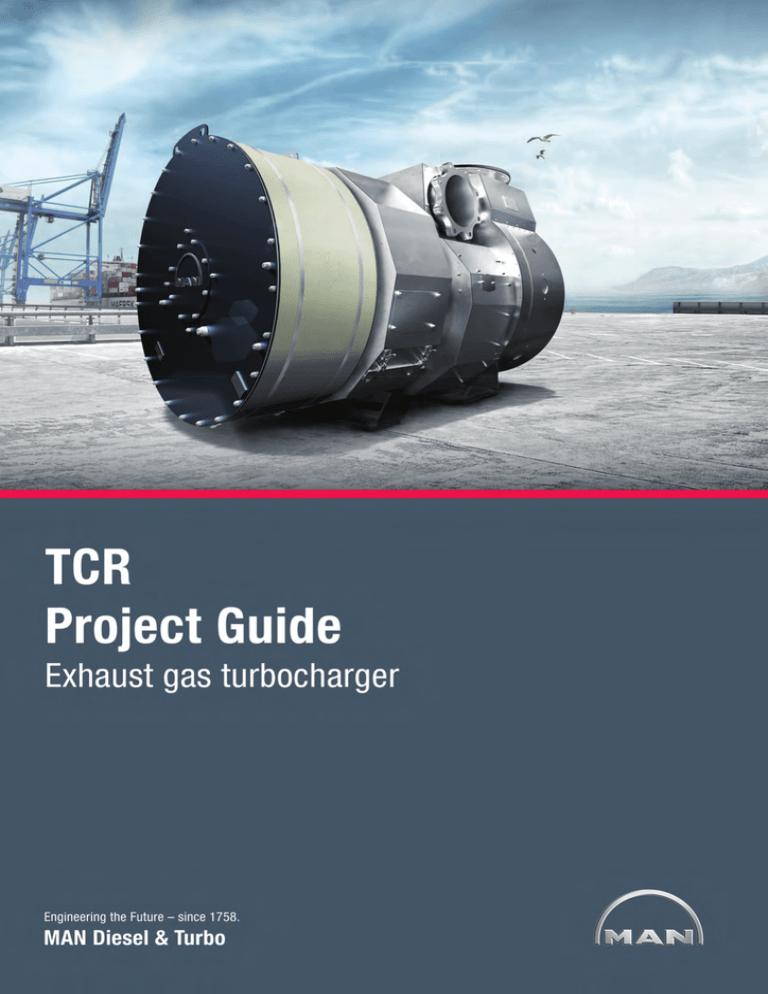

MAN Diesel & Turbo

Project Guide

TCR

Turbocharger

All data provided in this document is non-binding. This data serves informa­

tional purposes only and is especially not guaranteed in any way. Depending

on the subsequent specific individual projects, the relevant data may be sub­

ject to changes and will be assessed and determined individually for each

project. This will depend on the particular characteristics of each individual

project, especially specific site and operational conditions.

Translation of the original instructions

EN-US

TCR Project Guide

2014-07-16 - de

Date .................................................. 2014-07-16

MAN Diesel & Turbo SE

86224 Augsburg

Phone +49 (0) 821 322-0

Fax +49 (0) 821 322-3382

www.mandieselturbo.com

2014-07-16 - de

TCR Project Guide

MAN Diesel & Turbo

Copyright © 2014 MAN Diesel & Turbo

All rights reserved, including reprinting, copying (Xerox/microfiche) and translation.

EN-US

Table of contents

1

General .................................................................................................................................................. 6

1.1

1.2

1.3

1.4

1.5

1.6

1.7

2

Overview of series ............................................................................................................................... 12

2.1

2.2

2.3

2.4

2.5

2.6

2014-07-16 - de

3

Range of applications of the TCR Series ................................................................................. 12

Achievable power outputs per turbocharger .......................................................................... 12

Maximum compressor pressure ratios and exhaust gas temperatures ................................ 13

Weights of the subassemblies ................................................................................................. 14

Dimensions ............................................................................................................................... 15

Casing positions ....................................................................................................................... 17

Design – Characteristics of the subassemblies ................................................................................ 18

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

3.13

3.14

3.15

3.16

3.17

3.18

3.19

3.20

4

Characteristics of the TCR Series turbochargers ..................................................................... 6

Exhaust gas turbocharging ....................................................................................................... 7

Layout of the turbochargers on the engine ............................................................................... 8

Performance characteristics ..................................................................................................... 8

Intended use ............................................................................................................................... 9

Type plate ................................................................................................................................. 11

Reference values for pressure specifications in the Project Guide ....................................... 11

Table of contents

MAN Diesel & Turbo

Characteristics of the subassemblies ..................................................................................... 18

Turbine rotor ............................................................................................................................ 19

Compressor wheel ................................................................................................................... 19

Internal bearings ...................................................................................................................... 20

Bearings ................................................................................................................................... 21

Bearing casing ......................................................................................................................... 22

Compressor casing .................................................................................................................. 23

Diffuser ..................................................................................................................................... 24

Silencer with air filter .............................................................................................................. 25

Air intake casing ...................................................................................................................... 26

Gas admission casing .............................................................................................................. 27

Turbine nozzle ring .................................................................................................................. 28

Adjustable turbine nozzle ring ................................................................................................. 28

Gas outlet casing ..................................................................................................................... 29

Waste gate ................................................................................................................................ 30

Gas outlet elbow ...................................................................................................................... 31

Loads on connections and flanges .......................................................................................... 31

Permissible inclination ............................................................................................................ 38

Permissible vibration limit values ........................................................................................... 39

Noise emission ......................................................................................................................... 41

Systems ............................................................................................................................................... 42

4.1

4.2

Lube oil system ........................................................................................................................ 42

Lube oil flow rate ..................................................................................................................... 47

3 (129)

4.3

4.4

4.5

4.6

4.7

4.8

5

Quality requirements on operating media ......................................................................................... 56

5.1

5.2

5.3

5.4

5.5

6

6.3

Containment safety .................................................................................................................. 83

Disassembly dimensions for subassemblies .......................................................................... 83

Exhaust gas system ................................................................................................................. 87

Emergency operation and temporary shutdown ............................................................................... 90

8.1

8.2

4 (129)

Jet Assist .................................................................................................................................. 74

Turbine cleaning ...................................................................................................................... 75

6.2.1 Wet cleaning of the turbine .................................................................................... 76

6.2.2 Dry cleaning of the turbine .................................................................................... 78

Compressor cleaning ............................................................................................................... 80

Engine room planning ......................................................................................................................... 83

7.1

7.2

7.3

8

Quality requirements on fuels ................................................................................................. 56

5.1.1 MDO fuel (marine diesel oil) ................................................................................... 56

5.1.2 MGO fuel (marine gas oil) ...................................................................................... 57

5.1.3 HFO fuel (heavy fuel oil) ......................................................................................... 58

5.1.4 Biofuel ................................................................................................................... 63

5.1.5 Gas ....................................................................................................................... 64

5.1.5.1 Gas types, gas quality ........................................................................................... 64

Quality requirements on lube oil and additives ...................................................................... 64

5.2.1 Lube oil ................................................................................................................. 64

5.2.2 General requirements on lube oil ........................................................................... 65

5.2.3 Specifications ........................................................................................................ 66

Quality requirements on intake air .......................................................................................... 67

Quality requirements on cooling water for compressor wheel cooling ................................. 68

5.4.1 Additives for Cooling Water ................................................................................... 68

5.4.2 Requirements on untreated cooling water ............................................................. 69

5.4.3 Requirement for Effective Use of an Anticorrosive Agent ....................................... 70

5.4.4 Protective Measures ............................................................................................. 71

5.4.5 Analysis ................................................................................................................ 71

5.4.6 Permissible Cooling Water Additives ..................................................................... 71

Quality requirements on turbine cleaning granulate .............................................................. 73

Additional equipment .......................................................................................................................... 74

6.1

6.2

7

Lube oil pressure ..................................................................................................................... 47

Emergency lubrication ............................................................................................................. 49

Pre-lubrication and post-lubrication of the turbocharger ..................................................... 50

Quality assessment of the lube oil .......................................................................................... 52

Water cooling – bearing casing ............................................................................................... 54

Compressor wheel cooling ...................................................................................................... 55

Emergency operation ............................................................................................................... 90

Shutting Down and Restarting Operation ............................................................................... 92

8.2.1 Long-term shutdown for lay-up ............................................................................. 92

2014-07-16 - de

Table of contents

MAN Diesel & Turbo

9

Calculations ......................................................................................................................................... 94

9.1

9.2

Design calculations .................................................................................................................. 94

Turbocharger efficiency ........................................................................................................... 95

10 Speed measurement, matching, checking ........................................................................................ 97

10.1

10.2

10.3

10.4

10.5

Speed measurement ................................................................................................................ 97

Measurement of the air volume ............................................................................................ 100

Matching ................................................................................................................................ 102

Checking surge stability ........................................................................................................ 103

Characteristic maps ............................................................................................................... 103

Table of contents

MAN Diesel & Turbo

11 Quality assurance ............................................................................................................................. 106

11.1 Certification ............................................................................................................................ 106

11.2 Description of the quality criteria .......................................................................................... 109

12 Maintenance and inspection ............................................................................................................ 111

12.1

12.2

12.3

12.4

12.5

Maintenance work ................................................................................................................. 111

Bindingness and adaptability ................................................................................................ 111

Turbocharger on two-stroke engine ..................................................................................... 112

Turbocharger on four-stroke engine ..................................................................................... 112

Personnel and time required ................................................................................................. 113

13 Transportation ................................................................................................................................... 115

13.1 Fastening points ..................................................................................................................... 115

14 Preservation, packaging and storage .............................................................................................. 117

14.1 Corrosion prevention ............................................................................................................. 117

14.2 Packaging ............................................................................................................................... 117

14.3 Storage ................................................................................................................................... 117

15 Environmental protection and disposal ........................................................................................... 118

16 Spare parts ........................................................................................................................................ 119

16.1 Ordering spare parts .............................................................................................................. 119

17 Tools .................................................................................................................................................. 122

2014-07-16 - de

17.1 Tools ....................................................................................................................................... 122

18 Training and documentation ............................................................................................................ 124

18.1 Training programs ................................................................................................................. 124

18.2 Technical documentation ...................................................................................................... 124

19 Addresses .......................................................................................................................................... 125

19.1 MAN PrimeServ ...................................................................................................................... 125

5 (129)

1.1 Characteristics of the TCR Series turbochargers

1

MAN Diesel & Turbo

1

General

1.1

Characteristics of the TCR Series turbochargers

The cost-effective operation of modern engines is inconceivable without tur­

bochargers. Turbochargers from MAN Diesel & Turbo are equally tried and

tested with marine main engines, auxiliary engines and in stationary systems

under the most varied operating conditions. Reliability, easy maintenance

and long inspection intervals have been confirmed throughout decades of

experience.

With the TCR Series, expect not only clear increases in efficiency, but also

substantial improvements in reliability and service life.

Turbochargers of the TCR Series can be used on two-stroke and four-stroke

engines with constant-pressure and pulse turbocharging and engine outputs

from 390 to 7000 kW.

1

2

3

1 Exhaust gases

2 Charge air

3 Fresh air

Figure 1: TCR on in-line engine

1 General

2014-07-16 - de

The modular design of the TCR Series allows for optimal adaptation of the

turbochargers to the conditions for both four-stroke and two-stroke engines.

6 (129)

Project Guide, TCR, EN-US

1

1.2

Exhaust gas turbocharging

The turbochargers of the TCR Series are designed for constant-pressure and

pulse turbocharging.

Constant-pressure turbocharging:

With constant-pressure turbocharging, the engine exhaust gases flow into a

common exhaust manifold, accumulate there and flow with minor pressure

fluctuations to the exhaust turbine.

1 Exhaust gases

2 Charge air

1.2 Exhaust gas turbocharging

MAN Diesel & Turbo

3 Fresh air

Figure 2: Constant-pressure turbocharging

Pulse turbocharging:

1 General

2014-07-16 - de

With pulse turbocharging, the engine exhaust gases of the individual cylin­

ders are channelled into several narrow exhaust gas pipes and transfer the

outlet pressure pulses of the cylinders to the multi-socket gas admission

casing.

Project Guide, TCR, EN-US

7 (129)

1

1.4 Performance characteristics

MAN Diesel & Turbo

1 Exhaust gases

2 Charge air

3 Fresh air

Figure 3: Pulse turbocharging

1.3

Layout of the turbochargers on the engine

In many cases, the present necessity to realize the power adaptation on Vtype engines via two turbochargers can be avoided by the comprehensive

application range of the TCR Series and the higher efficiency of the turbo­

chargers. The characteristic diagrams of the TCR Series turbochargers indi­

cate that a safe distance between surge line and operating characteristic line

can be achieved on V-type engines, even with only one turbocharger.

The modular design of the TCR Series allows for optimal adaptation of the

turbochargers to the conditions for both four-stroke and two-stroke engines.

For individual turbocharger sizes in the TCR Series, both single-connection

as well as double-connection gas admission casings are available, enabling

optimum results to be achieved in terms of design and economy.

1.4

Performance characteristics

▪

Generator curve (constant engine speed)

▪

Fixed-pitch propeller curve (variable engine speed)

▪

Propeller curve at reduced engine speed (high torque)

▪

Combined curve (combination of generator and propeller curve)

▪

Vehicle engine curve.

1 General

Irrespective of the purpose for which the engine is being used, a safe dis­

tance is always required between all possible operating points and the surge

line of the compressor. This is ensured by dimensioning the compressor

accordingly.

8 (129)

Project Guide, TCR, EN-US

2014-07-16 - de

The following operating modes are distinguished:

1

1.5

Intended use

The turbocharger is intended for use on diesel, heavy-fuel-oil, gas-powered

and dual-fuel engines. It draws in the fresh air or air/gas mixture required for

engine operation and compresses it. The exhaust gas temperature must not

exceed the specified maximum values.

Any application beyond this must be discussed with and approved by the

manufacturer of the turbocharger. The turbocharger is not designed for oper­

ation in an explosive atmosphere, i.e. the engine room (room with the engine

and turbocharger) must be continuously vented.

1.5 Intended use

MAN Diesel & Turbo

Each turbocharger is specially adapted to the engine on which it is to be

operated. This means the turbocharger may be operated only on this engine

or one of identical design.

The turbocharger is considered as being implemented in accordance with its

intended use only if the following conditions are additionally fulfilled:

▪

by the engine manufacturer:

The engine manufacturer must ensure that the turbocharger is connected to

a supply of lube oil from the engine or plant. Any connection points in the

plant where an explosive mixture may be present must be appropriately

sealed.

The engine manufacturer must design the engine control system so that the

limit values of the turbocharger (max. permissible rotor speed and exhaust

gas temperature, permissible lube oil temperature and lube oil pressure,

vibrations, use of the specified operating media, max. permissible water

quantity and permissible water pressure) are not exceeded in the anticipated

operating conditions.

▪

by the installation contractor / manufacturer of the complete plant:

The installation location must afford sufficient space for maintenance and

installation/removal of the rotor assembly. The use of lifting equipment must

be possible.

The following flange loads and inclinations must be maintained:

Supply, measuring, control and regulating systems must enable troublefree

operation (design in accordance with the turbocharger manufacturer’s rec­

ommendations and state of the art).

It must be possible for operation to be monitored by means of suitable

measures.

by the user:

The turbocharger may be operated only when in perfect condition.

Work on the turbocharger may be carried out only by trained personnel. All

work is subject to compliance with the operating instructions and the statu­

tory occupational health and safety regulations.

Project Guide, TCR, EN-US

1 General

2014-07-16 - de

▪

The operating parameters (max. admissible rotor speed and exhaust gas

temperature, admissible lube oil temperature and lube oil pressure, use of

the specified operating media) must be observed and may not be exceeded

(see type plate, Chapter 1 - Type plate).

9 (129)

MAN Diesel & Turbo

Malfunctions that could influence safety must be remedied before starting or

resuming operation.

Service and maintenance work must be performed in accordance with the

maintenance schedule (see Chapter 12 - Maintenance and inspection).

Corrosion must be prevented on components that come into contact with an

explosive gas mixture.

2014-07-16 - de

Only original spare parts and fasteners of the specified quality (bolts, nuts,

washers, seals, etc.) may be used for repairs.

1 General

1.5 Intended use

1

10 (129)

Project Guide, TCR, EN-US

1

1.6

Type plate

The type plate is attached to the delivery socket of the compressor casing or

to the sound insulation of the compressor casing near the delivery socket. An

additional type plate is located on the silencer or the intake casing.

1

2

3

4

5

6

1.7

Turbocharger type

Speed n Smax – short-time operation (for test operation only)

Speed n Cmax – max. permissible speed for continuous operation

Works number (serial number)

Max. permissible turbine inlet temperature

Year of ex-works delivery

Reference values for pressure specifications in the Project Guide

NOTE

Reference value for pressure specifications

1 General

2014-07-16 - de

All pressures specified in bar in this planning manual are specified

as relative pressures (bar g).

1.7 Reference values for pressure specifications in the Project

Guide

MAN Diesel & Turbo

Project Guide, TCR, EN-US

11 (129)

2.2 Achievable power outputs per turbocharger

2

MAN Diesel & Turbo

2

Overview of series

2.1

Range of applications of the TCR Series

The turbochargers designed and manufactured by MAN Diesel & Turbo can

be used in a very wide range of applications for the charging of two-stroke

and four-stroke diesel- and gas-powered engines.

Figure 4: Turbocharger application range

Turbochargers of the TCR Series can be used on engines with constantpressure and pulse turbocharging and engine outputs from 390 to 7000 kW.

Achievable power outputs per turbocharger

2 Overview of series

Turbocharger type

12 (129)

Power of the charged engine per turbocharger in kW

2-stroke

4-stroke

le* = 7.0 kg/kWh

le* = 6.5 kg/kWh

TCR10

–

600

TCR12

–

880

TCR14

–

1300

TCR16

–

1850

TCR18

2700

2750

TCR20

4000

4000

TCR22

7000

6850

Table 1: Power of the charged engine per turbocharger

* le = specific air requirements

Project Guide, TCR, EN-US

2014-07-16 - de

2.2

2

2.3

Maximum compressor pressure ratios and exhaust gas temperatures

Turbocharger type

Maximum pressure ratio

Max. permissible exhaust gas temperature upstream of

turbine in °C

2-stroke

4-stroke

(standard)

4-stroke

(high-pressure)

2-stroke

4-stroke

TCR10

–

4.7

5.1

–

650

TCR12

–

4.7

5.2

–

650

TCR14

–

4.7

5.2

–

650

TCR16

–

4.7

5.3

–

650

TCR18

4.55

4.7

5.3

500

650

TCR20

4.55

4.7

5.4

500

650

TCR22

4.55

4.7

5.4

500

650

2014-07-16 - de

2 Overview of series

Table 2: Maximum pressure ratio and permissible exhaust gas temperatures

2.3 Maximum compressor pressure ratios and exhaust gas tem­

peratures

MAN Diesel & Turbo

Project Guide, TCR, EN-US

13 (129)

2.4 Weights of the subassemblies

2

MAN Diesel & Turbo

2.4

Weights of the subassemblies

Weights of subassemblies (without

optional subassemblies)

TCR10

TCR12

TCR14

TCR16

TCR18

TCR20

TCR22

Turbocharger, complete, without

accessories

47.7 kg

77.7 kg

107.7 kg

175.2 kg

305.7 kg

Gas admission casing, 1-channel

15.7 kg

26.2 kg

29.7 kg

45.0 kg

62.0 kg

104.7 kg

227.0 kg

-

-

41.7 kg

-

92.6 kg

154.3 kg

314.7 kg

-

-

-

-

91.8 kg

113.8 kg

-

-

-

-

-

93.8 kg

165.3 kg

-

-

-

23.1 kg

-

24.7 kg

66.8 kg

149.7 kg

13.1 kg

20.0 kg

38.2 kg

56.7 kg

88.3 kg

152.2 kg

351.5 kg

-

-

-

60.7 kg

94.3 kg

160.0 kg

363.4 kg

Adjustable turbine nozzle ring

-

-

-

-

16.0 kg

29.0 kg

64.7 kg

Adjustment device for VTA

-

-

-

-

25.5 kg

39.8 kg

43.2 kg

1.5 kg

2.1 kg

1.6 kg

3.0 kg

4.6 kg

7.8 kg

18.7 kg

13.1 kg

18.3 kg

22.7 kg

38.8 kg

87.8 kg

137.0 kg

290.0 kg

-

-

-

-

169.7 kg

-

183.0 kg

2.7 kg

4.8 kg

7.5 kg

14.2 kg

24.4 kg

42.0 kg

95.4 kg

Insert, compressor side

-

-

12.2 kg

12.7 kg

19.8 kg

34.9 kg

77.0 kg

Insert, turbine side

-

-

-

12.4 kg

20.9 kg

39.0 kg

31.3 kg

Diffuser

0.9 kg

5.4 kg

2.0 kg

3.1 kg

11.5 kg

11.9 kg

24.9 kg

Silencer *

7.2 kg

17.3 kg

31.0 kg

43.5 kg

69.0 kg

82.9 kg

300.5 kg

Air intake casing, 90°

-

-

11.6 kg

24.3 kg

41.3 kg

64.2 kg

141.8 kg

Air intake pipe, axial

-

-

17.9 kg

15.1 kg

24.8 kg

42.5 kg

92.7 kg

Compressor casing

13.8 kg

20.9 kg

32.0 kg

46.0 kg

74.7 kg

126.1 kg

279.5 kg

-

-

-

-

-

-

40.0 kg

4.7 kg

6.1 kg

16.0 kg

9.3 kg

14.5 kg

20.3 kg

53.5 kg

Covering on gas outlet elbow *

-

-

6.8 kg

-

-

30.1 kg

41.9 kg

Covering on gas outlet casing,

without waste gate *

2.6 kg

-

-

15.7 kg

23.7 kg

29.1 kg

53.4 kg

Covering on gas outlet casing,

with waste gate *

-

-

-

17.3 kg

20.9 kg

30.1 kg

53.4 kg

Covering on bearing casing *

-

-

-

1.0 kg

2.8 kg

4.1 kg

5.0 kg

Gas admission casing

504.4 kg 1043.8 kg

2-channel

Gas admission casing

3-channel

Gas admission casing

4-channel

Gas outlet elbow *

Gas outlet casing, without waste

gate *

Gas outlet casing,

Turbine nozzle ring

Bearing casing

Turbocharger foot *

2 Overview of series

Rotor, complete

14 (129)

Emergency lubrication tank *

Covering on gas admission cas­

ing *

Project Guide, TCR, EN-US

2014-07-16 - de

with waste gate

2

Weights of subassemblies (without

optional subassemblies)

TCR10

TCR12

TCR14

TCR16

TCR18

TCR20

TCR22

Sound insulation on compressor

casing

-

-

-

13.4 kg

20.0 kg

22.7 kg

32.4 kg

Cartridge (bearing casing with

rotor)

-

-

30.2 kg

53.0 kg

112.2 kg

179.0 kg

385.4 kg

* Optional

2.5 Dimensions

MAN Diesel & Turbo

Table 3: Weights for TCR turbocharger (approximate values)

2.5

Dimensions

Detailed dimensions can be read from the dimensioned 2D connection draw­

ings and 3D CAD models.

If required, please contact MAN Diesel & Turbo in Augsburg directly.

e-mail: Turbochargers@mandieselturbo.com

TCR for two-stroke engines

B

L

2014-07-16 - de

Type

L in mm

with silencer

L in mm

with air intake bend

L in mm

with air intake pipe

H in mm

B in mm

D in mm

TCR18

1294

1384

1049

1200

730

714

TCR20

1654

1706

1298

1688

852

834

TCR22

1957

2200

1657

1788

1068

996

Project Guide, TCR, EN-US

2 Overview of series

D

H

15 (129)

2

MAN Diesel & Turbo

2.5 Dimensions

TCR for four-stroke engines

B

L

D

H

L in mm

with silencer

L in mm

with air intake bend

L in mm

with air intake pipe

H in mm

B in mm

D in mm

TCR10

860

-

-

410

327

327

TCR12

889

-

-

496

401

401

TCR14

950

995

773

623

534

534

TCR16

1091

1162

887

658

590

590

TCR18

1311

1400

1066

870

730

714

TCR20

1662

1713

1307

970

852

834

TCR22

1990

2234

1691

1320

1068

996

16 (129)

2014-07-16 - de

2 Overview of series

Type

Project Guide, TCR, EN-US

2

Casing positions

For the best possible adaptation to the engine, certain casing assemblies of

the turbocharger can be supplied in any angular position up to 360° relative

to the vertical.

Compressor casing

Bearing casing

Gas admission casing

0°

0°

0°

V˞

0° - 360°

0°

0° - 360°

Other positions in consultation with

MAN Diesel & Turbo

Infinitely adjustable

Infinitely adjustable

Air intake casing

Gas outlet casing

Gas outlet elbow

0°

0°

0°

A˞

0° - 360° 1)

Infinitely adjustable

In the case of the TCR22, depend­

ing on the compressor casing, only

22.5° rotation possible

1)

2014-07-16 - de

Z˞

L˞

T˞

0° - 90° 1)

0° - 45°

270° - 360° 1)

315° - 360°

Infinitely adjustable

Infinitely adjustable

In the case of the TCR22-2 with gas

outlet elbow, only 0° - 45° and 315° 360°

1)

Other positions in consultation with

MAN Diesel & Turbo

NOTE

K˞

Casing positions viewed from the turbine side

Project Guide, TCR, EN-US

2 Overview of series

2.6

2.6 Casing positions

MAN Diesel & Turbo

17 (129)

18 (129)

MAN Diesel & Turbo

3

Design – Characteristics of the subassemblies

3.1

Characteristics of the subassemblies

1

2

3

4

5

Silencer

Diffuser

Semi-floating bearings

Turbine nozzle ring

Gas outlet casing

6

7

8

9

Turbine rotor

Gas admission casing

Compressor wheel

Compressor casing

The view illustrates the advanced design principle of the TCR Series:

▪

High efficiency

▪

Silencer

▪

Optional: Internal Recirculation (IRC)

▪

Easy-to-service compressor wheel with high efficiency

▪

Semi-floating bearings

▪

Integrated lube oil pipe

▪

Profiled turbine nozzle ring with long service life

▪

Standard flanges on gas outlet casing and air intake casing

▪

Easy inspection through large maintenance hatch

The flow-guiding components are developed with the aid of state-of-the-art

CFD calculation programs. Simulation of the complete turbine and compres­

sor stage allows realistic calculation of the operating performance and effi­

ciency of the turbocharger.

This enables a more compact design of many components as well as signifi­

cantly improved adaptation to the engine operating curve.

Project Guide, TCR, EN-US

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

3.1 Characteristics of the subassemblies

3

3

3.2

3.3 Compressor wheel

MAN Diesel & Turbo

Turbine rotor

Figure 5: Turbine rotor

The precision turbine rotor casting is made of a high-temperature resistant

nickel-based alloy and is joined to the rotor shaft by means of friction weld­

ing. CFD simulations, FEM calculations and extensive operational testing with

load measurement on the testbed ensure utmost reliability.

The turbine provides very good access for inspection and cleaning.

Compressor wheel

Figure 6: Compressor wheel

The highly stressed compressor wheel is milled from a forged aluminium

block. It builds up the charge pressure and supplies the engine with the

required amount of air.

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

2014-07-16 - de

3.3

19 (129)

3.4 Internal bearings

3

MAN Diesel & Turbo

3.4

Internal bearings

Figure 7: Internal bearings

For 70 years MAN Diesel & Turbo has been using plain bearings in turbo­

chargers with great success. The resulting wealth of experience has been

integrated into a long-life bearing concept.

The TCR Series combines tried-and-tested aspects of the axial and radial

bearing concept of the NR Series with new detail solutions.

20 (129)

▪

Semi-floating bearings

▪

Compact bearing concept with centrally fitted thrust bearing

▪

Shaft sealing with piston rings and no sealing air

Easy installation and removal of the bearings is ensured by the arrangement

of the radial bearings in the bearing bodies.

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

Characteristics of the bearing concept:

Project Guide, TCR, EN-US

3

3.5

3.5 Bearings

MAN Diesel & Turbo

Bearings

Figure 8: Bearings

The rotor shaft runs in plain bearings which ensure precise centring of the

rotor shaft. The centrally fitted thrust bearing serves for axial positioning and

for taking the axial thrust.

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

These bearings have ideal properties under extremely high axial and radial

forces and ensure a long service life. The high damping of the oil film makes

them insensitive to vibrations and imbalance.

Project Guide, TCR, EN-US

21 (129)

3.6 Bearing casing

3

MAN Diesel & Turbo

3.6

Bearing casing

Figure 9: Bearing casing

The bearing casing is manufactured of ductile cast iron. It contains the distri­

bution ducts for the lube oil, which is also used for cooling the casing.

22 (129)

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

For special applications with high exhaust gas or compressor temperatures,

a water-cooled bearing casing can be ordered.

Project Guide, TCR, EN-US

3

3.7

3.7 Compressor casing

MAN Diesel & Turbo

Compressor casing

Figure 10: Compressor casing

The angular position of the compressor casing is infinitely adjustable.

For the selectable positions of the casing, see Chapter 2 - Casing positions.

The newly calculated flow cross sections and the large outlet surfaces ensure

efficient conversion of the kinetic energy into pressure.

2014-07-16 - de

For special applications, the compressor casing can be sound-insulated.

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

The compressor casing is manufactured of ductile cast iron and has a single

outlet in the standard version. It is fastened to the bearing casing with clamp­

ing claws.

23 (129)

3.8 Diffuser

3

MAN Diesel & Turbo

3.8

Diffuser

Figure 11: Diffuser

The diffuser blank is manufactured of ductile cast iron, from which the vane

profile is then milled.

24 (129)

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

The compressor map can be optimally adapted to the engine by altering the

diffuser cross section (see Chapter 10 - Matching). This provides for optimal

conversion of the speed component into pressure downstream of the com­

pressor wheel.

Project Guide, TCR, EN-US

3

3.9

Silencer with air filter

Turbochargers for marine engines are equipped as standard with silencers

that are surrounded by a filter mat.

Silencer characteristics:

▪

Low intake pressure loss ensures good turbocharger performance

▪

Effective reduction of turbocharger noise emission

▪

Integrated compressor washing device

3.9 Silencer with air filter

MAN Diesel & Turbo

2014-07-16 - de

Filter mat characteristics:

▪

Permanent temperature resistance: up to 100 °C

▪

Air humidity resistance: up to 100%

▪

Reaction to fire: DIN 53 438 fire class F1, self-extinguishing.

▪

Effective filtration keeps the compressor, diffuser and charge air cooler

largely free from dirt particles.

▪

Easy replacement and installation.

▪

It is advisable to exchange the filter mat after 250-500 hours of opera­

tion, but gentle cleaning, including with mild cleaning agents, is possible

and permissible.

For this, rinse with warm water from the inside outwards, vacuum or blow

out with compressed air. If necessary, mild detergents can be added to the

water. Avoid heavy mechanical stress, such as wringing out or applying a

strong water jet.

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

Figure 12: Silencer

25 (129)

3.10 Air intake casing

3

MAN Diesel & Turbo

3.10

Air intake casing

Figure 13: Air intake casing, 90° / Air intake casing, axial

The air intake casing is used in the case of operation without a silencer. It

achieves constant distribution of pressure and velocity at the compressor

intake due to optimized flow ducts. The angular position of the air intake cas­

ing is infinitely adjustable relative to the bearing casing.

For the selectable positions of the casing, see Chapter 2 - Casing positions.

26 (129)

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

The air intake casing is available in 90° and axial variants.

Project Guide, TCR, EN-US

3

3.11

3.11 Gas admission casing

MAN Diesel & Turbo

Gas admission casing

Figure 14: Gas admission casing

The gas admission casing is manufactured of silicon-molybdenum alloyed

ductile cast iron. The uncooled casing is heat-insulated with a covering.

2014-07-16 - de

Optimized flow cross sections keep the flow losses at a low level. For pulse

turbocharging, the gas admission casing is available with multiple intake con­

nections for individual turbocharger sizes.

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

The gas admission casing is fastened to the bearing casing with clamping

claws; its angular position is infinitely adjustable.

For the selectable positions of the casing, see Chapter 2 - Casing positions.

27 (129)

3.13 Adjustable turbine nozzle ring

3

MAN Diesel & Turbo

3.12

Turbine nozzle ring

Figure 15: Turbine nozzle ring

The cast turbine nozzle ring with profiled blades largely contributes to the

excellent efficiency of the turbine of the TCR Series.

28 (129)

3.13

Adjustable turbine nozzle ring

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

Optimum adaptation of the turbocharger to the engine is achieved by means

of nozzle ring variants with different cross sections. The turbine nozzle ring is

made of a highly resistant material, which ensures a long service life.

Figure 16: Adjustable turbine nozzle ring

Project Guide, TCR, EN-US

3

The cross section of the turbine nozzle ring can be adapted to the engine

operation requirements by adjusting the guide vanes. A narrower cross sec­

tion of the turbine nozzle ring results in a higher gas admission speed to the

turbine rotor. The turbocharger speed increases, thereby causing the charge

pressure on the compressor side to rise.

The adjustment is carried out by an adjustment device driven by a servomo­

tor. The adjustment device for the turbine nozzle ring is fastened to the bear­

ing casing of the turbocharger.

NOTE

Further information about the adjustable turbine nozzle ring can

be found in the TCR - VTA Project Guide.

Gas outlet casing

Figure 17: Gas outlet casing

The gas outlet casing is manufactured of ductile cast iron. The casing is

uncooled and is heat-insulated with a covering.

2014-07-16 - de

Integrated in the gas outlet casing is an optimized, high-volume and very effi­

cient gas outlet diffuser. Its angular position in relation to the bearing casing

is infinitely adjustable.

For the selectable positions of the casing, see Chapter 2 - Casing positions.

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

3.14

3.14 Gas outlet casing

MAN Diesel & Turbo

29 (129)

3.15 Waste gate

3

MAN Diesel & Turbo

3.15

Waste gate

Figure 18: Gas outlet casing with waste gate

The gas outlet casing can be supplied with a waste gate connection:

30 (129)

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

The waste gate enables the exhaust gas to be diverted in order to prevent

the maximum turbocharger speed from being exceeded. The optimized

waste gate connection, aligned with the turbocharger axis, allows easy

mounting on the engine.

Project Guide, TCR, EN-US

3

3.16

3.17 Loads on connections and flanges

MAN Diesel & Turbo

Gas outlet elbow

Figure 19: Gas outlet elbow

Certain turbochargers of the TCR Series can also be supplied with a gas out­

let elbow.

3.17

Loads on connections and flanges

All turbocharger casing flanges , with the exception of the turbine outlet, may

only be subjected to loads generated by the gas forces. The specified maxi­

mum values must be observed, taking external forces and torques into con­

sideration.

This necessitates the use of compensators directly at the turbine inlet, at the

turbine outlet and downstream of the compressor.

2014-07-16 - de

The compensators must be pre-loaded in such a manner that thermal

expansion of the pipes and casings does not exert forces or torques in addi­

tion to those generated by the air and gas.

▪

Forces and torques according to API Standard 617

▪

Effective direction implemented in accordance with MAN Diesel & Turbo

Standard.

▪

Minimize anticipated loads as far as possible.

▪

Parameters include forces of fluids, masses and compensators.

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

The gas outlet elbow is made of ductile cast iron. The reduced space

requirement and the lower weight are an advantage for assembly.

31 (129)

32 (129)

MAN Diesel & Turbo

Connection of the charge air pipe

Figure 20: Maximum connection loads, compressor casing

Type

Fx in N

Fy in N

Fz in N

Mx in Nm

Mz in Nm

TCR10

1300

2700

2700

2000

1000

TCR12

1600

3200

3200

2400

1200

TCR14

1900

3900

3900

2900

1400

TCR16

2300

4600

4600

3500

1700

TCR18

2800

5700

5700

4300

2100

TCR20

3400

6900

6900

5200

2600

TCR22

3 900

7900

7900

6000

3000

Project Guide, TCR, EN-US

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

3.17 Loads on connections and flanges

3

3

3.17 Loads on connections and flanges

MAN Diesel & Turbo

d

k

D

Figure 21: Compressor casing connection

Type

D in mm

d in mm

k in mm

Bolts

TCR10

125*

84

95*

4

TCR12

146*

100

105*

4

TCR14

150*

121

167

4

TCR16

180

145

200

4

TCR18

231

177

220

8

TCR20

280

213

265

8

TCR22

370

279

350

8

Compensator fastened directly to the turbocharger flange.

2014-07-16 - de

▪

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

* Square connection

33 (129)

34 (129)

MAN Diesel & Turbo

Connection of the exhaust gas pipe (engine side)

Figure 22: Maximum connection loads on gas admission casing

▪

Type

Fx in N

Fy in N

Fz in N

Mx in Nm

Mz in Nm

TCR10

1300

2700

2700

2000

1000

TCR12

1600

3200

3200

2400

1200

TCR14

1700

3500

3500

2700

1300

TCR16

2100

4300

4300

3200

1600

TCR18

2600

5200

5200

3900

1900

TCR20

3100

6300

6300

4700

2300

TCR22

3800

7700

7700

5800

2900

Compensator fastened directly to the turbocharger flange.

Project Guide, TCR, EN-US

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

3.17 Loads on connections and flanges

3

3

3.17 Loads on connections and flanges

MAN Diesel & Turbo

d

k

D

Figure 23: Gas admission casing connection

Type

D in mm

d in mm

k in mm

Bolts

TCR10

128*

84

95*

4

TCR12

154*

100

117*

4

TCR14

150*

111

164

4

TCR16

180

134

195

4

TCR18

233

162

215

8

TCR20

275

195

260

8

TCR22

360

255

340

8

Compensator fastened directly to the turbocharger flange.

2014-07-16 - de

▪

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

* Square connection

35 (129)

36 (129)

MAN Diesel & Turbo

Connection of the exhaust gas pipe (system side)

Figure 24: Maximum connection loads on gas outlet casing / gas outlet elbow

Gas outlet casing

Type

Fx in N

Fy in N

Fz in N

Mx in Nm

Mz in Nm

TCR16

3800

7700

7700

5800

2900

TCR18

4100

8300

8300

6300

3100

TCR20

4400

8900

8900

6800

3400

TCR22

5000

10200

10200

7700

3800

Gas outlet elbow

Type

Fx in N

Fy in N

Fz in N

Mx in Nm

Mz in Nm

TCR10

2100

4200

4200

3200

1600

TCR12

2500

5000

5000

3800

1900

TCR14

3000

6100

6100

4600

2300

Project Guide, TCR, EN-US

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

3.17 Loads on connections and flanges

3

3

Gas outlet elbow

Type

Fx in N

Fy in N

Fz in N

Mx in Nm

Mz in Nm

TCR20

4200

8500

8500

6500

3200

TCR22

4800

9600

9600

7300

3600

d

k

D

3.17 Loads on connections and flanges

MAN Diesel & Turbo

Figure 25: Gas outlet casing / gas outlet elbow connection

Type

D in mm

d in mm

k in mm

Bolts

TCR16

357

256

335

12

TCR18

425

310

395

12

TCR20

540

373

495

16

TCR22

703

487

650

20

2014-07-16 - de

Gas outlet elbow

Type

D in mm

d in mm

k in mm

Bolts

TCR10

250

131

210

8

TCR12

285

157

240

8

TCR14

315

189

270

8

TCR20

490

333

445

12

TCR22

595

436

550

20

▪

Compensator fastened directly to the turbocharger flange.

▪

Flange connection in accordance with DIN 86044.

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

Gas outlet casing

37 (129)

3.18 Permissible inclination

3

MAN Diesel & Turbo

3.18

Permissible inclination

The turbochargers from MAN Diesel & Turbo must be installed horizontally

with respect to the axis of the rotor assembly.

For operation in ships, the turbocharger should be installed along the longitu­

dinal axis of the vessel.

In the case of installation perpendicular to the longitudinal axis of the vessel,

inclination angles may occur that can impair the operating ability of the turbo­

charger.

In the case of an installation position along the longitudinal axis of the vessel,

these limit values are not reached even under unfavorable external condi­

tions.

The following inclination angles can be handled by the turbocharger without

problems.

38 (129)

Inclination

Continuous

α

±25°

β

±25°

Table 4: Permissible inclination angles during operation of the turbocharger

2014-07-16 - de

3 Design – Characteristics of the subas­

semblies

In individual cases, larger inclination angles are also possible. If required,

please contact MAN Diesel & Turbo SE in Augsburg.

Project Guide, TCR, EN-US

3

3.19

Permissible vibration limit values

3.19 Permissible vibration limit values

MAN Diesel & Turbo

1 Silencer front plate

2 Flange of the compressor casing / silencer

3 Flange of the compressor casing / bearing casing, vertical to the turbo­

charger axis

During engine operation, the turbocharger is subject to stress from vibrations

that are generated by the engine and the turbocharger itself.

The excitation emanating from the engine lies within the low-frequency

range.

The resulting vibrations of the turbocharger structure subject the mounted

silencer and the connecting elements between casing parts and turbo­

charger feet to stress.

Natural frequencies of the turbocharger may be in the frequency range

excited by the engine.

2014-07-16 - de

The bearing load resulting from the engine excitation is negligible, as the

rotors of MAN Diesel & Turbo turbochargers are seated in plain bearings.

Vibrations excited by the turbocharger itself are generated by forces of imbal­

ance that are transmitted via the bearings into the casings. The relevant fre­

quency is in the high-frequency range.

The vibrations resulting from the circumferential imbalance forces do not

have a detrimental effect on the structure of the turbocharger casings, but

serve as an indicator of the balance condition of the rotor and thus of the

running behavior.

Imbalances occurring during operation can be caused by irregular dirt

deposits or damaged blades of the compressor wheel and/or turbine rotor.

If erratic running of the turbocharger is observed during operation, the condi­

tion can be improved in most cases by cleaning the compressor (see Chap­

ter Compressor cleaning) and the turbine (see Chapter Turbine cleaning).

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

Figure 26: Vibration acceleration measuring point

39 (129)

MAN Diesel & Turbo

If the running behaviour is still not satisfactory after repeated cleaning, the

rotor must be inspected and a balance check carried out if required. The

maximum permissible vibration acceleration values for both aforementioned

excitation types are listed below.

NOTE

Turbocharger vibration limit values

Turbo­

charger

type

Recommendation

f (Hz)

Meas.

Meas.

Meas.

Meas.

Meas.

pt.

pt.

pt.

pt.

pt.

pt.

mm/s

g

mm/s

g

mm/s

g

mm/s

g

mm/s

g

mm/s

g

TCR10

2.9

2.2

2.9

6.4

3.2

5.8

TCR12

2.6

2.0

2.6

5.8

2.9

5.2

TCR16

3 Design – Characteristics of the subas­

semblies

Consult

Turbochargers@mandieselturbo.com

Meas.

TCR14

40 (129)

The values specified in the following tables are only valid for

measurements on turbochargers installed on the engine. The

engine must be installed at the site of operation in accordance

with its intended use and fastened to the foundation in accord­

ance with the engine manufacturer’s specifications. The values

are not valid for turbochargers on the testbed (shop test).

2.0

3...300

45

1.7

1.6

35

1.4

2.0

45

1.7

4.5

100

3.8

2.2

50

1.9

4.0

90

3.5

TCR18

1.4

1.1

1.4

3.2

1.6

2.9

TCR20

1.2

0.9

1.2

2.6

1.3

2.3

TCR22

0.9

0.7

0.9

1.9

1.0

1.7

Table 5: Turbocharger vibration limit values – measuring points (1) and (2)

Turbocharger

type

Meas. pt.

TCR10 - 22

0.8 g

Table 6: 0-peak, single value measuring point (3)

2014-07-16 - de

3.19 Permissible vibration limit values

3

Project Guide, TCR, EN-US

3

3.20

3.20 Noise emission

MAN Diesel & Turbo

Noise emission

Figure 27: TCR16 noise emission (example)

The noise emission of the turbocharger varies according to the size, precise

specification and service point, in terms of both the dominated frequency

range and the level of noise emission. Typically, the noise spectrum is domi­

nated by the tonal noise components of the compressor; in typical engine

applications, these are in the range 2.5 to 16 kHz (1) for the TCR Series. The

maximum sound pressure levels are to be expected in the area of the filter

silencer (if provided). The turbocharger generally conforms to the IMO noise

limit values for ships’ engine rooms (2). The emission sound pressure level at

a distance of 1 m is less than 105 dB(A) (3).

Sound insulation is optionally available for reducing the noise emissions of

the compressor casing.

2014-07-16 - de

The diagram shows an example of the noise spectrum measured on the tur­

bocharger testbed.

(1)

1/3 octave frequency band

(2)

IMO "Code on Noise Levels on Board Ships"; the design of the engine

room with regard to noise levels is the responsibility of the system user.

(3)

A precondition is corresponding design of the engine-side peripherals, such

as suitable dimensioning and insulation of the connected charge air piping,

including that of the charge air cooler; this is the responsibility of the engine

manufacturer. This also applies to the piping on the intake side if the air

intake casing is used. In particular, it must be ensured that the compensa­

tors are sufficiently insulated!

Project Guide, TCR, EN-US

3 Design – Characteristics of the subas­

semblies

* Depending on the ambient acoustic conditions, the data may differ from

those specified.

41 (129)

4.1 Lube oil system

4

MAN Diesel & Turbo

4

Systems

4.1

Lube oil system

The lube oil is fed to the turbocharger from the lube oil system of the engine.

Lube oil connections on four-stroke engines

The turbocharger has two connections for lube oil feed at the bottom of the

bearing casing. The connection that is not required must be sealed off in the

area of the turbocharger bracket.

The connection for lube oil outlet is located between the two feed connec­

tions. The measuring point for the lube oil pressure is located at the top of

the bearing casing.

4 Systems

Type

42 (129)

Inner diameter of lube oil inlet

in mm

Inner diameter of lube oil outlet

in mm

TCR10

10

25

TCR12

12

30

TCR14

14

32

TCR16

16

37

TCR18

18

45

Project Guide, TCR, EN-US

2014-07-16 - de

Figure 28: Connections for lube oil (four-stroke engines)

4

Type

Inner diameter of lube oil inlet

in mm

Inner diameter of lube oil outlet

in mm

TCR20

20

54

TCR22

22

70

Lube oil connections on two-stroke engines

4.1 Lube oil system

MAN Diesel & Turbo

Connections for venting, lube oil feed and lube oil outlet are available on both

sides of the turbocharger foot. The connections that are not required must

be sealed off.

The measuring point for the lube oil pressure is located at the top of the

bearing casing.

1 Measuring point

2 Venting

3 Lube oil supply

4 Lube oil outlet

2014-07-16 - de

Type

Inner diameter of lube oil inlet

in mm

Inner diameter of lube oil outlet

in mm

TCR18

18

45

TCR20

20

54

TCR22

22

65

Project Guide, TCR, EN-US

4 Systems

Figure 29: Connections for lube oil (two-stroke engines)

43 (129)

4

MAN Diesel & Turbo

4.1 Lube oil system

Lube oil diagram for turbocharger on four-stroke engine

1

2

3

4

5

Feed pipe (engine)

Engine bracket

Ring duct *

Bearing casing *

Thrust bearing *

6

7

8

9

Bearing bush *

Pressure gauge

Pressure controller

Outlet pipe

* Scope of supply of turbocharger

Figure 30: Lube oil diagram for turbocharger on four-stroke engine

Function

The highly stressed bearing points in the turbocharger are lubricated and

cooled by means of a lube oil system integrated into the bearing casing of

the turbocharger.

4 Systems

2014-07-16 - de

The lube oil is normally fed from the lube oil system of the engine to the lube

oil system of the turbocharger via the feed pipe (1). The lube oil flows to the

radial and axial lubrication gaps of the turbocharger via the ring duct (3) and

bores in the bearings. On top of the bearing casing (4) is a connection for the

pressure gauge (7) and/or the pressure controller (8) for checking/monitoring

the lube oil pressure.

The oil flows back into the lube oil system of the engine through the outlet

pipe (9).

44 (129)

Project Guide, TCR, EN-US

4

Lube oil diagram for turbocharger on two-stroke engine

1

2

3

4

5

6

7

8

Feed pipe (engine)

Lube oil feed, turbocharger

Turbocharger foot *

Non-return valve *

Bearing casing *

Ring duct *

Thrust bearing *

Bearing bush *

9

10

11

12

13

14

4.1 Lube oil system

MAN Diesel & Turbo

Pressure gauge

Pressure controller

Emergency lubrication tank *

Overflow and ventilation pipe *

Lube oil outlet

Venting pipe

* Scope of supply of turbocharger

Figure 31: Lube oil diagram for turbocharger on two-stroke engine

Function

The highly stressed bearing points in the turbocharger are lubricated and

cooled by means of a lube oil system integrated into the bearing casing of

the turbocharger.

The lube oil flows to the radial and axial lubrication gaps of the turbocharger

via the ring duct (6) in the bearing casing (5) and bores in the bearings. On

top of the bearing casing (5) is a connection for the pressure gauge (9)

and/or the pressure controller (10) for checking/monitoring the lube oil pres­

sure.

The lube oil flows into the lube oil system of the engine via the lube oil outlet

(13).

Project Guide, TCR, EN-US

4 Systems

2014-07-16 - de

The lube oil is fed from the lube oil system of the engine to the lube oil sys­

tem of the turbocharger via the lube oil feed pipe (2). To prevent the lube oil

from flowing back into the lube oil feed pipe (1) in the direction of the engine

in the event of a failure of the oil supply on the engine side, a non-return valve

(4) is installed in the turbocharger foot (3).

45 (129)

4.1 Lube oil system

4

MAN Diesel & Turbo

Lube oil outlet

The outlet pipe should have as steep a gradient as possible, and it should be

amply dimensioned and free of resistances and back pressures.

▪

In the case of marine propulsion systems, the inclination of the outlet

pipe must be at least 5° greater than the maximum possible inclination of

the vessel.

▪

In the case of stationary systems, the outlet pipe must have an inclination

of at least 5°.

Separate lube oil system

If requested by the customer, MAN turbochargers can also be operated with

a lube oil system that is independent of the engine. With plain bearings, such

as those used in all MAN turbochargers, a separate lube oil supply of the tur­

bocharger is not required. The bearings used are designed for applications

with lube oil from the lube oil circuit of the engine. The turbocharger can,

however, be operated with a separate lube oil supply. The advantage of this

system is that the oil ages more slowly and that no combustion residues are

carried into the oil. Since the turbocharger does not require a separate lube

oil supply, MAN Diesel & Turbo does not offer it as an option, but can pro­

vide assistance in the form of a flowchart for the design of such a system.

If required, planning data can also be requested for a lube oil supply of the

turbocharger, independent of the engine lubrication circuit. If required, please

contact MAN Diesel & Turbo in Augsburg directly.

e-mail: Turbochargers@mandieselturbo.com

Venting

46 (129)

▪

The cross section of the venting pipe should correspond to that of the oil

outlet pipe.

▪

The venting pipe must be at least 5 m in length.

▪

In the case of marine propulsion systems, the inclination of the venting

pipe must be at least 5° greater than the maximum possible inclination of

the vessel.

▪

In the case of stationary systems, the venting pipe must have an inclina­

tion of at least 5°.

On TCR turbochargers for two-stroke engines, the venting facility is inte­

grated into the turbocharger foot. The connection for the venting pipe is

attached to the turbocharger foot.

Project Guide, TCR, EN-US

2014-07-16 - de

4 Systems

Up to 0.2% of the intake air escapes with the lube oil through the oil outlet

pipe via the bearing casing. This air volume can lead to an inadmissibly high

increase of the pressure prevailing in the crankcase.

To prevent this, the oil outlet must be vented. This must take place from a

compartment large enough to permit the oil to settle down. The oil pipe can

be vented by means of separate venting in the oil outlet or sufficiently dimen­

sioned crankcase venting.

4

Shaft sealing

The oil space is sealed on the turbine and compressor sides by piston rings.

For this reason, TCR turbochargers do not require sealing air and can be

pre-lubricated without time limits.

The robust piston ring sealing ensures ease of servicing.

4.2

Lube oil flow rate

The flow rate of the lube oil depends on the viscosity (SAE class) and tem­

perature of the oil. The bearings are rated for use of standard SAE 30 or

SAE 40 engine lube oils and can therefore be directly connected to the lube

oil system of the engine. High-alkaline cylinder oils are not suitable for lubri­

cation of the turbocharger bearings.

Lube oil characteristic/property

Viscosity

4.3 Lube oil pressure

MAN Diesel & Turbo

Characteristic value

SAE 30 or SAE 40

Min. lube oil inlet temperature

40 °C (SAE 40)

Max. lube oil inlet temperature

70 °C (SAE 40)

For information about lube oil quality, see Chapter 5 - Quality requirements

on lube oil and additives.

4.3

Lube oil pressure

The required lube oil pressure of the turbocharger is set in the lube oil feed.

The oil pressure must be set by the engine manufacturer prior to initial startup. The oil pressure must be checked via the measuring connection at the

top of the bearing casing.

The lube oil pressure must be selected so that a pressure of 1.3 – 2.2 bar is

present at this point at full engine load and with the lube oil at service tem­

perature.

The following parameters apply for the monitoring of the lube oil pressure:

Alarm points

Limit value in bar

Alarm

1.0

Direct load reduction of the engine

(slow down)

0.8

Engine shutdown

0.6

For differences in height between the pressure measuring point and the cen­

tre of the turbocharger, a value of 0.1 bar per metre must be taken into con­

sideration.

Example:

If the pressure gauge or the pressure controller is located three meters lower,

the pressure gauge must indicate a pressure 0.3 bar higher or the setting of

the pressure controller must be 0.3 bar higher than the specified operating

pressure. The required lube oil pressure is set by means of a throttle device

in the feed pipe.

Project Guide, TCR, EN-US

4 Systems

2014-07-16 - de

On start-up and during heating up of the engine, when the lube oil tempera­

ture is relatively low, a lube oil pressure of up to 6.0 bar is admissible for a

short period of time.

47 (129)

4.3 Lube oil pressure

4

MAN Diesel & Turbo

The required lube oil quantity depends on the viscosity of the oil and may

vary in accordance with the temperature.

Oil Pressures (reference point is the turbocharger centreline)

Measuring point

Limit value in bar

Lube oil pressure during operation

(lube oil inlet temperature 40 – 70 °C)

(SAE 40)

Max. lube oil pressure in cold condition

(only permissible briefly)

1.3 – 2.2

<6

Pre-lubrication (up to 10 minutes)

0.2 – 2.2

Pre-lubrication (over 10 minutes)

0.2 – 0.6

Continuous pre-lubrication

0.3 – 0.6

Post-lubrication (10 minutes)

0.2 – 2.2

Post-lubrication (10 – 30 minutes)

0.2 – 0.6

CAUTION

Lube oil pressure immediately after start-up

At low lube oil temperature (after start-up), the lube oil pressure

may briefly exceed the defined operating limits. By the time the

operating temperature has been reached, the lube oil pressure

must have dropped to within the defined range.

4 Systems

2014-07-16 - de

Indication of the pending alarm and the reaction of the engine control system

must occur at the same time. Therefore, the engine control system must

conform at least to category 3 in compliance with ISO 13849-1.

48 (129)

Project Guide, TCR, EN-US

4

4.4

Emergency lubrication

The worst-case scenario for the turbocharger bearings is a direct engine

shutdown from full load, which can occur in the event of a power failure. In

this phase, the bearings can easily overheat due to a lack of lube oil. To pre­

vent this, the following minimum requirements must be met.

For emergency lubrication, the turbocharger requires an oil pressure greater

than 0.05 bar (reference point: turbocharger centerline) if, in an emergency

situation, the engine initially continues to run at full power following failure of

the main lube oil supply (see Figure Emergency lubrication diagram).

NOTE

For differences in height between the pressure measuring point

and the centre of the turbocharger, a value of 0.1 bar per metre

must be taken into consideration.

4.4 Emergency lubrication

MAN Diesel & Turbo

If the main lube oil pump is not driven by the crankshaft of the engine, the

engine must be shut down no more than 10 seconds after a power failure.

These 10 seconds must be bridged using a separate lube oil tank or an

emergency pump (powered by battery or compressed air). The optional grav­

itation tank is designed to meet this requirement.

The lube oil pressure during emergency lubrication must be above the limit

value of 0.05 bar (reference point: turbocharger centreline) until the turbo­

charger speed has fallen to 20% of the maximum permissible speed indi­

cated on the type plate. Please note that the axial bearing of the turbo­

charger acts like a pump. For this reason, the turbocharger must be supplied

with sufficient lube oil. After this time, the lube oil pressure may fall below this

value. The remaining oil in the bearing casing is sufficient to protect the bear­

ings against damage or increased wear until the rotor has come to a stand­

still.

4 Systems

2014-07-16 - de

The installation height of a gravitation tank above the turbocharger axis must

not exceed 3 m, as refilling of the gravitation tank can no longer be assured

with increasing installation height, with the result that the correct filling height

may no longer be reached.

Project Guide, TCR, EN-US

49 (129)

engine

shut down

MAN Diesel & Turbo

blackout

4.5 Pre-lubrication and post-lubrication of the turbocharger

4

Lube oil pressure at the middle of the

turbocharger shall not drop below

this line at any time.

100%

turbocharger speed

nominal

lube oil pressure

min. post-lubrication

pressure

0,05 bar

20%

turbocharger speed

max.

10 sec.

max.

20 min

30 min

Figure 32: Emergency Lubrication Diagram

Emergency lubrication for two-stroke engines with gravitation tank

In systems with monitoring of the lube oil pressure (alarm and/or engine shut­

down if defined values are exceeded) the emergency lubrication bridges the

response time (max. 10 s) until the engine has shut down.

The gravitation tank is filled via the lube oil system during operation and con­

stantly purged with lube oil. If the pressure in the lube oil system drops, the

non-return valve in the oil feed pipe closes and the lube oil flows out of the