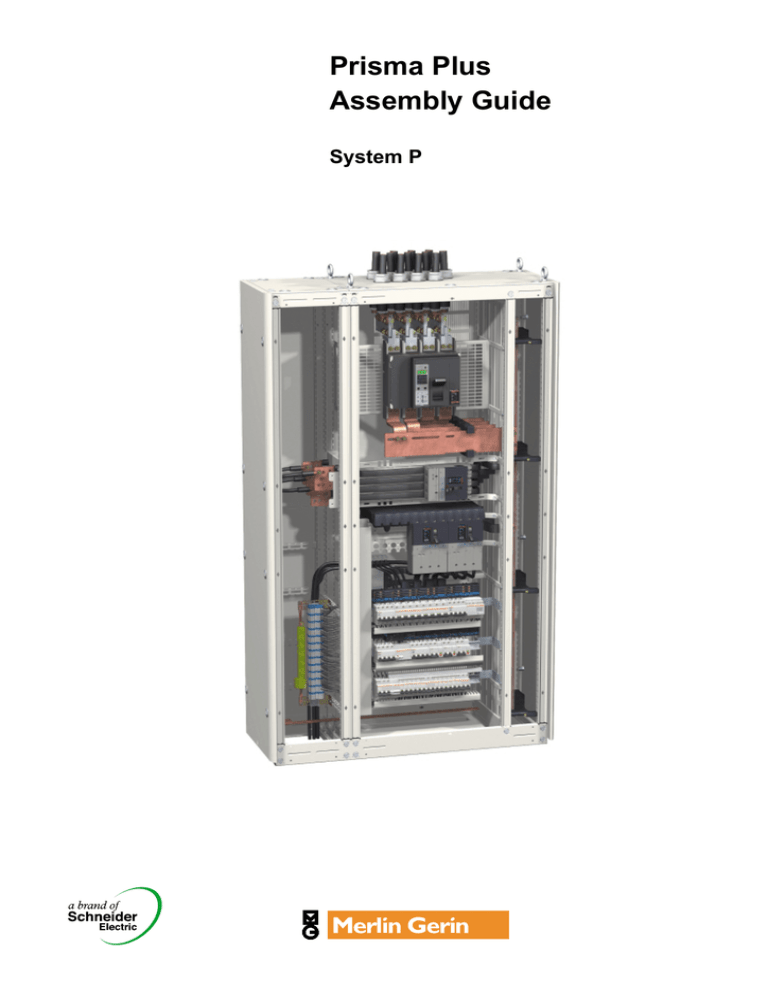

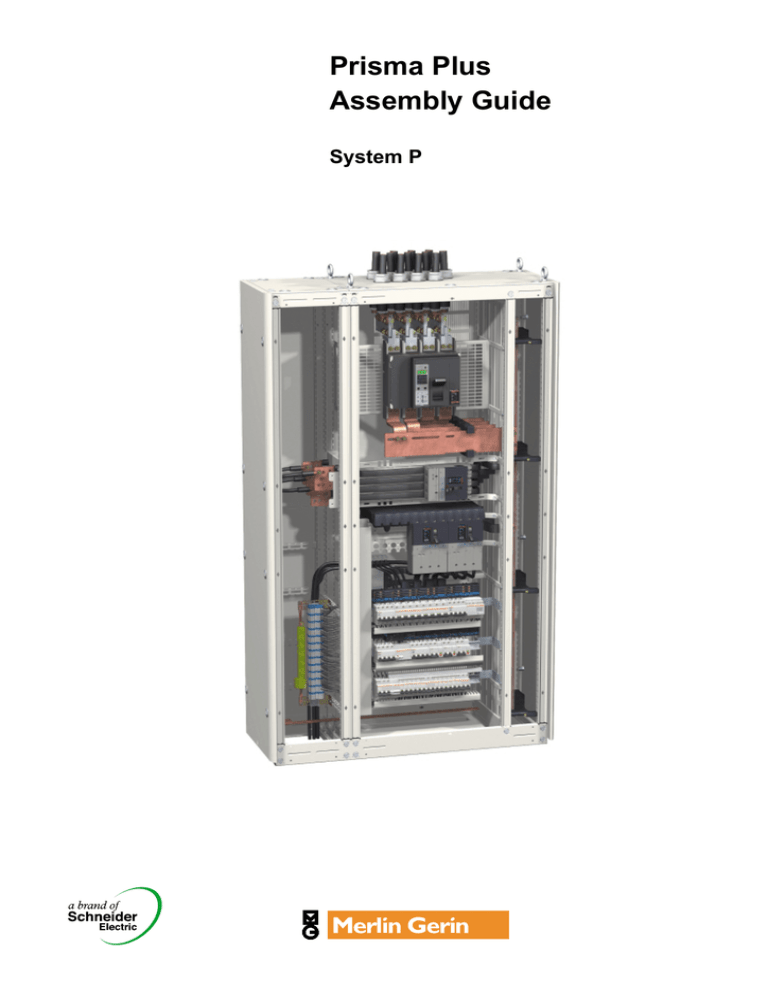

Prisma Plus

Assembly Guide

System P

Preface

This guide proposes a procedure for assembling the Prisma Plus “System P”.

We have designed it to help you successfully complete your first projects. It ensures

that assembling and cabling staff, for whom it is intended, will benefit from the

considerable experience in this field acquired by Schneider Electric and its

customers. In short, it is an essential workshop tool.

There are several approaches for assembling Prisma Plus components. In this

guide we propose one approach which you can add to according to your

professional organisation and experience.

This guide does not replace the technical manuals supplied in the packing of each

component, but recommends an assembly sequence for the components and

provides information to complement that given in the manuals (assembly tips and

tricks, specific assembly recommendations, warnings, etc.).

Assembly guide – System P – Version 4.0

1

Merlin Gerin

Contents

Preface ........................................................................................ 1

Presentation of the components ............................................... 4

Instructions for use .................................................................... 6

Tools

Assembling and cabling tools ............................................................................... 7

Inspection tools....................................................................................................... 7

Identify and sort the components ............................................. 8

Assemble the frameworks ......................................................... 9

Install the busbars

Installing the horizontal busbar........................................................................... 10

Installing the vertical busbar ............................................................................... 10

Coupling the busbars ........................................................................................... 12

Installing the PE and PEN .................................................................................... 13

Marking the busbars ............................................................................................. 13

Assembling the form 2 barrier for horizontal busbar ....................................... 13

Assembling the form 2 side barrier for vertical busbar.................................... 14

Install the mounting plates

Installing the mounting plates and switchgear.................................................. 15

Checking switchgear position ............................................................................. 16

Run and cable the power circuits

Power cables ......................................................................................................... 17

Installing the secondary distribution blocks ..................................................... 19

Installing the connection terminal blocks and the earth bars.......................... 20

Installing the wiring running accessories .......................................................... 20

Fitting the protection devices.............................................................................. 21

Run and cable the low power and auxiliary circuits

Installing the devices on door or front plate...................................................... 22

Installing the wiring running accessories .......................................................... 22

Cabling the auxiliary circuits ............................................................................... 22

Closing the trunking and wiring running accessories...................................... 22

Inspect the switchboard

Final factory inspection........................................................................................ 23

Install the partitioning

Installing the incoming unit partitioning ............................................................ 24

Installing the barriers for the incoming unit connections ................................ 24

Installing the form 3 horizontal barriers ............................................................. 24

Installing the bar duct barriers ............................................................................ 24

Finish and fit the switchboard with panels

Cleaning the switchboard .................................................................................... 25

Finishing the front panel ...................................................................................... 25

Installing the front panel on the framework ....................................................... 25

Fitting the switchboard panels ............................................................................ 26

Pack the switchboard

Packing .................................................................................................................. 27

Assembly guide – System P – Version 4.0

2

Merlin Gerin

Assembly guide – System P – Version 4.0

3

Merlin Gerin

Presentation of the components

Framework

1. Framework upright

2. Top cross-member

3. Bottom cross-member

4. Cable compartment upright

5. Roof

Mounting plates and switchgear

6. Mounting plate support

7. Mounting plate

8. Multi 9 mounting plate: Multifix rail

9. Masterpact incoming unit

10. Compact NS device

11. Multi 9 switchgear

Busbars

12. Bottom support for the Linergy channelled busbar

13. Linergy busbar support

14. Linergy busbars

15. Insulated flexible bar prefabricated connection

16. Rigid bar prefabricated connection

17. Neutral bar

18. PE protective conductor

Distribution blocks

19. Polypact

20. Multiclip

21. Comb busbar

Wiring running

22. Trunking

23. Trunking for fine wiring

Power cables

24. Connection transfer assembly in cable compartment

25. Protective barrier

26. Tie support

Partitioning

27. Form 2 barrier

Front panel finish

28. Front plate support frame

29. Front plate

Cover panels

30. Rear panel

31. Side panel

32. Transparent door

33. Plain wicket door

Assembly guide – System P – Version 4.0

4

Merlin Gerin

PD390592

Presentation of the components

5

2

1

30

7

27

4

31

9

6

24

16

25

10

15

19

22

13

20

26

14

17

21

11

28

29

33

32

Assembly guide – System P – Version 4.0

12

3

23

5

18

8

Merlin Gerin

Instructions for use

This manual describes a procedure for assembling the Prisma Plus “system P”. It

thus indicates the order in which the cubicle components are to be assembled: the

technical assembly instructions are found in the manuals supplied in the packaging

of each component

A) Before starting to assemble, you must first identify and sort the

components.

B) The actual assembly process, divided up into 7 stages, is organised as

follows:

1 – Assembling the framework

2 – Installing the busbars

3 – Installing the mounting plates

4 – Running and cabling the power circuits

5 – Running and cabling the low power and auxiliary circuits

6 – Installing the partitioning

7 – Finishing the front panel and fitting the switchboard panels

Each assembly stage is symbolised by a pictogram also found in the assembly

manual. In most cases, the pictogram in the manual can be seen through the

packaging’s plastic film.

For some configurations of the cubicle in question, you will not have to carry out all

the operations proposed.

C) Before the switchboard partitioning stage, testing as per standard IEC

60439-1 must be carried out.

D) The last stage consists of packing the switchboard to ensure protection

of the cubicles during transport.

Assembly guide – System P – Version 4.0

6

Merlin Gerin

Tools

The recommended tool lists for this section are not complete, but represent the

minimum tools required to assemble, cable and inspect the Prisma Plus “system P”

cubicles.

Assembling and cabling tools

b Individual tools

DD382258

DD382164

The tool kit belonging to the assembling and cabling staff must contain at least the

following tools:

Type of assembly

Tools

Switchboard mounting: enclosure, 1 ratchet wrench

mounting plate and panels except 1 extension piece

1 x 10 and 13 mm socket

for switchgear

1 wrench bit socket

1 screwdriver

1 wrench bit for screwdriver

1 x 5mm hexagon socket bit

1 wrench bit for pozidriv no. 2 recess

1 x 8 flat screwdriver

1 portable jig-saw

Mounting the switchgear and

tightening the connections

(Masterpact, Compact NS, etc.)

Socket 7, 8, 10, 13, 16, 17 and 19 mm

Hexagon wrench bit 4, 5, 6, 8 and 10

Wrench bit for pozidriv no. 1, 2 and 3 recess

Cabling the switchboard

1 flat screwdriver 3.5 mm – 4 mm – 5.5 mm

1 pozidriv no. 2 screwdriver

1 electrician’s knife

1 x 6 hexagon socket bit

1 flat nose pliers

1 stripping pliers

1 cable cutter

1 crimping tool

1 diagonal cutting pliers

1 half round nose pliers

1 bell or tester

b Group tools

K 1 torque wrench to tighten all electrical connections to the required torque (max.

K

K

K

K

K

torque 50 Nm).

1 set of shears to cut flexible bars.

1 punching machine for flexible bars.

1 electrical saw.

1 drill.

1 vacuum cleaner for switchboard cleaning.

DD382260

NB: When crimping the lugs, only the pliers recommended by the lug manufacturer

must be used.

Inspection tools

b Individual tools

b Group tools

K 1 control console.

K 1 dielectrometer.

K 1 multimeter.

DD382261

DD382263

The quality inspector’s basic individual tools are the same as for the assembling

and cabling staff, with in addition the few tools below:

K 1 small hinged mirror.

K 1 electrical lamp or portable lamp.

Assembly guide – System P – Version 4.0

7

Merlin Gerin

Identify and sort the components

DD382267

Aim: Identify and sort components to ensure subsequent proper

working organisation and fewer handling operations.

b Identify the assembly stage pictogram shown in the assembly manual

b Group the components of the cubicle, devices and accessories, by

assembly stage, from assembling of the framework through to fitting the

cubicle panels

DD382264

b Collect the components that will be used by the contractor, but do not

unpack them.

Assembly guide – System P – Version 4.0

Tip: When you receive your components in your workshop, don’t get carried

away, don’t unpack everything…

8

Merlin Gerin

Assemble the frameworks

DD382191

Aim: Assemble the structure and carry out the various combinations

if required.

A variety of framework types are available:

b Depth: 400 or 600

b Width: 300, 400, 650 or 800 mm.

Tip: For transport reasons, assemble 2 or 3 cubicles at most according to total

weight.

Pre-tighten beforehand.

Check alignment.

Tighten to torque.

NB: The cover panels are assembled once the internal components have been

mounted and cabled, thus guaranteeing 100% access to components throughout

assembly and installation.

back to back

DD382192

Assemble side by side

Assembling the frameworks

b Assemble the framework(s)

Tip: The frameworks must be assembled on a flat surface, protected to ensure

the paintwork is not damaged.

DD382194

When assembling the rafters, take care not to damage the gaskets located at the

end of the upright.

b Install the plinth unless its installation is scheduled for on site

DD382193

b Couple the frameworks

If the cubicles have to delivered separately:

K store the combination kits,

K couple temporarily using bolts.

Tip: For IP55 cubicles, do not forget to fit the gasket at the junction of the cubicles

to be coupled. Ensure you degrease the surfaces thoroughly before sticking on

the gaskets.

NB: For an L-shaped combination, the right-angle kit will be assembled on site.

b Install the gland plate support frames

Tip: For reasons of accessibility, the frames will be mounted immediately, while

the gland plates will be mounted before the switchboard panels are fitted.

DD382367

DD382366

DD382195

Tip: For reasons of accessibility and according to the position of the horizontal

busbars (top or bottom), we recommend that you reverse mounting of the combination kits:

Top busbars: long screws + spacers at the top of the framework uprights,

Bottom busbars: long screws + spacers at bottom.

m

0

x2

x2

± 25

1

N˚2

b Install the framework stabiliser

This device increases cubicle stability and enables it to be lifted using a pallet truck

or fork-lift.

Assembly guide – System P – Version 4.0

9

Merlin Gerin

DD382156

Install the busbars

L3

L2

Aim: This stage consists of positioning the supports and bars

making up the busbars.

Tip: If cutting oil is used, the bars must be cleaned prior to assembly as oil

adversely affects insulation properties.

L1

N

NB:

K Busbar overall dimensions do not vary with current strength.

K Whatever the busbar type (flat or channelled), the order of the horizontal and

vertical bars is always the same: from the front to the rear N, L1 ,L2 and L3.

N

L1

L2

L3

DD382196

DD382126

K With the rear busbar, the Neutral is to the left, then L1, L2, L3.

Install the horizontal busbar

b Install the horizontal busbar at the top or bottom of the cubicle

(dimensions for 3 modules). If a connection with a rear busbar is

provided, dimensions change to 5 modules. If the busbar is at the bottom,

fit a form 2 partition to prevent the risk of falling tools.

!

If cubicles have to be separated for transport, provide horizontal busbar

joints. The joints will be assembled on site and should preferably be used

at the inter-cubicle connections to simplify replacement. Ensure a 10 mm

space between the bars to be joined, i.e. 5 mm from the edge of the

cubicle.

Tip: Joining should preferably take place in a cable duct to simplify installation.

Install the vertical busbar

DD382199

DD382198

DD382197

b Install the single busbar in the busbar compartment

Linergy channelled busbar up to

1600 A

Assembly guide – System P – Version 4.0

10

Flat busbar up to 2800 A (IP y 31)

Merlin Gerin

Install the busbars

DD382201

DD382200

b Install the double busbar in the busbar compartment

Double flat busbar up to

3200 A

Linergy double channelled busbar up

to 3200 A

3 equipotential bonding connections are required between the busbars. Consult

the manuals to determine the number of supports as a function of installation lcw.

NB: The bottom support for the lateral flat busbar is not considered to be a bar

support.

b Install the busbar at the back of the cubicle

DD382284

DD382283

NB: The rear busbar is installed at a depth of 400, but can be installed at a depth

of 600. In the latter case, the assembling and cabling staff must make the busbar

connections themselves.

Channelled busbar up to

1600 A

Assembly guide – System P – Version 4.0

11

Flat busbar up to 1600 A

Merlin Gerin

DD382202

Install the busbars

Coupling the busbars

b Connect the busbars to one another

K connection between horizontal busbar and Linergy busbar in the bar

compartment

Tip: It is preferable to use torque nuts to secure the inter-busbar connections.

When using this type of nut, care must be taken to balance tightening by gradually

increasing the tightening of each nut until breakage occurs.

If you use other nut types, we recommend that you smear Swiss varnish on each

nut tightened to its torque.

NB: Connection of a 10 mm thick horizontal busbar requires no holes to be drilled,

unlike the 5 mm thick horizontal busbar.

Vertical busbar

10 mm bar

Linergy bar

Connection

DD382156

Horizontal busbar

L3

L2

L1

DD382286

Linergy bar

K connection between horizontal busbar and vertical flat busbar in the busbar

Horizontal busbar

Vertical busbar

10 mm bar

10 mm bar

DD382203

compartment.

5 mm bar

5 mm bar

DD382204

DD382122

5 mm bar

DD382285

N

Connection

For this connection type, holes must be drilled on the 5 mm horizontal bars.

K connection between horizontal busbar and Linergy rear busbar.

DD382287

This connection type must partially be carried out by the assembling and cabling

staff or on request by Schneider. For the dimensions of the bars to be made,

consult the bar drawing compendium.

Assembly guide – System P – Version 4.0

K connection between flat busbar and rear flat busbar.

This connection type must partially be carried out by the assembling and cabling

staff. For the dimensions of the bars to be made, consult the bar drawing

compendium.

12

Merlin Gerin

Install the busbars

DD382288

Installing the PE and PEN

b Install the PE

K for vertical mounting, it is normally installed in the cable compartment,

K for horizontal mounting, it is installed at the top or bottom of the switchboard

opposite the horizontal busbar.

DD382205

DD382289

NB: If the cubicles have to be separated for transport, produce PE joints.

Assembly guide – System P – Version 4.0

b Install the PEN

The PEN is mounted vertically, normally in the cable compartment.

It must be connected to the neutral by a removable joint allowing subsequent

taking of insulation measurements.

N

L1

L2

L3

Marking the busbars

NB: Marking of the protective conductors (neutral, PE and PEN) is compulsory.

Phase marking is strongly recommended.

13

Merlin Gerin

Install the busbars

DD382207

Mounting the form 2 side barrier for vertical busbar

DD382208

NB: The form 2 side barrier allows insertion of flexible or rigid connections less

than 12 mm thick between 2 flaps.

DD382209

To allow insertion of the connection for a large rating device (Masterpact,

Compact NS 1600 A, etc.) to a lateral vertical busbar, and if a Polybloc with flexible

connections is used (cat. no. 04405 and 04406) with form 2, a side barrier cut-out

must be installed. To identify the location of this cut-out, the position of the power

devices must be anticipated.

Assembly guide – System P – Version 4.0

14

Merlin Gerin

Install the mounting plates

DD382210

Installing the mounting plates and switchgear

Aim: This stage consists of defining the position of the mounting

plates in the cubicle and installing them with their devices.

The order of assembly of the mounting plates and devices depends on the

technical features of the devices.

To define the position of a mounting plate of a functional unit, you need to know

the overall dimensions of the functional unit, i.e. the number of modules (1 module

= 50 mm). This number is given in the mounting plate assembly manual and the

catalogue. The reference m0 is the reference starting point for installation of the

first mounting plate. There are 2 m0 references at the top and bottom of the

cubicle. This reference, in the form of a slot, is used to hook up a measuring tape

to measure the height to be complied with when installing a mounting plate.

Marks located every 50 mm, with a double marking every 100 mm, simplify module

counting.

m0

Table showing assembly order according to device type:

DD382212

DD382211

Device

Masterpact NW, NT, NS

> 630 A and INS > 630 A

Fixing

Fixed

Withdrawable b Install the mounting plate

b Install the cradle

b Plug the device into the cradle

Compact NS and Interpact

INS

Supplied by

Polypact

DD382214

DD382213

Compact NS and INS y 630 A Fixed

Assembly guide – System P – Version 4.0

Assembly order

b Install the mounting plate

b Place the device on the mounting

plate

Modular devices

15

b Insert the Polypact, connections

facing forward, into the cubicle

b Slope the Polypact assembly,

connections facing downwards,

while inserting them between the

form 2 barrier slats

b Swivel round the Polypact in the

cubicle and put it in the horizontal

position

b Install the 2 mounting plate

supports, with the right-hand

support straddling the first

connection

b Position and hold the Polypact in

place above the supports

b Secure the mounting plate (without

device) onto its supports

b Place the Polypact on the

mounting plate

b Assemble the devices

b Place the device on the mounting

plate

b Install the equipped mounting

plate

Withdrawable b Place the base or cradle on the

or plug-in

mounting plate

b Install the equipped mounting

plate

b Plug in the device

Modular

b Install the rail

system

b Place the modular devices on the

rail

Merlin Gerin

DD382215

Install the mounting plates

Checking switchgear position

This operation allows operator inspection and prevents incorrect positioning of the

functional unit with respect to the front panel, once the cubicle has been fully

cabled.

b Place the front plate support frame for front plate assembly

b Install the front plates to check device positioning

b Also check device positioning in depth

b Disassemble the front plate support frame after checking to simplify

cabling.

Assembly guide – System P – Version 4.0

16

Merlin Gerin

PD390586

Run and cable the power circuits

Power cables

Cabling of power devices > 630 A uses rigid bars: bar drawings can be supplied if

the prefabricated connections are not available in the catalogue.

You need to:

b know the position of the current transformers and partitions and check that they

can be mounted,

b tie the busbar tails onto the framework, and the cables with "1000 V" insulation

onto the device mounting plates,

b install tie supports according to fixing distances.

NB: The tightening torques for connection to the device terminals are given in the

device technical manual.

To avoid the risk of temperature rise, it is essential to comply with the size of the

connections or cables recommended in the assembly manuals or on the devices

and to use the screws and bolts delivered with the devices and connections.

The diameter 8 contact and flat washers must be mounted on hammer screws for

Linergy busbars.

b Upstream connections

Connection type

Connection by cable

Prefabricated connection to

the Linergy busbar

Connection to the flat busbar

DD382219

DD382218

y 630 A device

DD382216

Connection by Canalis

DD382217

Device type

> 630 A power

device

Connection by Polypact to the

Linergy busbar

DD380548

DD382220

NB: The prefabricated connections

for Compact NS 400/630 may be too

long in some assembly cases. If this

is so, then two prefabricated

connections must be inserted

between two form 2 partitioning

slats.

Connection by Polypact to

the flat busbar

NB: For connection to the flat

busbar, the panel builder

must make the connections

himself.

Assembly guide – System P – Version 4.0

17

Merlin Gerin

Run and cable the power circuits

Connection type

Connection by bars to the

Connections by bars to the

Linergy busbar

flat busbar

DD382222

Device type

> 630 A power

device

DD382221

b Downstream connections

NB: For connection to the

flat busbar, the panel builder

must make the connections

himself.

y 630 A device

DD382224

DD382223

Connection transfer assembly.

Universal power supply

block for Powerclip insulated

busbar

NB: The Powerclip 630 A

insulated busbar is used in

cubicles for distribution over

several device rows.

Assembly guide – System P – Version 4.0

18

Merlin Gerin

DD382268

Run and cable the power circuits

Installing the secondary distribution blocks

You need to comply with connection capacities, stripping lengths, the number of

cables connected and use the appropriate tools.

Do not use ferrules with the spring loaded terminals. Each terminal may only take a

single wire.

On the Multiclip 200 A, cable entry is via the bottom only to allow assembly of the

insulating covers and production of cable straps.

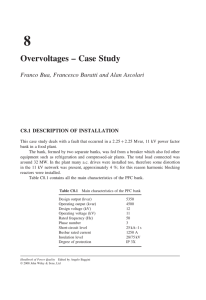

Type

Polybloc

2

4 - 10 mm

2

O

6 - 16 mm

_

2

12

2

12

16

12

16

6 mm

2

10 mm

6 - 16 mm 2

2

4 - 10 mm

4 mm

_

2

16 mm

Additional block

Connection

principle

Connection capacity

5,5 mm

16

2

16 mm2

25 mm

2

35 mm

pozidriv n°2

12

Distribloc

Power supply

ø 6,5

2,5

6 mm2

12

ø5

1,5

4 mm2

10

ø8

4

10 mm2

12

ø8

4

16 mm2

12

pozidriv n°2

Distribution

DD382269

5,5 mm

Multiclip 200 A

Power supply

12

10 mm2

n°6

Distribution

4 mm

Multiclip 80 A

Power supply

10

2

4 mm

pozidriv n°2

12

2

6 mm

Distribution

3,5 mm

Tap-off blocks

insulated busbar

2

10

2

12

4 mm

4 mm

6 mm

2

10 mm

12

NB: the downstream device connecting cables are delivered with the Multiclip and

Distribloc.

Assembly guide – System P – Version 4.0

19

Merlin Gerin

Run and cable the power circuits

DD382244

Installing the connection terminal blocks and the earth bars

b Install the supports for arrangement of the connection terminal blocks

and earth bars

NB: The connection terminal blocks and earth bars are installed:

K at the top or bottom of the cubicle,

K in the cable compartment.

DD382245

b Install the terminal blocks

b Install the earth bars

12

6 mm2

12

10 mm2

12

16 mm 2

12

DD382227

4 mm2

Connection principle

5,5 mm

DD382250

DD382247

Connection capacity

DD382249

DD382248

DD382246

Type

10

4 mm2

2

DD382251

35 mm incoming terminals

for flexible or rigid cables

3 mm

Screw terminals

2

16 mm outgoing terminals

for flexible or rigid cables

Installing wiring running accessories

b Install the horizontal and vertical cable straps

Assembly guide – System P – Version 4.0

DD382271

DD382270

The straps are used to guide the wires. They are easy and quick to implement and

can be clipped directly onto the mounting plates.

20

Merlin Gerin

Run and cable the power circuits

b Install the trunking for horizontal or vertical wiring

The trunking is used to carry wires to the switchgear zone. Trunking is secured:

K to some mounting plates on specially reserved locations,

K on the trunking supports by means of clip-on, ¼ turn removable screws.

DD382272

DD380866

The Polypact distribution block accommodates a trunking as standard to guide the

auxiliary wiring of the NS circuit-breakers that it supplies.

NB: Trunking is assembled onto its support simply by clipping on from the front.

b For an L-shaped installation with corner kit for busbars, an additional

corner kit can be added for wiring and earth conductor running.

Fitting the protection devices

b Prepare the various protective covers (cut-out, drilling, etc.)

b Fit the various protective covers:

K upstream and downstream terminal shields are compulsory for all Compact NS

DD382253

circuit-breakers and INS/INV switches with vertical or horizontal mounting,

cover for power supply block,

connection cover for cable,

cover for busbar,

tooth-caps, etc.

DD382252

K

K

K

K

b Install the cable tie-bars

NB: For connection by insulated flexible bars equipped with built-in terminal shields,

there is no point equipping Compact NS circuit-breakers with terminal shields.

DD382365

b Fit the puffing chamber barriers on the Compact NS/NT u 630 A circuitbreakers if bare copper connections are used.

Assembly guide – System P – Version 4.0

21

Merlin Gerin

Run and cable the low power and

auxiliary circuits

DD382273

Installing the devices on door or front plate

60

10

0

For safety reasons, it is forbidden to mount devices on the bar duct door. We

recommend that devices be transferred to the cable duct door.

40

60

40

60

40

10

0

10

0

60

40

10

0

b Install the partial doors with cut-outs or front plates with cut-outs

accommodating devices

NB: The devices can be installed on conventional plain doors by making a cut-out.

b Install the mounting plates and devices on the doors or front plates

DD382274

b Install an earthing braid when the door accommodates non-class 2

devices

DD382275

Tip: If there is not enough space between the door and the front plates, use the

visor.

Installing the wiring running accessories

30

b Install the trunking and the wire-guide straps

30

DD382254

b Install the terminal blocks for auxiliary wiring

NB: Holes are drilled in the mounting plates for rear insertion of cables.

b Install the auxiliary disconnectable terminal blocks

b Install the 4P auxiliary bus ducts

D382276

b Install the voltage tap-offs at the device exit

DD382278

DD382277

Cabling the auxiliary circuits

Flexible trunking

Grommet

b Mark the wires to simplify on-site connection and maintenance of

cubicles, thus avoiding laborious switchboard reworking that could cause

errors.

It is important to obtain customer approval of the marking technique. The marks

must be placed at the extremities of the conductors and, if necessary, along their

routes.

Tip: Thoroughly secure cables onto the door to avoid disconnecting the devices

when opening. We recommend you use protection devices for wiring through the

front panel or to the doors.

Closing the trunking and wiring running accessories

Tip: Trunking packing density must not exceed 70 %.

Assembly guide – System P – Version 4.0

22

Merlin Gerin

DD382263

Inspect the switchboard

Final factory inspection

On completion of assembly, the cubicles must undergo a variety of inspections and

tests. At the very least the 3 routine tests must be carried out as per standard IEC

60439-1 mentioned below:

b 1st test: overall inspection including examination of cabling, checking

connection tightening and, if necessary, an electrical operating test

b 2 test: checking insulation via a dielectric test

nd

b 3 test: checking direct contact protection measures and electrical

continuity of protection circuits

rd

For more details concerning inspections, consult the switchboard assembly and

installation guide.

DD382266

DD382261

b Drafting test reports

Assembly guide – System P – Version 4.0

23

Merlin Gerin

DD382206

Install the partitioning

Installing the form 2 barriers on the top or bottom horizontal

busbar

DD382279

NB: The barrier does not modify busbar dimensions.

Installing the incoming unit partitions

Tip: Before assembling the partition, remove the pre cut-outs required for cable

insertion.

DD382280

Installing the barriers for the incoming unit connections

Installing the form 3 horizontal barriers

DD382255

Tip: Before assembling the partition, remove the pre cut-outs required for busbar

or cable insertion.

Follow the order given in the manual.

Installing the bar duct barriers

b Install the front barrier

b Install the rear barrier for 600 deep cubicles

b In event of insertion of a PEN conductor through the front barrier, remove

the pre cut-out provided (compliance with clearances) and fit an

insulating plate (Polycarbonate T° > 960°C) to guarantee IP2X (consult

the front barrier assembly manual).

Assembly guide – System P – Version 4.0

24

Merlin Gerin

Finish and fit the switchboard

with panels

E68280

Cleaning the switchboard

b Remove dust from the inside using a vacuum cleaner

Tip: Do not use blow cleaning as this may cause shavings and detritus to

accumulate in a live area.

b Dust the outside

Tip: Use a neutral dissolvent that will not damage the paint.

b Touch up paintwork if necessary

b Check absence of foreign matter inside the switchboard (tools, screws

and bolts) that could prevent it from operating properly.

Finishing the front panel

b Secure the front plate support frame to the cubicle framework

b Install the markers: fit the label holders

DD382355

DD382256

b Install the blanking plates on the front plates

Installing the front panel on the framework

b On the front of the switchboard

A name plate should indicate at least:

K the name and address of the panel builder,

K the identity of the project.

b Device marking

This enables installation users to identify clearly the type of circuits used. Marking

should be fully legible, durable and properly attached next to the device.

There are 3 label formats that can be printed or engraved.

Assembly guide – System P – Version 4.0

25

Merlin Gerin

Finish and fit the switchboard

with panels

DD382257

Fitting the switchboard with panels

b Install the gland plates

b Fit the rear and side panels

NB: For L combinations, there is a specific assembly order: refer to the right-angle

kit assembly manual.

b Install the ventilation system, the resistors and the switchboard lighting, if

necessary

b Fit the roof

DD382282

DD382281

NB: For IP31 cubicles, do not forget to fit the gasket. Take care to degrease

surfaces thoroughly before sticking on the gaskets.

b Fit the doors or fixed frames

K door assembly is reversible,

Tip: For safety reasons, ensure that the door opening direction will not obstruct on

site access to an evacuation corridor or passageway. The door must open in the

direction of the evacuation.

K it is advisable to install barrels and inserts before fitting the handle on the door

and before mounting on the framework.

b Fit the lifting rings for lifting from the top (do not forget to fit the plugs).

Assembly guide – System P – Version 4.0

26

Merlin Gerin

E20551

Pack the switchboard

Packing

b Uncouple the cubicles electrically and mechanically if necessary

b Provide the contractor with the necessary accessories (joints, fixing

screws, etc.)

b Provide an installation guide for cubicle on-site coupling

b Compile a technical file containing a set of drawings, the device operating

manuals and the cubicle assembly manuals

b Attach the adhesive drawing holder to the back of the door with the

technical file

b Ensure cubicle protection for transport, particularly on the surface-mount

HSI surfaces

NB: Use the stabilisers to increase packing volume and re-use cover panel

protections (angle brackets, polystyrene, etc.).

b Pack the cubicles.

Assembly guide – System P – Version 4.0

27

Merlin Gerin

http://www.schneider-electric.com

As standards and equipment change from time to time, always ask for confirmation of the information given in this

document.

This document has been printed on

ecological paper.

Published by: Schneider Electric

Produced by: HeadLines

xxxx Version A © 2003 Schneider Electric – all rights reserved

Schneider Electric Industries SAS

89 boulevard Franklin Roosevelt

F-92500 Rueil Malmaison (France)

tel: +33 (0)1 41 29 85 00