SHC Annual report 2015

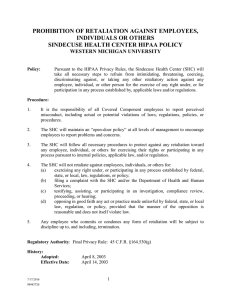

advertisement