05 Chain Slings

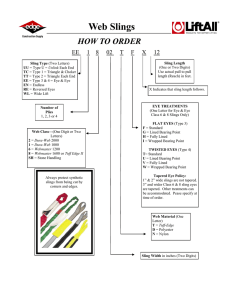

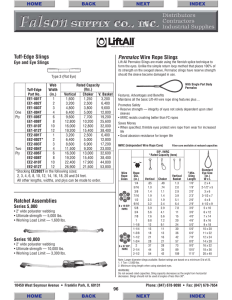

advertisement

15/2/12 5:36 PM Page 1 Chain Slings 05 Chain Slings.qxd 05 Chain Slings.qxd 15/2/12 5:36 PM Page 2 Chain Slings CHAIN SLINGS Types of Chain Slings With the exception of endless slings as described below the configurations are based on sling legs. The most commonly used chain assemblies are illustrated here but also illustrated are special assemblies that may be devised for lifting specific or unusually shaped loads. 2 Leg Basket Sling Oblong Link 2 Leg Sling Adjustable 2 Leg Sling Chain Slings Connecting Link Chain Effective Length Effective Length Effective Length Clevis Safety Hook or other end fitting Single Leg Sling Endless Sling Effective Length Single Leg Reevable Sling Effective Length 3 Leg Sling Effective Length 4 Leg Sling Effective Length Effective Length Sling Selection Multi - Leg Slings The following factors should be considered before making a selection: The WLL of slings comprising two or more legs shall not be more than the calculated WLL of the sling while it is supporting the load with two of its legs having a symmetrical configuration with an included angle between the two legs of 60°. The included angle shall never be greater than 120°. 1. Load – mass 2. Headroom 3. Type of load – steel, shipping containers, timber, fabricated sections or vessels 4. Length of sling 5. Method of slinging 6. Environmental elements such as corrosion or heat Calculation of Working Load Limit The sling chart details the working load limit for each size. Geometry The geometry of the sling is the number of chain legs of multi-leg slings and the angles between the legs and vertical. Angles should be assessed as shown in the figures below. When calculating angles the apex of the angles should not include the length of the oblong link or master link. 2 1 1 Sling Angle 60° Sling Angle 60° Sling Angle 60° 2 Four Leg Sling 104 05 Chain Slings.qxd 15/2/12 5:36 PM Page 3 Chain Slings CHAIN SLINGS Headroom & Special Slinging Methods Reeved Slings Use of lifting beams or spreader beams assists in overcoming headroom problems and these can be purpose built by Nobles to comply with all relevant standards and regulations. In the examples shown the WLL shall not be greater than 0.75 times the WLL of the chain to which it is attached. Maximum load = 0.75 x WLL Two leg sling in choke hitch Single leg sling in choke hitch Adjustable Slings Using Shortening Clutches Nobles can incorporate shortening clutches into all sling assemblies rendering them adjustable. Shortening clutches in multi-leg slings will adjust the leg length but care must be taken to ensure that no one leg is overloaded as a result. Bear in mind that if the legs are not equally disposed about vertical, the leg making the smallest angle to the vertical will carry a larger share of the load. Spreader bar fixed or adjustable Shortening clutches are the preferred devices for adjusting leg length as they maintain the correct ‘in line loading’ of the chain so that the rating is not affected. Some grab hooks that lock onto a link of the chain for this purpose require a 25% deration. Cradle grab hooks, which fully support the chain link, do not require a deration. WARNING • Shortening clutches MUST be used correctly with the load bearing chain always leading out from the bottom of the clutch. (See illustrations for correct and incorrect usage.) Lifting Beam fixed or adjustable Use of shortening hooks in adjustable slings Any special method of use should be approved and tested in the manner in which it is to be used. Endless Slings An endless sling shall never have a working load limit greater than 1.5 times the WLL of a single leg sling. Correct Incorrect Protection Special loads also may require protection and Nobles can provide various means to protect loads from marking or damage during lifting. WARNING • The swivel function on Swivel Self-Locking hooks is for positioning only. The hook is not designed to rotate under load. 105 Chain Slings Maximum load = 0.75 x WLL 05 Chain Slings.qxd 15/2/12 5:36 PM Page 4 Chain Slings CHAIN SLINGS Care In Use Inspection Before Use WARNING WARNING • Chain Slings should always be used in line with good lifting and rigging practice and as per the manufacturers recommendations. • Incorrect Chain Sling use could result in a dangerous situation that could cause property damage, serious injury or death. • Lifting equipment should be inspected before each use. The pre-use inspection for chain slings should take note of the following: Chain Slings 1. Clean sling before inspection. 2. Ensure the sling is correctly tagged and certified. 1. The operator should establish the weight of the load to be lifted as accurately as possible. 3. Every chain link should be individually inspected for any signs of wear, twisting, stretching, nicks, gouging, heat damage, chemical attack or excessive corrosion. 2. Ensure that the crane or other lifting equipment and the lifting points are adequate to lift the load. 3. Prepare the site where the load is to be landed in advance. Ensure that the sling is not trapped by the load in such a way that removal of the sling cannot be made by hand. Bend Bend 4. Check compatibility of the chain sling to the crane hook and the lifting points on the load. Twisted Link 5. Ensure the chain is free from twists and is protected from any sharp corners on the load. 6. Ensure the load is evenly distributed on all sling legs. This can be facilitated through the use of shortening hooks. Examine all Chain Links 4. Any worn links should be measured to determine the degree of wear, which should not exceed 10% in any plane. 7. When using a choke hitch, the bite should be allowed to assume its own position. 5. Upper and lower terminal links, hooks, etc. should be inspected for any signs of distortion, e.g. widening of any hook throat opening. 8. Commence the lift slowly, taking up the slack gradually. 9. Care must be taken to ensure that the load remains stable throughout the lift. 6. Connecting links or chain connectors should be inspected for any signs of wear at their load-bearing points and for any excessive play of the load pin. 10. A trial lift should be made prior to the full lift operation. If the load is not balanced it should be lowered and the slings re-positioned. 7. Wear may be tolerated until the thickness of any worn section has been reduced by 10% of the nominal section in any plane. 11. Sling hooks of a multi-leg sling should be positioned so that they face outward from the load. Storage & Handling • Chain slings should be kept on a properly designed rack in a clean, dry place. Links tend to close up and elongate • Lightly oil slings before any prolonged storage. • Never heat or heat-treat slings. New Link Stretched Link WARNING Look for Chain Stretch • Grade T Chain Slings should not be used in acid solutions, exposed to acid fumes or other corrosive environments. Heat As the temperature which a sling attains in-service increases, its strength decreases. Care must be taken to account for the maximum temperature that can be reached by the sling in service. Extreme Wear at Bearing Surfaces Wear Check for wear at Bearing Surfaces 8. Chain links or fittings having any defects should be clearly marked to indicate rejection, and the sling should be withdrawn from service until properly repaired. 9. Slings with damaged fittings may be repaired by replacing the fittings but the entire chain assembly must be proof load tested before being returned to service. Any damaged chain must be destroyed. Temperature of Sling Strength of Sling Up to 200ºC Nominal Strength of rating 200ºC - 300ºC 90% of strength rating 300ºC - 400ºC 75% of strength rating Over 400ºC DO NOT USE Note: The use of a sling within these temperature ranges does not imply any permanent reduction in strength when the sling is returned to normal temperatures. If slings are accidentally exposed to temperatures indicated in excess of the maximum permissible temperatures indicated above, they should be withdrawn from service and returned to A. Noble & Son Ltd for inspection, testing and or repair or replacement. 106 05 Chain Slings.qxd 15/2/12 5:36 PM Page 5 Chain Slings GRADE T LIFTING CHAIN & COMPONENTS TO AS 3776 (Components) A. Noble & Son Ltd. Is a leading manufacturer of Grade T chain slings in Australia. Nobles chain slings are manufactured to comply with Australian Standard 3775 and all chain slings manufactured by Nobles are fully proof tested to twice the WLL. TO AS 3775 (Chain Slings) Nobles Grade T components comply to AS 3776 ‘Lifting Components For Grade T Chain Slings’. Nine of Nobles branches throughout Australia are NATA Accredited Testing Laboratories with facilities to carry out proof and destruction type testing of chain and chain sling components. The Grade T alloy steel chain is manufactured to Australian Standard 2321 ‘Short Link Chain for Lifting Purposes’. This chain is electrically welded, fully heat treated and tested at manufacture. Testing incorporates non-destructive (proof) testing for the entire chain and destructive type (breaking load and elongation) tests on selected samples. Nobles chains may be supplied with the following markings T, 8, 80 or 800. Chain Slings TO AS 2321 (Chain) WLL TONNES Single Leg Slings Chain Straight *Adjustable Reeved Sling Sling size mm Sling 2, 3, or 4 Leg Slings 60˚ Straight Sling 90˚ 120˚ 60˚ Endless Slings Reeved Sling 90˚ 120˚ 60˚ Basket Sling 90˚ 120˚ Reeved Sling 6 1.1 1.1 0.8 1.9 1.6 1.1 1.5 1.2 0.8 1.5 1.2 0.8 1.7 7 1.5 1.5 1.1 2.6 2.1 1.5 2.0 1.6 1.1 2.0 1.6 1.1 2.3 8 2.0 2.0 1.5 3.5 2.8 2.0 2.6 2.1 1.5 2.6 2.1 1.5 3.0 10 3.2 3.2 2.4 5.5 4.5 3.2 4.1 3.4 2.4 4.1 3.4 2.4 4.8 13 5.3 5.3 4.0 9.2 7.5 5.3 6.9 5.6 4.0 6.9 5.6 4.0 8.0 16 8.0 8.0 6.0 13.8 11.3 8.0 10.4 8.5 6.0 10.4 8.5 6.0 12.0 20 12.5 12.5 9.4 21.6 17.6 12.5 16.3 13.3 9.4 16.3 13.3 9.4 18.8 22 15.0 15.0 11.3 26.0 21.2 15.0 19.5 15.9 11.3 19.5 15.9 11.3 22.5 26 21.2 21.2 15.9 36.7 29.9 21.2 27.6 22.5 15.9 27.6 22.5 15.9 31.8 32 31.5 31.5 23.6 54.5 44.4 31.5 41.0 33.4 23.6 41.0 33.4 23.6 47.3 * Assumes the use of 100% rated shortening hook Working Load Limit (WLL) is the maximum load that can be supported by a sling under general conditions of use. (d) Multi Leg Slings - The WLL of multi-leg slings shall be as follows: General conditions of use are equivalent to a group classification of crane mechanisms of M3 as specified in AS 1418.1. (i) Under other than general conditions of use (e.g. severe conditions, hazardous conditions involving safety of personnel), the WLL shall be derated to conform to the group classifications of crane mechanisms as specified in AS 1418.1 for conditions of use that apply. (ii) Where a sling is not symmetrically loaded, the WLL shall be based on an included angle equal to twice the largest angle from the vertical. (a) Endless Slings - The WLL of endless chain slings shall be not more that 1.5 times the WLL of the chain. (iii) The WLL for a multi leg sling having an included angle of 60° between the legs is the maximum WLL for the sling and shall not be exceeded, even where the included angle between the legs is less than 60°. (b) Non-vertically orientated leg of a sling - The WLL of a non-vertically orientated leg of a sling shall allow for its inclination to the vertical. (c) Adjustable Slings - The WLL of adjustable chain slings shall be as follows: (i) The WLL of a multi leg sling assembly with more than two legs shall not exceed that for the sling with only two of its legs used with an included angle of 60° between these two legs. That is, the WLL of multi leg sings comprising more than two legs shall be not more than the WLL of the sling used as a two-leg sling. (iv) Under no circumstances shall the included angle between the legs of a multi leg sling be allowed to exceed 120°. Where a special purpose hook (e.g. a shortening clutch) that fully supports the chain link and attains a 100% efficiency is used, the WLL shall be not more than the WLL of the chain to which it is attached. (ii) Where (i) above does not apply, the WLL shall be not more than 0.75 times the WLL of the chain to which it is attached. 107 05 Chain Slings.qxd 15/2/12 5:36 PM Page 6 Chain Slings STOCK CHAIN SLINGS TO AS 3776 Nobles' has a range of stock chain slings available to ensure fast delivery. All stock chain slings feature Large Series Oblong Links and include Clevis Grab Hook shorteners at the top of each leg and Self-Locking Hooks at the bottom of each leg. All Nobles stock chain slings are proof load tested and a NATA test certificate is provided. Single Leg Chain Slings Chain Slings Stock Code Chain Diameter (mm) Description Length (m) WLL (Tonnes) Straight Sling WLL (Tonnes) Reeved Sling CA08120LS Large Series Oblong Link, Clevis Grab Hook, Self-Locking Eye Hook, Tested 8 2 2 1.5 CA08140LS Large Series Oblong Link, Clevis Grab Hook, Self-Locking Eye Hook, Tested 8 4 2 1.5 CA10120LS Large Series Oblong Link, Clevis Grab Hook, Self-Locking Eye Hook, Tested 10 2 3.2 2.4 CA10140LS Large Series Oblong Link, Clevis Grab Hook, Self-Locking Eye Hook, Tested 10 4 3.2 2.4 CA13120LS Large Series Oblong Link, Clevis Grab Hook, Self-Locking Eye Hook, Tested 13 2 5.3 4 CA13140LS Large Series Oblong Link, Clevis Grab Hook, Self-Locking Eye Hook, Tested 13 4 5.3 4 Two Leg Chain Slings Description Chain Diameter (mm) Length (m) WLL (Tonnes) Sling @ 60º WLL (Tonnes) Reeved Sling @ 60º CA08220LS Large Series Oblong Link, Clevis Grab Hooks, Self-Locking Eye Hooks, Tested 8 2 3.5 2.6 CA08240LS Large Series Oblong Link, Clevis Grab Hooks, Self-Locking Eye Hooks, Tested 8 4 3.5 2.6 CA08260LS Large Series Oblong Link, Clevis Grab Hooks, Self-Locking Eye Hooks, Tested 8 6 3.5 2.6 Stock Code CA10220LS Large Series Oblong Link, Clevis Grab Hooks, Self-Locking Eye Hooks, Tested 10 2 5.5 4.1 CA10240LS Large Series Oblong Link, Clevis Grab Hooks, Self-Locking Eye Hooks, Tested 10 4 5.5 4.1 CA10260LS Large Series Oblong Link, Clevis Grab Hooks, Self-Locking Eye Hooks, Tested 10 6 5.5 4.1 CA13220LS Large Series Oblong Link, Clevis Grab Hooks, Self-Locking Eye Hooks, Tested 13 2 9.2 6.9 CA13240LS Large Series Oblong Link, Clevis Grab Hooks, Self-Locking Eye Hooks, Tested 13 4 9.2 6.9 CA13260LS Large Series Oblong Link, Clevis Grab Hooks, Self-Locking Eye Hooks, Tested 13 6 9.2 6.9 GRADE T LIFTING CHAIN TO AS 2321 This chain complies with the mechanical properties and testing requirements of AS 2321 for Lifting Chains.The Nobles range offers high strength and surface hardness and yet retains the ductility necessary for safety in chain slings. Nobles Grade T Lifting Chain is manufactured in Australia by PWB Anchor from the best quality high tensile alloy steel, which is then hardened and tempered to produce a chain with a load bearing capacity in excess of three times that of mild steel chain. Stock Code d P W Chain Size d (mm) WLL (Tonnes) Dimension P W (mm) (mm) Link Kg per Interval 100 Markings metres (mm) CMAC06 6 1.1 20.8 22.3 81.4 10 CMAC07 7 (7.1) 1.5 23.8 25.9 114 10 CMAC08 8 2.0 23.5 27.0 146 10 CMAC10 10 3.2 29.8 33.8 206 8 CMAC13 13 5.3 38.0 43.0 349 6 CMAC16 16 8.0 47.3 54.0 564 6 CMAC20 20 12.5 59.2 67.5 878 6 CMAC22 22 15.0 65.0 74.2 1066 4 CMAC26 26 21.2 78.0 96.2 1510 6 CMAC32 32 31.5 96.0 112.0 2300 4 Link dimensions and weights are indicative as Australian Standards allow tolerances of P =2.75d to 3.0d and W = 3.24d to 3.5d. Sizes 6 to 22mm manufactured in Australia. 108 05 Chain Slings.qxd 15/2/12 5:36 PM Page 7 Chain Slings GRADE T LIFTING CHAIN COMPONENTS TO AS 3776 The range of Oblong or Master Links allows greater flexibility in selection and construction of sling assemblies. The regular and large series of oblong link (in most sizes) can be used for both single and two leg applications. Large Multi Link Assemblies These assemblies consist of a master link and two intermediate links each with the same lifting capacity. These are designed for 2, 3 or 4-leg applications. Regular Series This range is designed for use in single and 2-leg applications. Regular Series Oblong Link Stock Code J K H Chain Size Chain Size WLL H J K Weight 1 Leg (mm) 2 Leg (mm) (tonnes) (mm) (mm) (mm) (kg) CMLRS10 6/10 6/8 3.5 88 44 13 0.3 CMLRS13 13 10 5.5 114 57 20 0.9 CMLRS16 CMLRS20 CMLRS22 16 20 22 13 16 20 9.2 13.8 21.6 130 160 180 70 80 90 22 30 33 1.2 2.7 3.7 CMLRS25 26 22 26.0 200 100 39 5.5 Large Series Oblong Link Stock Code J K H CMLLS07 Chain Size Chain Size WLL H J K Weight 1 Leg (mm) 2 Leg (mm) (tonnes) (mm) (mm) (mm) (kg) 6/7 1.9 130 70 13 0.4 CMLLS10 8/10 7/8 3.5 135 70 16 0.7 CMLLS13 13 10 5.5 200 100 22 1.7 CMLLS16 16 13 9.2 240 120 30 3.8 CMLLS20 20 16 13.8 280 140 33 5.4 CMLLS22 22 20 21.6 300 150 39 8.5 CMLLS25 26 22 26.0 330 165 42 10.5 CMLLS32 32 26 36.7 360 180 48 15.0 CMLLS3232 32 32 54.5 410 220 60 30.0 Large Multi Oblong Link J K H U V T Stock Code Chain Size WLL H J K T U V Weight (mm) (tonnes) (mm) (mm) (mm) (mm) (mm) (mm) (kg) CMLLM06 6/8 3.5 180 90 19 88 44 13 1.7 CMLLM10 10 5.5 240 120 24 114 57 20 4.0 CMLLM13 13 9.2 280 140 30 130 70 22 6.7 CMLLM16 16 13.8 300 150 33 160 80 30 11.1 CMLLM20 20 21.6 330 165 42 180 90 33 17.5 CMLLM22 22 26.0 360 210 48 200 100 39 25.2 CMLLM25 26 36.7 410 220 60 350 195 50 64.0 CMLLM32 32 54.5 450 250 70 410 220 60 103.0 Link dimensions and weights are subject to commercial tolerances 109 Chain Slings Large Series This range is most commonly selected and is both wider and longer than the regular series and has a particular application where large crane hooks are in use. The Large Series link can be used for both single leg and 2-leg applications. Oblong or Master Links 05 Chain Slings.qxd 15/2/12 5:36 PM Page 8 Chain Slings GRADE T LIFTING CHAIN COMPONENTS TO AS 3776 The Nobles Chain Connector is a fitting, which can be used to connect chain to master links, hooks and other components. It is easily assembled and can be disconnected if required. It is made from quenched and tempered alloy steel for high tensile strength and ductility. Chain Connector Chain Slings Stock Code C B E F Chain Size (mm) WLL (tonnes) B C E (mm) (mm) (mm) F Weight (mm) kg/pc CMAH06N 6 1.1 44 38 15 16 0.1 CMAH07N 7/8 2.0 57 51 20 23 0.2 CMAH10N 10 3.2 68 61 25 29 0.3 CMAH13N 13 5.3 82 76 30 33 0.7 CMAH16N 16 8.0 104 95 36 41 1.2 CMAH20N 20 12.5 125 109 44 50 1.9 CMAH22 22 15.0 152 135 49 - 3.0 CMAH26 26 21.2 162 157 55 - 4.6 CMAH32 32 31.5 202 197 69 - 8.6 F = Diameter hole to accept male leg Self-Locking Hooks Stock Code L M N D Chain Size (mm) WLL (tonnes) D L M (mm) (mm) (mm) N Weight (mm) kg/pc CMHL06N 6 1.1 73 23 106 28 0.5 CMHL07N 7/8 2.0 86 24 133 33 0.9 CMHL10N 10 3.2 110 32 167 45 1.6 CMHL13N 13 5.3 136 39 208 54 3.1 CMHL16N 16 8.0 173 49 250 67 6.2 CMHL20 20 12.5 - 64 282 90 8.5 CMHL22 22 15.0 - 70 319 80 11.2 CMHL26 26 21.2 - 80 343 99 14.5 Stock Code Chain Size (mm) WLL (tonnes) Clevis Self-Locking Hooks L M N D D L M (mm) (mm) (mm) N Weight (mm) kg/pc CMHPL06 6 1.1 73 6.5 98 28 0.6 CMHPL07N 7/8 2.0 86 10 122 33 0.9 CMHPL10N 10 3.2 110 12 150 45 1.7 CMHPL13N 13 5.3 136 15 186 54 3.3 CMHPL16N 16 8.0 173 17 215 67 6.3 CMHPL20 20 12.5 - 21 243 90 9.0 CMHPL22 22 15.0 - 24 273 80 14.1 CMHPL26 26 21.6 254 28 319 87 22.5 Dimensions are subject to commercial tolerances 110 05 Chain Slings.qxd 15/2/12 5:36 PM Page 9 Chain Slings GRADE T LIFTING CHAIN COMPONENTS TO AS 3776 Swivel Self-Locking Hooks M N D Chain Size (mm) WLL D L M N Weight (tonnes) (mm) (mm) (mm) (mm) kg/pc CMHV06 6 1.1 74 24 141 30 1.0 CMHV07N 7/8 2.0 88 27 182 36 1.3 CMHV10N 10 3.2 106 33 219 44 2.2 4.3 CMHV13N 13 5.3 136 41 278 50 CMHV16 16 8.0 - 50 328 60 7.6 CMHV20 20 12.5 - 82 388 90 11.7 CMHV22 22 15.5 - 95 457 80 17.9 CMHV26 26 21.2 - 115 535 99 29.5 WARNING • The swivel function on Swivel Self-Locking hooks is for positioning only. The hook is not designed to rotate under load. Safety Hooks C T B A Stock Code Chain Size (mm) WLL A B C T Weight (tonnes) (mm) (mm) (mm) (mm) kg/pc CMHY07N 7/8 2.0 138 98 28 18 0.5 CMHY10N 10 3.2 174 108 32 44 1.0 CMHY13N 13 5.3 214 134 41 55 2.0 CMHY16N 16 8.0 272 203 50 70 4.4 CMHY20N 20 12.5 330 242 62 89 8.5 Stock Code Chain Size (mm) CMHPY07N 7/8 2.0 9 85 134 18 0.6 CMHPY10N 10 3.2 11 102 159 22 1.1 CMHPY13N 13 5.3 14 137 198 27 2.0 CMHPY16N 16 8.0 18 167 257 70 4.5 CMHPY20N 20 12.5 23 225 313 87 8.8 Clevis Safety Hooks L T AR WLL L (tonnes) (mm) R A T Weight (mm) (mm) (mm) kg/pc Dimensions are subject to commercial tolerances Sling Hooks Stock Code Chain Size (mm) WLL (tonnes) L (mm) M (mm) N (mm) Weight kg/pc CMHS22 22 15.0 50 244 73 9.0 CMHS25 26 21.2 64 279 77 13.5 CMHS32 32 31.5 88 352 114 20.0 L N M Safety catches are not included on 22, 26 and 32mm Standard Sling Hooks. Please specify Safety Sling Hook if a safety catch is required. 111 Chain Slings Stock Code L 05 Chain Slings.qxd 15/2/12 5:36 PM Page 10 Chain Slings GRADE T LIFTING CHAIN COMPONENTS TO AS 3776 Grab Hooks Stock Code L E M Chain Slings D Chain Size (mm) WLL (tonnes) D E L (mm) (mm) (mm) M Weight (mm) kg/pc CMHG06 6 1.1 - 8 13 42 0.2 CMHG07N 7/8 2.0 53 9 15 58 0.3 CMHG10N 10 3.2 71 12 19 78 0.8 CMHG13N 13 5.3 91 16 24 102 1.4 CMHG16N 16 8.0 106 22 30 113 2.2 CMHG20N 20 12.5 122 25 37 135 3.5 CMHG22 22 15.0 - 26 38 187 4.8 CMHG25 26 21.2 - 29 41 230 10.5 CMHG32 32 31.5 - 37 57 267 20.0 Stock Code Chain Size (mm) WLL (tonnes) CMHPG07N 7/8 2.0 53 9 50 10 0.4 CMHPG10N 10 3.2 70 13 72 12 0.9 CMHPG13N 13 5.3 90 16 88 16 1.6 CMHPG16N 16 8.0 104 19 100 22 2.4 CMHPG20 20 12.5 - 23 124 23 4.7 Stock Code Chain Size (mm) WLL (tonnes) CMHPT07N 7/8 2.0 9 10 16 62 0.4 CMHPT10N 10 3.2 14 14 25 87 1.0 CMHPT13N 13 5.3 16 17 32 115 1.9 Stock Code Chain Size (mm) WLL (tonnes) CMHPT16 16 8.0 62 18 127 18 2.6 CMHPT20 20 12.5 74 22 157 23 3.5 Clevis Grab Hooks L N M D L M (mm) (mm) (mm) N Weight (mm) kg/pc D Clevis Shortening Hooks B C F A,B C E (mm) (mm) (mm) F Weight (mm) kg/pc E A Pinlok Shortening Hooks L D L M (mm) (mm) (mm) N Weight (mm) kg/pc M N D Dimensions are subject to commercial tolerances 112 05 Chain Slings.qxd 15/2/12 5:36 PM Page 11 Chain Slings VIP LIFTING CHAIN & COMPONENTS Higher WLL 25% more than the existing Grade 8 or 80. VIP Special Quality is a further development of Grade 8 or 80 lifting chain, which has been well established for more than 20 years. VIP identification is stamped on every chain link. Chains stamped VIP are manufactured with tighter tolerances in the inner width. Also they are permanently powder coated with a fluorescent pink colour. A foolproof chain connection is ensured due to the special fork head design. The high quality VIP chains and components have a duplex surface protection. Due to the two stages, i.e. pretreatment and pink powder coating, a considerably better surface protection is obtained compared to normal zinc plating. Overheating Indication The special fluorescent pink powder coating permanently changes colour at increased temperatures. Colour black signifies an application at more than 400° C. The chain should not be used at this high temperature. If the coating starts to bubble replace VIPchains or return them to Nobles for repair. 8S or 10 BG-Approved (German Statutory Authority) The special fluorescent pink powder coating permanently highlights the maximum temperature at which the VIP-chain has been used. The BG awarded for the RUD Special Quality VIP is stamped in short distances on the links. H1 indicates manufacturers number 1 = RUD and 8S or 10 meaning grade 10 or 100. Quality Verification At regular intervals chains are stamped with the serial number and the batch number. This identification guarantees a continuous record of manufacturing and proof data, for a period of 10 years. WARNING • If RUD VIP chain turns black further use is prohibited. Other Features Geometric construction and tolerances of VIP-chains are adapted to a higher quality class. All RUD-VIP chains and components are electromagnetically crack tested and are also subjected to cyclic testing (20,000 cycles) at 1.5 times the WLL. On request the super corrosion coating Corrud® DS can be supplied. This coating is 20 times more red rust resistant than zinc plating. VIP-Identification tag with integrated Testing Gauge Simple examination of the chain condition (wear and elongation) can be undertaken using the VIP-identification tag. Testing wear of nominal dia. 113 Testing elongation caused by overloading. Testing elongation of pitch caused by wear of nominal dia. Chain Slings RUD VIP is made from CrNiMo-special steel, which is quenched and tempered to produce unique characteristics of high toughness and minimum ultimate elongation for natural black ≥25%, surface treated ≥20%. VIP is less sensitive to notching and hydrogen embrittlement than Grade 8 or 80. The bending test, according to DIN or EN standards is far exceeded by VIP. 05 Chain Slings.qxd 15/2/12 5:36 PM Page 12 Chain Slings VIP LIFTING CHAIN The RUD fork head system ensures a foolproof connection of the correct component to the correct nominal VIP chain size. VIP Foolproof assembly system Hammer in tensioning sleeve so that the slot of the tensioning sleeve can be seen from the front. Use tensioning sleeve only once. Dim. X avoids connection of a larger VIP chain. VIP stamped chains are manufactured with tighter tolerances in the inner width (dim. W1). Dim. Y avoids the connection of the next smaller VIP chain. Chain Slings WARNING • VIP components must not be connected with chains of lower quality classes. • Use only original VIP components. VIP Chain p d Patented: VG Bolt of a smaller size will drop out. Stock Code WLL (tonnes) D (mm) P (mm) Weight (kg/m) CVVC04 0.63 4 12 0.36 CVVC06 1.5 6 18 0.85 CVVC08 2.5 8 24 1.5 CVVC10 4.0 10 30 2.4 CVVC13 6.7 13 39 4.0 Result: CVVC16 10.0 16 48 6.0 Only VIP chains and components having the same working load can be used. VIP chains 8S or 10 can only be connected with VIP components 8S or 10. CVVC20 16.0 20 60 9.5 CVVC22 20.0 22 66 12.3 CVVC28 31.5 28 84 18.6 VIP CHAIN SLINGS - WLL TONNES VIP WLL CHART Single Leg Slings Chain Straight Adjustable Reeved Sling Sling size mm Sling 2, 3, or 4 Leg Slings 60˚ Straight Sling 90˚ 120˚ 60˚ Endless Slings Reeved Sling 90˚ 120˚ 60˚ Basket Sling 90˚ 120˚ Reeved Sling 4 0.63 0.63 0.47 1.09 0.89 0.63 0.82 0.66 0.47 0.82 0.66 0.47 0.94 6 1.5 1.5 1.1 2.6 2.1 1.5 1.9 1.6 1.1 1.9 1.6 1.1 2.2 8 2.5 2.5 1.9 4.3 3.5 2.5 3.2 2.6 1.8 3.2 2.6 1.8 3.7 10 4.0 4.0 3.0 6.9 5.6 4.0 5.2 4.2 3.0 5.2 4.2 3.0 6.0 13 6.7 6.7 5.0 11.6 9.4 6.7 8.7 7.1 5.0 8.7 7.1 5.0 10.0 16 10.0 10.0 7.5 17.3 14.1 10.0 13.0 10.6 7.5 13.0 10.6 7.5 15.0 20 16.0 16.0 12.0 27.7 22.5 16.0 20.8 16.9 12.0 20.8 16.9 12.0 24.0 22 20.0 20.0 15.0 34.6 28.2 20.0 26.0 21.2 15.0 26.0 21.2 15.0 30.0 28 31.5 31.5 23.6 54.5 44.4 31.5 41.0 33.4 23.6 41.0 33.4 23.6 47.2 114 VIP temperature °C deration - 40 to + 200 = none, Over 200 to 300 = 10%, Over 300 to 380 = 40% 05 Chain Slings.qxd 15/2/12 5:36 PM Page 13 Chain Slings VIP MASTER LINKS VIP Master Links range from the smallest VBK’s for small hoist hooks up to the oversize VSAK links that are suited to high capacity hooks. Master link collection for every crane hook All VIP Master Links and Master Link assemblies feature foolproof clevis connections that ensure only the correct chain diameter can be fitted. Stock Code WLL (Tonnes) Chain Size B (mm) C (mm) T (mm) Weight (kg/pc) CVVBK106 1.5 6 25 CVVBK108 2.5 8 34 54 82 0.5 70 107 0.7 CVVBK110 4.0 10 CVVBK113 6.7 13 40 85 131 1.1 50 115 174 CVVBK116 10.0 2.0 16 65 140 211 CVVBK120 3.3 16.0 20 75 170 264 CVVBK122 7.6 20.0 22 110 200 294 9.0 Stock Code WLL (Tonnes) Chain Size B (mm) C (mm) T (mm) Weight (kg/pc) CVVAK106 1.5 6 60 110 138 0.6 T B C VIP VAK-1 Large Master Link Single Leg CVVAK108 2.5 8 60 110 147 0.9 CVVAK110 4.0 10 75 135 181 1.4 CVVAK113 6.7 13 90 160 218 2.4 CVVAK116 10.0 16 100 180 250 3.7 CVVAK120 16.0 20 180 340 434 14.7 CVVAK122 20.0 22 180 340 434 16.5 Stock Code WLL* (Tonnes) Chain Size B (mm) C (mm) T (mm) Weight (kg/pc) CVVAK206 2.6 6 60 110 138 0.7 VIP VAK-2 Master Link 2-Leg T C B CVVAK208 4.3 8 75 135 172 1.4 CVVAK210 6.9 10 90 160 206 2.3 CVVAK213 11.6 13 100 180 238 3.9 CVVAK216 17.3 16 110 200 270 6.6 CVVAK220 27.7 20 180 340 434 16 CVVAK222 34.6 22 180 340 434 20 * For straight slings at 60˚ included angle. WLL decreases for angles of 90˚ and 120˚ T B C VIP VAK-4 Master Link 4-Leg Stock Code WLL* (Tonnes) Chain Size B (mm) C (mm) T (mm) Weight (kg/pc) CVVAK406 2.6 6 75 135 217 1.5 CVVAK408 4.3 8 90 160 268 2.8 CVVAK410 6.9 10 100 180 311 4.6 CVVAK413 11.6 13 110 200 373 8.3 CVVAK416 17.3 16 140 260 470 13.7 CVVAK420 27.7 20 190 350 614 39.0 CVVAK422 34.6 22 190 350 614 40.1 * For straight slings at 60˚ included angle. WLL decreases for angles of 90˚ and 120˚ Oversize Master Links (VSAK) are also available. 115 Chain Slings T B C VIP VBK-1 Small Master Link Single Leg 05 Chain Slings.qxd 15/2/12 5:36 PM Page 14 Chain Slings VIP HOOKS VIP VCGH Cobra Hook The enlarged hook tip prevents misuse. Wear edges on both sides of the hook protect against abrasion of the chain when dragging chain assemblies along the ground. Gauge marks on the hook enable easy inspection for any deformation of the hook. The compact design of the VIP Cobra hook with a non protruding hook tip is far superior and safer than the common clevis sling hook. Supplied complete with a forged and tempered safety latch that locks into the hook tip and protects against lateral bending. B A D T F Chain Slings G Stock Code Chain WLL A B C D F F max G T (mm) (Tonne) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) Weight kg/pc CVVCGH06 6 1.5 38 22 16 20 25 45 72 76 0.4 CVVCGH08 8 2.5 50 28 20 28 30 52 95 97 0.9 CVVCGH10 10 4.0 60 36 26 36 35 65 118 108 1.5 CVVCGH13 13 6.7 76 46 30 37 40 73 135 126 2.7 CVVCGH16 16 10.0 83 56 36 49 48 87 161 152 4.3 CVVCGH20 20 16.0 112 68 50 69 63 114 218 195 10.0 CVVCGH22 22 20.0 117 78 50 74 63 114 223 198 11.5 C VIP VAGH (S) Self-Locking Hook sides of the hook protect the chain against abrasion when the assembly is dragged along the ground. Safety latch spare parts are available on demand. The extremely robust and proven design ensures the hook automatically locks when lifting the load. It can only be opened by activating the protected unlocking lever on the back of the hook. The VIP Self-Locking Hook also features a non protruding hook tip, and large mouth width. Wearing edges (dimension B) on both A B Stock Chain WLL (mm) (Tonne) Code B C D E F T (mm) (mm) (mm) (mm) (mm) (mm) Weight kg/pc CVVAGH08 8 2.5 40 30 27 28 97 44 121 1.0 CVVAGH10 10 4.0 49 37 30 31 107 48 135 1.5 CVVAGH13 13 6.7 61 48 32 42 120 47 150 2.9 D T F A (mm) E C VIP VWH Foundry Hook foundry hooks, special attention must be paid and a risk assessment carried out prior to use. The robust cross section (dimensions G and C) is resistant against increased lateral forces, with specially designed wearing edges to protect the chain link. The VIP Foundry Hook has a considerably larger mouth width than the Cobra Hook. Foundry Hooks do not have a safety catch and as such they should only be used where unintentional hooking is impossible. Do not use for overhead lifting and when using E (Tonne) A (mm) B (mm) C (mm) D (mm) E (mm) F (mm) Fmax (mm) G (mm) CVVWH06 6 1.5 30 22 18 30 22 50 63 CVVWH08 8 2.5 40 29 26 40 29 64 81 CVVWH10 10 4.0 46 37 30 50 36 76 CVVWH13 13 6.7 51 45 37 64 46 90 A Stock Code CVVWH16 16 10.0 64 56 40 75 56 100 CVVWH20 20 16.0 96 80 73 102 80 136 CVVWH22 22 20.0 96 80 73 102 80 136 T F Chain (mm) B D G WLL C 116 T (mm) Weight kg/pc 22 87 0.5 30 115 0.9 96 37 130 1.7 115 51 168 3.0 129 58 190 5.7 183 80 277 15.1 183 80 277 15.1 05 Chain Slings.qxd 15/2/12 5:37 PM Page 15 Chain Slings VIP HOOKS VIP VVH Grab Hook The VIP Grab Hook has no reduction of WLL and features a thickened hook tip to avoid misuse e.g. incorrect fitting of the chain. The ideal chain support is facilitated by the calibrated lugs. The U-bend insertion slot protects against accidental chain disengangement. T E C F D Stock Code Chain WLL A B C D E F T (mm) (Tonne) (mm) (mm) (mm) (mm) (mm) (mm) (mm) Weight kg/pc CVVVH06 6 1.5 31 18 20 43 7.5 23 50 0.25 CVVVH08 8 2.5 38 22 25 54 9.5 33 64 0.35 CVVVH10 10 4.0 47 28 31 68 12 42 80 0.8 CVVVH13 13 6.7 60 36 40 87 15 47 103 2.2 CVVVH16 16 10.0 75 45 50 108 18.5 57 125 2.9 CVVVH20 20 16.0 92 58 63 138 24 76 162 8.4 CVVVH22 22 20.0 102 62 69 151 26 83 179 11.0 VIP VMVK Multi Shortening Claw unintentional hooking out of the chain in both loaded and unloaded conditions. The hook is precisely shaped to accomodate the chain link and therefore there is no reduction in the WLL. The patented multi shortening claw can be fitted on the chain leg at any required position. No additional chain and coupling parts are required. The robust safety bolt with a spring prevents G B2 T Stock Code B1 Chain WLL A B1 B2 T G (mm) (Tonne) (mm) (mm) (mm) (mm) (mm) CVVMVK06 6 1.5 38 34 40 66 38 0.3 CVVMVK08 8 2.5 46 41 52 88 48 0.55 CVVMVK10 10 4.0 58 50 64 110 60 1.1 CVVMVK13 13 6.7 74 64 86 143 76 2.4 CVVMVK16 16 10.0 91 79 105 176 98 4.4 Weight kg/pc A VIP VVS-U Universal Chain Connector optionally combined to suit the application. No movement means no damage of the securing spring or the sleeves of the retention bolt. The Universal Chain Connector enables various external connections e.g. lifting points etc. They can be mounted in the locking bracket (A2 dimension). The bracket halves can be A2 Stock Code Chain WLL A2 B C D T (mm) (Tonne) (mm) (mm) (mm) (mm) (mm) Weight kg/pc 6 1.5 14 50 8.5 14 40 0.09 CVVS08 8 2.5 19 64 10.5 19 53 0.17 CVVS10 10 4.0 23 80 13 23 70 0.42 C D T CVVS06 B CVVS13 13 6.7 27 97 17 27 81 0.64 CVVS16 16 10.0 34 125 21 34 104 1.5 CVVS20 20 16.0 42 155 27 41 124 3.0 CVVS22 22 20.0 47 172 30 46 133 3.9 117 Chain Slings B A