Active Stall Control for Offshore HAWT

advertisement

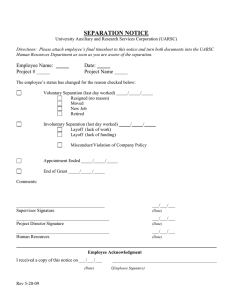

The Science of Making Torque from Wind - 2012 Active Stall Control for Offshore HAWT a study considering different actuation methods Ricardo Pereira 10-10-2012 Delft University of Technology Challenge the future Basic Idea The Research Question ‘Can the pitch system of HAWT be replaced by “modern” active stall control? Which is the best actuation method? ‘ 2 Approaches • Boundary Layer Transpiration • Trailing Edge Jets • Plasma Actuators 3 Question of Authority – NREL 5 MW • BEM model (Sheng Tip Correction) • Generic Actuator • Changes on Cl, Cd remains constant 4 Question of Authority – NREL 5 MW U=21 m/s 18 13 16 12 10 9 L=21m L=29m L=37m no actuation rated 10*DeltaCl / alpha [deg] Power [MW] 11 8 7 14 12 alpha 10*DeltaCl 10 8 6 6 5 0.4 0.5 0.6 0.7 Cl 0.8 0.9 1 35 40 45 50 radius [m] 55 60 5 Boundary Layer Transpiration - Aerodynamic Tool Rfoil_suc (Panel method + integral boundary Layer) - Blowing at the Leading Edge Region x/c ϵ [0.05; 0.2] - Similar behaviour for different airfoils 6 Trailing Edge Jets - Few Mechanisms (compared to Flaps) - Airfoil TE less loaded than LE - Not effective at large angles of attack - 25 times the mass of Leading Edge Blowing 7 Plasma Actuators - DBD •Dielectric Barrier Discharge •No moving parts •KV, Khz … 40 W/m •F=0.2 N/m •Must be placed exactly 8 DBD Separation - Laminar • Thwaites Laminar Separation Criterion • DBD as a point force 2 dU e 0.09 dx F U e 2 • Rfoil_suc data for BL parameters • NACA64618 at Re=10 million, alpha= 8, 11, 14, 17 deg 9 DBD Separation - Laminar alpha=11 deg 0.25 0.2 lambda [-] 0.15 •no separation for any alpha Fact=0.2 Fact=0.5 0.1 Fact=0.8 Fact=1.1 0.05 Fact=0 0 -0.05 -0.1 0 0.002 0.004 0.006 0.008 0.01 chord [-] 0.012 0.014 0.016 0.018 10 DBD Separation - Turbulent - Stratford Turbulent Separation Criterion dC p ' Re x C p ' x' k 6 dx 10 k 0.35;0.39 0.1 -h=5 mm & l= 25 mm x y sin - Body Force Distribution F ( x, y ) A sin l h dp 3 - F ( x) N / m Pa / m dx 11 DBD Separation - Turbulent alpha=14 deg 0.5 0.45 0.05c 0.1c 0.2c 0.3c clean separation Separation Criterion [-] 0.4 0.35 0.3 •no separation for any alpha 0.25 0.2 0.15 0.1 0.05 0 0 0.05 0.1 0.15 0.2 0.25 Chord [-] 0.3 0.35 0.4 0.45 0.5 12 Future Work-DBD Experiment DBD Actuator designed to provoke separation Usually interest is in maximizing Thrust Intermediate steps Large Re & against the flow decreasing electrode length increases pressure gradient Separation ??? 13 The Big Picture Stall Controlled Pitch Controlled • • • • • • • Known Technology 1.3% of ICC 5 % COE of OM & Replace Power Regulation Fatigue alleviation if IPC Aerodynamic brake No power used above rated • • • • • • • Known Technology 2.4% of ICC for Gen & PE 1.8% COE for Gen & PE Power Regulation No Fatigue alleviation No aerodynamic brake No power used above rated Active Stall Controlled • • • • • New Technology Power Regulation Fatigue alleviation? No aerodynamic brake Power used above rated ? 14 The Big Picture Pitch Controlled • • • • • • • Stall Controlled • Known Technology Known Technology • 2.4% of ICC for Gen & PE 1.3% of ICC Hybrid Solution • 1.8% COE for Gen & PE 5 % COE of OM & Replace • Active Power Stall Regulation Power Regulation • Design from scratch with • No Fatigue alleviation Fatigue alleviation Control if IPC • No aerodynamic brake Aerodynamic brake • No power) used above rated No power used •above rated Airfoil optimization ( Transpiration Active Stall • ControlDBD strategy • New Technology • Power Control • Blade Design combined with Passive • Fatigue alleviation? Stall • No aerodynamic brake • Power used above rated ? 15 Thank for your attention. Suggestions? Questions? 16 Power for Actuation and Practical Issues Boundary Layer Transpiration • Air Pump required • More Mechanisms • Power required to operate the pump • Unknown maintenance Plasma Actuators • Wet Environment – Electric Arcs • 1.5% power above rated • Degradation of the Dielectric • Unknown maintenance 17 DBD Transition Control • Less energy required for instability excitation • Airfoil design with distinct laminar/turbulent separation • Roughness and aoa sensitivity 18