Instructions

advertisement

Tools Needed For Assembly Of Upweller Pump

L

Z

3

4

5

6

7

8

9

Ll$"

and 3/16" allen wrenches for impeller

5132" allen wrench for shaft anode

3/L6" allen wrench for gear shaft coupling

7 f L6" wrenches for tube mounting bolts, motor frame mount bolts, and motor cover bolts

t/2' wrenches for gear adjustment mount bolts

9/L6" wrenches for water cutlass bearing mount bolts

WD 40 Spray

L/4" andSf t6" drill bits and drill

Jig saw

Link to YouTube Video

www.youtube.com/watch?v=3ndQDoPEOCA

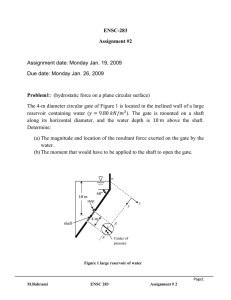

FLUPSY Stondord Length Tonk

Aliqn Motor Frome

With Reor lnside Foce

of Tonk

FLUPSY Long Tonk

Position Motor Frome Support Accordinq To Dimensions Below

Order Of Assembly Of Upweller Pump

1

2

3

4

5

6

7

Remove only nuts and washers from tube trim ring.

Remove bolts from feet on tube.

Position trim ring inside of deep end of tank with flat against bottom and X mark showing.

Center trim ring between sides and just up off of radius at bottom.

Mark and drilltop two holes {at 10:00 and 2:00 o-clock with%" drill bit}.

Position trim ring on outside of tank with X mark towards tank, flat at bottom, on two %,,

bolts thru holes and trace opening (inside of trim ring) and bolt holes from trim ring.

€ut your traced line fcr opening (cutting on outside of line with jig saw) and drilling all bolt

holes with 5/6" drill bit.

8

lnsert tube in tank thru opening and bolt holes and install trim ring to outside with X mark

towards tank. Bolt together using flats, locks, and nuts.

9

Drill two %" holes thru feet of tube and bolt using flats and bolts from outside and flats,

locks, and nuts from inside.

10

11

Lz

Lg

L4

15

16

tl

18

lnstall impeller on shaft with stabilizer fins pointing away from shaft, line up long set screw

with hole in shaft and tighten with a 3/!6" allen wrench. Then tighten other two smaller set

screws with a 1/8" allen wrench.

Spray WD4O on water cutlass bearing and end of

shaft. lnsert shaft thru tube and water

cutlass bearing from outside of tank until mark for shaft anode shows in front of water

cutlass bearing. Turn impeller till one blade points straight down and slowty lower shaft.

lnstall shaft anode on marked area of shaft with s/12" allen wrench.

Remove motor cover from motor frame {seven %" bolts}.

Remove six %" bolts from motor frame ends that hold the motor frame adjustable supports

{taking notice of position of backing plates}.

With tank in frame of Flupsy position motor frame adjustable supports on top flange of tank

as per drawing, drill six %" holes, and bolt both supports using flats and bolts from outside

and flats, locks, and nuts from inside tank. lf standard length tank supports go flush with

inside edge of shallow end of tank as pet drawing. lf long tank supports go l2-3l8" from

inside edge of shallow end of tank as per drawing.

Sit motor frame on supports with coupling facing tube and reinstall backing plates with flats

and bolts from underneath and flats, locks, and nuts on top all loosely. Center motor frame

from side to side and tighten all six bolts.

Loosen four 5f t6" gear adjusting bolts (opposite shaft coupling). tnsert shaft into coupling

with one person pivoting and turning motor/ gear and the other person pushing shaft into

coupling fully. Tighten all four allen cap screws {gear side and shaft side) on coupling evenly

until tight with a 3/16" allen wrench.

Without flexlng shaft between gear and water cutlass bearing, fully tighten the four 5/1G,,

gear adjusting bolts that were loosened in the step before. Fully tighten the other three

19

20

2L

22

23

24

25

26

5fL5" gear pivoting bolts (on coupling side of mount). Also fully tighten the three 3/8"

water cutlass bearing pivot bolts at the inside edge of the tube.

lnstall the two pieces of screen to inside edge of tube with tie straps thru holes in edge of

tube (position so they do not touch shaft),

Unwrap motor sealtight from gear by cutting only the tie strap that is around plastic bag,

but leave bag over plug for now. Lay seal tight down to side of coupling.

lnstall motor cover back on to motor frame by making sure that seal tight from motor is

positioned thru cutout to left side of shaft coupling. lnstall and tlghten all seven /r" bolts

with flats from top and flats, locks, and nuts from underneath.

Slide power cord thru slot at bottom of control box.

Feed motor seal tight up thru slot at bottom of control box directly over top of where it

comes out from under motor cover,

Remove cap from socket at bottom of control box by flipping locking clip away from cap.

Remove bag from motor seal tight plug and with screw on side of plug facing down, insert

into socket by wiggling from side to side until fully inserted {die electric grease will ooze

out), then flip the locking clip up against plug.

Push excess seal tight straight into motor cover and tie strap seal tight to power cord right

above power cord restraint ring.

27

Plug power cord in and test.