PrO-Soffit

FOR FLOORS

PrO-Soffit

Enhanced thermal insulation with Class O fire performance for semi-exposed concrete soffits

Polyisocyanurate (PIR) foam core with a range of class O facings to suit specific project demands

PrO-Soffit

FOR FREE TECHNICAL ADVICE

Call:

01268 597 212/213

Email: technical@ecotherm.co.uk

Description

PrO-Soffit is a rigid polyisocyanurate foam with a range of facing options to suit project requirements. All boards deliver improved thermal performance over standard PIR insulation. Facing options range from noncombustible building boards to foil facings with Class O fire performance.

Applications

Used for new-build and refurbishment of semi-exposed soffits in car-parks, office/ residential blocks and also basements. It provides a cost effective means of reducing

CO

2

emissions and for compliance with

Building Regulations.

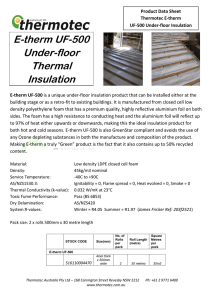

PRODUCT SPECIFICATION

PrO-Soffit can be tailored to suit the demands of individual projects. The following table will identify a suitable product, or alternatively you can contact our technical department who will be happy to guide you through the specification process.

Table 1

Finishing options

Product properties

Calcium

silicate building board

Magnesium silicate building board

Glass reinforced gypsum building board

Pure aluminium facing

Typical thicknesses

Flame resistant

8mm

Yes

6mm

Yes

6mm

Yes

N/A

Yes

Finished facing

Yes Yes Yes Yes

Product properties

Secondary finish

Yes

DIMENSIONS

PrO-Soffit is available in the following standard sizes:

Width (mm): 1200

Length (mm): 2400

Building board thickness: See table 1.

Further thicknesses available upon request.

Insulation thickness: 30mm - 200mm

Area: 2.88m

2

TYPICAL WEIGHT

Insulation weighs approximately 10kg per 100mm board

(2.88m

2 ).

Composite PrO-Soffit typically weighs 29kg per 88mm i.e.80mm PIR laminated to 8mm mineral board.

DENSITY

EcoTherm PrO- Soffit foam has a typical density of 31kgm 3 .

THERMAL CONDUCTIVITY

The thermal resistance of a PrO-Soffit board varies dependent upon the project requirements as a range of foil and building board options can be selected to suit the specification but a thermal conductivity ( λ value) of the main components are as follows:

Pure foil faced PIR foam core is 0.021 W/mK

Typical mineral board is 0.16 W/mK

The low emissivity surface of the reflective foil can cut radiated heat transferred across an adjoining unventilated air-space. The thermal resistances of PrO-Soffit are detailed in table 2.

Further details are available from EcoTherm Technical

Services.

DURABILITY

PrO-Soffit has an indeterminate life and its durability depends on the background/supporting structure and conditions of its use. It should not be used to isolate dampness nor be used in continuously damp/humid conditions.

Impact resistant

Moisture resistant

Appearance

Yes

Yes

FIRE RESISTANCE

All of PrO-Soffit’s facings offer Class O fire rating. When correctly installed, the insulation will be contained between the concrete soffit and a non-combustible lining board and/or a non combustible foil facing.

Therefore the insulation will not contribute to the development stages of a fire.

The insulation on its own achieves BS476-7 Class 1 rating for surface spread of flame. This plus a BS 476- 6 pass enables the PIR board on its own to claim a Class

O classification.

The specific fire resistance of the system will depend upon the conditions of use. For advice on the correct specification please contact EcoTherm Technical

Services.

RESISTANCE TO SOLVENTS

PIR foam resists attack from alkalis, dilute acids, mineral oil and petrol. The foam core is not resistant to ketonic solvents. Damaged boards should not be used.

-

Yes

Yes

Yes

Yes

Yes

-

-

Yes

ENVIRONMENTAL

EcoTherm PIR foam is CFC/HCFC free and has zero Ozone

Depletion Potential (ODP) with a Global Warming Potential

(GWP) of 3, less than the target value of 5.

PrO-Soffit has BRE Green Guide rating of A.

EcoTherm Insulation is manufactured under an ISO 9001

Quality Management System (British Standards Institute

Certificate – Q 05508)

EcoTherm Insulation is manufactured under an ISO 14001

Environmental Management System (British Standards Institute

Certificate – EMS 564550)

EcoTherm Insulation is manufactured under BS OHSAS 18001

Occupational Health and Safety Management System (British

Standards Institute Certificate – OHS 585004)

PrO-Soffit is not classified as a dangerous substance, so no special provisions are required regarding carriage/disposal to landfill.

The insulation core and facings resists attack by mould and microbial growth and do not provide any food value to vermin.

www.ecotherm.co.uk tel: 01702 520166

FOR FLOORS

Table 2

Thickness of insulation

(mm)

Thermal

Resistance of insulation

(m 2 K/W)

Indicative U-values for

PrO-Soffit (W/m 2 K)

Steel

Frame

System

Timber

Frame

System

Direct

Fix

Plastic fixings*

75 3.571 0.21 0.22 0.25

90 4.286 0.18 0.19 0.22

100

120

4.762

5.714

0.17

0.15

0.17 0.20

0.15 0.16

* Assuming fixings thermal conductivity less than 1 W/mK

Please Note: Calculations based on PrO-Soffit boards fixed to the underside of a semi exposed concrete slab.

These are indicative U-values only and a project specific calculation should be prepared by EcoTherm Technical Services.

This is particularly relevant when using metal fixings.

Design considerations

FIRE

When properly installed, the insulation will not contribute to the development of a fire. Further details on the fire performance of PrO-Soffit may be obtained from EcoTherm Technical Services.

TYPICAL U-VALUES

EcoTherm PrO-Soffit gives typical U-values as shown in table 2. Project specific U-value calculations and condensation risk analysis are available from

EcoTherm Insulation Technical Services on request.

VAPOUR RESISTANCE

PrO-Soffit has an integral vapour control layer to minimise the risk of interstitial condensation. Foil facings have a high water vapour resistance and will, therefore, provide a significant resistance to water vapour transmission.

If required, apply proprietary self-adhesive foil tape at board joints to complete the vapour control layer and to maximise thermal performance. The requirement for a vapour control layer should be assessed to BS5250: 2002 (Code of Practice for control of condensation in buildings)

COMPRESSIVE STRENGTH

Typical compressive strength for the foam exceeds

140kPa when tested to BS EN 826: 1996 Thermal Insulating

Products for Building Applications – Determination of

Compression Behaviour.

SPANNING

The maximum span should be 600mm, see Typical

Fixing Instructions.

SPECIFICATION CLAUSE

The insulation shall be EcoTherm PrO-Soffit Board _ _ mm thick: comprising of rigid polyisocyanurate (PIR) foam core with a Class O low emissivity textured aluminium foil facing on both sides or one side bonded to a mineral board.

The insulation aspect shall be manufactured in accordance to BS EN 13165: 2012 and Management System BS EN ISO

9001: 2008 / BS EN ISO 14001: 2004 / BS OHSAS 18001:

2007, with a blowing agent that has zero Ozone Depletion

Potential (ODP) and low Global Warming Potential (GWP).

EcoTherm PrO-Soffit must be installed in accordance with instructions issued by EcoTherm Insulation (UK) Limited.

Typical fixing instructions

EcoTherm strongly recommends seeking specific project advice from a suitable fixing manufacturer, or call EcoTherm Technical Services for advice.

Ensure the fixing device is long enough to give adequate penetration into either the framing or the concrete soffit.

The concrete soffit should be checked prior to installation to ensure that it is structurally sound by a competent person. Ensure boards are tightly butted together.

The fixings must be located greater than 50mm from the edges and corners of the board and never overlap board joints.

It is recommended that surface mounted services should be fixed back to the concrete soffit and not the surface mineral board.

3 fixing methods are available:

1

STEEL FRAME SYSTEM

Mechanically fix to proprietary steel frame system. Install PrO- Soffit at right angles to the framing using appropriate fixings at 600mm centres in the field of the board and at board ends ensuring a minimum 10mm penetration.

Follow manufacturer guidelines when installing a steel frame system.

2

TIMBER FRAME SYSTEM

Mechanically fix to 75mm x 50mm pre-treated timber framing at 600mm centres in the field of the board and at board ends. Install board at right angles to the framing using appropriate fixings ensuring a minimum 25mm penetration. The

75mm ensures sufficient bearing capability and

50mm provides good fixing depth.

3

DIRECT TO SOFFIT

Fix directly to soffit using proprietary noncombustible concrete fixings such as SPIT

Isomet Insulation Anchors, Insofast Fixings or

Ejot self-tapping concrete anchors at 400mm centres, strictly in accordance with manufacturer’s instructions.

Finishing/Decoration

Depending upon the specification of the PrO-Soffit facing, boards can be left undecorated or able to receive a decorative finish.

The Class O building boards used to face PrO-Soffit are of organic origin and as such, natural variances will occur between batches.

Complete fuss-free technical support for insulation

We have it covered

Call:

01268 597 212/213

Email: technical@ecotherm.co.uk

for full detailed

product information request our datasheets and installers guide online at:

www.ecotherm.co.uk

PrO-Soffit

FOR FLOORS

Site work

HANDLING

• Care should be taken when removing boards from pallets. Employ a two-man lift to ensure no marking or dragging occurs

• Secondary trades must take care when installing services, pipes and cable trays etc. to reduce the risk of damaging boards in situ

• Additional lifting equipment may be required and may need to be considered in the risk assessment

• Any light scratches or scuffs can be treated by light sanding, then wiped with a damp cloth

• If using a foil faced PrO-Soffit board, ensure all joints are taped

• Edge reveals being covered by building boards should be mechanically fixed to concrete soffit

• To cut - use a sheet saw with hardened steel teeth

• Do not breathe the dust, avoid contact with skin and eyes

• Wear appropriate hand and eye protection due to the sharp edges of the board

• Damaged boards should not be used

• Drilling can be carried out either by hand or power drills with high speed drill bits

• Edges can be planed using a surform or rasp

• Ensure accurate trimming to achieve close butt joints and continuity of insulation, particularly around projections

• Cutting with power tools generates non-hazardous dust, so should be kept to a minimum. Ideally all operations which produce dust should be carried out in well ventilated conditions; where possible a dust mask selected in accordance with

BS EN 149 should be worn

HEALTH AND SAFETY

EcoTherm PrO-Soffit is chemically inert and safe to use, COSHH information is available on request.

STORAGE

Store boards in a flat, dry area off the ground away from mechanical and water damage and sources of ignition.

The boards must be protected from prolonged exposure to sunlight and should be stored either under cover or covered with opaque polyethylene or tarpaulin.

Keep boards dry at all times. If boards do get wet, allow to dry fully before installation.

IT COULD NOT BE EASIER to process your request.

Please email us the following details to technical@ecotherm.co.uk or fax the form below to 01268 591 852. Alternatively you can call EcoTherm

Technical Services on 01268 597 212/213.

Project reference:

Project location:

Project m 2 :

Requested by:

Company:

Email:

Desired U-value:

Desired fire performance:

Will the facing be finished i.

e. paint (please tick):

Desired aesthetic finish:

Intended use of area:

Telephone

Yes

Any other information:

Date:

Signature:

No

Fax:

ISO14001 ISO9001 ISO18001

EMS 564550 Q05508 OHS 585004

EcoTherm Insulation (UK) Ltd

Harvey Road, Burnt Mills Ind. Est., Basildon, Essex, SS13 1QJ tel: +44 (0) 1702 520166 fax: +44 (0) 1702 420636 www.ecotherm.co.uk email: info@ecotherm.co.uk

Please consult EcoTherm for details of BBA certificate numbers for specific products

EcoTherm Insulation (UK) Ltd is registered in England No. 1873816

NOVEMBER 2011

September 2013