BalTec Maschinenbau AG

Obermattstrasse 65

CH - 8330 Pfäffikon ZH

Phone: +41 (0)44 953 13 33

Fax:

+41 (0)44 953 13 44

baltec@baltec.ch

http:\\www.baltec.com

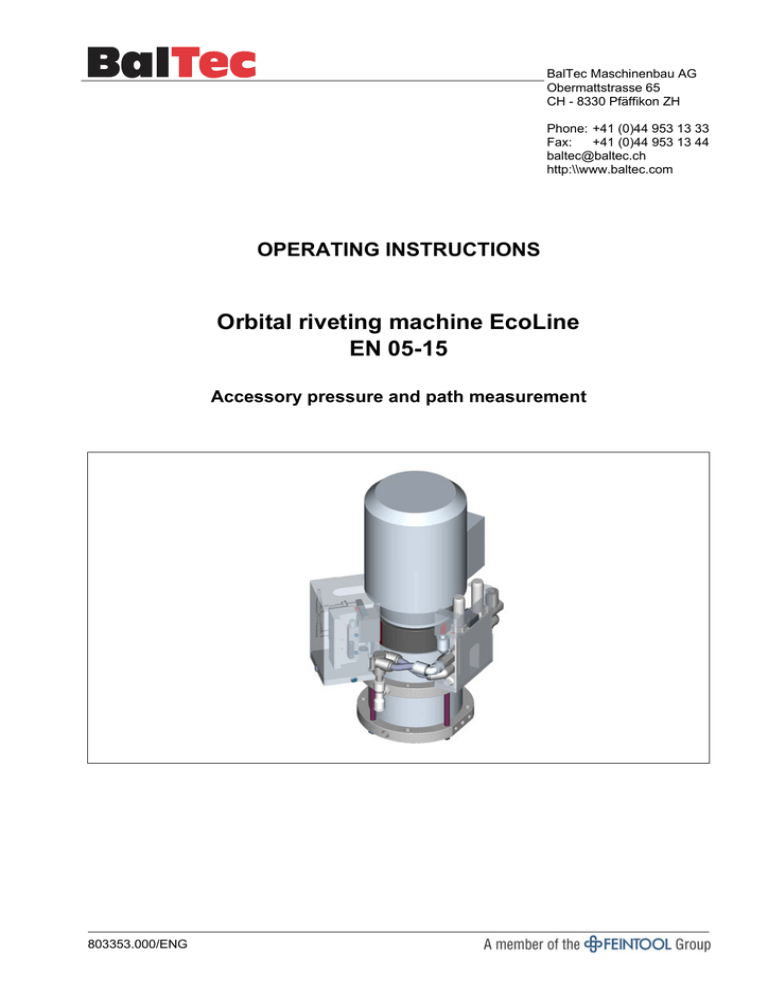

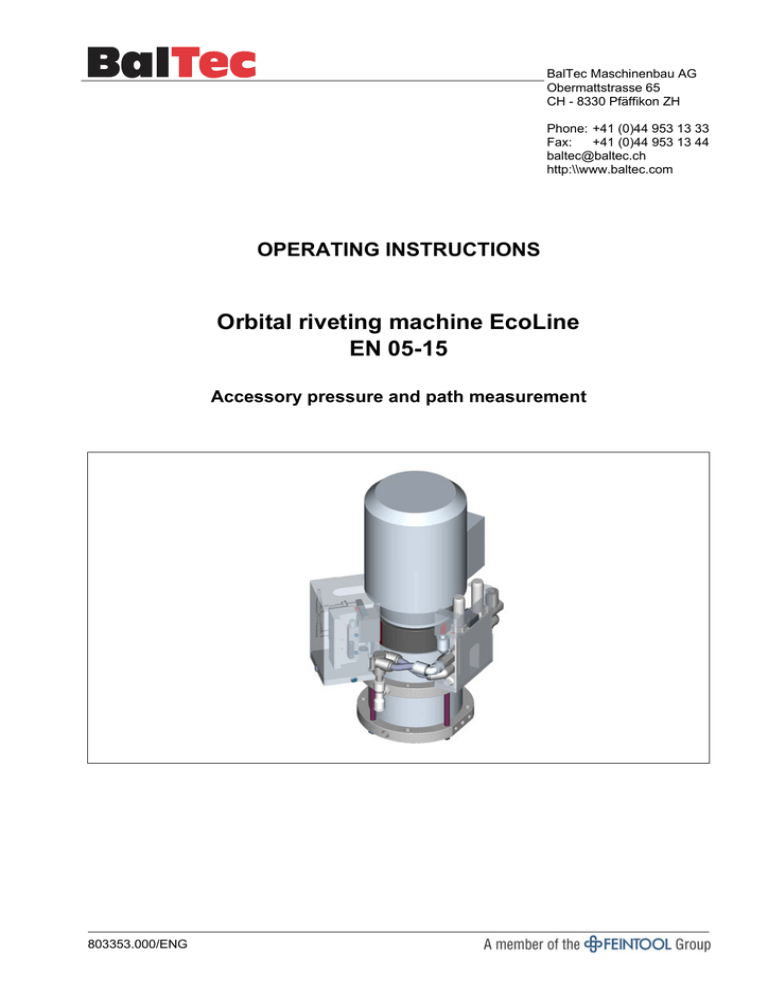

OPERATING INSTRUCTIONS

Orbital riveting machine EcoLine

EN 05-15

Accessory pressure and path measurement

803353.000/ENG

803353.000/ENG

Introduction

2

Orbital riveting machine EcoLine EN 05-15

803353.000/ENG

Orbital riveting machine EcoLine EN 05-15

Introduction

Contents

1

Introduction ............................................................................................................... 4

2

Product description .................................................................................................. 5

2.1

2.2

3

3.1

3.1

3.1.1

3.2

4

4.1

5

5.1

5.1.1

5.2

5.2.1

5.2.2

5.2.3

5.2.4

6

Details sensors EN..............................................................................................................................5

Technical specifications pressure and path measuring sensors EN ..................................................6

Commissioning ......................................................................................................... 7

Sensors mount on an existent riveting machine .................................................................................7

Pressure measurement.......................................................................................................................9

Conversion piston area – riveting force .........................................................................................9

Path measurement............................................................................................................................10

Operation ................................................................................................................. 11

Adjustment initiator lower end position .............................................................................................11

Appendix.................................................................................................................. 12

Schemata ..........................................................................................................................................12

Connections sensors EN .............................................................................................................12

Spare parts lists ................................................................................................................................13

Path and pressure sensors EN 896508-a....................................................................................13

Pressure sensors EN 896060-a...................................................................................................15

Path measuring sensor EN 896070-a..........................................................................................17

Gauge block EN sensors 896071 ................................................................................................18

Index ........................................................................................................................ 20

803353.000/ENG

3

Introduction

1

Orbital riveting machine EcoLine EN 05-15

Introduction

We are certain that you have made the right choice with our product and thank you

for your trust.

For your personal safety

Before carrying out any activities on or with the riveting machine, please carefully

read these operating instructions first, in particular the chapter on "Safety

regulations".

Application area of these operating instructions

These operating instructions describe the mount and the operation of the auxiliary

sensors for pressure and path measuring on the riveting machine EN.

For information concerning the riveting machine, please consult the operating

instructions of the riveting machine or riveting unit EN.

For more information concerning path measuring sensor please consult the

operating instructions of the company “Balluff”.

Questions or unclear points

Please contact your supplier immediately if you have any questions or unclear

points. Please provide them with the document and page numbers located in the

footer and the machine number listed on the title page.

Property rights (Copyright)

Reproduction of these operating instructions - including excerpts - is prohibited.

Without the express written authorization from the manufacturer, nothing may be

reproduced in any form or edited, copied, distributed or translated using any form

of electronic media, in particular photocopiers, photographic, magnetic or other

recording methods.

All rights reserved, in particular the right to reproduction, distribution, translation

and patent or registration rights.

4

803353.000/ENG

Orbital riveting machine EcoLine EN 05-15

2

Product description

Product description

2.1

Details sensors EN

2

8

9

6

3

8

4

7

5

1

10

Pos.

Part name

Pos.

Part name

1

Path measuring sensor

6

Initiator upper end position

2

Pressure sensor

7

Initiator lower end position

3

Motor flange

8

Gauging block

4

Protection tube

9

Stop damping piece

5

Screw machine body (M8x110)

10

Upper flange machine body

With the mount of these sensors it is possible to evaluate the riveting force and the

riveting path.

Additionally it is possible to use these values to control the riveting machine.

Example: Reversion of riveting spindle when a defined riveting force or riveting

stroke is reached,

BalTec only provides the signals of the pressure and path measuring. An evalution

or control with this signals has to be realised by the customer.

803353.000/ENG

5

Product description

2.2

Orbital riveting machine EcoLine EN 05-15

Technical specifications pressure and path measuring sensors EN

Pressure sensors

Measuring range

bar

0-10

Signal

VDC

0-10

Supply

VDC

13…30

mm

40

Path measuring sensor

Measuring range

Output

RS422

A-Signal

Output signal

B-Signal

Supply

VDC

5 ± 5%

Pol width

mm

1

max. traverse speed

m/s

1

Resolution (edge distance A/B)

mm

0,005

mm

1

Magnetic tape path measurement

Pol width

6

803353.000/ENG

Orbital riveting machine EcoLine EN 05-15

3

Commissioning

Commissioning

3.1

Sensors mount on an existent riveting machine

2

8

9

6

3

8

4

7

5

1

10

To mount sensors on an existent riveting machine procede as follows:

1.

The riveting machine has to be located on the upper position, disconnect the

riveting machine electrical and pneumatic from the mains

2.

Disconnect and lift the protection tube (Pos. 4)

3.

Disconnect and dissasemble the motor from the motor flange (pos. 3)

4.

Remove the protection tube (Pos. 4) (replaced by a new protection tube)

5.

Dismount and remove the motor flange (Pos. 3) from the spindle (replaced

by a new motor flange)

6.

Dismount upper flange of machine body and remove damping ring on the

underpart

Reason: By application of path measurement it have to be ensured, that the

riveting spindle pull out of the upper stop. Shock absorbing action is

executed in the assembly pressure sensors

7.

Install new protection tube

8.

Assemble the new motor flange, with mounted gauging block and stop

damping piece, on the spindle

9.

Mount again the motor flange on the motor

10.

Lock again the protection tube (Pos. 4) with the screw

803353.000/ENG

7

Commissioning

Orbital riveting machine EcoLine EN 05-15

11.

Mount assembly pressure sensors (assembly with Pos. 2) on the upper

flange of the machine body (Pos. 10). Therefore a screw has to be loosed

first from the riveting unit. These screw will be used subsequently again to fix

the base plate of the pressure sensors. By attaching the assembly pay

attention, that the damping piston is located on the stop damping piece (Pos.

9).

12.

According to drawing connect the pneumatic tubes on the assembly

pressure sensors

13.

Mount the assembly path measuring sensors (assembly with Pos. 1) on the

upper flange of the riveting machine. As the mounting of the pressure

sensors, a screw of the riveting unit (Pos. 5) has to be loosed here too first

Note

By mounting the assembly path measuring sensors, pay

attention, that the path measuring sensor is adjusted in a

distance of 0.01-0.35mm and laterally max. 1mm from the

magnetic tape (see notes on the following drawing).

8

803353.000/ENG

Orbital riveting machine EcoLine EN 05-15

3.1

Commissioning

Pressure measurement

By pressure difference measurement of the upper and lower pressure chamber

due to piston area the riveting force could be calculated.

3.1.1

Conversion piston area – riveting force

At riveting machine EN the upper and lower piston area is respectively identical:

Machine type

Active piston area

Theoretic resulting riveting

force with 6bar

EN 05

84,8 cm2

5088 N

EN 10

EN 15

2

10176 N

2

15270 N

169,6 cm

254,5 cm

The effective riveting force is calculated by the difference pressure of the upper

and lower pressure chamber and as a result of frictional loss could result a little

lower than the theoretic riveting force.

With a calibrated load cell a correction factor could be calculated, that has to be

considered with in the control unit.

803353.000/ENG

9

Commissioning

3.2

Orbital riveting machine EcoLine EN 05-15

Path measurement

Magnetic tape

Path measuring sensor

The installed path measuring sensor is based upon the principle of magnetic field

measurement.

The singular present magnetic fields on the magnetic tape are thereby analysed

from the sensor.

The signal of the path measurement sensor has to be analysed by an external

control unit.

Concerning connection and evaluation of signal see operating instructions of

company Balluff.

10

803353.000/ENG

Orbital riveting machine EcoLine EN 05-15

4

4.1

Operation

Operation

Adjustment initiator lower end position

If the riveting stroke is changing the cam lower end position has to be also

readjusted.

Initiator upper end position

Cam lower end position

Clamping screw

Initiator lower end position

Adjustment cam lower end position:

1.

Move the riveting machine in lower end position (example: with actuating

valve manually)

2.

Adjust the cam so that the initiator lower end position is switched

3.

Assure the cam with the clamping screw

Addicted of the used control unit it could be, that the initiator lower end position in

case of new start may not be active.

803353.000/ENG

11

Appendix

5

Orbital riveting machine EcoLine EN 05-15

Appendix

5.1

5.1.1

Schemata

Connections sensors EN

Pressure sensor 540342

Connector: Hirschmann, MAS 3100

Pin

Cable

Signal

1

BN brown

+ V (24VDC)

2

WH white

Signal

3

GN green

0 V (GND)

Magnetic field sensor 540402

Type: BML-S1A1-Q61F-M300-10-S184

With connector BKS-S184-PU-05

Pin

Cable

Signal

1

WH white

A

2

BN brown

/A

3

GN green

B

4

YE yellow

/B

5

GY grey

Z (not used)

6

PK pink

/Z (not used)

7

BU blue

GND

8

RD red

+5 V

For further information see operating instructions Balluff

Initiators upper / lower end position

connector 522532

12

803353.000/ENG

Orbital riveting machine EcoLine EN 05-15

5.2

5.2.1

Appendix

Spare parts lists

Path and pressure sensors EN 896508-a

803353.000/ENG

13

Appendix

Orbital riveting machine EcoLine EN 05-15

Pos.

No.

Part Name

Part No.

1

1

Assembly path measuring sensor

896070

2

1

Assembly pressure sensors

896060

3

1

Assembly gauge block

896071

4

1

Stop damping piece

896058

5

1

Plug connection

367766

6

1

Coupling piece

367767

7

1

Protection tube

896069

8

1

Motor flange

896059

9

2

Screw

341031

In-6kt M8x20

10

2

Screw

341119

In-6kt M4x30

11

2

Screw

341018

In-6kt M5x16

14

803353.000/ENG

Remarks

d10

Orbital riveting machine EcoLine EN 05-15

5.2.2

Appendix

Pressure sensors EN 896060-a

803353.000/ENG

15

Appendix

Orbital riveting machine EcoLine EN 05-15

Pos.

No.

Part name

Part no.

1

1

Support pressure sensor

896056

2

1

Cap damping

896056

3

1

Base plate pressure sensors

896057

4

1

Damping bushing

896054

5

1

Damping piston

896055

6

1

Cover pressure sensors

896061

7

1

One-way restrictor

368618

8

2

Pressure transmitter

540324

9

2

Elbow connection

367764

10

1

Non-return valve

367765

11

2

Elbow connection

367762

90°

13

2

Screw

341018

In-6kt M5x16

14

2

Countersunk screw

342810

In-6kt M5x10

15

2

Washer

348923

90° M5

16

1

O-Ring

362021

11-2

17

1

O-Ring

362215

11-1,5

18

1

O-Ring

362009

5-1,5

19

1

Pressure spring

316081

0,8/6,6/9,6 L0=68mm

16

803353.000/ENG

Remarks

45°

Orbital riveting machine EcoLine EN 05-15

Appendix

5.2.3

Path measuring sensor EN 896070-a

Pos.

No.

Part name

Part no.

1

1

Base plate

896062

2

1

Support

896063

3

1

Mounting angle initiators

896064

4

1

Cover

896065

5

2

Initiator

896065

6

2

Connector initiator

522532

7

1

Magnetic field sensor

540402

8

4

Screw nut

522519_2

9

4

Locking washer

522519_3

10

3

Countersunk screw

342802

In-6kt M3x8

11

3

Washer

348921

90° M3

12

2

Screw

341023

In-6kt M6x12

13

2

Screw

341015

In-6kt M5x8

14

2

Screw

341069

In-6kt M3x16

15

1

Cable with plug

540403

M9 BKS-S184-PU-05

803353.000/ENG

Remarks

M8

BML-S1A1-Q61F-M300-10-S184

17

Appendix

Orbital riveting machine EcoLine EN 05-15

5.2.4

Gauge block EN sensors 896071

Pos.

No.

Part Name

Part No.

1

1

Gauge block

896066

2

1

Cam

896067

3

1

Cam switch above

896068

4

1

Clamping screw

896048

5

2

Screw

341005

6

1

Magnetic tape

540404

18

803353.000/ENG

Remarks

In-6kt M3x10

BML-M01-I34-A0-M0031-R0000

L= 42mm

Orbital riveting machine EcoLine EN 05-15

803353.000/ENG

Appendix

19

Index

6

Orbital riveting machine EcoLine EN 05-15

Index

A

Q

Adjustment initiator lower end position .......................11

Questions or unclear points ..........................................4

C

S

Connections sensors EN ............................................12

Conversion piston area – riveting force ........................9

Schemata....................................................................12

Sensors mount on an existent riveting machine............7

Spare parts lists ..........................................................13

D

Details sensors EN .......................................................5

T

P

Technical specifications pressure and path measuring

sensors EN ...............................................................6

Path measurement .....................................................10

Pressure measurement ................................................9

Property rights (Copyright)............................................4

20

803353.000/ENG