Will LEDs replace neon

in channel-letter signs?

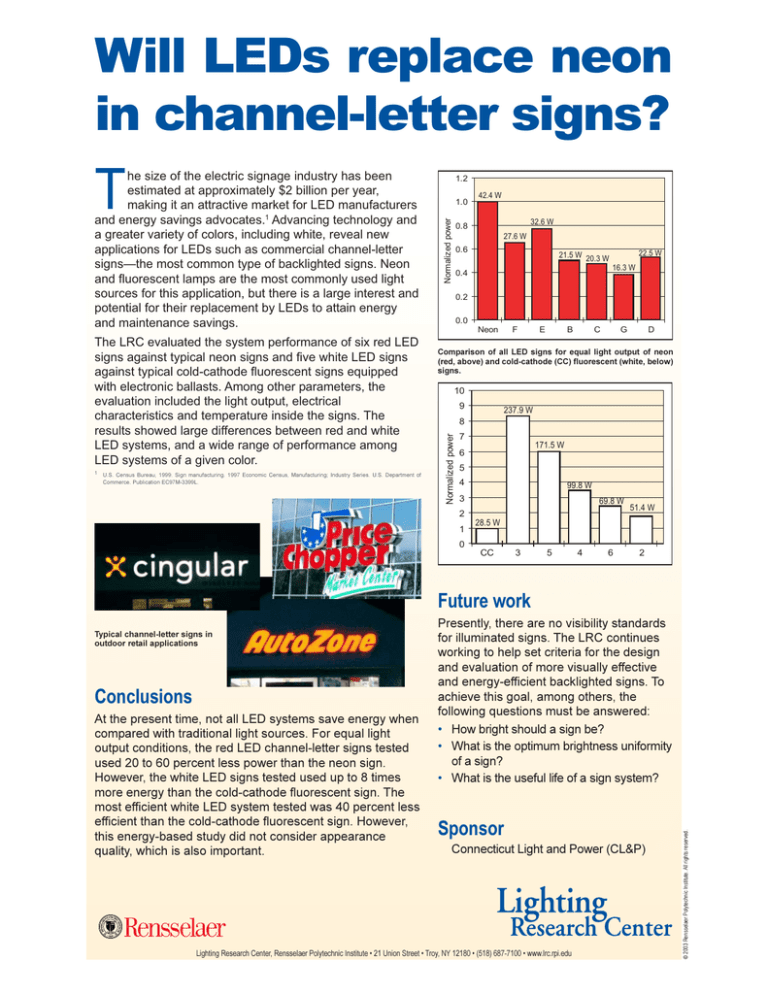

The LRC evaluated the system performance of six red LED

signs against typical neon signs and five white LED signs

against typical cold-cathode fluorescent signs equipped

with electronic ballasts. Among other parameters, the

evaluation included the light output, electrical

characteristics and temperature inside the signs. The

results showed large differences between red and white

LED systems, and a wide range of performance among

LED systems of a given color.

1

U.S. Census Bureau, 1999. Sign manufacturing. 1997 Economic Census, Manufacturing; Industry Series. U.S. Department of

Commerce. Publication EC97M-3399L.

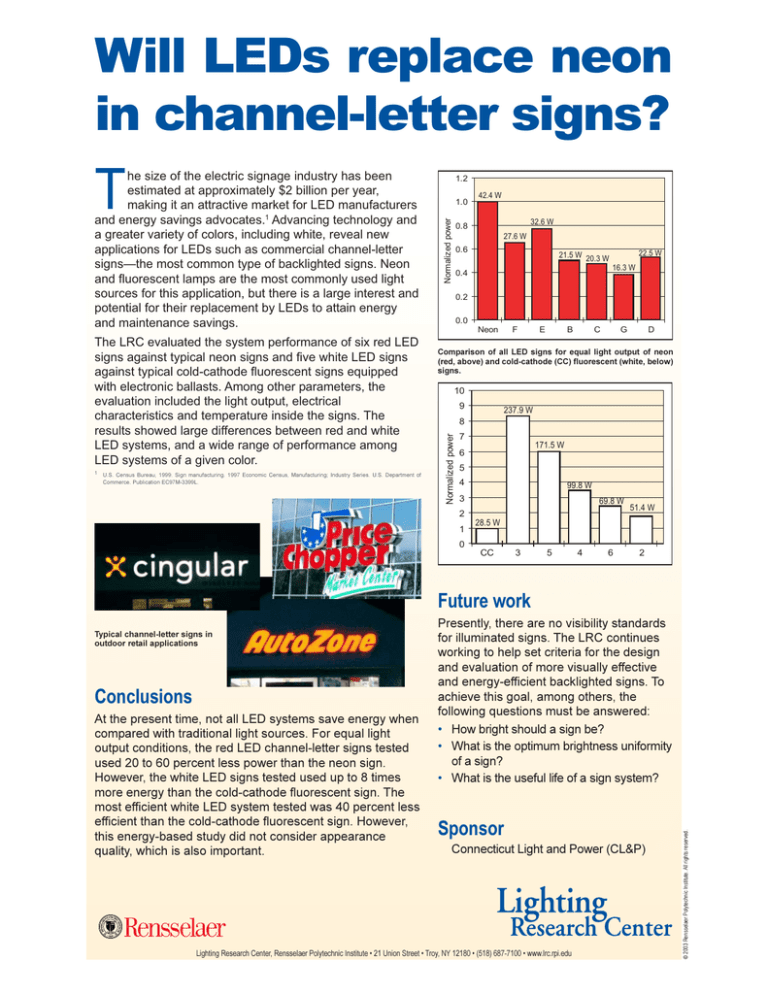

1.2

Normalized power

1.0

42.4 W

32.6 W

0.8

27.6 W

0.6

21.5 W 20.3 W

0.4

22.5 W

16.3 W

0.2

0.0

Neon

F

E

B

C

G

D

Comparison of all LED signs for equal light output of neon

(red, above) and cold-cathode (CC) fluorescent (white, below)

signs.

10

9

237.9 W

8

Normalized power

T

he size of the electric signage industry has been

estimated at approximately $2 billion per year,

making it an attractive market for LED manufacturers

and energy savings advocates.1 Advancing technology and

a greater variety of colors, including white, reveal new

applications for LEDs such as commercial channel-letter

signs—the most common type of backlighted signs. Neon

and fluorescent lamps are the most commonly used light

sources for this application, but there is a large interest and

potential for their replacement by LEDs to attain energy

and maintenance savings.

7

171.5 W

6

5

4

99.8 W

3

2

1

0

69.8 W

51.4 W

28.5 W

CC

3

5

4

6

2

Future work

Conclusions

At the present time, not all LED systems save energy when

compared with traditional light sources. For equal light

output conditions, the red LED channel-letter signs tested

used 20 to 60 percent less power than the neon sign.

However, the white LED signs tested used up to 8 times

more energy than the cold-cathode fluorescent sign. The

most efficient white LED system tested was 40 percent less

efficient than the cold-cathode fluorescent sign. However,

this energy-based study did not consider appearance

quality, which is also important.

Presently, there are no visibility standards

for illuminated signs. The LRC continues

working to help set criteria for the design

and evaluation of more visually effective

and energy-efficient backlighted signs. To

achieve this goal, among others, the

following questions must be answered:

• How bright should a sign be?

• What is the optimum brightness uniformity

of a sign?

• What is the useful life of a sign system?

Sponsor

Connecticut Light and Power (CL&P)

Lighting Research Center, Rensselaer Polytechnic Institute • 21 Union Street • Troy, NY 12180 • (518) 687-7100 • www.lrc.rpi.edu

© 2003 Rensselaer Polytechnic Institute. All rights reserved.

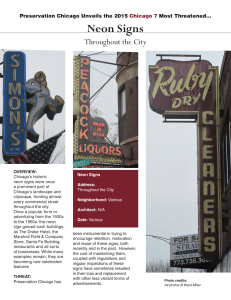

Typical channel-letter signs in

outdoor retail applications