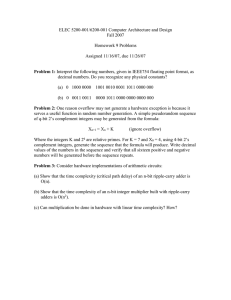

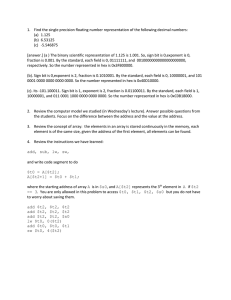

Manufacturing Tolerance Cost Minimization Using Discrete

advertisement