Optimal Enclosure Doors - Design and Evaluation

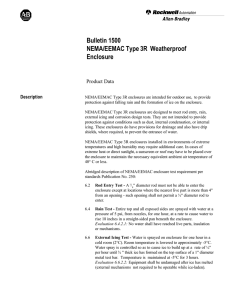

advertisement