Démolition de constructions

advertisement

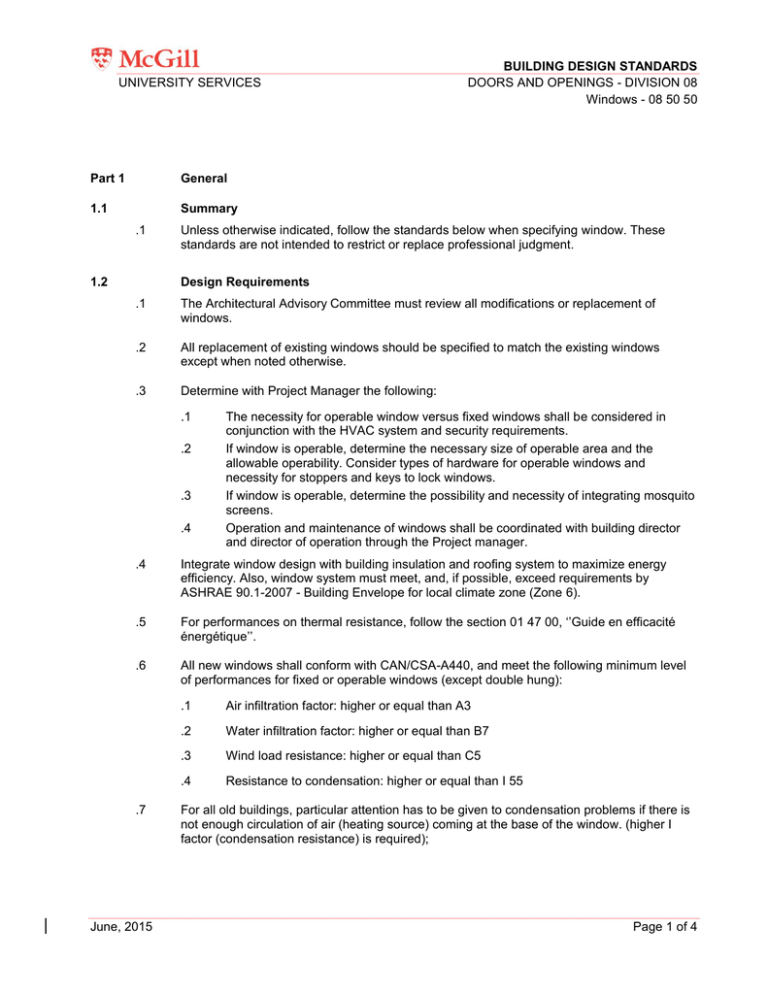

UNIVERSITY SERVICES Part 1 General 1.1 Summary .1 1.2 BUILDING DESIGN STANDARDS DOORS AND OPENINGS - DIVISION 08 Windows - 08 50 50 Unless otherwise indicated, follow the standards below when specifying window. These standards are not intended to restrict or replace professional judgment. Design Requirements .1 The Architectural Advisory Committee must review all modifications or replacement of windows. .2 All replacement of existing windows should be specified to match the existing windows except when noted otherwise. .3 Determine with Project Manager the following: .1 .2 .3 .4 The necessity for operable window versus fixed windows shall be considered in conjunction with the HVAC system and security requirements. If window is operable, determine the necessary size of operable area and the allowable operability. Consider types of hardware for operable windows and necessity for stoppers and keys to lock windows. If window is operable, determine the possibility and necessity of integrating mosquito screens. Operation and maintenance of windows shall be coordinated with building director and director of operation through the Project manager. .4 Integrate window design with building insulation and roofing system to maximize energy efficiency. Also, window system must meet, and, if possible, exceed requirements by ASHRAE 90.1-2007 - Building Envelope for local climate zone (Zone 6). .5 For performances on thermal resistance, follow the section 01 47 00, ‘’Guide en efficacité énergétique’’. .6 All new windows shall conform with CAN/CSA-A440, and meet the following minimum level of performances for fixed or operable windows (except double hung): .7 June, 2015 .1 Air infiltration factor: higher or equal than A3 .2 Water infiltration factor: higher or equal than B7 .3 Wind load resistance: higher or equal than C5 .4 Resistance to condensation: higher or equal than I 55 For all old buildings, particular attention has to be given to condensation problems if there is not enough circulation of air (heating source) coming at the base of the window. (higher I factor (condensation resistance) is required); Page 1 of 4 UNIVERSITY SERVICES 1.3 BUILDING DESIGN STANDARDS DOORS AND OPENINGS - DIVISION 08 Windows - 08 50 50 Guarantee .1 The products described in this section shall be guaranteed for a period of five (5) years from the date of substantial completion of the work. Part 2 Products 2.1 Preferred Products .1 Refer to MAT website (www.materialanalysis.ca) for selection of products for this section, except for prescribed items. Products selected on MAT should have score of 5 or above. .2 Specify thermally improved (thermal-break) construction in all cases, without exception. 2.2 Aluminium Finishes .1 Shall be anodized .1 .2 2.3 Finish with “DURANAR Coatings” from PPG or approved equivalent. Finishes must be reviewed by the Architectural Advisory Committee. Isolation Coating .1 Isolate aluminium from following components, by means of isolation coating as follows: .1 .2 .3 2.4 Dissimilar metals except stainless steel, zinc, or white bronze of small area; Concrete, mortar and masonry; Wood. Sealed Unit: .1 Hermetically sealed unit with basic components: .1 .2 .3 .4 2.5 Glazing of 6mm; Gas space (argon) of 12.7mm with non-conductive spacer; Acceptable product: “R-Max” as manufactured by Prelco or approved equivalent; Glazing of 6 mm. Glazing .1 Shall be factory sealed thermopane units with clear glass. Use of tints, reflective coatings, and other possible combinations must be reviewed by the Architectural Advisory Committee. .2 The U value of the assembly shall be lower than the maximum U value mentioned listed in ASHRAE 90.1-2007 (U=0, 24 or better) .3 Visible light or transmittance (%): .1 .4 June, 2015 Specify the maximum possible to save on indoor lighting, and no less than 63% transmittance. (For reference, clear glass thermos unit has a transmittance=78%) Solar Heat Gain Coefficient (SHGC): Page 2 of 4 UNIVERSITY SERVICES .1 .5 BUILDING DESIGN STANDARDS DOORS AND OPENINGS - DIVISION 08 Windows - 08 50 50 The SHGC value of the assembly has to be lower than the maximum SHGC value mentioned listed in ASHRAE 90.1-2007 (0, 42 or better). Low E coating .1 Should be use in position 2 or 3 to control Heat loss or Heat gain (accordingly) through windows if required. ‘Soft coating’ type of Low-E, applied by vacuum deposition is preferred. Degrees of low E are to be chosen according to characteristics needed, depending on the case. (Color, transmittance and reflectivity are factors to look at). Acceptable products: “Low E 272” on clear or “Low E 366” on clear as manufactured by Cardinal or approved equivalent; .6 Tempered or annealed glass to be determined on each specific project. .7 Muntins added on sun exposed high performance glazing create a differential in temperature in the glass that can make it cracked: tempered glass might be necessary. 2.6 Hardware .1 Hardware: stainless steel or white bronze sash locks and aluminium handles to provide security and permit easy operation of units .2 All operable hardware, hinges, handles, pulls, etc. shall be heavy duty. 2.7 Air Barrier / Vapour Retardant .1 Equip window frames with (factory site) installed air barrier and vapour retardant material for sealing to building air barrier and vapour retardant as follows: .1 .2 Material: identical to, or compatible with, building air barrier and vapour retardant materials to provide required air tightness and vapour diffusion control throughout exterior envelope assembly. Material width: adequate to provide required air tightness and vapour diffusion control to building air barrier and vapour retardant from interior. Sealant: (Refer to Section 07 92 10 – Joint Sealing) 2.8 .1 Sealant shall remain permanently elastic, non-shrinking, and non-migrating. .2 Sealant joint between window perimeter and masonry shall be of a chamfer joint shape. Exterior sealant between aluminum frames and masonry shall be of ½’’ to ¾’’, chamfer form and polyurethane based. Acceptable product: “Dymeric 240” as manufactured byTremco or an approved equivalent. 2.9 Glass-Fibre Mesh Insect Screen: .1 June, 2015 Specify 18 by 16 or 18 by 14 mesh of plastic-coated glass-fibre threads, woven and fused to form a fabric mesh that is resistant to corrosion, shrinkage, stretch, impact damage, and weather deterioration. Comply with requirements of ASTM D 3656. Page 3 of 4 BUILDING DESIGN STANDARDS DOORS AND OPENINGS - DIVISION 08 Windows - 08 50 50 UNIVERSITY SERVICES Part 3 Execution 3.1 Testing .1 InSitu tests have to be specified and executed after windows are installed to verify values asked. END OF SECTION June, 2015 Page 4 of 4