BRL-K23001/04

2010-07-01

Evaluation Guideline

for aerosol fire

extinguishing

for the product certificate for fixed dry aerosol fire

extinguishing components

Preface

This evaluation guideline has been accepted by the Board of Experts Fire Safety ,

wherein all the relevant parties in the field of for fixed dry aerosol fire extinguishing

components are represented. These Boards of Experts also supervises the certification

activities and where necessary require the evaluation guideline to be revised. All

references to Board of Experts in this evaluation guideline pertain to the above

mentioned Boards of Experts.

This evaluation guideline will be used by Kiwa in conjunction with the KiwaRegulations for Product Certification. This regulation details the method employed

by Kiwa for conducting the necessary investigations prior to issuing he product

certificate and the method of external control. The inspection frequency is determined

by the above mentioned Boards of Experts.

This guideline must be validated by the Board of Experts with a minimal frequency

of 5 years.

Information about product of performance requirements based public demands

based on European regulation is laid down in chapter 2 of this evaluation guideline.

Kiwa Nederland B.V.

Sir W. Churchill-laan 273

Postbus 70

2280 AB RIJSWIJK

The Netherlands

Tel. +31 70 414 44 00

Fax +31 70 414 44 20

www.kiwa.nl

© 2010 Kiwa Nederland B.V.

All rights reserved. No part of this book may be reproduced, stored in a database or retrieval system, or

published, in any form or in any way, electronically, mechanically, by print, photoprint, microfilm or any

other means without prior written permission from the publisher.

The use of this evaluation guideline by third parties, for any purpose whatsoever, is only allowed after a written

agreement is made with Kiwa to this end.

Validation

This evaluation guideline has been validated by the Director Certification and Inspection of Kiwa on

2010-07-01

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

-1-

BRL-K23001/04

July, 1st, 2010

Information

This evaluation guideline BRL-K23001 has to be used in conjunction with evaluation

guideline BRL-K23003.

The evaluation guideline BRL-K23001 covers following aspects;

• Product certification of separate components which are integrated into

systems.

• The certification covers the production through to the delivery to a certified

supplier, the minimum information for designers (basis for the specifications

and project definition) and the minimum level of servicing.

The evaluation guideline BRL-K23003 covers following aspects;

• This is a process certificate for the assessment of the following application

areas (i.e. secondary processes in four modules):

• Design of the installation, including drafting the specifications (basis of

design).

• Design of the installation, including component selection and detailing

(engineering).

• Installation of the fire protection system in accordance with the specifications

and the installation design, and commissioning the installation.

• Servicing. Certified installers shall be able to undertake at least one module

in full to be considered for the process certificate.

Inspection protocol design, installation, commissioning and servicing is incorporated

in BRL-K23003. The implementation protocol is addressed to independent inspection

bodies (ISO17020).

General

The intention is that a comprehensive and joined-up system of certification and

inspection arrangements are established, covering the entire process from

manufacturing through to the installed fire protection system.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

-2-

BRL-K23001/04

July, 1st, 2010

Contents

Preface

1

Information

2

Contents

3

1

Introduction

6

1.1

General

6

1.2

Field of application / scope

6

1.3

Terminology

7

1.4

1.4.1

1.4.2

Requirments and assesments methods

Requirements

Assessment methods

8

8

8

1.5

Acceptance of test reports provided by the supplier

8

1.6

Certificate

8

2

Product requirements and test methods

9

2.1

General

9

2.2

Extinguishing factor, EN2, Class A and B

9

2.3

Agent distribution, EN2, Class B

9

2.4

Discharge time

9

2.5

Ambient temperature and humidity operation ranges

10

2.6

Service life

10

2.7

Shelf life and storage conditions

10

2.8

Corrosion

10

2.9

Vibration

10

2.10

Mechanical shock

11

2.11

Discharge temperature

11

2.12

Activator device

11

2.13

Function reliability

11

2.14

Open fire conditions (optionel with requirment)

11

2.15

2.15.1

2.15.2

2.15.3

Rigidity and activation of the SFEA

Test method 1

Test method 2

Test method 3

12

12

12

12

2.16

2.16.1

2.16.2

Auto activation of the SFEA (optionel with requirment)

Test method 1

Test method 2

12

12

13

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

-3-

BRL-K23001/04

July, 1st, 2010

2.17

Fixing system of the fire extinguishing component

13

2.18

EN2, Class B, large liquid fires (optionel with requirment)

13

2.19

EN2, Class C, fires gas (optionel with requirment)

14

2.20

EN2, Class F, fires fat (optionel with requirment)

15

2.21

Classfication according to MSC.1/Circ.1270 (optional with requirment)

15

2.22

Qualification according to UL 2775 (optional with requirment)

16

2.23

2.23.1

Documentation

Design, installation and operation manual

16

16

2.24

Material Safety Data Sheet

16

2.25

2.25.1

2.25.2

2.25.3

2.25.4

2.25.5

Chemical stability of the fire extinguishing agent and extinguishing performance

Aerosol-generating chemical

Determination of the aerosol-generating compound

Determination of the effectiveness of a gaseous fire extinguishing agent

Equipment for activation issues on a fire suppression aerosol generator

Analytical results

16

16

16

17

17

17

2.26

Packaging, preservation, storage and identification

17

2.27

Marking

18

2.28

Certification mark

18

3

Quality system requirements

19

3.1

General

19

3.2

3.2.1

Manager of the quality system

Requirements concerning other verification personnel

19

19

3.3

Internal quality control / quality plan

19

3.4

Procedures and work instructions

19

3.5

Other Quality system requirements

20

3.6

Storage and handling

20

3.7

Receiving inspection SFEA

20

3.8

3.8.1

Process control of production batches

Activation and discharge mechanism

20

20

4

Summary of tests, audits and inspections

21

4.1

General

21

4.2

Assessment matrix

21

4.3

Design modifications

22

4.4

Verification of the quality system

22

5

Agreements on the performance of certification

23

5.1

General

23

5.2

5.2.1

5.2.2

Certification staff

General Qualification of certification staff

Specific Qualification of certification of staff

23

23

23

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

-4-

BRL-K23001/04

July, 1st, 2010

6

List of mentioned documents

25

6.1

Rules by public law

25

6.2

Standards

25

I

Model certificate

1

II

Model IQC-scheme

1

III

Additional information test procedure

2

6.3

6.3.1

6.3.2

Extinguishing EN2, Class A, fires solids materials

Extinguishing object, plastics

Extinguishing object, multilayer wood with / without plastics

3

3

4

6.4

6.4.1

Extinguishing EN2, Class B, fires liquid materials

Extinguishing object, liquid fires - test room 100 m3

5

5

6.5

Complete activation and discharge of the SFEA (electrical)

6

6.6

Thermal aging of the SFEA and electrical activator

6

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

-5-

BRL-K23001/04

July, 1st, 2010

1 Introduction

1.1

General

This Evaluation Guideline (BRL) contains all relevant requirements on the basis of

which Kiwa issues and maintains a Kiwa Product Certificate for Kiwa product

certificate for fixed dry aerosol fire extinguishing components. Product certification in

this Evaluation Guideline is based on EN45011.

This evaluation guideline replaces the following BRL:

BRL

BRL-K23001/03

Title

Product certificate for fixed dry aerosol fire

extinguishing components

Dated

2004-11-30

This BRL replaces BRL K23001/03 of 2004-11-30 and as of 2012-07-01 any previous

versions shall no longer be used for new initial assessments. Holders of current

certificates based on older versions of this evaluation guideline shall comply with the

new version as of 2010-07-01.

During the performance of the certification work, Kiwa is bound to the requirements

as laid down in the chapter “Agreements on the implementation of certification”.

1.2

Field of application / scope

These components for fixed fire extinguishing systems using dry aerosols are

intended for incorporation into a fire extinguishing system. The fire extinguishing

components are activated by the fire extinguishing system. These components

comprise a container filled with a dry solid fire extinguishing agent which upon

activation is discharged in the form of an aerosol to extinguish the fire. This

arrangement of components is called the aerosol generator.

The fire extinguishing components shall be suitable for extinguishing fires of the

following classes (EN 2):

• Class A (solid materials);

• Class B (liquid materials).

Additional testing is optional possible for a wider scope and application.

The additional test must be listed in the attest of the product certificate.

Following tests and applications are possible:

• Class B (large liquid fires);

• Class C (gasses);

• Class F (boiling oil and fat fires);

• Classification according to MSC.1/Circ.1270 based on IMO-regulations.

Note:

Melting plastics are assigned to Class A. Fires ignited due to electrical short-circuits

cause Class A, B or C fires.

The parts to build an aerosol generator are specified in paragraph 1 and 4 of CEN/TR

15276-1. Paragraph 14 in MSC.1/Circ.1270 specifies the arrangement of aerosol

extinguishing system. The fire extinguishing component consists of the following

parts:

• container with discharge port and mounting point;

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

-6-

BRL-K23001/04

July, 1st, 2010

•

•

•

•

•

solid fire extinguishing agent;

electrical activator; or

thermo cord activator;

fire extinguishing component packaging;

instruction manual

There are requirements for all parts and for the assembled product, which are

described in this evaluation guideline.

The application of the components for fixed fire extinguishing systems using dry

aerosols is a responsibility that belongs to specialists in fire safety.

The design, installation and maintenance are laid down in the Evaluation Guideline

for the Kiwa process certificate for design, installation, acceptance and aftercare of

fire-extinguishing systems based on aerosol.

The procedures and qualification requirements of technical staff applying these

products is also laid down in this evaluation guideline.

This document requires, as a precaution, that the room is evacuated and sealed off

whenever a generator is activated. Precautions include evacuation of the proximity

area, criteria for re-entering and other safeguards as stated in Clause 5 of CEN/TR

15276-2:2009.

1.3

Terminology

In this Evaluation Guideline the following definitions shall apply:

• Board of Experts: the Board of Experts “Fire Safety”;

• BRL: Evaluation Guideline;

• Supplier: the party responsible for ensuring that the products continuously fulfil

the requirements on which the certification is based;

Note: the ‘Supplier’ may also be the manufacturer of the certified product(s).

• IQC-scheme: a description of the quality inspections carried out by the supplier as

part of his quality system.

• Aerosol: colloidal mixture of a substance and a gas.

• Colloidal: the condition of materials which are finely divided in a liquid or gas, in

particulates larger than a molecule and smaller than those in a suspension.

• Suspension: liquid or gas in which another material is suspended as fine particles.

• Container: structure containing the dry solid fire extinguishing agent and from

which the agent is discharged into the surroundings through a discharge opening.

• Evaluation Guideline: arrangements concerning the subject covered by the

certification, as agreed by the Board of Experts.

• Fire extinguishing mechanism (chemical): after the activation of the dry fire

extinguishing agent it is discharged as a dry aerosol consisting of finely divided

particles (e.g. 40% of the mass), specifically alkali salts, and gasses (e.g. 60% of the

mass) primarily consisting of nitrogen, carbon dioxide and water vapour. The dry

aerosol has a chemical extinguishing action by interfering with the chain reactions

in the flames by binding to free radicals as well as a physical extinguishing action

by cooling the seat of the fire. Both reactions largely occur at the surface of the

microscopically small particulates in the dry aerosol. The smaller the particulates,

the more effective the mechanism will be.

• Solid fire extinguishing agent (SFEA): solid material which is transformed into an

aerosol by heat.

• Fire extinguishing system: system consisting of a number of components to detect

a fire, communicate it to the premises manager and possibly to others, and

independently activate other components to extinguish the fire.

• Fire extinguishing components: components which may be incorporated into a fire

extinguishing system. Examples: smoke detectors, fire detectors, manual call

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

-7-

BRL-K23001/04

July, 1st, 2010

•

•

•

•

•

•

•

•

•

•

•

1.4

points, cables, signals and alarm annunciators, fire extinguishing components and

other auxiliary components such as automatically closing doors. Here we are

concerned with a fire extinguishing component comprising a container filled with

dry fire extinguishing agent which, after activation, discharges a dry aerosol to

extinguish the fire.

EN: European standard.

Supplier: party which is responsible for ensuring that the products consistently

meet the requirements underlying the certification.

Internal quality monitoring plan: definition of the quality inspections undertaken

by the supplier as part of their quality system.

IMO: International Maritime Organisation.

ISO: International Standardization Organization.

NEN: Netherlands standard.

NFPA: National Fire Protection Association.

MVK: Dutch qualification for intermediate level safety experts.

HVK: Dutch qualification for senior level safety experts.

MBO: Dutch senior secondary vocational education qualification.

HBO: Dutch higher professional education qualification.

Requirments and assesments methods

This Evaluation Guideline defines requirements and assessment methods, including:

1.4.1

Requirements

Performance requirements: quantitative requirements concerning specified functional

properties of the component of the element (fire extinguishing component) defining a

limit which can be unambiguously calculated or measured.

Product requirements: quantitative requirements concerning identifiable properties

of the products used in the element (fire extinguishing component), defining a limit

which can be unambiguously calculated or measured.

1.4.2

Assessment methods

Initial assessment: assessment to determine if all the requirements defined in the

evaluation guideline are met.

Follow-up assessment: assessment undertaken after the issue of the certificate to

verify if the certified products continue to meet the requirements of the evaluation

guideline.

The assessment matrix indicates what is assessed by Kiwa during the initial and

follow-up assessments and how frequently follow-up assessments are undertaken.

1.5

Acceptance of test reports provided by the supplier

The rules for acceptance of test reports provided by the supplier are laid down in the

Kiwa Regulations for Product Certification.

1.6

Certificate

A model of the certificate to be issued on the basis of this Evaluation Guideline has

been included as an Annex.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

-8-

BRL-K23001/04

July, 1st, 2010

2 Product requirements and test methods

2.1

General

In the next chapters the requirements are embodied to which products have to

comply to.

Chapter x explains when determinations or type tests have to be undertaken as part

of the initial assessment or type test. Chapter 4 explains when determinations or tests

have to be made during manufacturing operations as part of the internal quality

monitoring efforts of the supplier.

This chapter 2 contains the performance requirements to be met by the fire

extinguishing component and the methods to determine if the requirements are

fulfilled.

2.2

Extinguishing factor, EN2, Class A and B

The performance requirements for the extinguishing factor are described in CEN/TR

15276-1, paragraph 5.2.

The test method is described in annex A of CEN/TR 15276-1 and must meet the

requirements. The factor found with the test for polymeric sheets (A6.3) and

composite wood (A6.4) must be applied for the wood crib test (A6.1). The total preburn time for this test may also be 4 minutes (3+1 minutes).

The findings of the determination and tests must be declared in the attest of the

product certificate. The attest must be specific about the declaration for the wood crib

test.

2.3

Agent distribution, EN2, Class B

The performance requirements for the agent distribution are described in CEN/TR

15276-1, paragraph 5.3.

The test method is described in paragraph 7.5 of CEN/TR 15276-1 and must meet the

requirements.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.4

Discharge time

The performance requirements for the discharge time are described in CEN/TR

15276-1, paragraph 5.4.

The test method is described in paragraph 7.6 of CEN/TR 15276-1 and must meet the

requirements.

The findings of the determination and tests must be declared in the attest of the

product certificate.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

-9-

BRL-K23001/04

July, 1st, 2010

2.5

Ambient temperature and humidity operation ranges

The performance requirements for the discharge time are described in CEN/TR

15276-1, paragraph 5.5.

The test method is described in paragraph 7.7 of CEN/TR 15276-1 and must meet the

requirements.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.6

Service life

The performance requirements for the service life are described in CEN/TR 15276-1,

paragraph 5.6.

The test method is described in paragraph 7.8 of CEN/TR 15276-1 and must meet the

requirements.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.7

Shelf life and storage conditions

The requirements for the shelf life and storage conditions of the aerosol generator are

described in CEN/TR 15276-1, paragraph 5.7.

The shelf life and storage conditions shall be specified by the manufacturer in its

instruction the appliers.

2.8

Corrosion

The performance requirements for corrosion resistance of the aerosol generator are

described in CEN/TR 15276-1, paragraph 5.8.

The test method is described in paragraph 7.9 and 7.10 of CEN/TR 15276-1 and must

meet the requirements. The mounting bracket shall be tested together with the

generator for corrosion, vibration and mechanical shock impacts as described in 7.9,

7.11, 7.12 and 7.13.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.9

Vibration

The performance requirements for vibration resistance of the aerosol generator are

described in CEN/TR 15276-1, paragraph 5.8.

The test method is described in paragraph 7.11 and 7.16 of CEN/TR 15276-1 and

must meet the requirements. The mounting bracket shall be tested together with the

generator for corrosion, vibration and mechanical shock impacts as described in 7.9,

7.11, 7.12 and 7.13.

The findings of the determination and tests must be declared in the attest of the

product certificate.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 10 -

BRL-K23001/04

July, 1st, 2010

2.10

Mechanical shock

The performance requirements for mechanical shock resistance of the aerosol

generator are described in CEN/TR 15276-1, paragraph 5.8.

The test method is described in paragraph 7.13 and 7.16 of CEN/TR 15276-1 and

must meet the requirements. The mounting bracket shall be tested together with the

generator for corrosion, vibration and mechanical shock impacts as described in 7.9,

7.11, 7.12 and 7.13.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.11

Discharge temperature

The specifications of the aerosol generator for the discharge temperature are

described in CEN/TR 15276-1, paragraph 5.11.

The test method is described in paragraph 7.14 of CEN/TR 15276-1 and must meet

the requirements.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.12

Activator device

The specifications of the electrical activator device of the aerosol generator are

described in CEN/TR 15276-1, paragraph 5.12.

The test method is described in paragraph 7.15 of CEN/TR 15276-1 and must meet

the requirements.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.13

Function reliability

The specifications of the function reliability of the aerosol generator are described in

CEN/TR 15276-1, paragraph 5.13.

The test method is described in paragraph 7.16 of CEN/TR 15276-1 and must meet

the requirements.

The findings of the determination and tests must be declared in the attest of the

product certificate

2.14

Open fire conditions (optionel with requirment)

The specifications for open fire conditions of the aerosol generator are described in

CEN/TR 15276-1, paragraph 5.14.

The test method is described in paragraph 7.17 of CEN/TR 15276-1 and must meet

the requirements.

The findings of the determination and tests must be declared in the attest of the

product certificate.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 11 -

BRL-K23001/04

July, 1st, 2010

2.15

Rigidity and activation of the SFEA

The performance requirement for the rigidity and activation of the SFEA is

determined following. The solid fire extinguishing agent (SFEA) shall maintain its

rigidity at temperatures from -50°C to 200°C and remain capable of being ignited by

the electrical and thermal activators.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.15.1

Test method 1

The SFEA without the container, but with the activator, is stored for 24 hours at 50°C. After this period the SFEA is removed from the store and shall not fragment.

The SFEA is ignited in a room at ambient temperature, within 1 minute of the

removal from the store. The SFEA shall ignite immediately.

2.15.2

Test method 2

The SFEA without the container, but with the activator, is stored for 24 hours at 50°C. After this period the SFEA is removed from the store and shall not fragment.

The SFEA is then stored at ambient temperature for 24 hours and is then ignited in a

room at ambient temperature, within 1 minute of the removal from the store. The

SFEA shall ignite immediately.

2.15.3

Test method 3

The SFEA without the container, but with the activator, is stored for 24 hours at 50°C. After this period the SFEA is removed from the store and shall not fragment.

The SFEA is then left for 1 hour at ambient temperature. After that the temperature of

the SFEA is increased by 10°C every 10 minutes. The SFEA is then stored for 24 hours

at a temperature of 200°C. The SFEA is then ignited in a room at ambient

temperature, within 1 minute of the removal from the store. The SFEA shall ignite

immediately.

2.16

Auto activation of the SFEA (optionel with requirment)

The performance requirement for the rigidity and auto activation of the SFEA is

determined following. The SFEA shall exhibit auto activation between a temperature

of 250 and 350°C.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.16.1

Test method 1

The SFEA without the container and without the activator is stored for 24 hours at 50°C. After this period the SFEA is removed from the store and shall not fragment.

The SFEA is then heated in stages. The temperature is increased in steps of 10°C.

Once a temperature stage is reached, it shall be maintained for 10 minutes. The SFEA

shall exhibit auto activation between the stated temperatures.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 12 -

BRL-K23001/04

July, 1st, 2010

2.16.2

Test method 2

The thermo cord is stored at -50°C. After this period the thermo cord is removed from

the store and shall not fragment. The temperature of the thermo cord is then

increased in steps of 10°C. Once a temperature stage is reached, it shall be maintained

for at least 10 minutes. Above 150°C the temperature steps shall amount to 5°C. The

thermo cord shall exhibit auto activation between the stated temperatures.

Note:

The SFEA contains a binder whose function may be impaired at low temperatures.

2.17

Fixing system of the fire extinguishing component

The performance requirement for the fixing system of the fire extinguishing

component is determined following. The supplier shall ensure that the fire

extinguishing components can be securely fixed in the room where the extinguishing

action is required. It shall be possible to fix the components to the ceiling, wall or

floor of the room concerned. The fixings of the fire extinguishing component

(minimum 100 g) shall withstand a load equivalent to the weight of the fire

extinguishing component multiplied by a factor of five without visible distortion.

Test method

The fire extinguishing component is fixed to a wall or ceiling in accordance with the

supplier’s instructions. Before assessing the fire extinguishing performance, a weight

of at least five times the weight of the actual fire extinguishing component is secured

to the component. This shall be maintained for 10 minutes. At the end of the

assessment of the fire extinguishing performance the fire extinguishing component

shall not exhibit any visible distortion.

The findings of the determination and tests must be declared in the attest of the

product certificate.

Note:

During the test the fixing to the ceiling by screws and plugs and the physical

condition of the ceiling are not directly tested. The system is intended for a rapid

response and extinguishing action. Hence, maintaining functionality for more than

e.g. 15 minutes is not relevant. The extinguishing action will always occur at approx.

300°C. A higher temperature due to the activation which results in thermal stress on

the fixing system is assessed during the fire extinguishing performance tests.

2.18

EN2, Class B, large liquid fires (optionel with requirment)

The performance requirement for large liquid fires of the fire extinguishing

component is determined following The solid fire extinguishing system shall meet

the determinations for Class B according to EN2.

Test method

The test objective is a liquid fire in a test room of 1250 m3. The room shall have the

following minimum dimensions: height 8 m, width 8 m, depth 12 m. These

dimensions shall be scaled up to 1250 m3. Central in the room is a steel fire pan

positioned of 1.8 x 1 m and a height of 10 cm.

The fire pan shall contain a layer of 45 l heptane on 5 cm of water with a burning time

of at least 5 minutes and a power of approx. 6 MW. The pan shall be placed on the

floor.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 13 -

BRL-K23001/04

July, 1st, 2010

The fire extinguishing components shall be suspended in accordance with the

supplier’s specifications and distributed as specified by the supplier. The fire cell

shall be placed at the edge of the radius of the design extinguishing area.

The heptane shall be ignited for each test and have a free burning time of 30 seconds.

After the end of the activation of the fire extinguishing agent the room shall remain

closed for at least 10 minutes. During this period the cell shall be monitored for signs

of active fire and signs of spontaneous activation, based on the temperature

measurements in the vicinity of the fire cell.

After this period the cell shall be inspected visually for signs of active fire and signs

of active activation outside the test room without the presence of the fire

extinguishing agent. Any signs of fire shall be described in the report. The

temperature after extinguishing shall be decisive. Visible fire is considered as a sign

of spontaneous activation, but solely smoke is not.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.19

EN2, Class C, fires gas (optionel with requirment)

The performance requirement for gas fires of the fire extinguishing component is

determined following The solid fire extinguishing system shall meet the

determinations for Class C according to EN2.

Test method

A triangular sand bed burner to EN13283 filled with two layers of sand and gravel.

A controlled volume of propane gas is blown through the sand bed burner.

After activation the propane gas shall have a thermal power of 30 kW. The total

burning time shall be 2 minutes.

The objects to be extinguished shall be placed in the centre of the test room at floor

level. The fire extinguishing components shall be suspended in accordance with the

supplier’s specifications and distributed as specified by the supplier.

After the end of the activation of the fire extinguishing agent the room shall remain

closed for at least 10 minutes. During this period the cell shall be monitored for signs

of active fire and signs of spontaneous activation, based on the temperature

measurements in the vicinity of the fire cell.

After this period the cell shall be inspected visually for signs of active fire and signs

of active activation without the presence of the fire extinguishing agent. Any signs of

fire shall be described in the report. The temperature after extinguishing shall be

decisive. Visible fire is considered as a sign of spontaneous activation, but solely

smoke is not.

The gas burner shall have a thermal cut-out which independently interrupts the flow

of gas when the burner is extinguished.

The findings of the determination and tests must be declared in the attest of the

product certificate.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 14 -

BRL-K23001/04

July, 1st, 2010

2.20

EN2, Class F, fires fat (optionel with requirment)

The performance requirement for fat fires of the fire extinguishing component is

determined following The solid fire extinguishing system shall meet the

determinations for Class F according to EN2.

Test method

A steel pan with a diameter of 38 cm and a depth of 30 cm is filled with approx. 15 kg

of solid deep-frying fat (Ossewit brand). The pan is placed on a metal frame with a

propane burner underneath it which heats the steel pan from the bottom. The fat is

heated to the auto activation temperature (approx. 320°C). After activation the fat

shall have a total free burning time of 30 s.

The object to be extinguished shall be located at one side of the test room, above floor

level. The top of the steel pan shall be 60 to 65 cm above the floor.

A metal extractor hood with an area of 0.8 m2 (minimum dimensions 1 x 0.5 m) shall

be suspended above the steel pan. The extractor hood shall be approx. 1.4 m above

the floor.

While the pan is being heated the flue gasses and grease fumes shall be extracted by

the hood.

After activation of the pan and before extinguishing, the flue gas duct shall be closed

and the extractor fan motor shall be switched off.

The fire extinguishing components shall be suspended in accordance with the

supplier’s specifications and distributed as specified by the supplier.

After the end of the activation of the fire extinguishing agent the room shall remain

closed for at least 30 minutes. During this period the cell shall be monitored for signs

of active fire and signs of spontaneous activation, based on the temperature

measurements in the vicinity of the fire cell.

After this period the cell shall be inspected visually for signs of active fire and signs

of spontaneous activation. The temperature shall have fallen below the auto

activation temperature.

Any signs of fire shall be described in the report. Visible fire is considered as a sign of

spontaneous activation, but solely smoke is not.

The gas burner shall be turned off after the auto activation of the fat in the

pan.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.21

Classfication according to MSC.1/Circ.1270 (optional with requirment)

The performance requirements for the aerosol are described in MSC.1/Circ.1270,

appendix 1.

The test methods are described in MSC.1/Circ.1270, appendix 1 and must meet the

requirements.

The findings of the determination and tests must be declared in the attest of the

product certificate. The classification in the attest is according to MSC.1/Circ.1270,

appendix A4.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 15 -

BRL-K23001/04

July, 1st, 2010

2.22

Qualification according to UL 2775 (optional with requirment)

The performance requirements for the aerosol are described in UL2775.

The relevant test methods for dry condensed aerosols are described in UL2775

paragraphs 20 until 60 and must meet the requirements.

The findings of the determination and tests must be declared in the attest of the

product certificate.

2.23

Documentation

The requirements for the documentation of the aerosol generator and system are

described in CEN/TR 15276-1, paragraph 5.16.

2.23.1

Design, installation and operation manual

At the time of delivery the product shall be accompanied by an operating manual.

This manual shall address at least the following topics:

• Preparations for application;

• Application details and conditions;

• Application scope, fire extinguishing capacity, discharge length and

temperature decay, surface temperature during fire extinguishing action;

• Use of the accessories;

• Quality inspections relevant to the application;

• Chemical resistance of the fire extinguishing component.

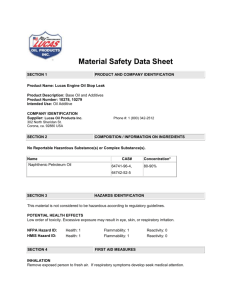

2.24

Material Safety Data Sheet

The fire extinguishing agent shall be safe to humans and the environment during

processing, storage and application. The application is in relation to its intended

goals. With respect to the user this shall be demonstrated by the Chemical Product

Safety Data Sheet or Material Safety Data Sheet in accordance with:

• NEN-ISO11014-1;

• EU Directive 91/155/EEC (Official Journal L76/91) of March 5th, 1991;

Registration has to be in according to REACH, see EU-GHS (EG. nr 1272/2008).

2.25

Chemical stability of the fire extinguishing agent and extinguishing

performance

The chemical composition shall be determined during the type tests and this

formulation shall be recorded by Kiwa and the supplier. All components of the

product shall be clearly identified.

2.25.1

Aerosol-generating chemical

The aerosol-generating chemical is a thermoplastic mixture consisting of an oxidiser,

a combustion binder and additives. The oxidiser is solid potassium nitrate (KNO3),

the binder is solid plasticised resin and other ingredients are for stabilisation.

The solid residual compound contains elementary species, potassium salts, mineral

fractions, retarded resin and a binding retarder as environmentally innocuous

chemically acting fire suppression additives.

2.25.2

Determination of the aerosol-generating compound

Powered fire-extinguishing medium extracts being prepared with water hydrolysis

by dissolving the chemical using ultra-sonic wave technology and acid digestion

using micro-wave destruction technology. Sample extracts for performing techniques,

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 16 -

BRL-K23001/04

July, 1st, 2010

such as ICP-MS, pH, potentiometric measurements on alkalinity and acidimetry, TOC

analyzer, CFA analyzer, total organic N analyzer and Ion chromatography, are

prepared. The original compound is analyzed by the two analytical procedures:

(1) ICP-MS after applying digestion techniques using pressed pellets and

(2) the water dissolved extracts will be analyzed for anions by Ion chromatography or

CFA, for pH by potentiometric measurement, hydrocarbonates and carbonates by

acidimetric measurements. The dissolved organic carbon is analyzed with TOC

equipment. C and S are determined with a combustion C and S analyzer and N with

a total organic N analyzer.

2.25.3

Determination of the effectiveness of a gaseous fire extinguishing agent

The effectiveness of a gaseous fire extinguishing agent, consisting of solid aerosolforming compound, is determined after activation by electrical ignition at a

temperature of 300ºC with a thermocord. The present residue after activation of the

extinguishing generators is directed to analytical testing with the performing

techniques see 2.25.2.

2.25.4

Equipment for activation issues on a fire suppression aerosol generator

A combustion chamber can be used for the activation of solid aerosol-forming

compound. Before the activation the combustion chamber need to be inspected and

cleaned before discharging the deleterious compound. Only by-products from the

activation itself have to be present on the integrated glass plate, which is integrated

into the combustion chamber. No unwanted by-products from the outside of the

combustion chamber could be present.

Residual aerosol particulates after activation of the solid aerosol-forming compound

being collected from the inert glass plate, which is integrated in the combustion

chamber. The collected particulates are directly analyzed by the different analytical

techniques.

2.25.5

Analytical results

All analytical experiments by 2.25.1 and 2.25.2 show the original specific composition

of the aerosol-forming compound (AFC’s) and the formed particulates after

activation at a temperature of 300°C in a combustion chamber. In these experiments

both samples of aerosol-forming compounds are analyzed according to several

European Standard Methods. The data before – and after activation are obtained by

analyzing the original compound and the formed residues. The transport of

particulates and gasses are calculated(1) in accordance with their model - and actual

chemical reactions based on the used original fire extinguishing compound and their

formed residual products.

(1) A special spreadsheet for chemical calculations on all different fire extinguishing

compounds before - and after activation at a temperature of 300°C can be used to

fulfil requirements on the formed products in relation to safety, corrosion - and

toxicological purposes.

2.26

Packaging, preservation, storage and identification

The packaging shall be appropriate for the application. If special preservation

measures are required then these shall be stated in the application instructions and on

the packaging identification label. In view of the preservation requirements the

storage shall be in accordance with the application instructions.

The identification on the container and/or packaging shall clearly provide the

following information:

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 17 -

BRL-K23001/04

July, 1st, 2010

Generator

X

X

X

X

X

Packaging

X

X

X

X

X

X

Marking

Manufacturer

Supplier’s address and telephone number

Supplier’s type designation

Reference to the application instructions*

Certification mark

Year and month of manufacturing and batch

number

Number of items

Fire Class to EN2

*The application instructions shall describe the scope of application, fire

extinguishing capacity, discharge length and temperature decay and the surface

temperature during fire extinguishing action.

2.27

Marking

The requirements for the marking of the aerosol generator and system are described

in CEN/TR 15276-1, paragraph 5.17.

2.28

Certification mark

The following marks and indications must be provided on each product and product

packaging in a clear, legible and indelible way.

The Kiwa certification mark to be applied to certified products shall be as shown

below, with the legend “BRL K23001”.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 18 -

BRL-K23001/04

July, 1st, 2010

3 Quality system requirements

3.1

General

This chapter contains the requirements that have to be fulfilled by the manufacturer’s

quality system.

3.2

Manager of the quality system

Within the manufacturer’s organisational structure an employee must be appointed

who is in charge of managing the quality system.

3.2.1

Requirements concerning other verification personnel

Function

Production manager

Education

Higher professional qualification in one of the

following disciplines:

•

Technical

Experience

1 year

Laboratory manager

Higher professional qualification in one of the

following disciplines:

•

Chemistry or comparable

1 year

The education and experience of relevant personnel shall be verifiably documented.

3.3

Internal quality control / quality plan

As part of the quality system the manufacturer must implement an internal quality

control schedule (IQC-scheme).

In this IQC-scheme the following must be demonstrably recorded:

• Which aspects are inspected by the manufacturer;

• According to which methods these inspections are carried out;

• How often these inspections are carried out;

• How the inspection results are registered and stored.

This IQC-schedule shall be in the format as shown in the annex. The schedule must

be detailed in such a way that it provides Kiwa sufficient confidence that

requirements will be continuously fulfilled.

3.4

Procedures and work instructions

The manufacturer must be able to submit:

• Procedures for:

o the handling of non-conforming products;

o corrective actions in case non-conformities are found;

o the handling of complaints regarding the products and / or services supplied;

• The work instructions and inspection sheets in use.

• Instructions for packaging and closing off of products during storage and

transport.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 19 -

BRL-K23001/04

July, 1st, 2010

3.5

Other Quality system requirements

The supplier (manufacturer) shall have an operative quality system based on ENISO9001.

3.6

Storage and handling

The storage and handling of the fire extinguishing agent shall be dry and protected

against the weather and the storage temperature and maximum relative humidity

shall be as specified by the supplier.

3.7

Receiving inspection SFEA

The chemical composition shall be determined during the type tests and be recorded

by Kiwa and the supplier. Every delivery of SFEA ingredients shall be accompanied

by delivery certificates issued by the supplier to demonstrate that the composition

meets the specifications. The delivery certificates shall be based on laboratory

analysis of the composition of each production batch of the SFEA. The receiving

inspection of the SFEA shall be carried out for each received delivery. The results

shall be determined through laboratory analysis.

3.8

Process control of production batches

The performance of completed product shall be tested using random samples. The

statistical process control shall be based on a defined sampling system with an

accepted level of quality to ISO2854. The minimum sample size shall be inspection

level S2 and the accepted quality level AQL 6.5.

3.8.1

Activation and discharge mechanism

The reliable operation of the activation and discharge mechanism and its initiation

shall be statistically demonstrated by multiple functional tests.

These tests shall clearly indicate the likelihood of failure, completeness of the

discharge and discharge quantity. This data shall be included in the statistical process

control for the completed products. This shall be governed by a test similar to that

described in section 2.2, 2.3 or 2.19.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 20 -

BRL-K23001/04

July, 1st, 2010

4 Summary of tests, audits and inspections

4.1

General

This chapter contains a summary of tests and inspections to be carried out during:

Initial evaluation: the investigation necessary in order to determine whether all

requirements of the evaluation guideline are fulfilled;

Inspection visit: the surveillances are carried out after issue of the certificate in order

to determine whether the certified products continuously fulfil the requirements of

this evaluation guideline. The surveillance audits and inspections are carried out

according to the frequency indicated;

Audit of the quality system: audit with regard to the correct implementation of the

IQC-schedule and procedures. The surveillance audits and inspections are carried out

according to the frequency indicated.

4.2

Assessment matrix

The initial evaluation (IE) consists out type tests (TT) of the product to determine if it

meets the relevant performance and product requirements. The matrix identifies the

requirements to be fulfilled to be eligible for certification. During the initial audit it is

also verified if the quality system of the product’s manufacturer meets the

requirements.

Requirement

BRL

chapter

Assessment for

Initial

Surveillance by Kiwa after issue of

Evaluation the certificate

+

Type Test

Audit & Inspection

Type Test

frequency

frequency

Fire extinguishing performance of the fire

2

extinguishing component

Complete activation/discharge (electrical or

2

thermo cord) of the fire extinguishing component

All further requirements

2

IE + TT

1/year

IE + TT

1/year

IE + TT

Product requirements

Installation and application manual

Packaging, preservation, storage, identification

Certification mark

3.3.1

3.3.2

3.3.3

IE

IE

IE

1/year

1/year

1/year

Quality system

4

IE

2/year

Once the certificate has been granted it shall be verified regularly if the manufactured

products continue to meet the relevant performance and product requirements,

which will require further type tests.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 21 -

BRL-K23001/04

July, 1st, 2010

There shall be regular audits to determine if the quality system of the manufacturer of

the products is still complying and if the product continues to be manufactured in

accordance with the specifications used for the initial tests.

4.3

Design modifications

Design modifications to the certified product shall always be notified to Kiwa before

being introduced in the production process. Kiwa shall assess to what extent the

design modifications will require new type tests of the product. The modified

product may only be supplied with the Kiwa mark after written approval by Kiwa of

the new product.

4.4

Verification of the quality system

The verification of the quality system can be demonstrated by production of a

certificate issued by an accredited certification body covered by EAC accreditation.

The tests and audits shall be carried out in accordance with the assessment matrix of

this Evaluation Guideline. The audit frequency is 2/year.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 22 -

BRL-K23001/04

July, 1st, 2010

5 Agreements on the performance of

certification

5.1

General

This chapter contains the by the Board of Experts elaborated agreements on the

performance of certification by Kiwa.

Furthermore are the general agreements on the performance of certification

applicable as laid down in the Kiwa-Regulations for Product Certification.

This includes in special the:

• The general procedures for execution of the pre-certification evaluation such as:

o The process in which the suppliers are informed about the handling of the

application for certification;

o The execution of the assessment;

o The decision based on the execution of the evaluation

• The general procedures for the execution of the audits and inspections and the

aspects for the evaluation;

• The sanctions by the certification body when non-conformities are found during

the audits and inspections;

• The sanctions by the certification body when improper use of the Product

Certificate, the Certification Mark, Pictograms and Logo’s.

• The procedures at whit drawing a Product Certificate;

• The possibility of an appeal lodged with the Board of Appeal against a decision

or measure taken by Kiwa.

5.2

Certification staff

The staff involved in the certification process is sub-divided into:

• Certification engineers: in charge of carrying out the pre-certification tests and

assessing the reports of the auditors / inspectors;

• Inspectors / auditor : in charge of carrying out external inspections / audits at the

supplier’s works;

• Decision-makers: in charge of taking decisions in connection with the precertification tests performed, continuing the certification in connection with the

inspections performed and taking decisions with regard to corrective actions.

5.2.1

General Qualification of certification staff

The qualification certification staff must meet the requirements of chapter 5 of

En45011. The quality system of Kiwa describes the procedures for general and

specific qualification of certification staff.

5.2.2

Specific Qualification of certification of staff

The Board of Experts has defined the following qualification requirements for the

scope of this Evaluation Guideline:

Certification personnel

Certification expert

Education

Higher professional qualification in one of the

following disciplines:

•

Chemistry, electrical engineering, mechanical

engineering or similar

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 23 -

Experience

3 years

BRL-K23001/04

July, 1st, 2010

•

•

•

Internal training in certification and Kiwa policies

Audit training

(Fire) Safety education or equivalent

Inspector / auditor

Senior secondary vocational education qualification in

one of the following disciplines:

•

Chemistry, electrical engineering, mechanical

engineering or similar

•

Internal training in certification and Kiwa policies

•

Audit training

•

(Fire) Safety education or equivalent

3 years

Decision-maker

Higher professional qualification in one of the

following disciplines:

•

Chemistry, electrical engineering, mechanical

engineering or similar

•

Internal training in certification and Kiwa policies

•

Audit training

5 years

Management

experience

The education and experience of relevant certification personnel shall be

adequately documented.

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 24 -

BRL-K23001/04

July, 1st, 2010

6 List of mentioned documents

6.1

Rules by public law

There is no legislation pertinent to this product.

6.2

Standards

Following standards are used in this evaluation guideline.

Standard

NEN-EN2

Subject

NEN-EN2: Classification of fires

Data

2004

EN13823

Single Burning Item test procedure

2002

UL2127

UL2127, Standard for Inert Gas Clean Agent Extinguishing

1999

System Units, first edition, March 31, 1999

Sampling procedures for inspection by attributes – Part 1:

1999

sampling schemes indexed by acceptance quality limit (AQL) for

lot-by-lot inspection

Technical corrigendum

2001

ISO2859

ISO2859

CEN/TR 15276-1

MSC.1/Circ.1270

NEN-ISO11014-1

ISO9001

UL 2775

Fixed fire fighting systems - Condensed aerosol extinguishing

systems - Part 1: Requirements and test methods for components

Revised Guidelines for the approval of fixed aerosol fire

extinguishing systems equivalent to fixed gas fire extinguishing

systems, as referred to in SOLAS 74, for machinery spaces

Safety data sheet for chemical products. Part 1: Content and

order of sections

Quality management systems - Requirements

Outline of Investigation for fixed condensed aerosol

extinguishing system units

Evaluation Guideline for aerosol fire extinguishing

© Kiwa Nederland B.V.

- 25 -

BRL-K23001/04

July, 1st, 2010

2009

2008

2009

2008

2008

I Model certificate

Product certificate

KXXXXXX/0X

Issued

Replaces

Page

1 of 2

Aerosol fire extinguishing

STATEMENT BY KIWA

With this product certificate, issued in accordance with the Kiwa

Regulations for Product Certification, Kiwa declares that legitimate

confidence exists that the products supplied by

Name Supplier

complying with the technical specifications as laid down in this product

certificate and marked with the Kiwa®-mark in the manner as indicated in

this product certificate, on delivery, may be relied upon to comply with the

Kiwa evaluation guideline BRL-K23001 “Kiwa product certificate for fixed

dry aerosol fire extinguishing components”.

Kiwa N.V.

ing. B. Meekma

director

Publication of the certificate is allowed.

Advice: consult www.kiwa.nl in order to ensure that this certificate is still

valid

Kiwa N.V.

Sir W. Churchill-laan 273

Postbus 70

2280 AB RIJSWIJK

The Netherlands

Tel. +31 70 414 44 00

Fax +31 70 414 44 20

E-mail info@kiwa.nl

www.kiwa.nl

Supplier

Certification process

consist of initial and

regular inspection of:

• quality system

• product

•

Kiwa® product certificate

Aerosol fire extinguishing

Product specification

The products mentioned below belong to this certificate

Application and use

Marking

The Kiwa®-mark products are marked with the wordmark “KIWA

Place of the mark:

Compulsory specifications:

xxx

Method of marking:

•

Non-erasable;

•

visible after assembly

RECOMMENDATIONS FOR CUSTOMERS

Check at the time of delivery whether:

-

the producer has delivered in accordance with the agreement;

the mark and the marking method are correct;

the products show no visible defects as a result of transport etc.

If you should reject a product on the basis of the above, please contact:

and, if necessary,

-

Kiwa N.V.

Consult the producer's processing guidelines for the proper storage and transport methods.

KXXXXX/0X

II Model IQC-scheme

Subjects

Raw materials or materials

supplied:

•

Recipe sheets

•

Incoming inspection raw

materials

Production process,

production equipment,

material:

•

procedures

•

work instructions

•

equipment

•

release of product

Finished-products

Measuring and testing

equipment

•

measuring equipment

•

calibration

Logistics

•

internal transport

•

storage

•

preservation

•

packaging

•

identification or marking

of semi finished and

finished products

Aspects

Method

Frequency

Registration

III Additional information test procedure

The fixed fire extinguishing components based on a dry aerosol shall effectively

extinguish objects of the relevant fire class. A further requirement is that the fire

extinguishing components are connected to and initiated by an effective fire detection

system. A fast detection and response are essential. Effective extinguishment means

that the object to be extinguished is no longer burning after the test and does not

reignite later. To provide a correlation between the extinguishing performance of fire

extinguishing components and the fire classes referred to in the scope, the fire

extinguishing components are tested for each fire class requested by the supplier for

the certification assessment.

The tests are undertaken using the aerosol for which the supplier wants to receive a

certificate. During the tests the supplier’s design formula for the use of his fixed fire

extinguishing components is also verified. The formula used by the supplier shall

incorporate:

• the dimensions of the room containing the object to be extinguished and the

length, width and height ratios;

• aerosol dispersal factor;

• the amount of fire extinguishing agent, expressed as grams of agent per m3

room.

The test is carried out in a substantially sealed room. Doors and windows shall be

closed. However, a limited area of ventilation grids may be present. Any forced

ventilation systems shall be shut down. The test shall be based on the exact

arithmetical calculation of the number of grams per volume unit as this governs the

value stated in the certificate. There shall be no physical obstructions in the room. The

additional safety factors (1.2 or 1.3) required under the NFPA guidelines for project

design shall not be used when testing the fire extinguishing performance and design

formula. The design formula shall allow for the quantity of remaining fire

extinguishing agent in the cooling effect of the fire extinguishing component. When

testing Class B fires the operation of the fire extinguishing agent in relation to its

dispersal shall be tested more extensively.

The test of the fire extinguishing effect shall be made under the following conditions.

Function

Fire class

Assessment method to EN2 and

BS7937

Thermal energy/power

Burning time due to catalyst

Catalyst

Performance

A, B, C, F

See fire extinguishing test object

See fire extinguishing test object

Heptane to Table 34.2 UL2127 for

Class A

60 ± 20

Relative humidity in the room, before

the fire, measured with a hygrometer

Ambient temperature before the fire, 15 ± 10

determined by a thermocouple

immediately outside the room with

∆T 10 sec recording using a data

logger

Temperature in the room, determined TBD

using at least 4 thermocouples on the

ceiling with ∆T 10 sec recording using

Unit

Minutes

%

°C

°C

a data logger

Dimensions of the test room

Length at least 4 * Width at least 4 *

Height at least 3.5

Volume at least 100

For F and section 2.2.6 volume at

least 80

Ventilation during the fire time, using Adequate ventilation, i.e. 20.7% O2 ±

constant measurement

0.5% O2

Ventilation area and position during

0.1% of the volume of the room,

extinguishing

distributed evenly across the room

Air flow through the room

Natural

Closing of the test room after igniting 30

the fire

Required amount of fire extinguishing Supplier’s design formula

agent according to the formula

Extinguishing time

60

Monitoring time

600 for Class A, B and C.

1800 for Class F

Agent discharge

Direction and homogeneity

Weight of agent to determine

Before and after extinguishing

percentage of agent discharged

Activation

Supplier’s system

m and m3

% O2

m2

S

g/m3

S

S

Visual

G

Ventilation area during extinguishing = 0.1% (e.g.: 1000 m3 = 1 m2 and 100 m3

= 0.1 m2)

Additional registrations during the test, in seconds:

• Time of activation of the heptane.

• Time of activation of the plastic.

• Time of initial activation of the fire extinguishing components.

• End time of the activation of the aerosol.

• Time at which the flames are extinguished.

There shall be adequate ventilation during the burning time and the oxygen

concentration in the test room shall be maintained. If this cannot be guaranteed then

during the activation the oxygen percentage at the level of the source of fuel shall not

deviate more than 0.5 vol% from the normal percentage under ambient conditions

and the oxygen percentage shall be measured with a calibrated oxygen gauge using a

sensor at the same level as the source of fuel.

6.3

Extinguishing EN2, Class A, fires solids materials

The solid fire extinguishing agent shall meet both determinations for Class A.

6.3.1

Extinguishing object, plastics

Each plastic fire cell consists of 4 plastic panels with a thickness of 1 cm, length of 40

cm and width of 20 cm. The panels are positioned as shown in Figure 34.1 of UL2127.

The base of the plastic fire cell is positioned 20 cm above the floor and the panels are

mechanically joined to each other. A steel fire shield with plates on two sides and at

the top is placed around the fire cell as shown in Figure 34.1 of UL2127. The steel fire

shield is 38 cm wide, 85.1 cm high and 61 cm deep. The other sides and the base are

open. The fire cell is positioned such that the 20 cm side of the fire cell runs parallel to

the 61 cm side of the fire shield.

Two external baffles, 1 m2 and 30 cm in size shall be fixed externally to the fire shields

as shown in Figure 34.2 of UL2127. The baffles shall be placed 9 cm above the floor.

The low baffle shall be positioned with its side parallel to the fire shield and the top

baffle shall be turned 45° relative to the low baffle.

The fire extinguishing components shall be suspended above the fire cell in

accordance with the supplier’s specifications and distributed as specified by the

supplier. The fire cell shall be placed at the edge of the radius of the design

extinguishing area.

The test shall be carried out using two plastic fuels: polymethylmethacrylate (PMMA)

and polypropylene (PP). The properties of these materials are defined in Table 34.1

of UL2127. The source of activation shall be a square pan of 5.1 x 5.1 cm, with a depth

of 2.2 cm, filled with heptane. The pan shall be centred 1.3 cm below the bottom of

the plastic panels. The volume of heptane shall provide a burning time of at least 90

seconds.

The pan with heptane shall be ignited and the panels shall have a total free burning

time of 210 seconds. After the end of the activation of the fire extinguishing agent the

room shall remain closed for at least 10 minutes. During this period the cell shall be

monitored for signs of active fire and signs of spontaneous activation, based on the

temperature measurements in the vicinity of the fire cell. After this period the cell

shall be inspected visually for signs of active fire and signs of spontaneous activation

outside the test room and without the presence of the fire extinguishing agent. Any

signs of fire shall be described in the report. The loss of weight and temperature after

extinguishing shall be decisive. Visible fire is considered as a sign of spontaneous

activation, but solely smoke is not.

6.3.2

Extinguishing object, multilayer wood with / without plastics

Each fire cell consists of compressed wood panels, i.e.:

• Particleboard with a plastic facing on both sides (furniture panel) with a

burning time of 6 minutes using a catalyst.

• MDF panel with a burning time of 6 minutes using a catalyst.

• Plywood panel with a burning time of 6 minutes using a catalyst.

Specifications of these panels;

• Particleboard to ISO17064; 2004 “Wood-based panels - Fibreboard,

particleboard and oriented strand board” and NEN-EN312; 2003

“Particleboards - Specifications”.

• MDF to ISO17064; 2004 “Wood-based panels - Fibreboard, particleboard and

oriented strand board” and NEN-EN316; 1999 “Wood fibreboards Definition, classification and symbols”.

• Plywood to ISO17064; 2004 “Wood-based panels - Fibreboard, particleboard

and oriented strand board” and draft NEN-EN14755; 2003 “Extruded

particleboards - Specifications”.

The dimensions of the panels are approx. 2 cm thick, 40 cm long and 20 cm wide. The

panels are positioned as shown in Figure 34.1 of UL2127. The base of the plastic fire

cell is positioned 20 cm above the floor and the panels are mechanically joined to each

other. A steel fire shield with plates on two sides and at the top is placed around the

fire cell as shown in Figure 34.1 of UL2127. The steel fire shield is 38 cm wide, 85.1 cm

high and 61 cm deep. The other sides and the base are open. The fire cell is positioned

such that the 20 cm side of the fire cell runs parallel to the 61 cm side of the fire

shield.

Two external baffles, 1 m2 and 30 cm in size shall be fixed externally to the fire shields

as shown in Figure 34.2 of UL2127. The baffles shall be placed 9 cm above the floor.

The low baffle shall be positioned with its side parallel to the fire shield and the top

baffle shall be turned 45° relative to the low baffle.

The fire extinguishing components shall be suspended above the fire cell in

accordance with the supplier’s specifications and distributed as specified by the

supplier. The fire cell shall be placed at the edge of the radius of the design

extinguishing area.

The test shall be carried out using two plastic fuels: polymethylmethacrylate (PMMA)

and polypropylene (PP). The properties of these materials are defined in Table 34.1

of UL2127. The source of activation shall be a square pan of 5.1 x 5.1 cm, with a depth

of 2.2 cm, filled with heptane. The pan shall be centred 1.3 cm below the bottom of

the plastic panels. The volume of heptane shall provide a burning time of at least 90

seconds.

After the end of the activation of the fire extinguishing agent the room shall remain

closed for at least 10 minutes. During this period the cell shall be monitored for signs

of active fire and signs of spontaneous activation, based on the temperature

measurements in the vicinity of the fire cell. After this period the cell shall be

inspected visually for signs of active fire and signs of active activation outside the test

room without the presence of the fire extinguishing agent. Any signs of fire shall be

described in the report. The loss of weight and temperature after extinguishing shall

be decisive. Visible fire is considered as a sign of spontaneous activation, but solely

smoke is not.

6.4

Extinguishing EN2, Class B, fires liquid materials

The solid fire extinguishing agent shall meet both determinations for Class B

6.4.1

Extinguishing object, liquid fires - test room 100 m3

This test shall be performed according to annex A5 of CEN/TR 15276-1.

The fire extinguishing components shall be suspended above the fire cell in

accordance with the supplier’s specifications and distributed as specified by the

supplier. The fire cell shall be placed at the edge of the radius of the design

extinguishing area.

For each test the heptane shall be ignited and have a free burning time of 30 seconds.

After the end of the activation of the fire extinguishing agent the room shall remain

closed for at least 10 minutes. During this period the cell shall be monitored for signs

of active fire and signs of spontaneous activation, based on the temperature

measurements in the vicinity of the fire cell.

After this period the cell shall be inspected visually for signs of active fire and signs

of active activation outside the test room without the presence of the fire

extinguishing agent. Any signs of fire shall be described in the report. The

temperature after extinguishing shall be decisive.

Visible fire is considered as a sign of spontaneous activation, but solely smoke is not.

The source of activation shall be a square pan 5.1 x 5.1 cm, 2.2 cm deep, filled with

heptane. The heptane shall have a burning time of at least 90 seconds.

6.5

Complete activation and discharge of the SFEA (electrical)

The performance requirement for the complete activation and discharge of the SFEA

(electrical) from the fire extinguishing component is determined following.

After activation by the electrical activator no less than the design quantity of SFEA

shall be discharged from the container through the discharge port provided, with a

tolerance of -15%. This determination shall be carried in triplicate for each component

to provide reliable discharge data.

Assessment method

Weigh the fire extinguishing component to 0.1% before assembly. The electrical

activator in the container is activated at ambient temperature. After activation all the

SFEA stated by the supplier shall be discharged, with a maximum tolerance of -5%.

The electrical activator shall be initiated electrically using the minimum specifications

(Volt, Ampere) stated by the supplier, with a tolerance of 5%. This shall be measured

with a Class 1.5 VA meter. After activation, the amount of fire extinguishing agent

discharged shall be determined by weighing and it shall be verified visually if this

occurred homogeneously through the discharge port provided. This may be done by

determining if the container exhibits any cracks or punctures.

6.6

Thermal aging of the SFEA and electrical activator

The performance requirement for the thermal aging of the SFEA is determined

following.

The product (SFEA and discharge system) must have a design lifespan of 15 years if

stored in a dry, non corrosive environment.

Assessment method

The lifespan is determined by thermal aging. The assembly comprising the

extinguishing agent and activator is tested in its original container. The container is

placed in a temperature controlled room in which the temperature can be cycled

(aging cabinet). The following test is then undertaken.

The aging cabinet is set to -10 °C and 50 °C (± 2 °C) and alternates between these

temperatures every 4 hours. Once cycle amounts to a full transition from -10 °C to 50

°C, and then back to -10 °C within 8 hours. Fifty cycles are completed, after which the

fire extinguishing performance of the agent is determined in accordance with section

2.2.1.5.

Note:

This test is used for several materials of construction. The stability of the molecular

structure of the material is tested by the temperature cycles. During each cycle the

material passes the dew point which will lead to condensation on the exterior of the

object. During the cold period this may lead to freezing in hairline cracks in the

material which may affect the structure of the material. In use the components are not

exposed to rain, i.e. they are not exposed to a full water load, but they may be

affected by condensation, which is simulated by this test. This thermal aging method

is adopted in several standards to obtain information about the long-term behaviour

of materials in the short term. The effect of this on the fire extinguishing performance

is realistic and functional.