“AD-1” and “ADL-1” Tension Packers

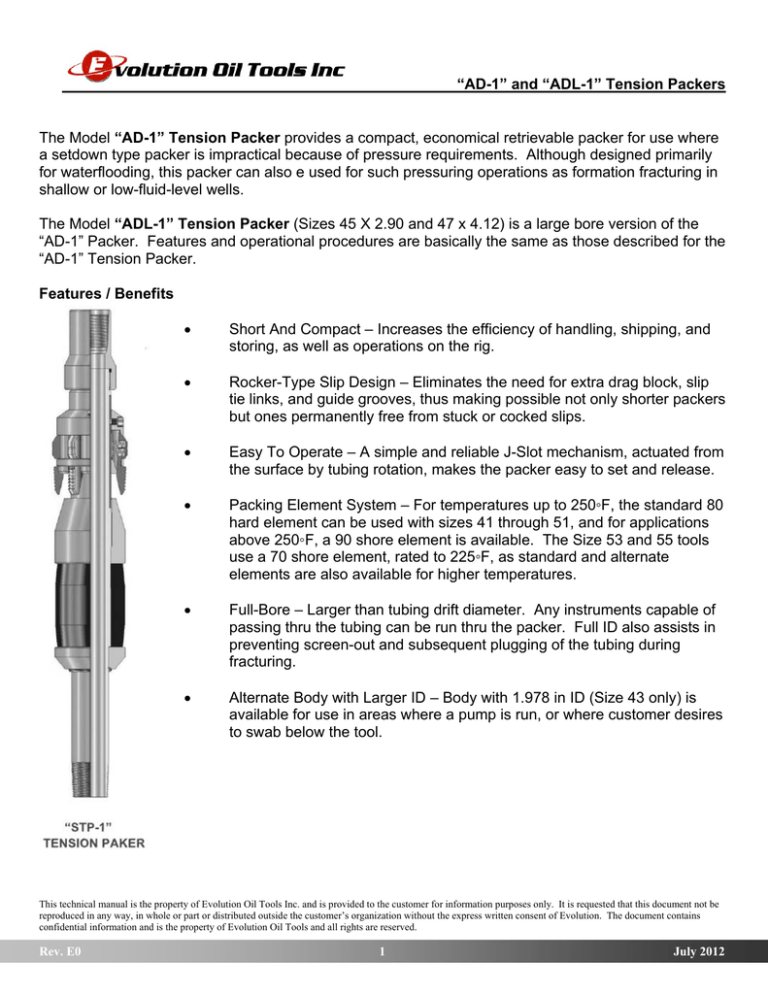

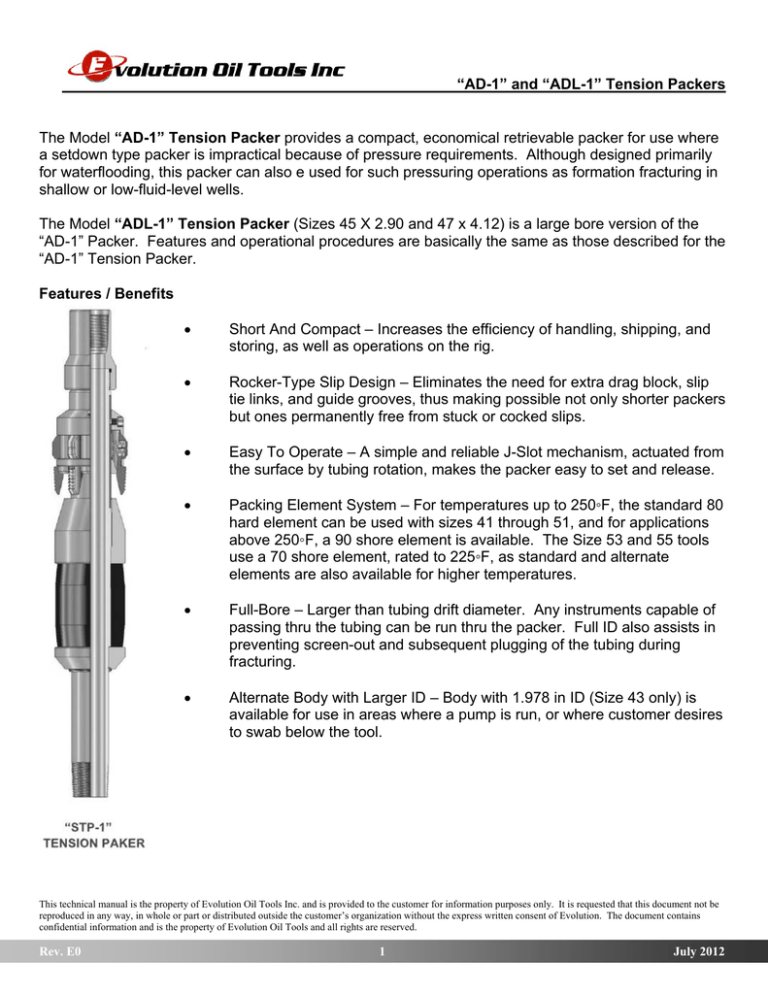

The Model “AD-1” Tension Packer provides a compact, economical retrievable packer for use where

a setdown type packer is impractical because of pressure requirements. Although designed primarily

for waterflooding, this packer can also e used for such pressuring operations as formation fracturing in

shallow or low-fluid-level wells.

The Model “ADL-1” Tension Packer (Sizes 45 X 2.90 and 47 x 4.12) is a large bore version of the

“AD-1” Packer. Features and operational procedures are basically the same as those described for the

“AD-1” Tension Packer.

Features / Benefits

Short And Compact – Increases the efficiency of handling, shipping, and

storing, as well as operations on the rig.

Rocker-Type Slip Design – Eliminates the need for extra drag block, slip

tie links, and guide grooves, thus making possible not only shorter packers

but ones permanently free from stuck or cocked slips.

Easy To Operate – A simple and reliable J-Slot mechanism, actuated from

the surface by tubing rotation, makes the packer easy to set and release.

Packing Element System – For temperatures up to 250◦F, the standard 80

hard element can be used with sizes 41 through 51, and for applications

above 250◦F, a 90 shore element is available. The Size 53 and 55 tools

use a 70 shore element, rated to 225◦F, as standard and alternate

elements are also available for higher temperatures.

Full-Bore – Larger than tubing drift diameter. Any instruments capable of

passing thru the tubing can be run thru the packer. Full ID also assists in

preventing screen-out and subsequent plugging of the tubing during

fracturing.

Alternate Body with Larger ID – Body with 1.978 in ID (Size 43 only) is

available for use in areas where a pump is run, or where customer desires

to swab below the tool.

This technical manual is the property of Evolution Oil Tools Inc. and is provided to the customer for information purposes only. It is requested that this document not be

reproduced in any way, in whole or part or distributed outside the customer’s organization without the express written consent of Evolution. The document contains

confidential information and is the property of Evolution Oil Tools and all rights are reserved.

Rev. E0

1

July 2012

“AD-1” and “ADL-1” Tension Packers

Operation

To Set Packer

Run the packer to desired setting depth, making the last movement down before attempting actual set.

Rotate the tubing to the left one-quarter turn at the tool, and pick-up on the tubing string to obtain packoff. Refer to chart below for upstrain required to set the various size packers.

Required Upstrain On Tubing String

To Set Tension Packers

Size Tool

Upstrain (lbs)

41

2,000

43 & 45

5,000

47

7,500

49-55

15,000

To Release Packer

Lower the tubing string at least one (1) foot more than is necessary to remove the applied tension (this will move

the J-Pin to the top of the J-Slot) and rotate to the right sufficiently to obtain one-quarter turn at the packer.

Emergency Release

For use under extreme conditions, two safety release method s are available.

1.

These packers have an emergency Shear Ring installed on the Body, below the Guide, Application of

from 25,000 to 50,000 lbs tension (dependent on strength of Shear Ring) will shear the Shear Ring, permitting

the Cone, Packing Element and Guide to drop against the Bottom Sub where they will remain as the Packer is

retrieved from the well.

2.

If it is not desirable or practical to pull 50,000 lbs through the tubing, apply approximately 10,000 lbs

strain and rotate the tubing 20 or more turns to the right. This unscrews the left-hand safety thread between the

Top Sub and the Body and allows removal of the tubing string and the Top Sub. To remove the remaining

portion of the Packer, install a set of Jars made up above an overshot, socket or spear (or the Top Sub), engage

the Packer Body and actuate the Jars to free the Packer Body form the casing.

This technical manual is the property of Evolution Oil Tools Inc. and is provided to the customer for information purposes only. It is requested that this document not be

reproduced in any way, in whole or part or distributed outside the customer’s organization without the express written consent of Evolution. The document contains

confidential information and is the property of Evolution Oil Tools and all rights are reserved.

Rev. E0

2

July 2012

“AD-1” and “ADL-1” Tension Packers

“AD” Specification Guide

Casing

O.D.

T&C

Weight

Lbs / ft

Size

4

9.5-11.6

41/2"

5"

Preferred

Range of

Casing ID's

Packer

Bore

Packing

Element

OD

Absolute

Minimum

Collapsed

Diameter of

Slips

Absolute

Maximum

Casing ID

Slip

Travel

3.374

3.548

Min.

Max

41A

3.428

3.548

12.615.1

41B

3.697

3.958

9.5-13.5

43A

3.910

4.160

3.771

3.719

3.787

4.170

15-18

43B

4.161

4.408

4.125

3.938

4.103

4.409

43C

4.408

4.560

4.250

4.156

4.255

4.561

20-23

45A2

4.625

4.778

4.500

4.375

4.543

4.966

15.5-20

45A4

4.778

4.950

4.641

45B

4.950

5.190

4.781

4.688

4.825

5.248

5.191

5.390

5.062

5.391

5.560

5.156

11.5-15

Model

Guide

Ring

OD

1.895

3.188

3.609

Thread

Specifications

Box Up X Pin

Down

3.958

26

51/2"

2-3/8 OD

EU 8 Rd

13-15.5

53/4"

22.5

1.978

26

6"

65/8"

20-23

45C

15-18

45D

34.00

45E2

5.561

5.595

5.406

28-32

45E4

5.596

5.791

5.484

47A2

5.830

5.921

5.656

24

7"

38

65/8"

17-20

47A4

32-35

47A4

26-29

47B2

20-26

7"

7 5/8"

AD-1

5.922

6.135

5.812

6.136

6.276

5.968

47B4

6.276

6.456

6.078

17-20

47C2

6.456

6.538

6.266

33.7-39

47C4

6.539

6.765

6.453

24-29.7

47D2

6.766

7.025

6.672

20-24

47D4

7.025

7.125

6.812

2.416

5.059

5.482

5.197

5.620

5.25

5.449

5.872

5.5

5.653

6.262

4.938

5.781

5.919

6.528

6.125

6.357

6.966

6.500

6.607

7.216

2 - 7/8 OD

EU 8 Rd

This technical manual is the property of Evolution Oil Tools Inc. and is provided to the customer for information purposes only. It is requested that this document not be

reproduced in any way, in whole or part or distributed outside the customer’s organization without the express written consent of Evolution. The document contains

confidential information and is the property of Evolution Oil Tools and all rights are reserved.

Rev. E0

3

July 2012

“AD-1” and “ADL-1” Tension Packers

“ADL-1” Specification Guide

Casing

O.D.

T&C

Weight

Lbs / ft

Size

51/2"

39-46.3

45B x 2.90

6"

23-26

45C x 2.90

18-20

45D x 2.90

23-29

47B x 4.12

Model

95/8"

103/4"

113/4"

123/4"

133/8

Bore

2.900

ADL-1

7"

85/8"

Preferred Range

of Casing ID's

Packer

Packing

Element

OD

Absolute

Minimum

Collapsed

Diameter of

Slips

Absolute

Maximum

Casing ID

Slip

Travel

4.688

4.749

5.059

5.064

5.296

Min.

Max

Guide

Ring

OD

4.876

5.044

4.750

5.140

5.240

5.000

5.241

5.424

5.218

5.216

5.448

6.136

6.366

5.968

5.781

5.968

6.417

6.367

6.538

6.266

6.125

6.284

6.657

7.921

8.097

7.600

7.125

7.798

8.250

7.511

7.725

7.312

7.725

7.921

7.531

6.938

7.300

8.059

7.500

7.798

8.369

7.938

8.051

8.934

4.938

4.120

17-20

47C x 4.12

24-32

49A4 x 4.0

40-49

49A2

32-40

49A4

4.000

3.000

20-28

49B

7.922

8.191

7.781

47-53.5

51A2

8.300

8.681

8.218

40-47

51A4

8.631

8.835

8.437

29.3-36

51B

8.836

9.063

8.593

8.312

8.548

9.244

32.7-55.5

53A

9.625

10.192

9.500

9.250

9.548

10.192

AD-1

Thread

Specifications Box

Up X Pin Down

3-1/2 OD

EU 8 Rd

4-1/2 OD 8 Rd Lg Csg

x 4-1/2 OD

8 Rd Short Csg

4-1/2 OD

8 Rd Lg Csg

3-1/2 OD

EU 8 Rd

4-1/2 OD 8 Rd Lg Csg

x 4-1/2 OD

8 Rd Short Csg

4.000

38-60

53B

10.605

11.200

10.500

10.000

10.503

11.263

48-53

55A

11.750

12.300

11.625

10.875

11.675

12.435

48-72

55B

12.300

12.715

12.000

11.688

12.173

12.745

4-1/2 OD x 5"

OD Lg Csg

* Plain end: 12.24 – 14.98 lbs/ft

* Packer shown for this weight is recommended and should be run where possible; however, the other size

packer listed for this same weight may be run under certain circumstances, such as unusual hole conditions or

running mixed string.

NOTE: Repair Kits (including such items as packing elements, seal rings, etc.) are available.

Strain Required When Annulus Pressure Is Greater Than Tubing Pressure

Since the Tension Packers have only one set of Slips, which serve only a keep the Packer from moving up the

hole, special consideration must be given those operating conditions in which the annulus pressure will be

greater than tubing pressure.

When this situation exists, the Packer tends to pump down the hole with the result that it may come unpacked, or

under extreme conditions, the Shear Sub or Ring on the bottom of the Packer may be pumped off. Within

reasonable limits, how-ever, the annulus pressure may be greater than tubing pressure provided the downward

This technical manual is the property of Evolution Oil Tools Inc. and is provided to the customer for information purposes only. It is requested that this document not be

reproduced in any way, in whole or part or distributed outside the customer’s organization without the express written consent of Evolution. The document contains

confidential information and is the property of Evolution Oil Tools and all rights are reserved.

Rev. E0

4

July 2012