 Series offers identification of both radial and circumferential direction roughness variations of less than 0.1 Angstroms. 6300 Series Radial Topography Data for three different media suppliers. Modeled flying-height for three different media suppliers. * “Effect of radial and circumferential disk features on slider dynamics”, Rohit Ambekar–UC Berkeley, Lanshi Zheng–WD , et. al. Surface topography with the 6300 series can be measured in either the circumferential or radial direction. Optical Surface Analyzer Full Surface, 2D Data Excellent correlation to AFM on bare glass and metal substrates – thus minimizing testing time and costs. The radial channel (4.3 to 500 microns) is used to detect topography along the circumferential direction while the circumferential channel (4.3 to 2000 microns) is used to detect topography along the radial direction. Nano-roughness correlation to AFM on metal substrate. Micro-roughness correlation to AFM on glass substrate. Intra- and inter-disk topography variation. METROLOGY & INSPECTION Candela 6300 Series Glass Substrate Candela 6320 Candela 6300 A fully automated cassette-to-cassette system, KLA-Tencor’s Candela 6320 offers a completely automated operation, making it ideal for routine production monitoring applications. The system design minimizes operator interaction with the disk and system – as well as the potential for human error. A ULPA filtration system maintains a Class 10 environment in the scan area. The Candela 6300 is a manual system well suited for both laboratory and low volume production applications. Highly versatile and easy to use, the 6300 inspects both metal or glass substrates and finished media. Mechanical Polish Wash Texture Final Wash Laser Texture Sputter 6100 series Aluminum Substrate Final Tape Glide and Certify Test Burnish Lube Media Finished 6100 series Carbon uniformity analysis Scratch inspection Carbon void inspection Particle inspection Soft under layer uniformity analysis Scratch and ridge inspection Roughness and waviness analysis Defect inspection Texture uniformity analysis Lube uniformity analysis Defect Inspection Roughness and waviness analysis Particle and stain inspection As a leading provider of process control and yield management solutions for the data storage industry, KLA-Tencor offers a portfolio of products to help customers rapidly understand and resolve complex manufacturing problems — resulting in faster time to market and increased product yields. In the front-end of thin film head wafer manufacturing, KLA-Tencor is the leading provider of the same process control equipment with which we serve the semiconductor industry, with particular strength in photo-lithography and magnetics control. In the back-end of head manufacturing, we provide a range of test equipment, including fly-height and head resonance testers and surface profilers. In substrate and media manufacturing, we offer metrology and defect inspection solutions with our Candela™ optical surface analyzers and ADE magnetic and optical mappers. Leveraging our experience in magnetics, we also meet our customers’ challenges in the emerging MRAM (magnetic random access memory) market. KLA-TENCOR SERVICE/SUPPORT Customer service and support are an integral part of KLA-Tencor’s yield optimization solution. Our vast customer support organization services our worldwide installed base and is responsible for customer support following shipment of equipment and software. Services include system installation, secure online monitoring, on-site repair, telephone support, relocation services, and selected post-sales applications. © 2007 KLA-Tencor Corporation. All brands or product names may be trademarks of their respective companies. KLA-Tencor reserves the right to change the hardware and/or software specifications without notice. Printed in the USA PB-CAN6300-02/07 KLA-Tencor Corporation 160 Rio Robles San Jose, CA 95134 phone 408.875.3000 fax 408.875.4144 www.kla-tencor.com