M a n u fa c tu rin g R e a d in e s s L e v e ls

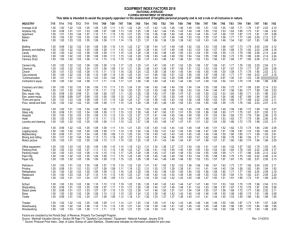

advertisement

5000.2 TRL MRL Considerations MRL Exit Criteria Materiel Development Decision 2 3 8 Assess at TRL 1 – 3 Identify IB Sources Characterize Basic Materials for Mfg. Identify Material Concerns Identify Funding Identify Advanced ManTech Initiatives Coordinate with Technology Plan Advanced Technology Development Advanced Research Assess at TRL 5 IB Analysis Finished KPPs Allocated Key Characteristics Identified SEP includes MFG/QA approach Funding to Meet Next Level ManTech Initiatives Initiated Early Supply Chain assessment Mfg. Cost Drivers Identified 5 Assess at TRL 6 IB Capability Assessment Initial Trade Studies Materials Matured Similar Lines Funding to Meet Next Level ManTech Solutions Developed in Relevant Env Acquisition Strategy includes Mfg/QA Quality Thresholds Established Assess at TRL 7 IB Monitored PEP Completed Materials Being Proven Funding to Meet Next Level ManTech Solutions Demonstrated Supply Chain being assessed BOM Identified QA data collected Supply Chain Mgmt in place Equipment in a Relevant Env. Env. Assess at TRL 8 Est. Multi-Sources Pilot Line Builds Validated Materials Proven Funding to Meet Next Level ManTech Solutions Validated Quality Characteristics Validated BOM Supports LRIP Supply Chain stable for LRIP Mfg. Processes Proven All Materials Ready for LRIP Producibility Improvement Underway Pilot Line Demo/ Ready for LRIP Process Maturity Demonstrated 7 Mfg. Processes in Development Production Representative Environment Post CDR Assessment Engineering and Manufacturing Development Trade Studies 6 6 B Long Lead Items Identified Cost Drivers Analyzed Mfg. Processes Demonstrated in Relevant Env. Env. Produce system in a Relevant Environment A Red Diamond indicates a Proposed Mandatory Review Point Assess at TRL 4 Identify IB Gaps Assess DFX Baseline Materials and Issues Funding/Budgeting for Trade Studies Identify ManTech or Other Initiatives Technology Development Strategy should include elements of Mfg/QA Producibility Assessments Initiated Key Processes Identified Producibility Assessments OnOn-going Produce components in a Relevant Environment Mfg. Processes Identified 4 Basic Research Produce in a Lab Environment Mfg. Processes Emerging 3 5 System Technology Development Component Mfg. Feasibility determined 2 4 A Manufacturing Concepts Identified Research 1 Manufacturing Readiness Levels 1 Technology Readiness Levels PrePre-MSA Materiel Solution Analysis Manufacturing Readiness Levels 8 7 C Assess at TRL 9 IB Supports Sched. Continuous Process Improvement is Ongoing Materials in Control Funding to Meet Next Level Quality Validated with LRIP Articles Make/Buy Supports FRP IB Capabilities Assessment Supply Chain Established and Meeting Lead Times Mfg. Processes Operating at Target Quality, Cost and Performance LRIP in place/ Ready for FRP 9 8 9 Ops & Support Dated: V7.1 May, 2009 Monitor and Manage all Key Characteristics at a Six Sigma Level Funding to Meet 6σ goals No Make/Buy Changes Key/Critical Suppliers all meet Six Sigma Goals Meeting or Exceeding Cost, Schedule and Performance Goals Lean/Six Sigma Production in Place FRP / Lean 10 FRP Decision Production and Deployment