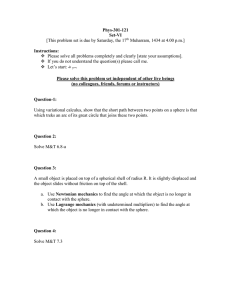

Application of FEA in large storage tanks` shell course repairs

advertisement

The 8TH Australian Congress on Applied Mechanics (ACAM 8) Application of FEA in large storage tanks’ shell course repairs - A case study assessment to determine membrane deformation and structural stability Arash Zamani , Yong Wang Saunders International Limited November 2014 The 8TH Australian Congress on Applied Mechanics (ACAM 8) Background • Storage tanks have been in use for decades in many industrial plants • Oil refineries, petrochemical plants, Power plants, water facilities • They are used to store liquids for different purposes The 8TH Australian Congress on Applied Mechanics (ACAM 8) • • • Introduction Composed of a flat floor and a cylindrical shell The roof can be either fixed or floating In some cases there is no roof at all (Open top) The 8TH Australian Congress on Applied Mechanics (ACAM 8) Inspection and Maintenance • Tanks usually store liquids, such as petrochemical products, chemicals • Any failure in storage tanks can cause a disaster • They should be periodically inspected, assessed and repaired if necessary • API653 and EEMUA 159 Failure of a 8 m diameter, 10 m high steel tank containing 350 m3 of waste solvent in 2009 The 8TH Australian Congress on Applied Mechanics (ACAM 8) Objectives • • • • • The approaches we use to solve challenges in a real maintenance job How we use FEA for engineering assessment in repair work What items are Important for calculation How we assess and accept the results How we use a simplified manual calculation for verifications The 8TH Australian Congress on Applied Mechanics (ACAM 8) Problem Definition Tank • A 17.5m dia x 18m high open top tank • Inspection showed heavy corrosions on bottom strake • Replace bottom strake plates The 8TH Australian Congress on Applied Mechanics (ACAM 8) Challenges • • • • • Complex plant Accessories such as mixer, vibrators, piping and etc. were installed on top of the tank on a platform Two other tanks were located very close to this tank Difficulty in access due to congestion Removal of the existing plates and transportation and installation of new ones The 8TH Australian Congress on Applied Mechanics (ACAM 8) Methodology • Make an opening in the roof platform • A lifting rail was designed and installed on one of the top shell courses • The rail with a hoist provides the ability of grabbing, lifting and moving the plates around the tank • The tank to be on temporary supports during the replacement of bottom strake • The temporary supports transfer the vertical loads to the ring wall and pad The 8TH Australian Congress on Applied Mechanics (ACAM 8) FEA Modelling • • FEA is suitable for complex geometry Shell buckling due to weight of lifted plate • Temporary structure strength and buckling • Minimize the shell deflection at supports • Quad4 plate elements and Beam elements • A Linear static and linear buckling solver The 8TH Australian Congress on Applied Mechanics (ACAM 8) Boundary Condition and Loadings • • • • • Cylindrical coordinate system A portion of the shell was modelled Symmetric boundary condition on edges Pin Type boundary at supports Fixed radial displacement at shell top • Weight of top platform estimated to be 450 Ton which applied as uniform load Weight of plate to be lifted 4.2 Ton • The 8TH Australian Congress on Applied Mechanics (ACAM 8) Lifting Rail Design • • • • 3x9 meter in 20 millimetres plates (4.2 Ton) The load impose bending moments to the shell Permanent deformation Failure of rail members should be checked • • AS 1170.0: 1.2x DL + 1.5x Q A SF of 1.2 considered for dynamic load effects The 8TH Australian Congress on Applied Mechanics (ACAM 8) Lifting Rail Design • • Changing the design configuration Selecting the appropriate member size • • • Stress in structural members : 243 MPa Von Misses stress in the shell: 150 MPa Allowable: 85% of the yield strength • • Max shell out-of-roundness : 6.3 mm Moving concentrated load effects as a result of hoist movement was studied along the rail The 8TH Australian Congress on Applied Mechanics (ACAM 8) Verification: Manual calculation • 1): Axial stress: T/A • 2): BM: (Pv x L )/4 , Sb= BM/Z The 8TH Australian Congress on Applied Mechanics (ACAM 8) Shell and Support Check • • Possibility of shell buckling can be reduced by increasing the number of supports, or adding stiffeners The number of supports should be selected based on the shell buckling limitation • Optimal solution should be selected • 38 sets of supports made of 150x150x5 square hollow section and 250x150x5 rectangular hollow section These configuration transfers the load to ring wall and pad • The 8TH Australian Congress on Applied Mechanics (ACAM 8) Shell Stiffening • Combined with supports two rows of 100x75x8 unequal angle temporary stiffeners were installed • Lowering the chance of shell buckling • Even distribution of load on supports • Adding stiffeners reduce shell deflection by 22% The 8TH Australian Congress on Applied Mechanics (ACAM 8) Shell and support Stress • Maximum VM stresses in the shell : 90 Mpa • Maximum fibber stresses in the supports: 161 Mpa • maximum shell deflection :1.8 mm The 8TH Australian Congress on Applied Mechanics (ACAM 8) Verification: Manual calculation • 1) load is divided equally between the ring and pad • 2) a portion of shell equal to 16 times the plate thickness is considered to be effective • 3) Simple beam theory was used • 4) ��� = ��8 , � = • • 2 5) ��� = 0.5�ℎ� 6) � = � �ℎ�� , � = � �� 1 � −� 1 �� ,� = ��� The 8TH Australian Congress on Applied Mechanics (ACAM 8) Summary • A comprehensive engineering assessment for a typical tank repair work • Involves step by step design and analysis • Various aspects to be considered in an engineering evaluation of a maintenance job The 8TH Australian Congress on Applied Mechanics (ACAM 8) Acknowledgement Saunders International Limited Specialist in Design, Construction and Maintenance of Bulk Storage Facilities