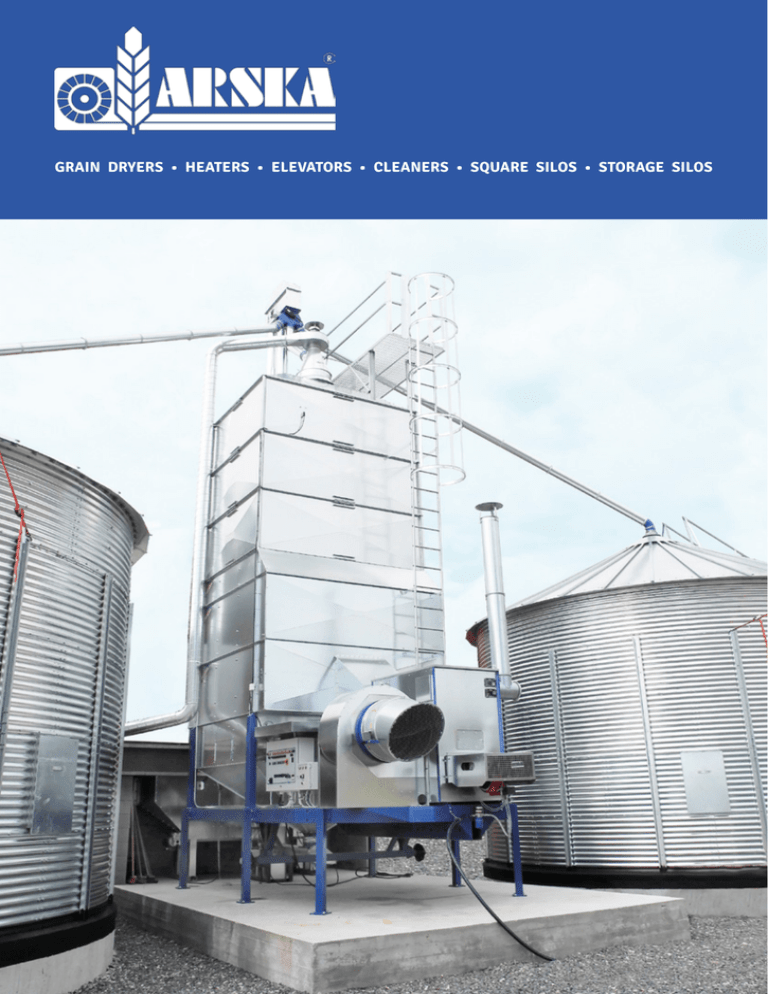

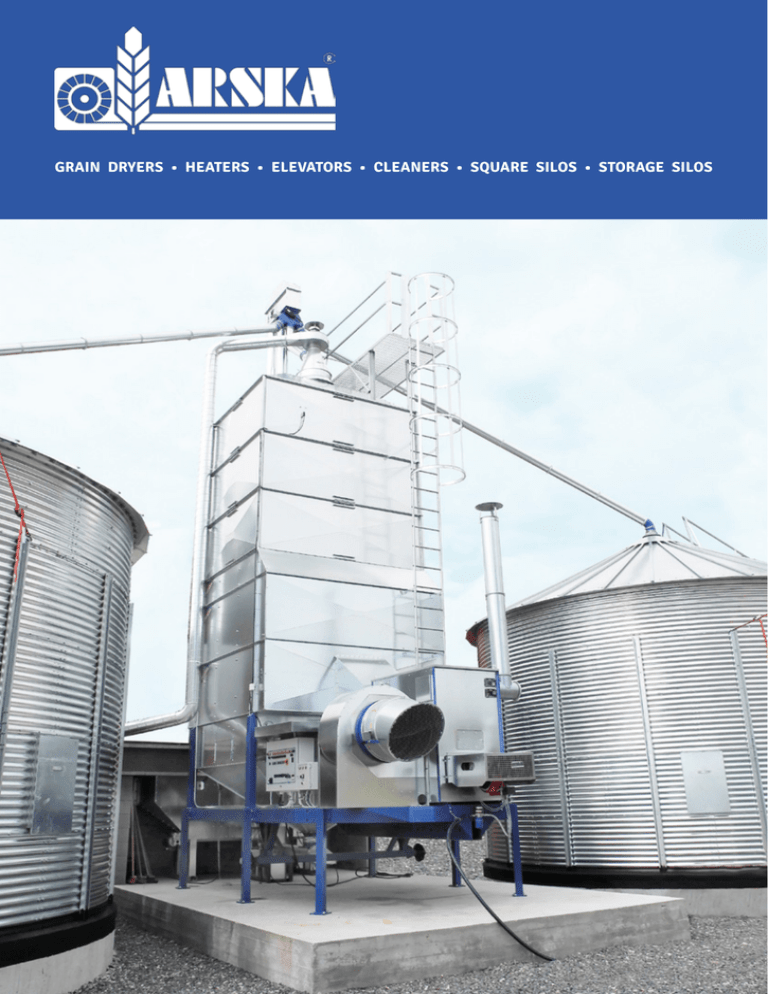

GRAIN DRYERS • HEATERS • ELEVATORS • CLEANERS • SQUARE SILOS • STORAGE SILOS

ARSKAMETALLI OY

ALWAYS A STEP AHEAD.

Arskametalli Oy is located in Somero, in

the middle of the most important grain

growing area of Finland. The factory has

been operating for three generations and has

manufactured grain dryers, heaters, elevators

and cleaners since 1958.

Our business is based on customer

satisfaction, which we get by making the

grain handling equipment efficient and

competitive. We respect the protection of

environment in all our actions.

ARSKAMETALLI OY

Saarentaantie 33

Somero, Finland

Switchboard +358 2 748 9700

posti@arskametalli.fi

en.arskametalli.fi

We are concentrated only on grain drying

and storing, so we can focus our all efforts

on maintaining top quality in our products

and staying in the lead of drying technology

development.

Being the oldest dryer manufacturer in

Finland we know everything about dryers

from engineering to production.

FARMERS ARE VERY DEMANDING

CUSTOMERS

As specialist of their field they give high value on our product’s

top quality and durability.

PROFESSIONAL WORKMANSHIP

APPEARS IN ARSKA PRODUCTS.

The details of dryers, heaters and other equipment

have been developed based on the feedback received

from farmers over many decades of experience.

We produce high quality products without

compromises and use leading manufactory

technology in production.

ARSKA REMAINS FROM FATHER TO SON.

We give our products fair warranties:

Heater internals:

8 years

Dryer machineries:

5 years

Silos:5 years

Elevators:5 years

Electrical parts:

1 year

GRAIN DRYERS

At the first sight many dryers may look similiar to each other, but Arska dryer’s best features

can be found beneath the surface. Designing the structures and details we paid attention to

costs of drying and the quality of the outcome.

There are many details and strong arguments for the solutions. This way we’ve achieved more

efficient drying, smoother recyling, stronger structure and more affordable price.

As usual, we only offer the best. There’s no haggling on the details: the delivery package

includes all the utilies you need.

KEY FOR MORE EFFICIENT AND

ECONOMICAL GRAIN DRYING

MACHINERY

Grain moves as an equal layer at the both

sides of the air channels in the heat cell.

Every other channel is an inlet air channel

and every other is an outlet air channel.

Drying happens at the humid side of the grain

pillar, heading towards to the dry side. Warm

air moving through the grain pillar cools that

part of the grain that has heaten the most at

the previous heat cell.

Air notches are higher than usual and equal

on both sides of the dryer. Walls of the air

notches permeate air on the entire area.

Spearing triangles are located evenly in the

center of each grain pillar. Those supplement

mixing of the grain layers and prevent the

condensation.

Grain on the base is constantly under drying,

because there are heat ridges on the lowest

cell. There are manholes on the sides of the

base and control hatches over the feeder.

Bottom fan keeps the base hopper in the low

pressure, which promotes the grain to dry.

Bottom fan’s connection is based low enough

to achieve a sufficient low pressure to the

bottom cone.

LARGE DRYING AREA

In Arska heat cell the grain circulates smoothly and certainly. In the highest and in the lowest

heat cell the drying air is lead in from the half notches, which are located in the sides of the

cells. Outlet air channel’s permeability is remarkably higher compared to the inlet air channels,

so the humidity exits efficiently and the internal parts of the cell remain clean.

Outlet air channel’s wall

is made of non-clogging

and highly permeable

galvanized steel net.

Inlet air channel’s wall is

galvanized scaled steel,

which ensures efficient

drying from top to bottom.

CROSS TRACK FEEDING

Depending on the model, P, S, M or F-dryers

have 4 - 12 feeding tracks. Smooth feeding is a

typical feature on Arska dryers.

Four-bladed cross track feeder keeps the feed

amount the same from the start to the finish

of the drying, regardless of grain moisture.

The feeding speed increases during the

cooling. Recycling works reliably with all grain

species, along the small grains. Recycle speed

is adjusted variably with a frequency inverter.

ACCESSORIES FOR THE GRAIN DRYERS

› tipping hopper 1,2m3 / 1.5kW

› tipping hopper cover

› pre-cleaner A150

› cyclone (GV / painted)

› small grain mesh

› mobile phone alarm

› JEMA conveyors /

tipping hopper

› motored 3-way divider

› motored shutter for

elevator

P, S, M AND F MACHINERIES: BASIC COLLECTION

PLANTATION

Volumes 13,5 - 24,5m3

Base size 200 x 167cm

PLANTATION

135

166

190

221

245

Total volume [m3]

13,5

16,6

19

22,1

24,5

Heat cell volume [m3]

6

6

8,4

8,4

10,8

/ cells [pcs]

/ 2,5

/ 2,5

/ 3,5

/ 3,5

/ 4,5

Storage container volume [m3]

6,2

9,3

9,3

12,4

12,4

/ containers [pcs]

/2

/3

/3

/4

/4

Dryer height [m]

6,20

7,12

8,04

8,96

9,88

Elevator height [m]

10,5

11,5

12,5

13,5

14,5

Elevator recommendation [tn]

68

68

68

68

68

Heater recommendation [model]

3000S

3000S

4000S

4000S

6000S

Fuse size recommendation [A]

25

25

25

25

35

SPECIAL

207

237

275

305

343

Total volume [m3]

20,7

23,7

27,5

30,5

34,3

Heat cell volume [m3]

7,5

10,5

10,5

13,5

13,5

/ cells [pcs]

/ 2,5

/ 3,5

/ 3,5

/ 4,5

/ 4,5

Storage container volume [m3]

11,4

11,4

15,2

15,2

19

/ containers [pcs]

/3

/3

/4

/4

/5

Dryer height [m]

7,12

8,04

8,96

9,88

10,80

Elevator height [m]

11

12

13

14

15

Elevator recommendation [tn]

68

68

68

92

92

Heater recommendation [model]

4000S

6000S

6000S

6500S

6500S

Fuse size recommendation [A]

25

35

35

50

50

SPECIAL

Volumes 20,7 - 34,3m3

Base size 200 x 207cm

OTHER VOLUMES ARE ALSO AVAILABLE!

MAGNUM

Volumes 25,6 - 43m3

Base size 200 x 257cm

MAGNUM

256

302

348

384

430

Total volume [m3]

25,6

30,2

34,8

38,4

43

Heat cell volume [m3]

14,4

14,4

14,4

18,5

18,5

/ cells [pcs]

/ 3,5

/ 3,5

/ 3,5

/ 4,5

/ 4,5

Storage container volume [m3]

9,2

13,8

18,4

18,4

23

/ containers [pcs]

/2

/3

/4

/4

/5

Dryer height [m]

7,58

8,5

9,42

10,34

11,26

Elevator height [m]

11,5

12,5

13,5

14,5

15,5

Elevator recommendation [tn]

68

68

68

92

92

Heater recommendation [model]

6000S

6000S

6000S

6500S

6500S

Fuse size recommendation [A]

35

35

35

50

50

FARM

Volumes 38,8 - 93m3

Base size 200 x 340cm

FARM (PLANTATION / MAGNUM)

P388

P498

M602

M768

M930

Total volume [m3]

38,8

49,8

60,2

76,8

93

Heat cell volume [m3]

16,8

21,6

25,2

32,4

39,6

/ cells [pcs]

/ 3,5

/ 4,5

/ 3,5

/ 4,5

/ 5,5

Storage container volume [m3]

18,6

24,8

27,6

36,8

46

/ containers [pcs]

/3

/4

/3

/4

/5

Dryer height [m]

9,69

11,53

9,69

11,53

13,37

Elevator height [m]

13

15

15

17

18

Elevator recommendation [tn]

92

92

118

118

118

Heater recommendation [model]

2 x 4000S

2 x 6000S

2 x 6000S

2 x 6500S

2 x 6500S

Fuse size recommendation [A]

50

63

63

80

80

COMPACT DRYERS

PROVEN

TECHNOLOGY

IN A MODERN,

SIMPLE FORM.

Volumes 16,9 — 43m3

EVEN SUITABLE FOR ALREADY

EXISTING BUILDINGS

Basis for designing the Compact dryer was a

fast factory delivery and an easy setup. All you

need to assemble Compact is a solid ground and

enough height for the elevator. The dryer is

80% electrified by the manufacturer.

COMPACT (SPECIAL)

S169

S207

S237

S275

S305

Total volume [m3]

16,9

20,7

23,7

27,5

30,5

Heat cell volume [m3]

7,5

7,5

10,5

10,5

13,5

/ cells [pcs]

/ 2,5

/ 2,5

/ 3,5

/ 3,5

/ 4,5

Storage container volume [m3]

7,6

11,4

11,4

15,2

15,2

/ containers [pcs]

/2

/3

/3

/4

/4

Elevator height [m]

9

10

11

12

13

Elevator recommendation [tn]

68

68

68

68

68

Heater recommendation [model]

4000S

4000S

6000S

6000S

6500S

Fuse size recommendation [A]

25

25

35

35

50

COMPACT (MAGNUM)

M256

M302

M348

M384

M430

Total volume [m3]

25,6

30,2

34,8

38,4

43

Heat cell volume [m3]

12,6

12,6

12,6

16,2

16,2

/ cells [pcs]

/ 3,5

/ 3,5

/ 3,5

/ 4,5

/ 4,5

Storage container volume [m3]

9,2

13,8

18,4

18,4

23

/ containers [pcs]

/2

/3

/4

/4

/5

Elevator height [m]

11,5

12,5

13,5

14,5

15,5

Elevator recommendation [tn]

68

68

68

92

92

Heater recommendation [model]

6000S

6000S

6000S

6500S

6500S

Fuse size recommendation [A]

35

35

35

50

50

STANDARD EQUIPMENTS

› elevator A68 / A92

› pre-cleaner A200 / A250

› bottom fan 0.75kW

› bottom screw 1.5kW

› tipping hopper 1,2m3 / 1.5kW

› control box

› service platform and ladder

› circulating piping

› air piping (3m)

TANDEM

DOUBLE DRYERS

Volumes 41,4 — 61m3

THERE’S MULTIPLE ENERGY OPTIONS: TANDEM HEATS WITH

OVER OR LOW PRESSURE HEATER OR WITH AN ECOHEATER.

YOU DECIDE THE FORM OF ENERGY.

Two dryer machineries on top of the frame, one heat source, one cooling fan. Both dryers have

their own elevators for recycling and emptying - filling has it’s own elevator.

TANDEM (2 x SPECIAL)

2 x 207

2 x 237

2 x 305

Total volume [m3]

41,4

47,4

61

Heat cell volume [m3]

2 x 7,5

2 x 10,5

2 x 13,5

/ cells [pcs]

/ 2 x 2,5

/ 2 x 3,5

/ 2 x 4,5

Storage container volume [m3]

2 x 11,4

2 x 11,4

2 x 15,2

/ containers [pcs]

/2x3

/2x3

/2x4

Elevator heights [m]

11

12

14

/ fill elevator height

/ 13

/ 14

/ 16

Elevator recommendation [tn]

68

68

68

Fuse size recommendation [A]

25

35

50

STANDARD EQUIPMENTS

› 3x elevator A68

› 2x pre-cleaner A200

› bottom fan 0.75kW

› tipping hopper 1,2m3 / 1.5kW

› control box

› service platform and ladder

› circulating piping

SUPERWAGON DRYERS

NEW! SUPERWAGON DRYERS ARE NOW AVAILABLE

WITHOUT THE BOTTOM CONVEYOR!

Volumes 16 — 43m3

Only wagon dryer on the market which works without conveyors.

Wagon dryer can be converted to a stationary dryer if needed!

SUPERWAGON

(MAGNUM)

SW160 SW183 SW219 SW242 SW278 SW301 SW348 SW384 SW430

Total volume [m3]

16

18,3

21,9

24,2

27,8

30,1

34,8

38,4

43

Heat cell volume [m3]

5,6

5,6

9,2

9,2

12,8

12,8

12,8

16,4

16,4

/ cells [pcs]

/ 1,5

/ 1,5

/ 2,5

/ 2,5

/ 3,5

/ 3,5

/ 3,5

/ 4,5

/ 4,5

Storage cont. volume [m3]

6,8

9,2

9,2

11,4

11,4

13,8

18,4

18,4

23

/ containers [pcs]

/ 1,5

/2

/2

/ 2,5

/ 2,5

/3

/4

/4

/5

Elevator height [m]

8

8,5

9,5

10

11

11,5

12,5

13,5

14,5

/ w/o the bottom conveyor

/9

/ 9,5

/ 10,5

/ 11

/ 12

/ 12,5

/ 13,5

/ 14,5

/ 15,5

Elevator rec. [tn]

68

68

68

68

68

68

68 / 92

68 / 92

68 / 92

Heater rec. [model]

3000S

3000S

4000S

4000S

6000S

6000S

6000S

6500S

6500S

Fuse size rec. [A]

25

25

25

25

35

35

35

50

50

Pre-cleaner [model]

A200

A200

A200

A200

A200

A200

A250

A250

A250

STANDARD EQUIPMENTS

› elevator A68 / A92

› pre-cleaner A200 / A250

› circulating piping

› bottom screw 1.5kW

› bottom fan 0.75kW

› tipping hopper 1,2m3 / 1.5kW

› control box

› service platform and ladder

› supply cable

MULTIWAGON DRYERS

MULTIWAGON DRYERS USE A LOW

PRESSURE HEATER WHICH IS PLACED

NEXT TO THE FRAME.

Volumes 53,2 — 93m3

ADVANTAGES OF A STATIONARY DRYER IN THE FORM OF A WAGON

The dryer is equipped with JEMA Agro’s efficient and gentle conveyor.

Wagon dryer can be converted to a stationary dryer if needed!

MULTIWAGON

(FARM-MAGNUM)

MW532

MW602

MW695

MW768

MW860

MW930

Total volume [m3]

53,2

60,2

69,5

76,8

86

93

Heat cell volume [m3]

18

25,2

25,2

32,4

32,4

39,6

/ cells [pcs]

/ 2,5

/ 3,5

/ 3,5

/ 4,5

/ 4,5

/ 5,5

Storage container volume [m3]

27,6

27,6

36,8

36,8

46

46

/ containers [pcs]

/3

/3

/4

/4

/5

/5

Elevator height [m]

13

14

15

16

17

18

Elevator recommendation [tn]

92

92

92

118

118

118

Heater recommendation [model]

8000S

8000S

8000S

8000S

8000S

8000S

Fuse size recommendation [A]

50

50

50

80

80

100

STANDARD EQUIPMENT

› elevator A92 / A118

› pre-cleaner A250

› JEMA Agro conveyor

› control box

› service platform

and ladder

› supply cable 10m

› circulating piping

HEATERS

EVEN AND EFFICIENT HEAT

MODEL A

Arska dryers are know from their

excellent efficiency and clean burning

without soot residues. Even though

the dryers are small on the outside,

they are sustainable and their oil

consumption is low.

MODEL B

With top quality materials and rational

designing we’ve made the heaters easy to

maintain and keep clean. The cover can be

opened and there’s a handy control hatch in

the front wall. To make the installation simple

the flue pipe is on the side and it goes through

the heater room wall horizontally. Outer walls

are made from galvanized steel plate, which

withstands any circumstances.

The flame burns freely in the middle and

heats evenly in the cylindrical furnance. It

doesn’t crash into walls or weak the structure.

Furnance is made of the best raw material

possible: fireproof special steel, having the

temperature level of peeling 1050°C.

STANDARD EQUIPMENT

› 2-stage burner

› 2-stage thermostat

› flue piping (4m)

with soot hatch

› LTM thermostat

THERE ARE FIVE HEATER MODELS TO CHOOSE,

ALL OF THEM EQUIPPED WITH AN OILON

2-STAGE BURNER, MANUFACTURED IN FINLAND!

Over pressure heaters: 178 - 413kW

(10 900 - 24 300 m / h / 60mmH2O)

3

Low pressure heaters: 556 - 819kW

(24 300 - 49 600 m3 / h / 60mmH2O)

HEATER MODEL

3000S

4000S

6000S

6500S

8000S (low pres.)

Air amount [m3 / h]

10 900

15 300

18 600

24 300

24 300 - 48 600

Min - max. oil consumption

10 - 17,6

14 - 24,3

18 - 30,3

20 - 40,1

52,5 - 78,8

Max. thermal power [kW]

178

254

310

412

556 / 712 / 819

Motor power [kW]

4,0

5,5

7,5

11

2 x 5,5 / 2 x 7,5 / 2 x 11

Lenght with burner [cm]

183

196

196

265

351

Width [cm]

75

84

84

86

145

Width with fan [cm]

169

185

200

202

-

Height [cm]

140

150

165

180

145

[kg / h]

HEATER INTERIORS HAVE 8 YEARS OF WARRANTY!

DRYING WITH BIO ENERGY IS CHEAPER!

FONT CHAMBER

HEATER

FITS IN ALL HEATER MODELS,

INCLUDING OTHER BRANDS!

Front chamber heater is an accessory for the oil heater. Inlet air is vacuumed through

the heater and flue gases are derived to the heat exchanger of the oil heater.

Changing back to oil use is easy and fast.

BURNER MODEL

300

400

500

Air amount [m3 / h]

18 600 - 24 300

18 600 - 24 300

24 300 - 37 200

kg / h (pellet)

60

60 - 75

75 - 100

Max. thermal power [kW]

254

412

494

Flue gas fan power [kW]

1.1

1.1

1.1 - 2.2

Lenght without burner [cm]

180

180

180

Width [cm]

160

160

160

Height [cm]

160 / 200

160 / 200

160 / 200

BIO BURNERS FROM FINNISH MANUFACTURERS:

ECOHEATER

THE FIRST BIO HEATER ON THE MARKET

BASED ON LOW PRESSURE TECHNOLOGY!

EcoHeater is designed for solid fuels and it developes a low pressure technology.

The furnance is spacious and the structure of the heater doesn’t require a high heater room.

BURNER MODEL

300

400

500

650

Air amount [m3 / h]

18 600 - 24 300

18 600 - 24 300

24 300 - 37 200

24 300 - 48 600

kg / h (pellet)

60

60 - 75

75 - 100

100 - 125

Max. thermal power [kW]

400

500

600

700

Flue gas fan power [kW]

2.2

2.2

2.2

2.2

Lenght without burner [cm]

309

309

309

309

Width [cm]

185

185

185

185

Height [cm]

200

200

200

200

ELEVATORS

Arska elevators made of galvanized steel convey the grain fast and

certainly. Motor attached to top part’s axle ensures a certain start in

any circumstances.

The elevator is easy to maintain and keep clean. There’s a removable

cover on top part and large cleaning hatches on the sides of the bottom part. Pre-cleaner attached to the top part keeps the square silo

dust-free, even while moving the grain.

Wedge-shaped bottom part, even and small clearance between the

cups and their trajectory where the cups are on horizontal position

when they face the grain coming from the tipping hopper provides

many advantages. Cups are always subjected to a maximum fill and

they don’t kick back.

— open handle pulleys on bottom and top parts

— direct-drive gear motors

— self-supporting structure

ELEVATOR MODEL

A68

A92

A118

Power [tn / h]

68

92

118

Pipe size Ø [mm]

210

280

280

Belt width [mm]

140

170

170

Cup amount [pcs / m]

7

6

6

Cup size [inch]

5,5

7

8

Crop pipe Ø [mm]

160

200

200

Motor power [kW]

4

5.5 - 7.5

7.5

STANDARD EQUIPMENT

ACCESSORIES

› speed control

› 3-way divider Ø160 / Ø200

› inlet 4 x Ø160 / Ø200

› inlet for tipping hopper

› pre-cleaner A150 (to top)

› motored 3-way divider

› motored shutter

› inlet 2 x Ø160 / Ø200

CLEANERS

CLEAN AND DRY!

PRE-CLEANER

Pre-cleaner removes trash, dust, chaff, small grains and other

impurities from the grain. The equipment stays clean and

drying is more perfect. According to the model of the precleaner it’s installed to the dryer cover or on the top part of the

elevator - when wanted the best results, to both. Then there’s

two pre-cleaners working on the machinery at the same time.

PRE-CLEANER MODEL

A150

A200

A250

Crop pipe Ø [mm]

-

160

200

Trash pipe Ø [mm]

160

200

200

Motor power [kW / RPM]

0.75 / 3000

1.5 / 3000

2.2 / 3000

Elevator rec. [tn]

68 / 92 / 118

68

92 / 118

(to elevator)

(to dryer

cover)

(to dryer

cover)

CYCLONE

SMALL GRAIN MESH

Cyclone prevents impurities from the

pre-cleaner from spreading to the surroundings of the dryer. It closes trashes to one

place - for example, to a trailer. Available

in galvanized and painted versions.

Small grain mesh separates the grains,

weed seeds and other impurities

damaged during the recycling, which

the pre-cleaner doesn’t separate.

Sieve: 2mm / 2,5mm / solid

AUTOMATION

CONTROL BOX

START IT — FORGET IT.

Equip your Arska dryer with a thermostat

controlling the machinery and operated

by temperature. The system works fully

automatically, whether you choose an digital or

a logic control box. Sensor located in the outlet

air channel starts the cooling after the grain

has dryed into the set value.

Water and dust proof cover protects the

automation. High quality control box is made

in Finland and the automation is designed and

produced specifically for Arska dryers.

CONTROL BOX STANDARD EQUIPMENT

› Y-Δ starter: fan

› soft starter: elevator

› digital ammeter: elevator

› speed control: elevator

› fill automation (standby)

› re-start automatism in case of

a blackout (memory automatism)

› hour meter 230V 50Hz

› digital thermostats readable and controllable

from the control box

› signal lights monitoring the operation and

status of the devices

› feeder control with a variable

frequency inverter

MOBILE PHONE ALARM

Provides information of the cooling or drying time ending and

all problems in the dryer straight to your cell phone:

— burner malfunction

— elevator rotation speed

— feeder stopping

— thermal releases

— other malfunctions

AUTOMATISM ACCESSORIES

› thermostat

› hygrostat

› motored divider

› motored shutter for elevator

› scale packages

› auxiliary switch for feeder

› mobile phone alarm

(read more from above)

SQUARE SILOS

ARSKA SQUARE SILO IS A HOME FOR THE DRYER

AND A STORAGE FOR THE GRAIN.

Thousands of finnish farmers are using

Arska equipment to process their grain.

The square silo is designed according to

customer’s wishes and needs.

There are suitable models both for a ranch

feed grain drying and storaging as for a large

farm’s commercial harvest handling.

If needed, it’s possible to organize the space

for a sorting facility into the same building.

BASIC COLLECTION

138,8 - 825,6m3

ACCESSORIES

tipping hopper grid

double or slide doors

cover hatches

heater room

roof trusses

stairs

Element structured silos work as side walls

of the Arska square silo. Number of silos and

total height will vary according to the size of

the square silo.

Machinery and the construction elements

are made of high quality raw materials

with professional manners and experience.

Outer surfaces of the elements can be

painted already at the factory by the color of

customer’s wishes.

TO SLOPE TERRAIN OR TO FLAT LAND?

It’s most favorable to constuct square silo on slope terrain to accomplish convient emptying

and use of space. Drive-under silo shutters are directed diagonally towards the car platform

below. Emptying the silos constructed on flat land happend with an elevator.

WALL ELEMENTS

SILO BASES

2 x 2m / volume 3,8m3 / height 86cm

2 x 2,5m / volume 4,8m3 / height 86cm

2,5 x 2,5m / volume 5,8m3 / height 86cm

2 x 2m / volume 1,2m3 / height 87cm

2 x 2,5m / volume 1,8m3 / height 100cm

2,5 x 2,5m / volume 2,3m3 / height 123cm

— made of galvanized steel plate

— also available with painted outer walls

— material thickness 1,5 - 2mm / 3mm

— inlet elements for air pipes

— fully welded structure

— primed or top painted

— outlet 0° / 45°

— knife shutter or valve

Model 4x3 / S6+2

with 2m elements

Model 4x3 / S6+2

with 2,5m elements

Base size 8,55 x 6,44m

5 layers / volume 138,8m3

6 layers / volume 169,2m3

Base size 10,55 x 7,94m

6 layers / volume 250,4m3

7 layers / volume 296,8m3

Model 4x4 / S10+2

with 2m elements

Model 4x4 / S10+2

with 2,5m elements

Base size 8,55 x 8,55m

7 layers / volume 299,6m3

8 layers / volume 345,2m3

9 layers / volume 390,8m3

Base size 10,55 x 10,55m

7 layers / volume 468,4m3

8 layers / volume 538m3

9 layers / volume 607,6m3

Model 4x5 / S14+2

with 2m elements

Model 4x5 / S14+2

with 2,5m elements

Base size 8,55 x 10,66m

7 layers / volume 414,4m3

8 layers / volume 472m3

9 layers / volume 529,6m3

Base size 10,55 x 13,16m

7 layers / volume 640m3

8 layers / volume 732,8m3

9 layers / volume 825,6m3

Spacious upstairs

Welded silo bases

Silo with timber cladding

STORAGE SILOS

A good harvest year means more grain to storage. Also the trading companies price

increments encourage to farm storaging. Storing the home-grown forage at ranches is a basis

for economical feeding. Your grain is safe from wind, blizzards and small rodents inside

Arska storage silo’s tight walls. The silo is made from strong, molded, corrugated iron.

YOU CAN ALSO GET METAL CONE BASES FROM US!

Ø5,6

Ø5,6

Ø5,6 - 6,4 - 7,2 Ø5,6 - 6,4 - 7,2 Ø5,6 - 6,4 - 7,2 Ø5,6 - 6,4 - 7,2 Ø5,6 - 6,4 - 7,2

4 layers

5 layers

6 layers

7 layers

8 layers

9 layers

10 layers

96m3

117m3

138 - 224m3

159 - 258m3

180 - 292m3

201 - 326m3

222 - 360m3

HAVE YOU RECEIVED MORE RENTED LANDS?

IS THERE ENOUGH STORAGING SPACE IN YOUR SQUARE SILO?

THERE IS A LOW-COST SOLUTION FOR YOUR STORAGING PROBLEMS.

EASY TO ASSEMBLE, QUICK

TO RAISE

WE RECOMMEND

A BASE RECESS

Strongly profiled elements made of corrugated

iron are easy to attach to each other.

Supporting wall raises rapidly. There’s no

need for special tools but the whole setup

can be done by yourself. Farm’s square silo or

forage handling area is most suitable for silo’s

place for setup, because you can use existing

machinery for filling and eptying.

Planning the base casting made before setup

you should pay attention to the convenient

emptying. V-shaped base decreases the

shoveling to minimum and the silo discharges

nearly down to the last grain with a screw.

Other base solutions can be made within the

limits of the ground.

Ø5,6m / LAYERS

4

5

6

7

8

9

10

Volume [m3]

96

117

138

159

180

201

222

Wall height [cm]

336

420

503

587

671

755

839

Fill height [cm]

476

560

643

727

811

895

979

Ø6,4m / LAYERS

6

7

8

9

10

Volume [m3]

178

205

232

259

286

Wall height [cm]

503

587

671

755

839

Fill height [cm]

663

747

831

915

999

Ø7,2m / LAYERS

6

7

8

9

10

Volume [m3]

224

258

292

326

360

Wall height [cm]

503

587

671

755

839

Fill height [cm]

683

767

851

935

1 019

CONVEYORS

JEMA Agro’s conveyors are made of hot galvanized steel which makes them particularly

suitable for outdoor applications. Conveyors are designed for transportation of the grain and

other bulk goods. A quality roller chain fitted with rubber or synthetic carriers ensure that all

material transport is conducted quietly, safely and effectively.

Conveyors work in horizontal position as well as with an upward angle. They’re efficient in

both versions and have a low power consumption in relation to it’s capacity.

All parts are made with an CNC-machine, so they fit perfectly into each other. This makes

installation very simple. The manufacturer has pre-set 40% of their maximum output.

CONVEYOR MODEL

T44

T45

T49

T57

Capacity [m3 / h]

40

80

140

200

RPM

180

Chain speed [m / s]

1,1

180 / T57 -transportöör

45 / 60

T49

45 -kuljettimet

AØ

200

200

H mm

960

B mm on chain

C mm [mm]

D mm

Pitch

330

300

400

E mm

330

300

400 [kN]

Tensile

strenght

(dyn.)

Carrier

material

IØ

J mm

200

500

215

215

K mm

L mm

328

330

960

Thickness

drive

station

200

500

328 [mm]

330

O mm

Thickness

boot

section

[mm]

P mm

QØ

R mm

S mm

190

250

190

200

375

Thickness

other

parts

[mm] 670

1,1

F mm

41,4

500

500

min.

G mm

805

17,8805

Mrubber

Ø

N mm

200

3

200

3 / 1,5

580

580

T mm

U mm

210

225

285

1,5

230

200

440

730

210

V mm

X mm

Y mm

Z mm

Æ mm

Ø mm

890

400

750

100

420

405

890

400

750

100

420

405

0,79 / 0,99

TRANSPORTÖÖR

A mm

T49

290

T57

290

TRANSPORTÖÖR

G mm

41,4

min. 17,8

rubber

T49

3

45 / 60

T57

3TRANSPORTÖÖR

/ 1,5

290

290

0,79 / 0,99

125

B mm

C mm

E mm

750

125

D mm

465

1 000

750

465

118

465

750

118

1 000

750

465

HØ

I mm

JØ

PEHD 240

1000

KØ

L mm

240

240

300

300

300

PEHD 240

1000

3

770

300

770

3

F mm

M mm

O mm

P 4,0 kW

870

400

3

P 2,0 kW

400

3

N mm

T49

550

585

620

T57

510

3

980

500

3

550

585

620

TRANSPORTÖÖR

P 7,5 kW

P 11 kW

P 15 kW

Q mm

R mm

S mm

T49

650

730

780

1 300

550

1 020

T57

650

730

780

1 300

550

1 130

1,5

Accurate dimensions: en.arskametalli.fi/material-bank

T49 / T57 -TRANSPORTÖÖR © JEMA AGRO A/S & ARSKAMETALLI OY 2015-01

P 5,5 k

JEMA AGRO’S CHAIN CONVEYORS ARE MADE OF STANDARD

ELEMENTS WHICH CAN EASILY BE FITTED INTO ANY

CONVEYING INSTALLATION.

HORIZONTAL CONVEYORS

STANDARD EQUIPMENTS

› directly mounted gear motor

› outlet hopper for drive station

› inspection hatch in drive station and

tightening section

› inlet

ACCESSORIES

› intermediate outlet

› rain cover for intermediate outlet

› shutter for drive station /

tightening section

› wire suspension

› speed control

TIPPING HOPPER CONVEYORS

STANDARD EQUIPMENT

› directly mounted gear motor

› torque arm for shock absorption

› outlet hopper for drive station

› tensioner, inspection and cleaning hatches in

drive station and tightening section

› adjustable plates in the inlet troughs

ACCESSORIES

FINALIZE YOUR DRYER STRUCTURE AND IMPROVE IT’S

FUNCTIONALITY WITH HIGH QUALITY AND RESISTANT

ACCESSORIES. THESE PARTS FIT

TO OTHER BRANDS TOO!

2-WAY DIVIDERS

AR422

AR4220

AR460

AR4600

2-way divider Ø160

2-way divider Ø160 (motored)

2-way divider Ø200

2-way divider Ø200 (motored)

3-WAY DIVIDERS

AR3057

AR3000

AR3527

AR4000

3-way divider Ø160 / A68

3-way divider Ø160 / A68 (motored)

3-way divider Ø200 / A92 - A118

3-way divider Ø200 / A92 - A118 (motored)

CROP PIPES

AR400

AR402

AR404

AR406

AR408

AR420

AR410

AR442

AR444

AR446

AR448

AR660

AR663

AR658

Crop pipe Ø160 / 23cm

Crop pipe Ø160 / 48cm

Crop pipe Ø160 / 98cm

Crop pipe Ø160 / 196cm

Telescope Ø160 / 1 - 2m (handle)

Telescope Ø160 / 2 - 4m (handle)

Top telescope Ø160 / 1 - 2m

Crop pipe Ø200 / 23cm

Crop pipe Ø200 / 48cm

Crop pipe Ø200 / 98cm

Crop pipe Ø200 / 196cm

Telescope Ø200 / 1 - 2m (handle)

Telescope Ø200 / 2 - 4m (handle)

Bottom telescope Ø200 / 1 - 2m

CURVES

AR466

AR490

AR484

AR495

AR664

AR666

AR690

AR695

Curve Ø160 / 15°

Curve Ø160 / 15° / 3mm

Curve Ø160 / 45°

Curve Ø160 / 45° / 3mm

Curve Ø200 / 15°

Curve Ø200 / 45°

Cast curve Ø200 / 15°

Cast curve Ø200 / 45°

OPEN CURVES

AR424

AR880

AR884

AR425

AR450

Open curve Ø160

Open curve Ø200

Open curve Ø200 / Ø160

Flexible curve Ø160 / 50cm

Flexible curve Ø200 / 50cm

SHUTTERS

HJ9150

HJ9175

HJ9200

Shutter Ø160 (knife)

Shutter Ø200 (knife)

Shutter Ø200 (valve)

C/O PARTS

AR617

AR882

AR883

C/O part Ø160 - Ø150

C/O part Ø200 - Ø160

C/O part Ø200 - Ø150

AIR PIPES

AR200

AR202

AR204

AR210

AR212

AR214

AR220

AR222

AR224

AR230

AR232

Air pipe Ø500 / 23cm

Air pipe Ø500 / 48cm

Air pipe Ø500 / 98cm

Telescope Ø500 / 20 - 40cm

Conversion part Ø500 - Ø600

Conversion part Ø500 - Ø630

Air pipe Ø630 / 23cm

Air pipe Ø630 / 48cm

Air pipe Ø630 / 98cm

Telescope Ø630 / 20 - 40cm

Conversion part Ø630 - Ø600

BINDS

AR440

AR486

AR468

AR864

AR208

AR228

Bind Ø160

Quick bind Ø160

Bind Ø200

Quick bind Ø200

Bind Ø500

Bind Ø630

ELECTRICAL PARTS

AR7777

AR6006

AR6004

AR6005

AR6002

AR9999

AR625

AR1234

AR7000

AR1235

AR2100

Digital display + thermostat (replaces the hygrostat)

Outlet air channel thermostat (replaces the hygrostat)

Temperature thermostat (LTM)

2-stage thermostat

Hygrostat

Frequency inverter + supplies

Mobile phone alarm

Auxiliary switch for feeder

Motored shutter for elevator

Hour meter 230V 50Hz

Thermometer

Contact us. We advise and serve you in drying issues. Let’s plan

together a drying solution according to your needs!

Finland: Markku Koivisto

Finland: Pauli Sundman

Baltic, Ukraine, Russia and

Belarus: Hannes Lauri

Baltic: Teet Laanemets

tel. +358 2 748 9708

markku.koivisto@arskametalli.fi

tel. +358 2 748 9712

hannes.lauri@arskametalli.fi

tel. +358 2 748 9705

pauli.sundman@arskametalli.fi

tel. +358 2 748 9713

teet.laanemets@arskametalli.fi

© Arskametalli Oy 2015

All rights reserved. In the photos in this brochure or other publications may occur devices

which are not standard equipment. Technical specifications are approximate.