METAL GRAPHITE NANOCOMPOSITE MATERIALS OF

advertisement

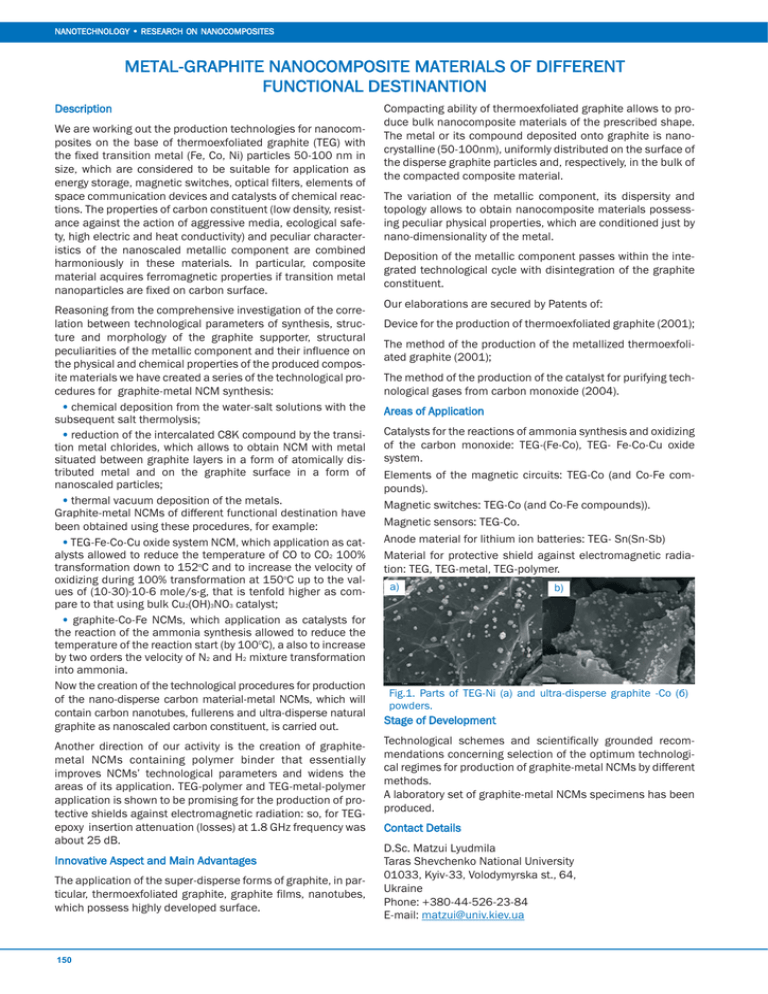

NANOTECHNOLOGY • RESEARCH ON NANOCOMPOSITES METALGRAPHITE NANOCOMPOSITE MATERIALS OF DIFFERENT FUNCTIONAL DESTINANTION Description We are working out the production technologies for nanocom posites on the base of thermoexfoliated graphite (TEG) with the fixed transition metal (Fe, Co, Ni) particles 50100 nm in size, which are considered to be suitable for application as energy storage, magnetic switches, optical filters, elements of space communication devices and catalysts of chemical reac tions. The properties of carbon constituent (low density, resist ance against the action of aggressive media, ecological safe ty, high electric and heat conductivity) and peculiar character istics of the nanoscaled metallic component are combined harmoniously in these materials. In particular, composite material acquires ferromagnetic properties if transition metal nanoparticles are fixed on carbon surface. Reasoning from the comprehensive investigation of the corre lation between technological parameters of synthesis, struc ture and morphology of the graphite supporter, structural peculiarities of the metallic component and their influence on the physical and chemical properties of the produced compos ite materials we have created a series of the technological pro cedures for graphitemetal NCM synthesis: • chemical deposition from the watersalt solutions with the subsequent salt thermolysis; • reduction of the intercalated C8K compound by the transi tion metal chlorides, which allows to obtain NCM with metal situated between graphite layers in a form of atomically dis tributed metal and on the graphite surface in a form of nanoscaled particles; • thermal vacuum deposition of the metals. Graphitemetal NCMs of different functional destination have been obtained using these procedures, for example: • TEGFeCoCu oxide system NCM, which application as cat alysts allowed to reduce the temperature of CO to CO2 100% transformation down to 152oC and to increase the velocity of oxidizing during 100% transformation at 150oC up to the val ues of (1030)·106 mole/s·g, that is tenfold higher as com pare to that using bulk Сu2(OH)3NO3 catalyst; • graphiteCoFe NCMs, which application as catalysts for the reaction of the ammonia synthesis allowed to reduce the temperature of the reaction start (by 1000С), а also to increase by two orders the velocity of N2 and H2 mixture transformation into ammonia. Now the creation of the technological procedures for production of the nanodisperse carbon materialmetal NCMs, which will contain carbon nanotubes, fullerens and ultradisperse natural graphite as nanoscaled carbon constituent, is carried out. Another direction of our activity is the creation of graphite metal NCMs containing polymer binder that essentially improves NCMs’ technological parameters and widens the areas of its application. TEGpolymer and TEGmetalpolymer application is shown to be promising for the production of pro tective shields against electromagnetic radiation: so, for TEG epoxy insertion attenuation (losses) at 1.8 GHz frequency was about 25 dB. Innovative Aspect and Main Advantages The application of the superdisperse forms of graphite, in par ticular, thermoexfoliated graphite, graphite films, nanotubes, which possess highly developed surface. 150 Compacting ability of thermoexfoliated graphite allows to pro duce bulk nanocomposite materials of the prescribed shape. The metal or its compound deposited onto graphite is nano crystalline (50100nm), uniformly distributed on the surface of the disperse graphite particles and, respectively, in the bulk of the compacted composite material. The variation of the metallic component, its dispersity and topology allows to obtain nanocomposite materials possess ing peculiar physical properties, which are conditioned just by nanodimensionality of the metal. Deposition of the metallic component passes within the inte grated technological cycle with disintegration of the graphite constituent. Our elaborations are secured by Patents of: Device for the production of thermoexfoliated graphite (2001); The method of the production of the metallized thermoexfoli ated graphite (2001); The method of the production of the catalyst for purifying tech nological gases from carbon monoxide (2004). Areas of Application Catalysts for the reactions of ammonia synthesis and oxidizing of the carbon monoxide: TEG(FeCo), TEG FeCoCu oxide system. Elements of the magnetic circuits: TEGCo (and CoFe com pounds). Magnetic switches: TEGCo (and CoFe compounds)). Magnetic sensors: TEGСо. Anode material for lithium ion batteries: ТEG Sn(SnSb) Material for protective shield against electromagnetic radia tion: TEG, TEGmetal, TEGpolymer. а) b) Fig.1. Parts of TEGNi (а) and ultradisperse graphite Со (б) powders. Stage of Development Technological schemes and scientifically grounded recom mendations concerning selection of the optimum technologi cal regimes for production of graphitemetal NCMs by different methods. A laboratory set of graphitemetal NCMs specimens has been produced. Contact Details D.Sc. Matzui Lyudmila Taras Shevchenko National University 01033, Kyiv33, Volodymyrska st., 64, Ukraine Phone: +380445262384 Email: matzui@univ.kiev.ua