Gasket Material Lid Fixing Enclosure Mounting Equipment

advertisement

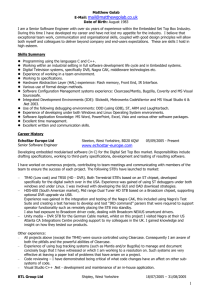

Crouse-Hinds are premier manufactures of high quality and robust enclosure / termination assemblies configured to meet the requirements of the most demanding hazardous area environment applications. With over 30 years of experience in the design, engineering and manufacture of enclosures and termination assemblies, Crouse-Hinds provides a proven, tried and tested solution to meet the toughest project and installation needs. The STB range is an “ATEX certified” enclosure / termination solution available in various options of materials and finishes fully compliant with the impact, thermal and ingress requirements of EN50014, and is available in a comprehensive range of 12 different sizes. Each with the for many configuration possibilities for a multitude of applications. Using the highest quality materials, unique design benefits and precision manufacturing the STB range is the benchmark in heavyduty gauge enclosures of its class. Material / Finish Options 316L Stainless Steel (1.4404 to EN 10088)1.5mm / 2.0mm. - electro chemically polished. 400 Series Stainless Steel (1.4003 to EN 10088) – Polyester powder coated to RAL 7015. Sheet Steel - Polyester powder coated to RAL 7032. Gasket Material High integrity “one piece” closed cell chloroprene. Silicone gasket used for STB 163812 & 254013 Silicone Lid Fixing 4 x M6 slotted hex head captive screws. Enclosure Mounting STB 121208 - 252512 = 2 x external welded lugs x 8mm Ø holes. STB 163812 - 354030 = 4 x external welded lugs x 8mm Ø holes. Equipment Mountings Internally welded TAS 20 rail on which terminal rail may be fitted. Enclosure Entries Optional to meet clients requirements. (See reverse for full details) Enclosure Earthing M6 internal / external earth stud assembly. Ingress protection IP66 to EN 60529 Operating Temp Range Chloroprene gasket -30°C to +95°C, Optional Silicon gasket -65°C to +135°C. Ambient Temp Range Chloroprene gasket -30°C to +40°C for T6 & -30°C to +55°C for T5. Silicon gasket -30°C to +40°C for T6 & -65°C to +55°C for T5. Impact Resistance 7 J (Nm) to EN 50014. Certification ATEX ll 2GD EEx e II T6 or T5. cULus to UL50 / C22.2, no. 94-M91 types 3S, 4, 4X. Germanischer Lloyd (GL). GOST Approval. Applications ATEX Category 2 (Zone 1), UL 50 Type 4x & Industrial IP66. Enclosure / terminal assemblies configured to meet clients specification within certification parameters Refer to our website: www.enclosures-crouse-hinds.uk.com for further company & product information. STB DATASHEET 0804 REV 0804 STB ENCLOSURE TECHNICAL DATA ENCLOSURE DIMENTIONS (HEIGHT X WIDTH X DEPTH) 120 x 120 x 80 150 x 120 x 80 150 x 150 x 90 190 x 150 x 90 190 x 190 x 100 250 x 250 x 120 160 x 380 x 120 250 x 400 x 130 380 x 380 x 220 380 x 380 x 220 400 x 600 x 220 400 x 600 x 220 600 x 400 x 220 600 x 400 x 220 145 175 175 175 215 275 405 X 80 425 X 150 435 X 250 435 X 250 264 X 656 264 X 656 464 X 456 464 X 456 WEIDMULLER CROSS REFERENCE STB 1 STB 1-1 STB 2 STB 2-1 STB 3 STB 4 STB 5 STB 6 STB 7 STB 7 STB 8 STB 8 STB 9 STB 9 0, 1 or 3 Gland Plated Version 0 GP 0 GP 0 GP 0 GP 0 GP 0 GP 0 GP 0 GP 0 GP 3 GP 0 GP 3 GP 0 GP 3 GP 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.4 1.6 1.9 2.3 3.0 3.7 3.7 5.4 8.5 11.8 13.0 16.5 13.0 16.5 ENCLOSURE FIXING CENTRES HORIZONAL X VERTICAL IN MM. MATERIAL THICKNESS BODY LID WEIGHT KG. (EMPTY ENCLOSURE) TERMINAL MOUNTING RAIL RAIL FIXING CENTRES VERT 62 90 90 130 130 180 300 180 280 280 300 300 500 500 OVERALL RAIL LENGTH VERT 82 110 110 150 150 200 320 200 300 300 320 320 520 520 114 x 63 114 x 63 70 x 63 114 x 63 144 x 63 100 x 63 144 x 73 144 x 73 100 x 73 144 x 73 184 x 73 130 x 73 184 x 83 184 x 83 140 x 83 244 x 103 244 x 103 200 x 103 372 x 103 154 x 103 330 x 103 394 x 113 244 x 113 350 x 113 374 x 203 374 x 203 324 x 203 337 x 124 337 x 124 261 x 124 594 x 203 394 x 203 344 x 203 504 x 124 337 x 124 304 x 124 394 x 203 594 x 203 544 x 203 337 x 124 337 x 124 337 x 124 TOP & BOTTOM M16 M20 M25 M32 M40 M50 M63 14 3 2 2 0 0 0 14 3 2 2 0 0 0 18 7 3 2 2 0 0 18 7 3 2 2 0 0 30 9 7 3 2 2 0 53 18 10 8 3 3 2 80 30 16 12 5 4 4 85 32 17 13 6 5 4 165 60 40 24 15 8 7 87 27 23 11 9 4 3 265 96 68 42 26 14 11 132 41 35 17 14 6 5 170 63 43 26 17 9 7 87 27 23 11 9 4 3 LEFT M16 M20 M25 M32 M40 M50 M63 14 3 2 2 0 0 0 14 3 2 2 0 0 0 18 7 3 2 2 0 0 23 9 4 3 2 0 0 30 9 7 3 2 2 0 53 18 10 8 3 3 2 33 11 6 4 2 2 1 53 18 10 8 3 3 2 165 60 40 24 15 8 7 87 27 23 11 9 4 3 170 63 43 26 17 9 7 87 27 23 11 9 4 3 265 96 68 42 26 14 11 87 27 23 11 9 4 3 RIGHT M16 M20 M25 M32 M40 M50 M63 8 2 1 1 0 0 0 12 2 2 1 0 0 0 12 4 2 1 1 0 0 15 6 3 2 2 0 0 22 7 5 2 2 1 0 43 15 8 6 3 2 2 73 26 14 11 5 4 3 75 29 15 11 5 4 3 140 51 35 22 14 7 5 66 20 17 8 7 3 2 150 54 38 22 14 8 6 78 24 20 10 8 4 3 240 90 60 38 24 13 10 87 27 23 11 9 4 3 AVAILABLE GLANDING AREA TOP & BOTTOM LEFT RIGHT MAXIMUM NUMBER OF ENTRIES TERMINAL CONTENT Terminal Type (thickness) Terminal Rail Orientation 2.5mm sq. (6mm wide) VERT 1x8 1 x 13 1 x 13 1 x 21 1 x 21 2 x 31 1 x 55 2 x 31 3 x 42 3 x 42 3 x 46 3 x 46 5 x 79 5 x 79 4mm sq. (6.5mm wide) VERT 1x6 1 x 11 1 x 11 1 x 18 1 x 18 2 x 36 1 x 46 2 x 36 3 x 39 3 x 39 3 x 424 3 x 424 5 x 73 5 x 73 6mm sq. (8mm wide) VERT 1x5 1x8 1x8 1 x 13 1 x 13 2 x 19 1 x 34 2 x 19 3 x 32 3 x 32 3 x 34 3 x 34 5 x 59 5 x 59 10mm sq. (10mm wide) VERT 1x4 1x7 1x7 1 x 10 1 x 10 2 x 15 1 x 28 2 x 15 3 x 25 3 x 25 3 x 27 3 x 27 5 x 47 5 x 47 Based on the physical constraints of the enclosure. Refer to the certificate rating tables for hazardous area applications