Dimensioning, Selection and Designs of Plug-and-Socket

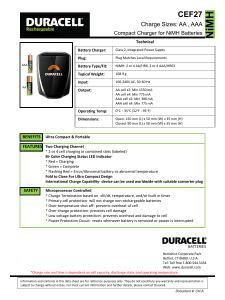

advertisement

Fachverband Batterien Postfach 70 12 61 60591 Frankfurt am Main Lyoner Straße 9 60528 Frankfurt am Main Tel.: (0 69) 63 02-209 Fax: (0 69) 63 02-488 e-mail: batterien@zvei.org Information Leaflet Dimensioning, Selection and Designs of Plug-and-Socket Devices and Connecting Cables for Traction Batteries and Battery Chargers A General Information When selecting plug-and-socket devices and connecting cable in: electrical industrial trucks <–> traction batteries <–> battery charger systems it is important to make sure that – plugs are correctly and uniformly selected – they have the necessary cable cross-sections and – the cables have the correct lengths. Please use the check-list (under Point C 9) for the selection. B Dimensioning Cable Cross-Sections and Lengths 1. Traction Batteries The cross-sections of the battery terminal connectors are dimensioned to prevent excessive heating based on the battery operating current I2 [A] = 0.8 x C5 [Ah] / 2h (equals 40 A per 100 Ah C5). These have to be the largest calculated cross section. As an alternative, the length of the terminal connectors can be given as the proximity dimension L to the outside edge of the tray which requires a sketch (refer to the example below). This applies to standard lengths up to 1.5 m. Larger cross-sections are necessary if longer terminal connectors are used. Cable lengths may differ for positive and negative terminal connectors and they should be given separately. Only one cable cross-section has to be used even with varying cable lengths. This leaflet was prepared by the Working Group „Industry Technique“ of the Product Division „Industrial Batteries“ of the German Electrical and Electronic Manufacturer’s Association, ZVEI. (Revised Edition August 2009). 1 For example: 24 V Circuit A 2. Battery Chargers Each manufacturer designs its own cross-sections for the charging cables depending upon the rated current for the equipment. The standard length for the charging cables is approximately 3 m. The cross-sections should be adjust-ed correspondingly if longer charging cables are needed to compensate for the higher voltage drop. Battery chargers with programmable cable lengths do not have to increase the crosssection. Adjusting the cross-section may change the size of the plug-andsocket device (refer to Table 1). The cross-section should be adapted in accordance with the cable calculated for direct current. A = 2.L.I κ . Ua A = cable cross-section in mm2 L = single cable length in m I = current in Ampere (the battery charger rated current) Ua = voltage drop in V κ = specific conductivity in m 2 (for copper = 56 Ω . mm For simplification, we recommend an increase in the cable cross-section corresponding to the ratio of the cable length (Lnew : Lstandard). Lnew [m] Lstandard [m] Anew [mm2] = Astandard . Anew = minimum cross-section needed with extended charging cables Example calculation: standard charging cables 3m extended charging cables (new) 5 m Anew = 25 mm2 . . mm2 5 25 . = 41,66 m2 selected: 50 mm2 3 Comment: Always round up the calculated value! If it is not possible to increase the cross-section, clarify if the characteristic values of the battery charger can be adapted. 2 m 2) Ω . mm 3. Electrical Industrial Trucks The cross-sections of the connecting cable of electrical industrial trucks are defined as applying rated motor currents. C Dimensioning and Designing Plug-andSocket Devices 1. The Socket Device and Plug Device in Conformity with DIN 43 589-1 With these plug-and-socket devices: – the socket device with female contacts is mounted on the battery – the plug device with male contacts is mounted on the battery charger 3 plug and socket designs are defined for rated currents 80, 160 and 320 A in conformity with DIN 43 589-1 (Equipment Plugand-Socket Devices 80, 160, 320 A, 150 V for Electrical Industrial Trucks). Plug-and-socket devices have to satisfy requirements and pass tests in conformity with DIN EN 1175-1 including Appendix A. The plug housing, contacts and cable terminal points have to be dimensionally stable and the plug housing materials have to be resistant to acid for a permanently safe plug-and-socket connection. The rated current is the current in A that the plug-in contacts can conduct permanently without exceeding the maximum acceptable temperature increase in permanent DC operation of 65 K. – the plug device with male contacts is mounted in the electrical industrial truck In addition to these standardised plug-and-socket devices, there are also designs with flat contacts where there is no differentiation made between the plug and socket. These designs call for additional coding to define the plug and socket component. High current plug-and-socket devices: These higher currents can cause higher surface temperatures on the housings of plug-and-socket devices. If these plug-and-socket devices are used to conduct currents higher than the standard rated currents, please make sure that all 3 system plugs (electrical industrial truck / battery / battery chargers) have identical permissible current load. The cable cross sections have to be adapted accordingly and cable insulation have to meet higher temperatures. The plug device of the electrical industrial truck or battery charger defines the current load and should be coded accordingly. If the plug device is used for higher currents, a connection with a standard socket device must be prevented. In contrast, a high current-socket device can be equipped with a standard plug device. Plug manufacturers have approved new plug-and-socket devices for rated currents higher than 80, 160 or 320 A if other housing materials and/or special contact materials and/or solid extruded connecting cables are used. For example: 2. Rated Current and Rated Voltage of the Plug-andSocket Device plug-and-socket device (standard size) higher rated current 2.1 The Rated Current The system plug-and-socket device should be selected according to the maximum rated current for the electrical industrial truck or of the battery charger. 80 A 160 A 320 A 120 A 250 A 400 A 3 Example: Coding pins for high current plug-and-socket devices for batteries with liquid electrolytes, flooded Coding pin for plug device (electrical industrial truck/charger) Coding pin for socket device (battery) These special coding pins which prevent standard plug devices and high current plug devices from being plugged together are not yet available for all plug products. If coding is not possible, we urgently recommend just selecting the standard rated currents. Always follow the rules of electrical industrial truck manufacturers, especially when replacing a system plug-and-socket device. Special plug and socket devices should be used for higher voltages. 3. Rated Cross-Section of the Cable Terminals DIN 43 589-1 states that the following rated cross-sections of the cable terminals are available with the 3 plug-and-socket device sizes (Table 1). The connecting cables should be crimped according to the recommendation of the plug manufacturer. Reduced bushings can be used if it has to be adjusted to the next smaller cross-section, although reducing bushes inserted into one another should not be used for technical reasons. Reduced bushings are generally not allowed with high current plug-and-socket devices. Reducing of cross-sections in cables is not permitted. 2.2 The Rated Voltage of the Plug-and-Socket Device Do not observe only the rated currents, but also the maximum acceptable voltages. Standard plug-and-socket devices in conformity with DIN 43 589-1 are designed for a maximum direct voltage of 150 V. Since this rated voltage has to be based on the maximum charging voltage, this equals a maximum battery rated voltage of 96 V. Table 1 rated cross-section mm2 2,5 10 16 25 35 50 70 95 for the plug-and-socket device / type safety disconnect and auxiliary contacts 80 A * 80 A, 160 A * 80 A, 160 A * 160 A 160 A, 320 A * 320 A 320 A * Continuous current limited by the cable cross-section 4 4. Coding Each plug-and-socket device has to have coding equipment which guarantees that a plug device can only be inserted into an socket device of the same operating voltage. There are only some coding pins available with additional current coding that keeps standard plugand-socket devices and high current plug-and-socket devices from being plugged together (refer to Point C 2.1). Different coding exists for correctly selecting battery chargers to battery technology with liquid (flooded) or fixed electrolytes (VRLA / dry). Example: Coding system for a rated operating voltage 24 V 5 Table of potential coding pin combinations Table 2 coding pin battery coding pin battery charger coding pin electrical industrial truck HS N U T T U N N U HS HS U HS HS HS HS N HS HS N T U = = = = high current design battery, flooded battery, dry electrical industrial truck, universal 5. Safety Disconnect and Auxiliary Contacts auxiliary contacts An option is to equip the plugand-socket devices with safety disconnect and/or auxiliary contacts. Safety disconnect contacts are used to switch off the charging current before the main contacts of the plug are completely disconnected from the battery charger if the plug-and-socket device (battery charger) is not correctly handled. The prerequisite for this safety function is that the battery charger has the optional equipment of a safety disconnect contact control. At the battery socket device the safety disconnect contacts are short-circuited. Auxiliary contacts are used for tapping auxiliary voltages (partial voltages) from the battery. 6 pilot contacts / air adapter Important comment: If a 2-channel air adapter is mounted as optional equipment for air agitation instead of safety disconnect contacts (refer to Point C 6.), the safety disconnect control can be implemented via the auxiliary contacts. If the safety disconnect contacts are used for safety disconnect control for the battery charger and the auxiliary contacts are used to pick off auxiliary voltage, the air agitation can only be supplied with separate air coupling. 6. Air Supply System for Batteries with Air Agitation Example: air adapter for air agitation Some plug-and-socket devices can be equipped with optional 2-channel air adapters at the position of the safety disconnect contacts for traction batteries with air agitation. The air supply system designs are manufacturer-specific so that the plug-andsocket devices may not be compatible. 7. Optional Combinations These designs allow the following combinations: – plug device / socket device – plug device / socket device with safety disconnect contacts – plug device / socket device with air adapter – plug device / socket device with air adapter and auxiliary contacts – equipment plug / equipment socket with safety disconnect contacts and with auxiliary contacts 8. References to Standards DIN EN 1175-1; VDE 0117 Part 1, Safety of industrial trucks – Electrical requirements DIN EN 50272-3; VDE 0510 Part 3, Safety requirements for secondary batteries and battery installations – Traction batteries DIN EN 60204-1; VDE 0113 Part 1, Safety of machineryElectrical equipment of machines – General requirements DIN 43531; 43535; 43536, Bleiakkumulatoren – Antriebsbatterien 48V; 24V; 80V mit Zellen Maßreihe L für Flurförderzeuge DIN 43537, Bleiakkumulatoren – Antriebsbatterien 24V, 36V, 48V, 80V mit Zellen Maßreihe E für Flurförderzeuge DIN 43589-1, Geräte – Steckvorrichtungen 80A, 160A, 320A, 150V für Elektro-Flurförderzeuge 7 9. Check-List for defining Plug-and-Socket devices and connecting cables 1. Electrical Industrial Trucks (plug device with male contacts) information required for ordering 2. rated current cable cross-section plug model and product coding Urated ** option ………. A ………. mm² ………. A / ………. ………. V HS Battery (socket device with female contacts) information required for ordering *** battery capacity length of terminal cable cable crosssection plug model and product ….. Ah pos. … m neg. … m ….. mm² ………. A / ………. 3. coding ** option flooded dry Urated HS PK* HK* EUW* G Z .... V Charger (plug device with male contacts) information required for ordering rated current for charger length of charging cable cable crosssection plug model and product ….. A ..… m ….. mm² ………. A / ………. HS = PK = HK = EUW = G = Z = coding ** option flooded dry Urated HS PK* HK* EUW* G Z .... V high current design safety disconnect contact assignment auxiliary contact assignment air adapter for air agitation plug-and-socket device with grip strain relief (standard with DIN plugs) * If an optional air adapter is needed for air agitation (mounted at the position of the safety disconnect contact) and safety disconnect control is needed, the safety disconnect control can be implemented via the auxiliary contacts. Important: This configuration has to be designed uniformly with the battery socket device and battery charger plug device. ** Also refer to Table 2 for the coding pin combination *** More information is needed on the cable type and battery connection design if the complete battery terminal connectors are ordered separately. Important comments: I) plug type + coding (Urated): has to be identical with the industrial truck, battery and battery charger. II) plug type + plug product + coding (Urated): has to be identical with the EUW option with the industrial truck, battery and battery charger. III) plug type + plug product + coding (Urated): If the industrial truck or battery charger is equipped with an HS plug device, the battery also has to be equipped with an HS socket device. IV) plug type and cable cross-section: They have to be adapted in accordance with the maximum possible rated current of the industrial truck or battery charger. V) cable cross-section battery connecting cable: If the cable cross-section battery charger and/or industrial truck < battery connecting cable, it is not necessary to adapt it. If the cable cross-section battery charger and/or industrial truck > battery connecting cable, then it is necessary to adapt to the maximum. VI) cable type: 8 satisfies the requirements of DIN EN 50272-3 / VDE 0510, Part 3.