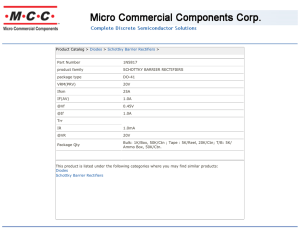

MCC - Farnell

advertisement

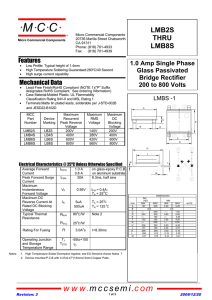

MCC TM Micro Commercial Components Features x x x x • Glass Passivated Diode Construction High Surge Overload Rating:35A peak Saves Space on Printed Circuit Board High Temperature Soldering Guaranteed: 260к/10 Second UL Recognized File # E165989 Mechanical Data x Case Material: Molded Plastic. Classification Rating 94V-0 x Terminals: Plated Leads Solderable per MIL-STD-750, Method 2026 Moisture Sensitivity: Level 3 per J-STD-020C x MCC Part Number Device Marking MB05S MB1S MB2S MB4S MB6S MB8S MB10S MB05S MB1S MB2S MB4S MB6S MB8S MB10S Maximum RMS Voltage Maximum Recurrent Peak Reverse Voltage 50V 100V 200V 400V 600V 800V 1000V Typical Junction Capacitance Rating For Fusing Operating Junction and Storage Temperature Range (1) (2) IF(AV) IFSM 35V 70V 140V 280V 420V 480V 700V MBS -1 Maximum DC Blocking Voltage 50V 100V 200V 400V 600V 800V 1000V 0.5 A(1) 0.8 A(2) 35A See Fig.1 IFM = 0.4A; TA = 25OC IR 5PA 100PA TA = 25к TA = 125к RTJA RTJA RTJL CJ 85к/W(1) 70к/W(2) 20к/W(1) 13pF It TJ TSTG 5.0A s -55to+150 к D B E ∼ + F C A Notch in case K M J G H N 8.3ms, half sine 1.0V 2 ∼ L VF 2 0.5 Amp Single Phase Glass Passivated Bridge Rectifier 50 to 1000 Volts UL Flammability Electrical Characteristics @ 25OC Unless Otherwise Specified Average Forward Current Peak Forward Surge Current Maximum Instantaneous Forward Voltage Maximum DC Reverse Current At Rated DC Blocking Voltage Typical Thermal Resistance MB05S THRU MB10S omponents 20736 Marilla Street Chatsworth !"# $ % !"# per leg Measured at 1.0MHz, VR=4.0V t<8.30ms On glass epoxy P.C.B. mounted on 0.05 x 0.05”(1.3 x 1.3mm)pads On aluminum substrate P.C.B. with an area of 0.8” x 0.8”(20 x 20mm) mounted on 0.05 x 0.05”(1.3x 1.3mm) solder pad C D L M N .252 .144 .179 .017 .090 .004 .019 .058 .195 .110 .039 .006 .272 .161 .195 .029 .106 .008 .038 .062 .205 .114 .049 .016 6.40 3.65 4.55 0.43 2.30 0.10 0.48 1.47 4.95 2.80 0.99 0.15 6.90 4.10 4.95 0.74 2.70 0.20 0.96 1.57 5.21 2.90 1.24 0.41 Mounting Pad Layout 0.023 MIN. (0.58 MIN.) 0.272 MAX. (6.91 MAX.) 0.030 MIN. (0.76 MIN.) 0.105 (2.67) 0.095 (2.41) Revision: 8 www.mccsemi.com 1 of 3 2006/10/06 MCC MB05S thru MB10S TM Micro Commercial Components Figure 2 Typical Reverse Characteristics Figure 1. Derating Curve for Output Rectified Current 100 60 Average Forward Rectified Current (A) 0.8 Aluminum Substrate 40 0.7 0.6 20 0.5 10 Glass Epoxy P.C.B. 0.4 0.3 6 4 0.2 2 Resistive or Inductive Load 0.1 µAmps 1 0 0 20 40 60 100 80 120 140 .6 160 Ambient Temperature (°C) .4 .2 TA=25°C .1 .06 Figure 3 Typical Forward Characteristics .04 20 .02 10 .01 20 40 60 6 80 100 120 140 Volts% Instantaneous Reverse Leakage Current - MicroAmperesversus Percent Of Rated Peak Reverse Voltage - Volts% 4 2 25°C Amps Figure 5 Peak Forward Surge Current 1 60 .6 50 .4 40 .2 30 .1 Amps .06 .04 20 10 .02 0 .01 .4 .6 .8 1.0 1.2 1 2 4 6 1.4 8 10 20 40 60 80 100 Cycles Volts Peak Forward Surge Current - Amperes versus Number Of Cycles At 50Hz - Cycles Instantaneous Forward Current - Amperesversus Instantaneous Forward Voltage - Volts www.mccsemi.com Revision: 8 2 of 3 2006/10/06 MCC TM Micro Commercial Components ***IMPORTANT NOTICE*** Micro Commercial Components Corp . reserves the right to make changes without further notice to any product herein to make corrections, modifications , enhancements , improvements , or other changes . Micro Commercial Components Corp . does not assume any liability arising out of the application or use of any product described herein; neither does it convey any license under its patent rights ,nor the rights of others . The user of products in such applications shall assume all risks of such use and will agree to hold Micro Commercial Components Corp . and all the companies whose products are represented on our website, harmless against all damages. ***APPLICATIONS DISCLAIMER*** Products offer by Micro Commercial Components Corp . are not intended for use in Medical, Aerospace or Military Applications. www.mccsemi.com Revision: 8 3 of 3 2006/10/06