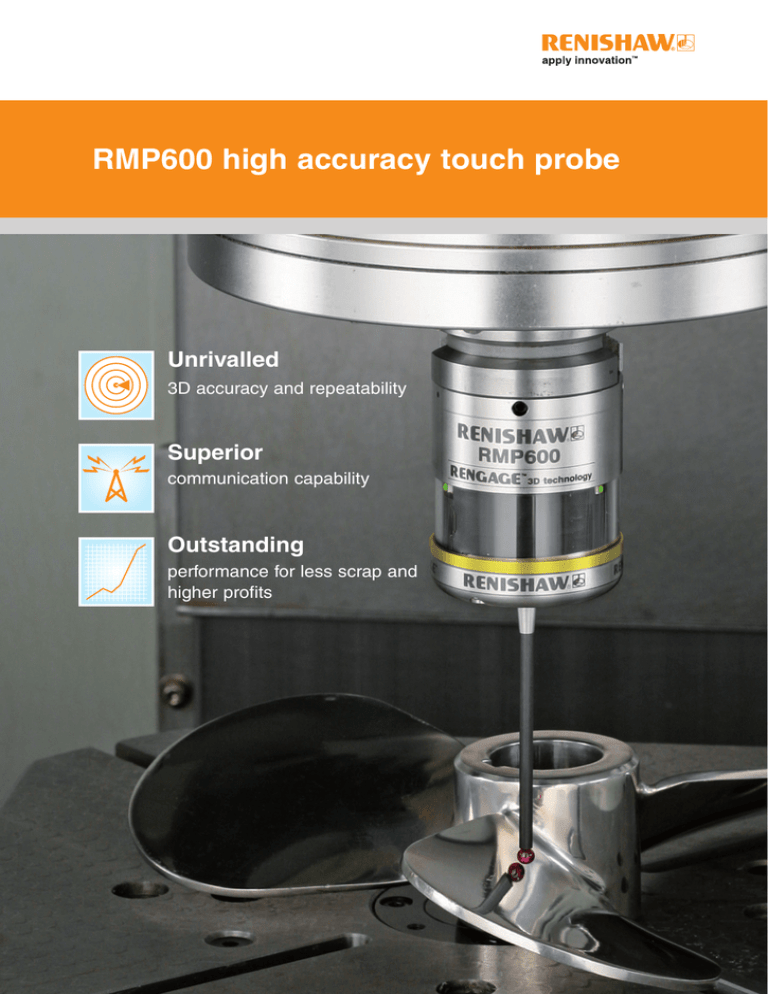

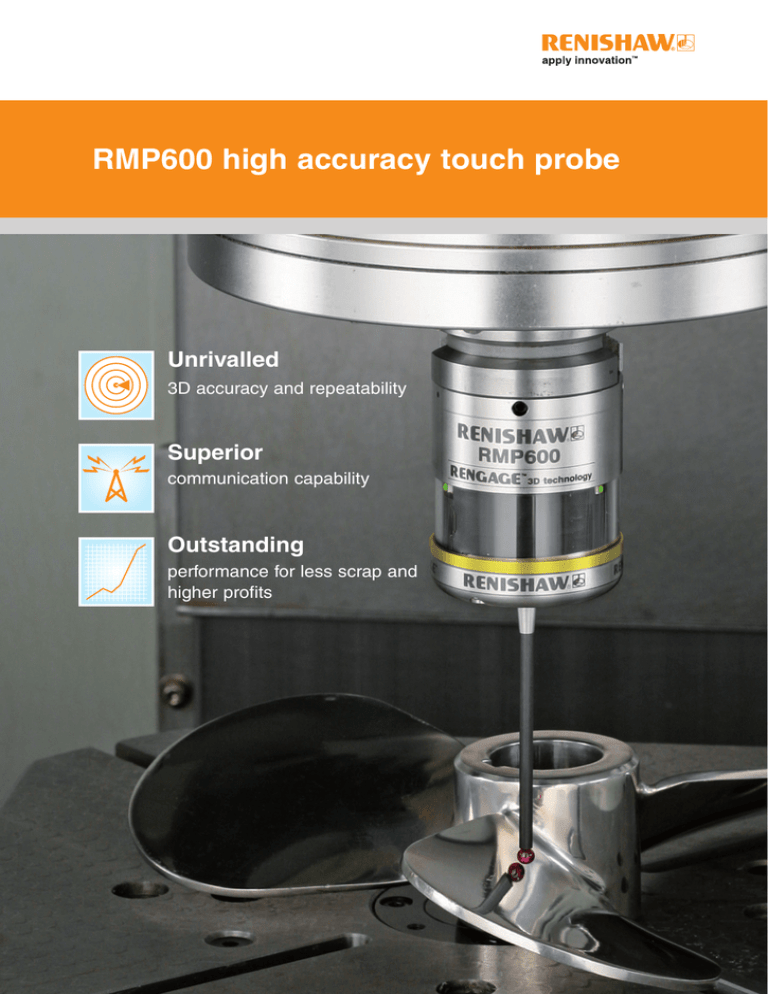

RMP600 high accuracy touch probe

Unrivalled

3D accuracy and repeatability

Superior

communication capability

Outstanding

performance for less scrap and

higher profits

RMP600 – innovative process control

Tackle process variation at source, and reap the rewards

The higher the degree of human involvement in the manufacturing process, the higher the

risk for error. Automated in-process measurement using Renishaw probes can help eliminate

the risk. The Renishaw RMP600 radio probe system can facilitate the following measures for

enhanced management of your production leading to an increase in your profits.

Postprocess

monitoring

In-process control

Process setting

Process foundation

Process foundation

Optimisation and monitoring of machine tool performance.

RMP600 used in conjunction with Renishaw’s machine specific software,

AxiSet™ Check-Up, provides fast, accurate and reliable performance data

with powerful yet simple reporting.

• Eliminate machine errors

• Reduce unplanned stoppages

• Produce consistently good parts

Process setting

Automated on-machine measurement of component position and alignment.

Y

RMP600 is the most flexible, high precision machine tool radio probe in the world.

Unlike conventional probes from other brands, increased stylus lengths can be

supported with no significant decrease in probe performance, which means

previously difficult job set-ups are more easily accommodated.

• Eliminate costly fixtures and manual setting errors

• Introduce new processes quickly and respond to new customer needs

• Set up faster, improve quality and reduce scrap

In-process control

Automated measurement of roughed and finished multi-axis features.

RMP600 submicron 3D performance enables probing of complex geometry not

possible with conventional probes from other brands. Adaptive machining can be

seamlessly integrated when used in conjunction with Renishaw’s Productivity+™.

• Improve process capability and traceability

• Compensate for environmental and machine conditions

• Reduce non-productive time and scrap, increase productivity and profits

Post-process monitoring

Verification of component conformance prior to removal from machine.

RMP600 used in conjunction with Renishaw’s on machine verification software,

OMV, enables reliable verification against a CAD model, which means less

inspection off-machine and therefore less set-up and rework.

• Reduce off-machine inspection time and costs

• Rapid, traceable reporting of part conformance to specification

• Increase confidence in manufacturing process

X

Probing pays...

Machine tools that are optimised to cut more metal,

more reliably and more accurately will quickly maximise

productivity, profits and your competitive edge.

... the Renishaw way

Renishaw, an established world leader in metrology solutions

invented the touch-trigger probe in the 1970s.

Decades of customer focus and investment in development,

coupled with our own manufacturing experience enables us

to provide innovative and exceptional products that are

unmatched for technical excellence and performance.

Automated part setting with the Renishaw RMP600 probe is

up to 10 times faster than manual methods, which means

immediate and significant cost savings.

Part set-up

Manual

st

Co

Automated

Time

Scrap and rework reduce productivity and profits.

The Renishaw RMP600 probe helps guarantee

“right first time” parts which means reduced waste

and increased profits.

RMP600 key features

Customer comment

• Compact design with radio transmission for medium to

large machining centres and mill-turn centres

“There’s hardly a part or a die in our shop without a

parabolic, compound curved or cone shape.

Rapid, precise measurement of machining work on these

parts, whilst fixtured on the machine tool is essential to

our lean manufacturing. The RMP600 probe provides the

“in-process” performance needed for consistent,

high-accuracy measurement of small hole diameters,

contours and geometric tolerances”.

• RENGAGE™ technology — proven and patented

• Trigger Logic™ for quick and easy set-up

• Delivers interference free transmission through the use of

frequency hopping spread spectrum (FHSS)

• Globally recognised 2.4 GHz waveband — compliant with

radio regulations in all major markets

Gary Medlock, Triumph Fabrications

RMP600 – an unrivalled combination of

flexibility and accuracy

RENGAGE™ superior 3D performance

RENGAGE™ technology

Lobing, a characteristic of all probes, is caused by bending

of the stylus and movement of the probe mechanism before

the probe registers contact with a surface. It is therefore

dependent upon:

Rengage combines proven silicon strain gauge technology

and ultra compact electronics to achieve unparalleled

performance and capabilities. Suitable for a wide range

of machine tool applications and able to address the 3D

performance limitations of many alternative probe designs,

only Renishaw’s MP250, OMP400 and RMP600 probes

feature this technology.

• Length and stiffness of the stylus

• Force required to trigger the probe

• Direction of contact with the surface

• Design of the probe mechanism

Rengage technology as featured in RMP600 was tested for

3D accuracy against products from other brands. The results

as illustrated in the error plots below are compelling.

Pole

Test method

25 mm calibration sphere

probed at 5º increments

around X Y planes at

four different latitudes.

Mechanism

Strain gauge

independent of

mechanism

Close-up of

strain gauge

67.5°

45°

22.5°

0° equator

Structure

A typical other brand

Scale in µm

m&h

60

50

40

Sensing is independent of the probe mechanism which

means that probes with Rengage technology provide

capabilities not associated with conventional design.

30

20

10

0

-10

-20

-30

67.5°

45.0°

Advantages

22.5°

0° Equator

• Unbeatable 3D accuracy and repeatability enables reliable on-machine gauging/measurement

• Improved accuracy with long styli means dificult parts can be probed more easily

Rengage probe

Scale in µm

• Unmatched low trigger force for delicate work helps eliminate surface and form damage

OMP400

60

• Compact design enables better access in restricted spaces and small machines

50

40

30

• Robust, even in the harshest environment, means reliable measurement and long service life

20

10

0

-10

-20

-30

Key benefits

67.5°

45.0°

22.5°

0° Equator

• Reduced set-up and calibration time

• Improved control processes and quality set-up

• Reduced costs

For further details regarding lobing and superior

3D performance please refer to:

www.renishaw.com/rengage

RMP600 and radio machine interface (RMI or

RMI-Q) optimised for reliable and safe operation

The benefits of FHSS

In addition to its high performance optical systems

Renishaw offers a reliable radio solution for larger

machines and/or installations where line-of-sight

applications are not possible.

Frequency hopping spread spectrum (FHSS) is a robust

and proven technology, that enables devices to jump from

channel to channel.

Unlike other protocols which may require manual

intervention, Renishaw’s products will continue to work as

other devices such as Wi-Fi, Bluetooth and microwave enter

the same environment.

Operating within the recognised 2.4 GHz frequency band,

RMI-Q is compliant with radio regulations in all major

markets. It is the preferred choice of many leading machine

builders and experienced users.

Ease of use and reliability

Engineered for superior performance

Unique to Renishaw, Trigger Logic™ is a simple method

enabling the user to quickly adjust probe mode settings for

specific applications.

Through the optimisation of transmission and power,

RMI-Q partnered with Renishaw’s radio transmission

probes provides high operational integrity, long battery

life and the superior capabilities required in demanding

machine shop environments.

Constructed from the highest grade materials, Renishaw

probes are robust and reliable in the harshest environments

including shock, vibration, temperature extremes and even

continual liquid immersion.

• Multiple Renishaw radio probes will reliably co-exist in

machine shops of any size

• Combine up to four second generation* probes and/or

tool setters with a single RMI-Q

• Negligible interference from other radio sources ensures

consistent and reliable performance

• Does not require a carefully managed radio/wireless

environment

• Renishaw probes work with widely available

“off-the-shelf” batteries

* Second generation radio probes are easily identified by a ‘Q’ symbol.

For further details, please refer to the

RMP600 data sheet H-5312-8200.

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire GL12 8JR

United Kingdom

T +44 (0) 1453 524524

F +44 (0) 1453 524901

Euk@renishaw.com

www.renishaw.com

About Renishaw

Renishaw is an established world leader in engineering technologies, with a strong history of innovation in product development

and manufacturing. Since its formation in 1973, the company has supplied leading-edge products that increase process

productivity, improve product quality and deliver cost-effective automation solutions.

A worldwide network of subsidiary companies and distributors provides exceptional service and support for its customers.

Products include:

•

Additive manufacturing, vacuum casting, and injection moulding technologies for design, prototyping, and production applications

•

Advanced material technologies with a variety of applications in multiple fields

•

Dental CAD/CAM scanning and milling systems and supply of dental structures

•

Encoder systems for high accuracy linear, angle and rotary position feedback

•

Fixturing for CMMs (co-ordinate measuring machines) and gauging systems

•

Gauging systems for comparative measurement of machined parts

•

High speed laser measurement and surveying systems for use in extreme environments

•

Laser and ballbar systems for performance measurement and calibration of machines

•

Medical devices for neurosurgical applications

•

Probe systems and software for job set-up, tool setting and inspection on CNC machine tools

•

Raman spectroscopy systems for non-destructive material analysis

•

Sensor systems and software for measurement on CMMs

•

Styli for CMM and machine tool probe applications

For worldwide contact details, please visit our main website at www.renishaw.com/contact

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY,

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

© 2014 Renishaw plc. All rights reserved.

Renishaw reserves the right to change specifications without notice

RENISHAW and the probe symbol used in the RENISHAW logo are registered trade marks of Renishaw plc in the United Kingdom and other countries.

apply innovation and names and designations of other Renishaw products and technologies are trade marks of Renishaw plc or its subsidiaries.

All other brand names and product names used in this document are trade names, trade marks or registered trade marks of their respective owners.

*H-2000-3246-06-A*

Issued: 0912 Part no. H-2000-3246-06-A