Surface

LEVEL 1 CAPABILITY

Well Testing

| Level 2 Capability (if applicable)

Coflexip® Flexible Pipe

HIGH PRESSURE FLEXIBLE FLOW LINES

OVERVIEW

When an application calls for flexible flow lines, Halliburton Testing and Subsea often

relies on Coflexip flexible pipe. These flexible lines run from the flow and kill wings of the

surface test tree for the purpose of conveying fluids to and from the surface test tree to

the rest of the surface well test package, kill pumps, or stimulation package.

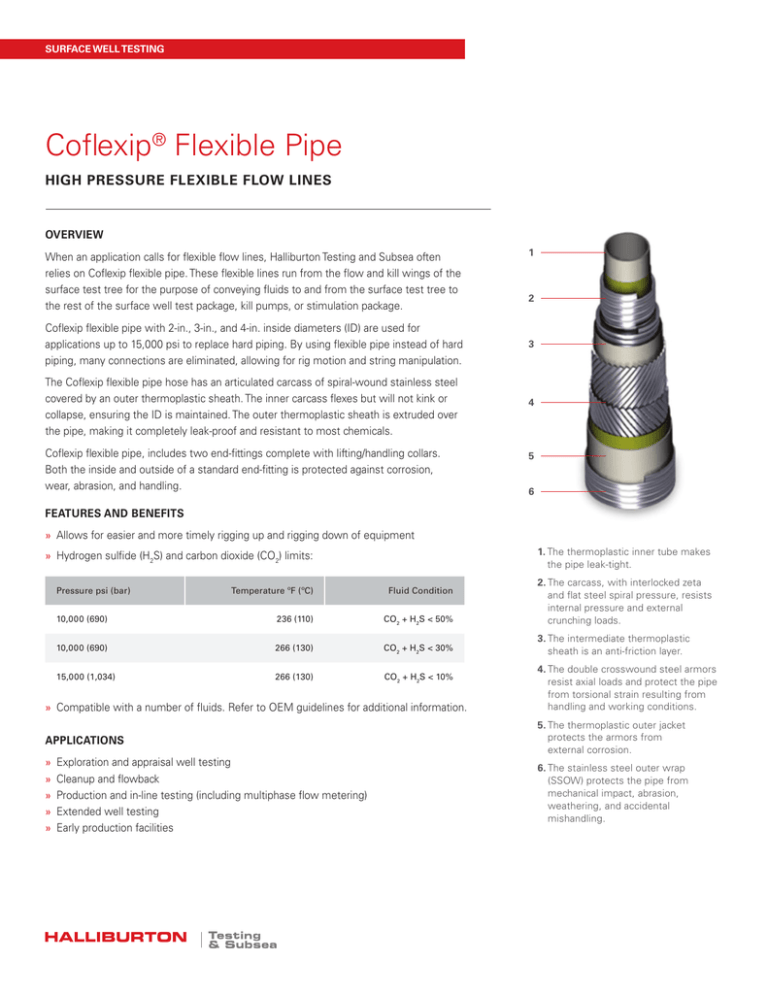

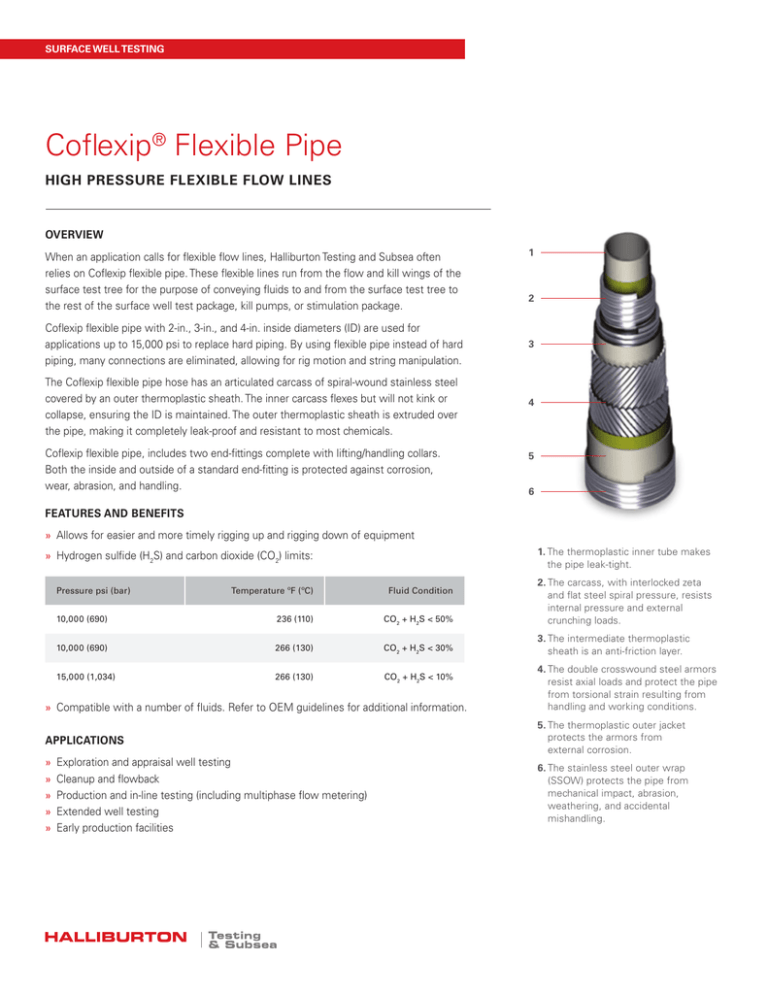

1

2

Coflexip flexible pipe with 2-in., 3-in., and 4-in. inside diameters (ID) are used for

applications up to 15,000 psi to replace hard piping. By using flexible pipe instead of hard

piping, many connections are eliminated, allowing for rig motion and string manipulation.

3

The Coflexip flexible pipe hose has an articulated carcass of spiral-wound stainless steel

covered by an outer thermoplastic sheath. The inner carcass flexes but will not kink or

collapse, ensuring the ID is maintained. The outer thermoplastic sheath is extruded over

the pipe, making it completely leak-proof and resistant to most chemicals.

4

Coflexip flexible pipe, includes two end-fittings complete with lifting/handling collars.

Both the inside and outside of a standard end-fitting is protected against corrosion,

wear, abrasion, and handling.

5

6

Features and Benefits

»» Allows for easier and more timely rigging up and rigging down of equipment

1. The thermoplastic inner tube makes

the pipe leak-tight.

»» Hydrogen sulfide (H2S) and carbon dioxide (CO2) limits:

Temperature ºF (ºC)

Fluid Condition

10,000 (690)

236 (110)

CO2 + H2S < 50%

2. The carcass, with interlocked zeta

and flat steel spiral pressure, resists

internal pressure and external

crunching loads.

10,000 (690)

266 (130)

CO2 + H2S < 30%

3. The intermediate thermoplastic

sheath is an anti-friction layer.

15,000 (1,034)

266 (130)

CO2 + H2S < 10%

Pressure psi (bar)

»» Compatible with a number of fluids. Refer to OEM guidelines for additional information.

Applications

»» Exploration and appraisal well testing

»» Cleanup and flowback

»» Production and in-line testing (including multiphase flow metering)

»» Extended well testing

»» Early production facilities

4. The double crosswound steel armors

resist axial loads and protect the pipe

from torsional strain resulting from

handling and working conditions.

5. The thermoplastic outer jacket

protects the armors from

external corrosion.

6. The stainless steel outer wrap

(SSOW) protects the pipe from

mechanical impact, abrasion,

weathering, and accidental

mishandling.

Surface

Well Testing

LEVEL 1 CAPABILITY

| Level 2 Capability (if applicable)

Equipment Specifications

Nominal

ID Size

2 in.

(50.8 mm)

3 in.

(76.2 mm)

4 in.

(101.6 mm)

Part No.

Working

Pressure

psi

(bar)

Design

Temperature

ºF

(ºC)

Length

ft (m)

OD

in (cm)

102079794

15,000

(1034)

−4 to 266

(−20 to 130)

25

(7.6)

102107829

15,000

(1034)

−4 to 266

(−20 to 130)

102284390

15,000

(1034)

102058509

Dimensions

Liner Type

Weight

lb

(kg)

Connections

4.9

(12.4)

Coflon®

737.5

(334.5)

2-1/16-in., 15,000-psi

API 6A Type 6BX flanges

30

(9.1)

4.9

(12.4)

Coflon®

885

(401.4)

2-1/16 in., 15,000 psi

API 6A Type 6BX flanges

−4 to 266

(−20 to 130)

55

(16.8)

4.9

(12.4)

Coflon®

3404

(1544)

2-in., Fig. 2202

MALE (W) x FEMALE (T)

15,000

(1034)

−4 to 266

(−20 to 130)

55

(16.8)

4.9

(12.4)

Coflon®

1925

(873)

2-1/16 in., 15,000 psi

API 6A Type 6BX flanges

102136919

15,000

(1034)

−4 to 266

(−20 to 130)

85

(25.9 m)

4.9

(12.4)

Coflon®

2900

(1315)

2-1/16-in., 15,000-psi

API 6A Type 6BX flanges

101754846

15,000

(1034)

−4 to 266

(−20 to 130)

55

(16.8)

6.5

(16.5)

Coflon®

3404

(1544)

3-1/16-in., API 6A

hubs (BX−154)

102284391

15,000

(1034)

−4 to 266

(−20 to 130)

55

(16.8)

6.5

(16.5)

Coflon®

3200

(1451)

3-in., Grayloc®

D27 connections

102107821

15,000

(1034)

−4 to 266

(−20 to 130)

60

(18.3)

6.5

(16.5)

Coflon®

3468

(1573)

3-1/16-in., API 6A

hubs (BX−154)

102107820

15,000

(1034)

−4 to 266

(−20 to 130)

65

(19.8)

6.5

(16.5)

Coflon®

3732

(1693)

3-1/16-in., API 6A

hubs (BX−154)

102107819

15,000

(1034)

−4 to 266

(−20 to 130)

70

(21.3)

6.5

(16.5)

Coflon®

3404

(1544)

3-1/16-in., API 6A

hubs (BX−154)

102130108

15,000

(1034)

−4 to 266

(−20 to 130)

85

(25.9)

6.5

(16.5)

Coflon®

4133

(2279)

3-1/16-in., API 6A

hubs (BX−154)

102144706

10,000

(690)

−4 to 266

(−20 to 130)

60

(18.3)

7.2

(18.3)

Coflon®

3730

(1692)

4-1/16-in., API 6A

flange (BX−155)

102272862

10,000

(690)

−4 to 266

(−20 to 130)

60

(18.3)

7.2

(18.3)

Coflon®

3730

(1692)

4-1/16-in., API 6A

hubs (BX−155)

Notes:

» The maximum continuous flow rate for all smooth-bore hoses is 49 ft/s (15 m/s).

» For individual equipment specifications, refer to the equipment data book.

» Equipment is designed/certified to API 16C, NACE MRO175, CE/PED, and NORSOK standards as applicable, and documented on

individual equipment specification data sheets.

» These ratings are guidelines only. Contact your local Halliburton Surface Well Testing (SWT) representative for more information.

» Coflon and Coflexip are registered trademarks of Technip. Grayloc is a registered trademark of Oceaneering International, Inc.

For more information, contact your local Halliburton representative

or visit us on the web at www.halliburton.com.

Sales of Halliburton products and services will be in accord solely with the terms and conditions

contained in the contract between Halliburton and the customer that is applicable to the sale.

H012193 6/16 © 2016 Halliburton. All Rights Reserved.