GUARDIAN CONTROL

™

GUARDIAN Fire Safety Solutions for Fume Control Systems

™

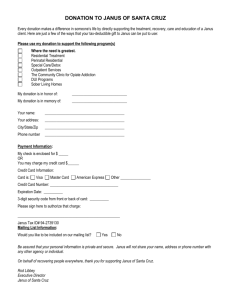

FIRE DETECTION PANEL

APPLICATIONS:

The fire detection panel processes the signals from the temperature, spark

and smoke sensors and activates the alarm and fire suppression system. To

secure the overall functionality, Guardian Control™ monitors the wiring loops

of sensors as well as the suppression system. Guardian Control™ includes

a battery pack to guard against power failure.

The Guardian Control™ is part of Lincoln Electric’s

GUARDIAN™ fire safety solutions for fume control

systems and is recommended for applications with

an increased fire risk, such as:

• Robotic welding of oily stamped products

• Robotic and automatic welding of oily products

• Manual welding of oily products

• Cutting tables

• Schools/Other areas with risk of cigarette butts

JFS-C1

Releasing Control Panel

SPECIFICATIONS:

• Physical Dimensions and Properties:

•Material: 18 gauge sheet steel

• Single-Hazard Operation

•Dimensions (H x W x D):

18.25 x 14.5 x 4.75 in (484 x 368 x 121 mm)

• Four Class B Initiating Circuits

• Color: Red

2

Features

Dimensions: 18 ¼” x 14 ½” x 4 ¾”

(483.6 mm x 368.3 mm x 120.7 mm)

APPROVALS/CERTIFICATES

UL Standard 864

ULC S527-99

• Two Class B Supervisory Circuits

Technical Data:

• Four Class B Output•Circuits

•Input Power:

• Programmable Cross Zoning

120V AC (60Hz/165VA)

• Supervised Microprocessor

220V AC (50Hz/185VA)

• Battery Type:

2 x Display

12V sealed lead acid in series

• 32 Character Alpha-Numeric

LCD

•

Battery

Fuse:

5A;

x 0.25 in (32 x 6.3

mm)

• Custom Banner Message and Zone1.3Description

Text

• No. of Detection Circuits: 3; 22.5 to 25.9V DC

• Custom Zone Description Text

•No. of Sounder Circuits: 1; 22.5 to 25.9V DC

• On Board Menu Driven•Extinguishant

Programming

Controls

release output:

• Releasing Circuits Protected

from

False

Activation

24V DC; rated 1 A each; 2.5

A

total

for

all

4

circuits

• Continuous or Timed Discharge

• Ambient Condition:

• 40 Event History Buffer

•Operating

Temperature:

• Walktest with Automatic

Time-Out

Minimum: 32°F (0°C)

• Alarm, Trouble, Supervisory,

Relays

Nominal:and

68°F Waterflow

(20°C)

• Optional Class A InitiatingMaximum:

Zone 120°F

and (49°C)

Output Module

• Max. Relative Humidity:

93% non-condensing

• 34 Character LED Supplemental

Display

Outdoor Use Allowed: No

• 32 Standard Programs•in

Panel Memory

•Storage Conditions:

• Password Protection for32-120°F

all Programming

(0-49°C); relative humidity max. 95%

• 24 Hour Clock

• Suitable for Agent or Water Based Extinguishing

• Programmable Pre-Discharge Timers1

• One Class B Abort Circuit1 (defaults to additional

supervisory zone in water based mode.)

• Three Abort Modes

• Programmable Spurt Function3

• Programmable Remote Reset4

available in chemical mode only

one zone programmable as abort in chemical mode

3

Janus Based mode only

4

Janus Based mode only and limited to requirements set forth in

JFS-C1 manual DOC105 (5403552)

1

2

Enclosure: NEMA 1 Rated

P/N 18630

www.lincolnweldfumecontrol.com

The Janus Fire Systems® JFS-C1 Releasing Control Panel is a flexible single-hazard releasing con-

BT-80

GUARDIAN CONTROL

1

12 Volt, 8 AH Battery

anual Pull Station

1

Features

DualAction

ScrewTerminalConnections

DCandACVoltageContactRatings

GoldPlatedAlarmContacts

SurfaceorWeatherproofBack-Box

Deeper Back-Boxes Available to Provide More ™

FEATURES (INCLUDED WITH GUARDIAN CONTROL )

SpaceforWireand/orAddressableModule.

Features

Two battery packs 12V

™

GUARDIAN Fire Safety Solutions for Fume Control Systems

anual Pull Station

™

WORLD-CLASS WELD FUME

CONTROL EXPERTISE

H-1224 Series

DualAction

MEA

ScrewTerminalConnections

DCandACVoltageContactRatings

GoldPlatedAlarmContacts

SurfaceorWeatherproofBack-Box

Features

Deeper Back-Boxes Available to Provide More

SpaceforWireand/orAddressableModule.

anualpullstationdesignedtomeettherequirements

Fire Alarm Sounder

DualAction

a

rugged,

lightweight,

die-cast metal alloy for

ScrewTerminalConnections

• but

33 sound

option settings

DCandACVoltageContactRatings

MEA

GoldPlatedAlarmContacts

opencontactconnectedtoaterminalstripthatcan

ntactsaregoldplatedtominimizeriskofcorrosion.

SurfaceorWeatherproofBack-Box

Deeper Back-Boxes Available to Provide More

ncompliancewiththepullforcerequirementsofthe

SpaceforWireand/orAddressableModule.

Overview

Standard

Features

Our technical

sales team is trained and

Select-A-Horn

SG-42SK1

•

•

•

•

•

knowledgeable

about 12

theVolts

methodology of

Nominal Voltage:

substation,

isolation, 8and

a key

Rated Capacity:

AHventilation.

(20 hourAsrate)

partner,

a wealth

experience and

Length:with

5.94”

(151ofmm)

knowledge

of welding,

welding fume and

Width: 2.56”

(65 mm)

welding

removal,

we can assist you to

Height:fume

3.74”

(95 mm)

identify

the right 3.98”

weld fume

Total Height:

(101control

mm) solution for

Terminals:

F1-Faston

Tab No.

your

application.

Lincoln Electric

has187

a global

network

of facilities

33 sound

output

settings and people to provide quick

response

and personalized

attention, no matter

Horn or

chime sound

output

Indoor/outdoor*

where yourlisted

welding operations are located.

•

•

•

•

•

•

•

Pre-wire back plate

Universal

back plate

mounting (single

gang, double

SUPPORT

& TRAINING

PROGRAMS

gang, octagon, or 4” square)

offermounting

support materials, training tools, free

SingleWe

screw

seminars

and courses to enhance your welding

Low current

draw

P/N: 18641

Die-Cast

Metal Manual Pull Station

•

•

and cutting safety program.

Manual Call Point

Patents

The BT-80 sealed lead acid battery is rated

at Pending

12 Volts, 8 AH, making it of appropriate size, Amp

Features Our service and support programs are

anualpullstationdesignedtomeettherequirements

* Outdoor

installation

requires backup

the BBK-1 (P/N

hour rating, and proper terminal connections

fordesigned

use

as toa meet

battery

Fire18865)

AlarmorSystems

your needs. Forfor

on-going

MEA metal alloy forand as an uninterruptible power supply.• DualAction

BBX-5 (P/N 99984)

a rugged, but lightweight, die-cast

preventive maintenance and support, our team

armarked“PUSH”andpullingthehandlemarked

• ScrewTerminalConnections

P/N: 18645

can train your staff, conduct evaluations or

•

DCandACVoltageContactRatings

willgo.Atthatpoint,thehandlewilllockinplaceand

• GoldPlatedAlarmContacts

audits and deliver the services you need to stay

opencontactconnectedtoaterminalstripthatcan

Dimensions

nhandleisresetbyopeningthestationwiththekey, The H-1224 Electronic Horn allows a number

of applications on a single device. The horn settings

• SurfaceorWeatherproofBack-Box

productive

and

effective.

in

(mm)

ntactsaregoldplatedtominimizeriskofcorrosion.

include

Temporal,

Non-Temporal,

March

Time

and

a

Chime sound.

The to

horn

also has

•

Deeper

Back-Boxes

Available

Provide

MoreLow, Mid and

positionandrelockingthestation.

SpaceforWireand/orAddressableModule.

ncompliancewiththepullforcerequirementsofthe High volume settings for each pattern and tone. The tones include 2400 Hz, Electro-Mechanical,

VALUABLE CUSTOM SOLUTIONS

0.19 (4.75)

anualpullstationdesignedtomeettherequirements Broadband and Chime.

The

weld fume control team

The

voltage

input

can

be

either

regulated

DC

or

fullLincoln

waveElectric

rectified

P/N:18703

a rugged, but lightweight, die-cast metal alloy for

MEA (FWR) 12 volt or 24 volt

understands and recognizes that each welding

0.13 (3.2)

application

is unique

its0.25

own

set ofdouble

variables;

(6.35)

The H-1224 utilizes a universal mounting plate that

will mount

on awith

single

gang,

gang,

one equipment

and

consumable

opencontactconnectedtoaterminalstripthatcan octagon and 4” square electrical boxes. Outdoor installations

must

use

either thesolution

BBK-1 does

4” square

armarked“PUSH”andpullingthehandlemarked

ingle-gangback-box.

not fit every

application.

Ourback

teamplate

will engineer

(weatherproof bell backbox) or the BBX-5 (weatherproof

backbox).

The

allows the

ntactsaregoldplatedtominimizeriskofcorrosion. Description

willgo.Atthatpoint,thehandlewilllockinplaceand

0.03

(0.8)

TheSG-42SK1isasinglecontact,key-reset,manualpullstationdesignedtomeettherequirements

ms®SGB-32Sorthedeepermetalback-box(SGBinstaller

to

mount

the

plate

and

terminate

the

wire

connections.

The

horn

attaches

in

a hinge

fashion

a

system

to

efficiently

and

effectively

remove

ncompliancewiththepullforcerequirementsofthe for many applications. It is constructed from a rugged, but lightweight, die-cast metal alloy for

nhandleisresetbyopeningthestationwiththekey, from the top and is secured by a single mounting screw.

The

horn

completely

covers

the

mounting

welding fume and particulate from your

increasedperformanceandlongevity.

back plate, therefore it can be mounted before other

trades work

is completed and not affect the

positionandrelockingthestation.

metalworking

operations.

tems® SGB-32C or the deeper die-cast, weather- TheSG-42SK1isprovidedwithonenormallyopencontactconnectedtoaterminalstripthatcan

finallook.

accommodatewiringfrom#22to#12AWG.Contactsaregoldplatedtominimizeriskofcorrosion.

Contact us today!

2.56 (65)

5.94 (151)

AllmodelshavebeentestedbyULandfoundincompliancewiththepullforcerequirementsofthe

Installation

AmericanswithDisabilitiesAct(ADA).

ORDER INFORMATION

Automation Service Hotline

armarked“PUSH”andpullingthehandlemarked

A jumper plug is provided to test for

1-888-935-3878

Operation

willgo.Atthatpoint,thehandlewilllockinplaceand

Product Name

Product

Number

Number/Package

operation.

correct wiring in the supervisory mode

3.98 (101)

3.74 (95)

nhandleisresetbyopeningthestationwiththekey, Thestationsareoperatedbypushinginthebarmarked“PUSH”andpullingthehandlemarked

Automation

Technical

Support

only. DoAfter-Hours

not pass alarm

current

through

ingle-gangback-box.

Fire Detection Panel

AD1387-29

1

“PULL”onthefrontoftheunitasfardownasitwillgo.Atthatpoint,thehandlewilllockinplaceand

the jumper.

positionandrelockingthestation.

1-888-532-8001

iseasilyvisiblefromupto50feet.Theactivationhandleisresetbyopeningthestationwiththekey,

ms®SGB-32Sorthedeepermetalback-box(SGBplacingthe“PULL”handletoitsnormaluprightpositionandrelockingthestation.

tems® SGB-32C or the deeper die-cast, weather-

The operation of welding fume control equipment is affected by various factors including proper use and positioning of the equipment,

Mounting Configurations

maintenance of the equipment and the specific welding procedure and application involved. Worker exposure level should be checked upon

installation

and

periodically

thereafter

to

be

certain

it

is

within

applicable

OSHA

PEL and ACGIH TLV limits.

anus Fire Systems® is a registered trademark of Janus Fire Systems.

Semi-Flush--Allmodelsmountonastandardsingle-gangback-box.

Surface Mount Interior--UseJanusFireSystems®SGB-32Sorthedeepermetalback-box(SGBingle-gangback-box.

32SD).

ms®SGB-32Sorthedeepermetalback-box(SGBDS1073

Revised:

© 2008 Janus Fire Systems. All rights reserved (12/2008) Janus Fire Systems® is a registered trademark of Janus Fire Systems.

C U S 9-Nov-2009

T O M E R A S S I S TA N C E P O L I C Y

Surface Mount Exterior--Use Janus Fire Systems® SGB-32C or the deeper die-cast, weatherThe business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment,

consumables, and cutting equipment. Our challenge is to meet

proofback-box(SGB-32CD)

The Lincoln Electric Company

Automation Division

Accordingly, Lincoln Electric does not warrant or guarantee or assume any liability with respect to such information or advice. Moreover, the provision of such information

22801 St. Clair Avenue

or advice does not create, expand, or alter any warranty on our products. Any express or implied warranty that might arise from the information or advice, including any

implied warranty of merchantability or any warranty of fitness for any customers’ particular purpose is specifically disclaimed. Cleveland, OH 44117-1199 U.S.A.

Note: Installation must comply in accordance

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole

1-216-481-8100

standards.

responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the with

resultsapplicable

obtained in applying

these types of fabrication methods and service

requirements.

Email: WeldFumeControl@lincolneletric.com

anus Fire Systems®

a registered

trademark

of Janus

Fire

Systems.

Subject toisChange

– This information

is accurate

to the

bestDS1089

of our knowledge

at the time of printing. Please refer to ©

www.lincolnelectric.com

for any

updated

information.

Revised: 9-Nov-2009

2009 Janus Fire Systems.

All rights

reserved

(3/2009) Janus Fire

Systems® is a registered trademark of Janus Fire Systems.

www.lincolnweldfumecontrol.com

www.lincolnelectric.com/safety

© 2008 Janus Fire Systems. All rights reserved (7/2008) Janus Fire Systems® is a registered trademark of Janus Fire Systems.

the needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for information or advice about their use of our products.

Our employees respond

inquiries

to the best of die-cast,

their ability based on

information provided to them by the customers and the knowledge they may have concerning

tems® SGB-32C

ortothe

deeper

weatherthe application. Our employees, however, are not in a position to verify the information provided or to evaluate the engineering requirements for the particular weldment.

E13.101 (07/12)

DS1017

Revised: 9-Nov-2009

© Lincoln Global, Inc. All Rights Reserved. Printed in the U.S.A.