Modular Spool Gun for MIG Welding Operating

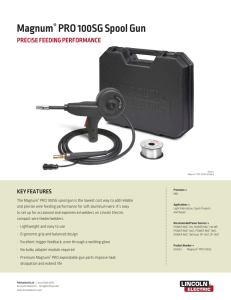

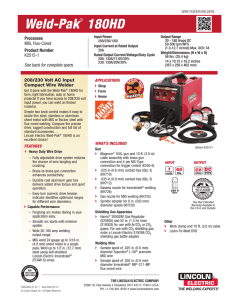

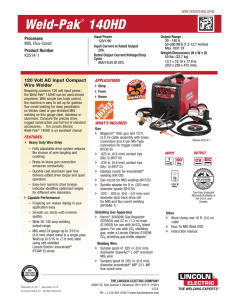

advertisement

Spool Gun Operating and Safety Manual FORM NO. 0056-1867 EFFECTIVE MAY, 2001 IMPORTANT Operating and Safety Instructions Modular Spool Gun for MIG Welding For Your Safety.... PLEASE READ CAREFULLY! 1 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL TABLE OF CONTENTS 1. Introduction .................................................................................................3 2. Safety Instructions ........................................................................................5 3. Product Description ......................................................................................9 4. Installation..................................................................................................10 1. Connecting Spool Gun to Power Source ...........................................10 2. Installing Wire Spool .........................................................................11 3. Wire speed adjustment .....................................................................13 5. Maintenance ..............................................................................................14 1. 2. 3. 4. Controls ............................................................................................14 Changing drive rolls ..........................................................................15 Changing outlet liner ........................................................................16 Troubleshooting Check List ...............................................................17 6. Technical Data Sheet..................................................................................18 7. Electric Connections ...................................................................................19 8. Spare Parts Lists .........................................................................................20 9. Warranty ....................................................................................................23 2 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL The 180 Amp Spool Gun Introduction The Spool Gun is the best solution for situations where the power source can not be brought close enough to your the work. The Firepower Spool Gun is a professional MIG gun suitable for welding carbon steel, stainless steel or aluminum, using solid wire and also for flux cored wire. Wire is driven by a DC electric motor in the gun, wire speed is controlled by an adjustable potentiometer mounted in the base of the gun handle. WARNING: Before attempting to connect, operate or adjust this product, please read this instruction manual completely. Following these instructions carefully will facilitate the use of the spool gun. 3 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL WARNING Introduction This User’s Guide provides pertinent information needed to safely and effectively use your Firepower Spool Gun. It gives instructions on set-up, installation and actual use of your Firepower Spool Gun. Items in this manual that significantly affect safety are identified with the following headings. Please read and understand this manual. Pay special attention to items identified with these headings. Safety Profile WARNING – Means there is a possibility of injury or death to you or others. CAUTION – Means there is the possibility of damage to the Firepower Spool Gun or other property. NOTICE – Indicates point of interest for more efficient and convenient installation or operation. Tradesmen respect the tools and equipment with which they work. They are also aware that tools and equipment are dangerous if used improperly or abused. NOTE: Read this guide prior to using your Spool Gun. It enables you to do a better and safer job. You will also learn the Spool Gun’s application, limitations, and the specific potential hazards peculiar to welding. Read all Safety and Warning Instructions Carefully before attempting to install, operate or service this welding unit. Your failure to comply with the instructions could result in personal injury and/or property damage. Safety Information The following safety information is provided to you as a guideline. Use it to operate your new Firepower Spool Gun under the safest possible conditions. Any equipment that uses electrical power is potentially dangerous to use when the safety or safe handling instructions are not known and/or are not followed. This safety information gives you the necessary information for safe use and operation. IMPORTANT RETAIN THESE INSTRUCTIONS FOR YOUR FUTURE REFERENCE. 4 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL Safety Symbols Familiarize yourself with the warning symbols listed on the following pages. These symbols identify important safety messages in this manual. When you see one of these symbols, be alert to the possibility of personal injury and carefully read the message that follows. Indicates that the possibility of ELECTRIC SHOCK exists during the operation of the step(s) that follow. Indicates that the possibility of FIRE HAZARD exists during the step(s) that follow to protect against eye damage and burns due to flash hazard. Indicates that the HELMET MUST BE WORN during the step(s) that follow to protect against eye damage and burns due to flash hazard. Indicates that the POSSIBILITY OF TOXIC GAS hazard exists during operation of the step(s) that follow. Indicates that the POSSIBILITY OF BEING BURNED by hot slag exists during operation of the step(s) that follow. Indicates that EYE PROTECTION SHOULD BE WORN to protect against flying debris in the following step(s). Indicates that the POSSIBILITY OF INJURY OR DEATH exist due to improper handling and maintenance of compressed gas cylinders or regulators. ELECTRIC SHOCK CAN KILL! Reduce the risk of death or serious injury from shock: Read, understand and follow the following safety instructions. Additionally, make certain that anyone else who uses this welding equipment, or who is a bystander in the welding area, understands and follows these safety instructions as well. 5 FIRE OR EXPLOSION CAN CAUSE DEATH, INJURY AND PROPERTY DAMAGE! Reduce the risk of death, injury or property damage from fire or explosion. Read, understand and follow the following safety instructions. Additionally, make certain that anyone else who uses this welding equipment, or who is a bystander in the welding area, understands and follows these safety instructions as well. Remember, welding by nature produces sparks, hot spatter, molten metal drops, hot slag and hot metal parts that can start fires, burn skin and damage eyes. ARC RAYS CAN INJURE EYES AND BURN SKIN! Reduce the risk of injury from arc rays. Read, understand and follow the following safety instructions. Additionally, make certain that anyone else who uses this welding equipment, or who is a bystander in the welding area, understands and follows these safety instructions as well. FUMES, GASES AND VAPORS CAN CAUSE DISCOMFORT, ILLNESS AND DEATH! Reduce the risk of discomfort, illness or death. Read, understand and follow the following safety instructions. Additionally, make certain that anyone else who uses this welding equipment, or who is a bystander in the welding area, understands and follows these safety instructions as well. IMPROPER HANDLING AND MAINTENANCE OF COMPRESSED GAS CYLINDERS AND REGULATORS CAN RESULT IN SERIOUS INJURY OR DEATH! Reduce the risk of injury or death from compressed gases and equipment hazards. Read, understand and follow the following safety instructions. Additionally, make certain that anyone else who uses this welding equipment, or who is a bystander in the welding area, understands and follows these safety instructions as well. Firepower SPOOL GUN OPERATING AND SAFETY MANUAL Health Hazards WARNING Electric Shock Can Be Fatal. A person qualified in First Aid techniques should ALWAYS be present in the working area. If a person is unconscious and electric shock is suspected, DO NOT touch the person if he or she is in contact with electric wires or touch leads. Disconnect power from the machine, then use First Aid. Use dry wood or other insulating materials to move cables, if necessary, away from the person. The welding process can be hazardous to your health. Therefore, follow these precautions: 1. ALWAYS wear protective clothing without pockets and cuffs. Wear a helmet, gloves and shoes with an insulating sole. 2. ALWAYS use a welding mask or helmet with the properly tinted protective glass in the shade adequate to the welding operation being performed and to the current intensity. 1. Never touch or come in physical contact with any part of the input current circuit and welding current circuit. 3. Make certain that bystanders in the welding area are also following these precautions. 2. Frequently check that the input cable and plug are in good condition. 4. ALWAYS keep the welding mask glass clean. Replace it if it is cracked or chipped. 3. Make sure that the welder is disconnected from the main power supply BEFORE attempting any repairs, opening the side panels of the machine or repairing the input cable. 5. NEVER weld in a damp area or come in contact with a moist or wet surface when welding. 6. If the welding area lacks proper ventilation, use fume extractors. 7. Clean the welding pieces of solvents or grease which develop toxic gases when exposed to heat. 4. Fit the main line BEFORE the distribution outlet, with a three-pole switch with adequate delayed fuses (check the characteristics plate for fuse values). 5. DO NOT weld with cables, torch or earth clamp in poor shape. Electric Shock 6. DO NOT coil the torch or the earth cables around your body. WARNING Electric Shock Can Kill! Reduce the risk of death or serious injury from shock. Read, understand and follow ALL safety instructions. Be sure that everyone who uses this welding equipment or who is a bystander in the welding area understands and follows ALL safety instructions as well. 7. DO NOT point the welding torch against yourself or against bystanders. 8. Should you feel the slightest electrical shock, STOP welding IMMEDIATELY! DO NOT use the welder until the fault is found and resolved. 6 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL General Welding Safety Instructions Safety Instructions For your safety, BEFORE connecting the power source to the line, follow these instructions: WARNING Welding processes of any kind can be dangerous not only to the operator but to any person situated near the equipment, if safety and operating rules are not strictly observed. 1. Insert an adequate two-pole switch, equipped with time-delay fuses, before the main outlet. 2. Make the single-phase connection with a two-pole plug compatible with the above mentioned socket. Personal Protection 1. WARNING Wear closed, non-flammable protective clothing, without pockets or turned up trousers. 3. The two wires of the two-pole input cable are used for the connection with the single-phase line. The yellow/green wire is for the compulsory connection to the ground in the welding area. 2. WARNING Wear a non-flammable welding helmet to shield the neck, face and sides of the head. Keep the protective lens clean. Replace the protective lens if broken or cracked. Position a transparent glass between the lens and the welding area. Weld in a well ventilated area that does not open into other working areas. 4. When working in a confined space, keep the power source outside the welding area and fix the ground cable to the workpiece. Never work in a damp or wet area. 5 DO NOT use damaged input or welding cables. 3. WARNING Never look at the arc without proper protection for the eyes. 6. WARNING NEVER operate the power source without its panels in place. This could cause serious injury to the operator and could damage the equipment. 4. WARNING Thoroughly clean metal of rust or paint to avoid producing harmful fumes. Parts degreased with a solvent must dry before welding. 5. WARNING Never weld on metals or coated metals containing zinc, mercury, chromium, graphite, lead, cadmium or beryllium unless the operator and the people standing in the same area use an air-supplied respirator. 7 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL Fire Prevention Welding operations use fire or combustion as a basic tool. respiratory protection equipment in these circumstances. BEFORE welding, read and understand the Material Safety Data Sheet for the welding alloy. Electromagnetic Compatibility 1. The work area MUST have a fireproof floor. BEFORE installing a MIG power source, inspect the surrounding area checking the following points: 2. Work benches or tables used during welding operations MUST have fireproof tops. DO NOT weld on wooden work benches. 1. Make sure there are no other power supply cables, control lines, telephone cables or other devices close to the power source. 3. Use heat-resistant shields or other approved material to protect nearby walls or unprotected flooring from sparks and hot metal. 2. Make sure that telephones, televisions, computers or other control systems are not in the working area. 4. Keep an approved fire extinguisher of the proper size and type in the work area. Inspect it regularly to ensure that it is in proper working order. Know how to use the fire extinguisher. 3. People with pace-makers or hearing aides should keep far from the power source. In particular cases, special protection measures may be required. 5. Remove all combustible materials from the work site. If you can not remove them, protect them with fireproof covers. Reduce interference by following these suggestions: 1. If there is interference in the power source line, mount an E.M.T. filter between the power supply and the power source. WARNING NEVER perform welding operations on a container that has held toxic, combustible or flammable liquids or vapors. NEVER perform welding operations in an area containing combustible vapors, flammable liquids or explosive dust. 2. Shorten the output cables of the power source, keep them together and connected to ground. Ventilation 3. Securely fasten the panels of the power source in place after performing maintenance. WARNING Ventilate welding work areas adequately. Maintain sufficient air flow to prevent accumulation of explosive or toxic concentrations of gases. Welding operations using certain combinations of metals, coatings and gases generate toxic fumes. Use 8 SPOOL GUN OPERATING AND SAFETY MANUAL Firepower 3. Product Description Wire Spool Drive roll pressure adjustment screw Wire tension adjustment nut Drive Rolls Trigger Drive roll pressure release lever Nozzle Cable Wire Speed Adjustment (Potentiometer) Figure 1 9 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL 4. Installation The manufacturer will not be responsible for damages caused by incorrect installation. Any service required due to incorrect installation will not be covered by the warranty. 4.1. Connecting Spool Gun to the Power Source The Spool Gun is provided with two connectors: • • Connection for power cable, gas hose, liner, and trigger. 6 pin connector for motor power and wire speed control. 1. Before connecting the Spool Gun, switch off the power source. 2. Connect spool gun Euro Connect adapter to power source terminal and rotate the lock ring clockwise until it is firmly locked. (Do not over tighten) Figure 2 3. Connect spool gun 6 pin connector to power source terminal and rotate the lock ring clockwise until it is firmly locked. (Do not over tighten) Figure 3 4. Once the connections have been made properly, switch the power source on. For more information please refer to spool gun electric schematic (see page 19). 10 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL 4.2. Installing Wire Spool For the choice of right contact tip and wire please refer to spool gun data sheet (see par.6.) 1. Before operating on the torch, switch off the welder. 2. Remove nozzle. 3. Make sure that liner and contact tip match with diameter of welding wire. 4. Remove any burrs or sharp points from end before fitting into torch. 5. Open the wire spool cover and insert the spool into spool shell (wire feeds from top). 6. Adjust the friction nut on the spool shaft to find the correct wire tension 11 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL 7. Thread wire into inlet liner 8. Push and hold red drive roll pressure release lever 9. Thread wire to the middle of drive rolls 10. Release red lever 11. Replace the spool cover and switch the power source on 12. Turn the wire speed adjustment to minimum wire speed (see page 13 ) 13. Press gun trigger to feed wire through outlet liner and out the end of the contact tip 2” (50mm). WARNING — Never place finger over end of gun. Wire may be driven through finger 14. Install nozzle 15. Pressing gun trigger to feed wire, adjust the drive roll pressure to provide smooth wire travel without crushing the wire. 16. Cut off wire 12 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL 4.3. Wire speed adjustment 1. Turn wire speed adjustment to minimum wire speed 2. Start welding by pressing the trigger. 3. Increase wire speed to achieve the desired arc by turning the wire speed adjustment clockwise. 13 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL 5. Maintenance 5.1 Controls Before you maintain or replace spool gun parts, turn the power source off. Replace contact tip if hole is enlarged or deformed. Always make sure to use the correct diameter for the wire Replace liner if hole is obstructed. Smooth head of liner. Periodically clean inside of nozzle and holes of gas diffuser. Use an anti-spatter spray. Periodically clean drive rolls. Check condition of cable. Do not make temporary repairs. Repairs should only be made by qualified personnel. Do not bend cables and hoses too tightly, to avoid damage that may prevent gas from flowing freely. Repairs must be done only by skilled and qualified personnel. Used parts should be recycled in a proper way, meeting the local requirements. 14 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL 5.2. Changing drive rolls 1. Be sure to select replacement drive rolls to match the wire diameter to be used. NOTE that the lower drive roll is slotted for the key. 2. Before removing the transparent drive roll cover, turn off the power source. 3. Remove the transparent drive roll cover. 4. Relieve pressure on the drive rolls by pressing down the red lever. 5. Changing upper drive roll: Remove screw and washer and lift out the drive roll. Slide the new drive roll onto shaft and secure with washer and screw. 6. Changing lower drive roll: Remove screw and washer and lift out the drive roll. (NOTE - the key will normally come out with the drive roll, be careful not to lose the key.) Place the key in the shaft slot and slide the new drive roll onto the shaft. Secure with washer and screw. 7. Reinstall the transparent drive roll cover. 15 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL 5.3. Changing outlet liner 1. Remove the gas nozzle and the contact tip from the gun tube 2. Pull the liner out of the gun tube 3. Make tip of liner round before fitting into torch. NO SHARP EDGES. 4. Carefully insert the new liner into the gun tube of the torch. 5. Install the contact tip and the gas nozzle onto the end of the gun tube 16 SPOOL GUN OPERATING AND SAFETY MANUAL Firepower 5.4. Troubleshooting Check List Trouble Possible cause Incorrect drive rolls Be sure the wire diameter being used is stamped on drive rolls. Replace drive rolls if necessary Incorrect drive rolls pressure Check and correct drive roll pressure. Turn pressure adjusting screw clockwise, enough to prevent slipping. (see page 11) Worn or dirty drive rolls Clean or replace drive rolls (see page 15) Incorrect wire spool friction Adjust the friction nut on the spool shaft to find the correct wire tension (see page 11) Worn or dirty outlet liner Clean or replace liner (see page 16) Rusty or dirty wire Replace wire (see page 11) Partially flashed, melted or improper size contact tip Replace contact tip Contact tip worn or incorrect size Replace contact tip Drive rolls turn but wire will not feed or wire feeding is rough Variable arc Remedy Incorrect speed wire 17 feeder Adjust wire speed by turning pot ring clockwise (to max) or counter-clockwise (to min). (see page 13) SPOOL GUN OPERATING AND SAFETY MANUAL Firepower 6. Technical Data Sheet WELDING PARAMETERS Welding current Duty cycle Cooling Power cable size Gas 150 A 60 % Gas 16 mm2 Argon - 100% CONSUMABLES Gas Diffusor Gas Nozzle diameter Contact tip diameter TW 1 1/2" as required WIRE FEEDER Voltage supply Power Average current draw RPM (motor) Gear ratio RPM (drive roll) Wire feeder speed Max wire feeder speed Wire diameters for standard drive rolls Maximum spool size Overall dimensions Net Weight (without spool) 24 V DC 16 W 1-15 A 6000 RPM 1:20 300 RPM Adjustable 1kOhm potentiometer 780 in./min. (20m/min.) .030" –.040" (.08 – 1.0mm ) Diameter: 4” (100mm) Width: 1.75"(45mm) Length: 360mm (14.2”) Width: 90mm (3.5”) Height: 195mm (7.7”) 2.5 lb. (1.15 kg) OPTIONS .023" (0.6mm) .045" (1.2mm) Drive rolls for steel and flux core wire .030/.035" (0.8/0.9mm) .045" (1.2mm) Drive rolls for aluminum wire 18 SPOOL GUN OPERATING AND SAFETY MANUAL Firepower 7. Electric Connections Six Pin Connector Euro Connector Euro Connector Two Wires for Torch Trigger Torch Trigger Wiring for MIG Spool Gun With Speed Regulation On The Handle 19 SPOOL GUN OPERATING AND SAFETY MANUAL Firepower 8. Spool Gun Spare Parts List 8.1 Table 1 – Gun Ref # 1 2 2 2 2 2 2 3 4 5 6 7 8 9 10 11 12 13 14/15/16/18 17 17 17 17 17 19 20 21 22 23 24 25 26 27 28 29 30 31 Case P/N 1444-0051 1444-0025 1444-0026 1444-0027 1444-0028 1444-0029 1444-0030 1444-0080 1444-0619 1444-1620 1444-1621 1444-0622 1444-0623 1444-0624 1444-0636 1444-0637 1444-0638 1444-0639 1444-0640 1444-0625 1444-0626 1444-0627 1444-0628 1444-0629 1444-0630 1444-0631 1444-0632 1444-0641 1444-0642 1444-0643 1444-0644 1444-0645 1444-0646 1444-0647 1444-0648 1444-0649 1444-0650 Description Gas Nozzle 1/2” Contact Tip .023” Contact Tip .030” Contact Tip .035” Contact Tip .040” Contact Tip. 045” Contact Tip. 045” Aluminum Gas Diffuser Insulator Torch Body Red Teflon Liner Neck Cover Neck 0-Ring Neck Screw Block O-Ring Sleeve Nut Rolls Assembly Accessories Set/Drive Roller for .023” Wire (Small) Set/Drive Roller for .030” and .040 Wire Standard (Medium) Set/Drive Roller for .030” and .040 Wire Aluminum (Medium) Set/Drive Roller for .045” Wire Standard (Large) Set/Drive Roller for .045” Wire Aluminum (Large) Wire Feed (Ratio 1:20) Kit Handle Rubber Sleeve Friction Spacer Friction Nut Spool Cover Wire Guide Drive Rolls Cover Handle Screw Switch Assembly Trigger/Potentiometer Connection Cable Potentiometer 1kOhm Potentiometer Knob 8.2 Table 2 – Cable Assembly and Central Adapter Ref # A B C D E F G H J P/N 1444-0651 1444-0652 1444-0653 1444-0654 1444-0655 1444-0656 1444-0657 1444-0658 1444-0659 Description Complete Cable Gas Hose Current Cable 16mm2 6m Control Cable Back Box Box Screw Gun Plug Nut Euro Central Adaptor Body Connector 8.3 Table 2 – Accessories Ref # K P/N 1444-0660 Description 20 Feet Power Cable Extension To maintain the performance of your Spool Gun, use only original manufacturer’s suggested spare parts listed above. 20 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL 21 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL 22 Firepower SPOOL GUN OPERATING AND SAFETY MANUAL FIREPOWER LIMITED WARRANTY SCOPE OF LIMITED WARRANTY: Firepower, a division of Thermadyne Industries, Inc. (hereinafter, “Seller”) warrants that its products are free of defects in workmanship, or material. If an authorized distributor or the customer of an authorized distributor (hereinafter, collectively, “Purchaser”) who purchases Seller’s product, notifies Seller within the time set forth below that the product has a defect in workmanship or material even though it has been stored, installed, operated, and maintained in accordance with Seller’s specifications, instructions, recommendations and in accordance with recognized standard industry practice, and the product was not misused, repaired, neglected, altered, or damaged, the Seller may repair or replace, in its sole discretion, those parts of the product determined by Seller to be defective in workmanship or material if said defect is not attributable to Purchaser’s acts or omissions. THIS WARRANTY EXCLUDES ANY WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR OTHER WARRANTY OF QUALITY, WHETHER EXPRESSED, IMPLIED OR STATUTORY. LIMITED WARRANTY PERIOD: Except as otherwise limited below, this limited warranty is effective for twelve months from the date Seller sells the product to an authorized distributor, or for twelve months after an authorized distributor sells the product to its customer, whichever is longer, except that in no event will this warranty exceed eighteen months from the date the product is sold from Seller to an authorized distributor. Notwithstanding the foregoing: • Firepower oxygen / acetylene products will be covered by a two-year product replacement warranty • Firepower plasma cutting equipment will be covered by a one-year (parts & labor) warranty. • Firepower Spool Gun will be covered by a limited one-year warranty • Firepower engine-driven welding machines will be covered by a one-year (parts & labor) warranty. Engines will be covered by the manufacturer’s warranty. • Firepower ADF (auto-darkening) welding helmets will be covered by a one-year warranty. Any ADF helmet claims must be made directly to Jackson / Morsafe products, Belmont, MI 800-253-7281. • Firepower welding electrodes, MIG (& flux cored) wire, and brazing rods, although manufactured to AWS Class specifications, are considered perishable items. As such, these products are sold “as is” and “with faults” and without warranty, either express or implied, including the warranties of merchantability and fitness for a particular purpose. • Products used in rental applications are warranted for one year from the date sold by the Seller to an authorized distributor, without regard to when they were later sold by the authorized distributor. LIMITED WARRANTY CLAIM METHOD: To make a claim under this warranty, Purchaser must notify Seller of the details of such claim within thirty days of discovering a defect in material or workmanship. If the claim is covered by this warranty, Seller will direct Purchaser to return the product to an authorized warranty repair center. The Seller will not be responsible for transportation costs or risks of any kind under this warranty. The Purchaser will be responsible for all such transportation, costs and risks. LIMITATION OF LIABILITY: Seller shall not, under any circumstances, be liable for special, indirect, incidental or consequential damages (regardless of the form of action, whether in contract or in tort including negligence), including, but not limited to, damage or loss of other property or equipment, loss of profits or revenue, cost of capital, cost of purchased or replacement goods, or claims of Purchaser for service interruption. In no event will this warranty obligate Seller for any amount exceeding the price of the goods upon which liability is based. Correction of non-conformities, in the manner and time provided herein, constitutes fulfillment of all Seller’s obligations to Purchaser with respect to Purchaser’s purchase of Seller’s product. This warranty is invalid if the product was sold by non-authorized entities. This warranty is invalid if replacement parts or accessories were used that in the Seller’s sole opinion impaired the safety or performance of Seller’s product. This warranty supersedes all previous warranties. 23 The Quality System of the Denton and Abilene, Texas, locations of Victor Equipment Company, Victor de Mexico in Hermosillo, Mexico and Victor de Brazil in Rio de Janeiro, Brazil, are registered by Det Norske Veritas (DNV), to meet the requirements of ISO-9001, 1994 WORLD HEADQUARTERS: 101 S. Hanley Road • St. Louis, MO 63105 • 314-721-5573 • Fax 314-721-4822 THERMADYNE ® Victor Equipment Company U.S.A. Customer Service P.O. Box 1007 Denton, TX 76202-1007 800-382-8187 FAX 800-535-0557 International Customer Service 2070 Wyecroft Road Oakville, Ontario L6L5V6 Canada 905-827-9777 FAX 905-827-9797 Form No. 0056-1867 (6/01) Canada Customer Service 2070 Wyecroft Road Oakville, Ontario L6L5V6 Canada 905-827-1111 FAX 905-827-3648 24 Europe Europa Building Chorley North Industrial Park Chorley, PR6 7BX, England 44-1257-261755 FAX 44-1257-261756 Asia/Pacific PTE, Ltd. Hillview House Units 401-403 1 Jalan Remaja Singapore 2366 65-763-4022 FAX 65-763-5812 © Victor Equipment Company, 2001 Mexico Calle de Zaragoza #25 Col. Santa Cruz Atoyac C.P. 03910 Mexico, D.F. 52-5-605-8408 FAX 52-5-604-9671 Printed in U.S.A.