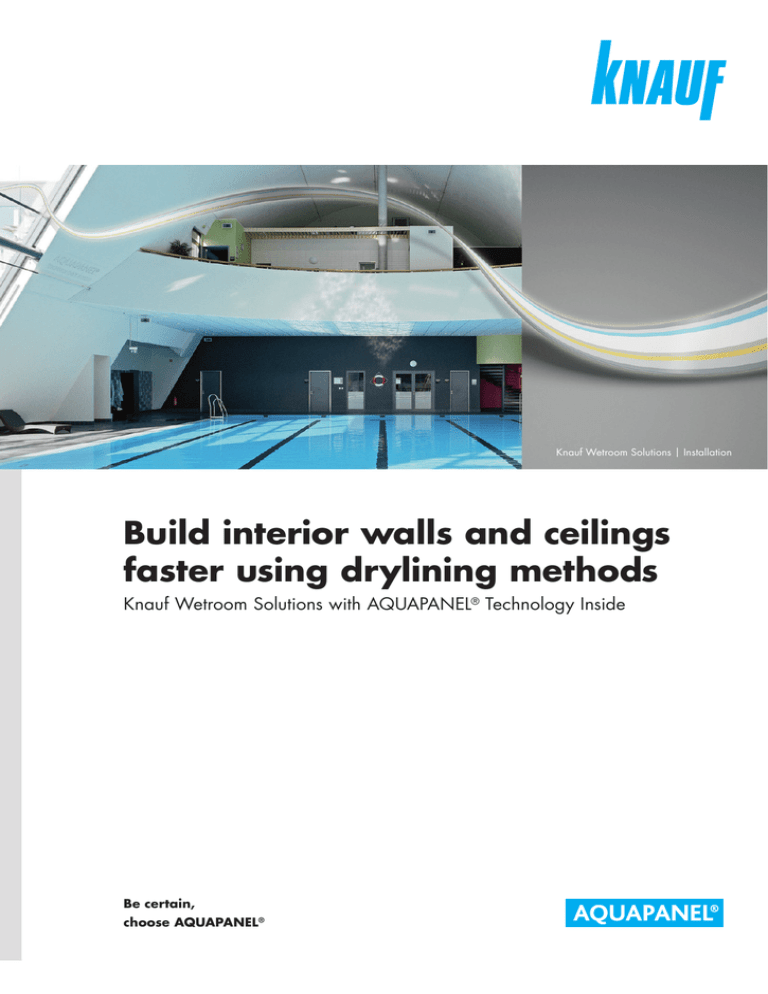

Knauf Wetroom Solutions | Installation

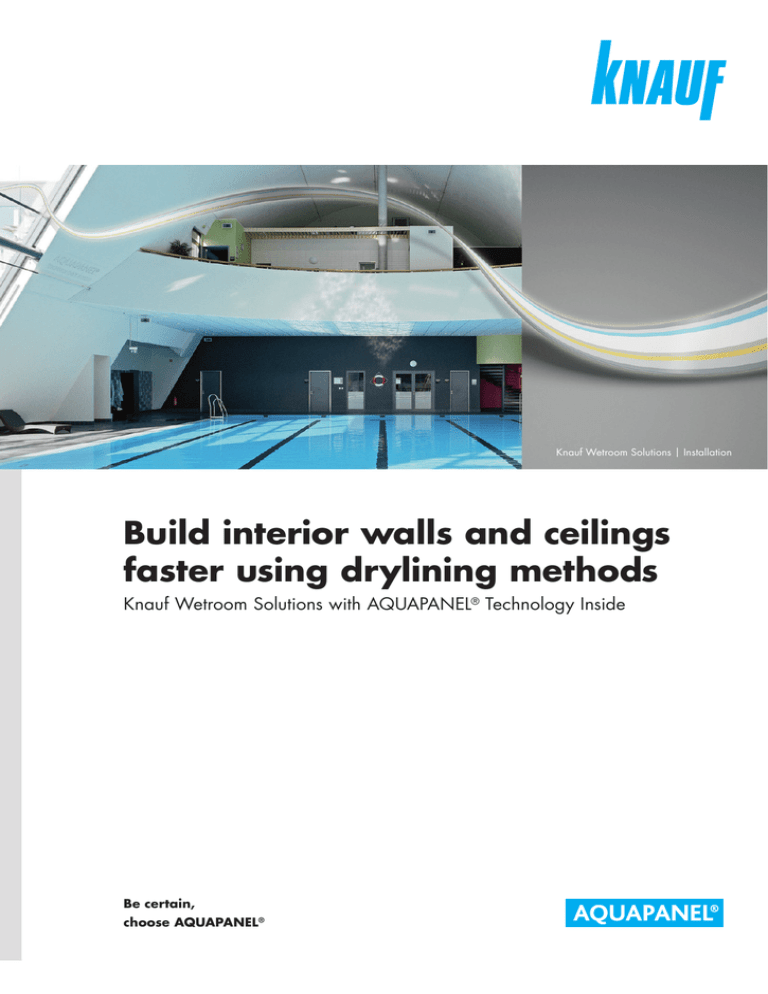

Build interior walls and ceilings

faster using drylining methods

Knauf Wetroom Solutions with AQUAPANEL® Technology Inside

Be certain,

choose AQUAPANEL®

Knauf Wetroom Solutions with

AQUAPANEL® Technology Inside:

improved performance with lower

costs and installation time

Knauf Wetroom Solutions with AQUAPANEL® Technology

and mildew. Knauf Wetroom Solutions enable installers to

Inside are the more economical, sustainable and high-

avoid the time-consuming methods necessary with brick and

performing solution to tile backing in wet or damp areas.

mortar; and they can do it with greater flexibility and the

ability to contend with specific needs such as extra moisture

Constructed from aggregated Portland cement with coated

protection or sound insulation.

glass fibre mesh embedded surfaces, these unique cement

boards are 100% water-resistant and resistant to mould

www.AQUAPANEL.com

coNtENtS

Product range __________________________________ 4

g i v E S PA c E

Processing/handling ____________________________ 22

Installation of Knauf Wetroom Solutions with

Give space to more room with Knauf wetroom solutions. it’s an

AQUAPANEL® Technology Inside _________________ 23

invitation to raise the roof of possibility with a wall system that gives

space to new ways of thinking and smarter ways of building.

Surface finishing _______________________________ 25

Be limited only by your ambition, not the materials you use.

Installation details ______________________________ 34

Ceiling installation _____________________________ 36

Tool recommendations __________________________ 43

Knauf Wetroom Solutions | Systems

A better way to build

interior walls and ceilings

in wet and humid areas

Knauf Wetroom Solutions | Techniques

Technical solutions for

interior walls and ceilings

Knauf Wetroom Solutions with AQUAPANEL® Technology Inside

Reference of additional documentation ____________ 45

Knauf Wetroom Solutions with AQUAPANEL® Technology Inside

Be certain,

Be certain,

choose AQUAPANEL®

choose AQUAPANEL®

See additional documentation for more detailed

information on Knauf Wetroom Solutions

2 _3

Product range

Interior walls/ceilings

Lining

AQUAPANEL® cement Board indoor

Aggregated Portland cement

board with coated glass fibre

mesh embedded in back and front

surfaces. The ends are square cut

and the edges reinforced and

finished smoothly (EasyEdge™).

Thickness: 12.5 mm

Width: 900 mm

Length: 1200, 2400, 1250,

2500 mm

Weight: approx. 15 kg/m2

Packaging:

1200/1250 mm length:

50 pieces/pallet

2400/2500 mm length:

25 pieces/pallet

Building material category: A1

interior and exterior applications.

Screws have a special corrosionproof coating, which gives a

guaranteed 720 hours corrosion

resistance in a salt spray test.

Packaging:

SN 39: 500 pieces/carton

SN 25: 1000 pieces/carton

SN 55: 250 pieces/carton

SB 39: 250 pieces/carton

SB 25: 250 pieces/carton

Fastening

AQUAPANEL® maxi Screws

AQUAPANEL® Maxi Screws

have been specially developed

for fixing AQUAPANEL® Cement

Board Indoor onto frameworks

of differing thicknesses.

Both needlepoint and drill point

versions with countersunk are

available. AQUAPANEL® Maxi

Screws can be used for both wall

and ceiling applications in

Collated screws available

on request.

Metal framework

Timber framework

Metal thickness 0.6 – 0.7 mm

Single layer

AQUAPANEL Maxi Screw SN 25

✓

AQUAPANEL® Maxi Screw SN 39

✓

®

AQUAPANEL Maxi Screw SN 55

®

Double layer

Metal thickness 0.8 – 2.0 mm

Triple layer

Single layer

✓

Single layer

Double layer

✓

✓

✓

AQUAPANEL Maxi Screw SB 25

✓

AQUAPANEL® Maxi Screw SB 39

✓

®

Double layer

✓

Approved accessories: Walls

AQUAPANEL® Joint Adhesive (PU)

AQUAPANEL® Joint Adhesive

(PU) is used to bond individual

AQUAPANEL® Cement Board

Indoor panels.

Coverage: approx. 50 ml/m2

(approx. 6.5 m2 per cartridge)

Packaging:

310 ml/cartridge

20 cartridges/carton

AQUAPANEL® Board Primer

AQUAPANEL® Board Primer is a

ready-to-use synthetic dispersion

for priming AQUAPANEL®

Cement Board Indoor panels to

provide maximum adhesion of

tiles and plasters.

Coverage: approx. 40 - 60 g/m2

Dilution: 1: 2 with water

Packaging:

15 l/bucket

2.5 l/bucket

AQUAPANEL® Q4 Finish is a

ready-to-use and water-repellent

skim coat for high-quality finely

finished surfaces up to Q4

standard.

Application: Above the tiled

area or as an all-over skim

coating over AQUAPANEL®

Joint Filler & Skim Coating

– white & AQUAPANEL®

Interior Reinforcing Mesh.

Coverage: approx.

1.7 kg/m2/mm coating depth

Packaging: 20 kg/bucket

Coverage: approx. 3.5 kg/m2

Note: Machine processing is

possible with PFT RiTMO (230V)

(A3-2L pump unit, SWiNG

sprayer, LK 402 air compressor)

AQUAPANEL® Q4 Finish

Note: For joint reinforcement, use

Knauf glass fibre cover strips.

AQUAPANEL® Joint Filler & Skim Coating – white

AQUAPANEL® Joint Filler & Skim

Coating – white is a cementbound material for skim coating

AQUAPANEL® Cement Board

Minimum layer thickness 4 mm

Packaging: 10 kg/bag

Indoor beyond the tiled area.

AQUAPANEL® Reinforcing Mesh

must be embedded.

4 _ 5

Product range

Interior walls/ceilings

AQUAPANEL® Reinforcing Mesh

AQUAPANEL® Reinforcing Mesh

is a glass fibre fabric used to

reinforce AQUAPANEL® Joint

Filler & Skim Coating – white.

Coverage: approx. 1.1 m2/m2

Packaging:

100 cm wide roll, 50 m long

30 rolls/carton

Additional accessories

AQUAPANEL® Traverse

AQUAPANEL® Traverses are

used for attaching light console

loads to walls constructed from

AQUAPANEL® Cement Board

Indoor.

Axis frame dimensions:

600/625 mm

Height: approx. 290 mm

Plate thickness:

0.75 mm with special

corrosion protection layer

M type: Without impregnated

wood packing

MH type: With core-impregnated

MDF filler, approx. 18 mm thick

Sizes: 300 x 300 mm

400 x 400 mm, 500 x 500 mm

Please indicate application

details when ordering.

AQUAPANEL® Access Doors

AQUAPANEL® Access Doors

can be installed in partition

and plumbing walls as well as

in ceilings.

Type 1:

AQUAPANEL® Access Door

Splash Water Protection

Type 2:

AQUAPANEL® Access Door

Humid Rooms

Other sizes (e.g. tile dimension)

available on request.

Approved accessories: Ceilings

AQUAPANEL® Tape

AQUAPANEL® Tape is a glass

fibre tape with an alkali-resistant

coating. AQUAPANEL® Interior

Tape is used to reinforce joints

in interior ceiling applications.

It is embedded into the

AQUAPANEL® Joint Filler

– grey or AQUAPANEL® Joint

Filler & Skim Coating – white.

Coverage: approx. 2.1 m/m2

Packaging:

10 cm wide roll, 50 cm long

20 rolls/carton

AQUAPANEL® Joint Filler – grey

AQUAPANEL® Joint Filler – grey

is a cement-bound filling material

for setting AQUAPANEL® Tape

for ceiling applications.

Coverage: approx. 0.7 kg/m2

Packaging: 10 kg/bag

AQUAPANEL® Board Primer

AQUAPANEL® Board Primer is a

ready-to-use synthetic dispersion

for priming AQUAPANEL®

Cement Board Indoor panels to

provide maximum adhesion of

tiles and plasters.

Coverage: approx. 40 - 60 g/m2

Dilution: 1: 2 with water

Packaging:

15 l/bucket

2.5 l/bucket

6 _ 7

Product range

Interior ceilings

AQUAPANEL® Joint Filler & Skim Coating – white

AQUAPANEL® Joint Filler &

Skim Coating – white is a

cement-bound material for skim

coating AQUAPANEL® Cement

Board Indoor beyond the tiled

area. AQUAPANEL® Reinforcing

Mesh must be embedded.

Coverage: approx. 3.5 kg/m2

Minimum layer thickness 4 mm

Packaging: 10 kg/bag

Note: Machine processing is

possible with PFT RiTMO (230V)

(A3-2L pump unit, SWiNG

sprayer, LK 402 air compressor)

AQUAPANEL® Reinforcing Mesh

AQUAPANEL® Reinforcing Mesh

is a glass fibre fabric used to

reinforce AQUAPANEL® Joint

Filler & Skim Coating – white.

Coverage: approx. 1.1 m2/m2

Packaging:

100 cm wide roll, 50 m long

30 rolls/carton

AQUAPANEL® Q4 Finish is a

ready-to-use and water-repellent

skim coat for high-quality finely

finished surfaces up to Q4

standard.

Ceiling use: Only use as all-over

white skim coat on top of

AQUAPANEL® Joint Filler &

Skim Coating – white and

AQUAPANEL® Reinforcing Mesh.

AQUAPANEL® Q4 Finish

Glass fibre joint covering strip

GLASS FIBRE JOINT COVERING

STRIPS are used to reinforce

interior joints and to avoid

cracks. It can be embedded

in gypsum fillers and

AQUAPANEL® Q4 Finish.

Width: 50 mm

Length: 25 m/roll

Packaging: 40 rolls/carton

Coverage: approx.

1.7 kg/m2/mm coating depth

Packaging: 20 kg/bucket

Product range

Interior walls + Interior ceilings

Air-tightness accessories

LDS 100 (vapour barrier)

Vapour control layer made

from polypropylene special foil,

LDS 100 is resistant to aging

(sd-value ≥ 100m). Conforms to

EN 13859 and ETAG 007.

Width: 2 m or 4 m

Length: 50 m or 25 m

10 m2/roll

Packaging: 46 or 100 rolls/pallet

LDS 2 Silk (vapour barrier)

Vapour control layer made from

polypropylene spunbonded

fabric, LDS 2 Silk is resistant to

aging and is resistant to tearing

(sd-value ≥ 2m). Conforms to

conforms to EN 13984 and

ETAG 007.

Width: 1.50 m or 2 m

Length: 50 m

m2/roll: 75 m2 or 100 m2

Packaging: 20 rolls/pallet

Self-adhesive sealant tape

which is paper-based. For use

in interior applications to bond

overlapping layers.

Width: 60 mm

Length: 40 m

Thickness: 0.35 mm

Packaging: 8 rolls/carton

Self-adhesive sealant tape which

is reinforced polyethylene-based

with either full surface or halfsurface covering paper. For

exterior applications where it

is used as an elastic sealant for

corners, windows and openings.

Width: 60 mm

Length: 25 m

Thickness: 0.28 mm

Packaging: 10 rolls/carton

LDS Soliplan

LDS Solifit/ LDS Solitwin

8 _ 9

Product range

Interior walls + Interior ceilings

Lining with Gypsum Board

Gypsum Board

The ideal standard interior lining

for Interior Walls. It offers an

economic building solution and is

ideal for all types of living spaces

without additional requirements.

Width: 1250 mm

Length: 2000/2500/

2600/2750/3000 mm

Thickness: 12.5 mm

Weight: 9.2 kg/m2

Number of boards: 50

Net weight per pallet:

min. 1150/max. 1725 kg

The ideal interior lining for

Knauf Wetroom Solutions where

a robust solution is required.

Especially suited to shaft wall

construction.

Width: 625 mm

Length: 2000/2500/

2600 mm

Thickness: 25 mm

Weight: 21 kg/m2

Number of boards: 20

Net weight per pallet:

min. 525/max. 682.5 kg

Massivbauplatte

Impregnated Gypsum Board

The ideal interior lining for

Knauf Wetroom Solutions for

damp rooms in living areas

where there is occasional

exposure to water spray. Boards

remain impervious to moisture

and create an even surface for

untiled areas. They are ideal for

painting or for further surface

finishing (with appropriate sealing

for gaps, edges and surfaces).

The ideal interior lining for Knauf

Wetroom Solutions where higher

mechanical surface resistance is

required. This higher density

impregnated fire-rated board also

achieves a higher sound

insulation than standard boards

with the same system build-up.

Width: 1250 mm

Length: 2000/2500 mm

Thickness: 12.5 mm

Weight: 13.5 kg/m2

Width: 1250 mm

Length: 2000/2500/

2600/3000 mm

Thickness: 12.5 mm

Weight: 10.2 kg/m2

Number of boards: 50

Net weight per pallet:

min. 1275/max. 1912.5 kg

Diamant

Number of boards: 40

Net weight per pallet:

min. 1350/max. 1687.5 kg

10 _ 11

Product range

Interior walls + Interior ceilings

Vidiwall Gypsum Fibre Board

The ideal interior lining for Knauf

Wetroom Solutions where higher

mechanical surface resistance is

required. (Performance is

comparable to Diamant Hard

Gypsum Board, however, board

is not impregnated.)

Width: 1250 mm

Length: 2000/2540/

2570/3000 mm

Thickness: 12.5 mm

Weight: 14.8 kg/m2

Number of boards: 40

Net weight per pallet:

min. 1480/max. 2220 kg

The ideal interior lining for Knauf

Knauf Wetroom Solutions where

high fire protection requirements

are critical. This special board

with glass fleece coating is used

for fire-rated linings. In general,

the planking thickness is lower

compared with standard

carton-coated Gypsum Board. An

impregnated version is available:

Impregnated Fireboard.

The ideal interior lining for

Knauf Wetroom Solutions where

high sound reduction is key.

Heavier than Diamant Hard

Gypsum Board.

Width: 625 mm

Length: 2000/2500 mm

Thickness: 12.5 mm

Weight: 17.5 kg/m2

Number of boards: 42

Net weight per pallet:

min. 918.75/max. 1148.44 kg

Fireboard

Silentboard

Width: 1250 mm

Length: 2000 mm

Thickness: 12.5 mm

Weight: 10.7 kg/m2

Number of boards: 50

Net weight per pallet:

min. 1337.5 kg

Product range

Fastening of Gypsum Board

Drywall Screw

High quality screws for dry lining

with Gypsum Boards on metal

frameworks (metal thicknesses up

to 0.7 mm). For single/double/

triple layer (depending on

length). Suitable for fire-resistant

and sound insulating walls.

Length: 25/35/45/55 mm

Screw head diameter:

3.5 mm

Packaging:

TN 3.5 x 25, 250 pieces/carton

TN 3.5 x 25, 1000 pieces/carton

TN 3.5 x 35, 250 pieces/carton

TN 3.5 x 35, 1000 pieces/carton

TN 3.5 x 45, 250 pieces/carton

TN 3.5 x 45, 1000 pieces/carton

TN 3.5 x 55, 1000 pieces/carton

Joint compounds and plasters for Gypsum Board

Uniflott

Uniflott is the standard gypsum

compound that is used for filling

joints of drywall systems and is

applied by hand. This special

gypsum-based, synthetictempered, powdery material

contains mineral filler and

additives for easy application.

It is used for filling of Gypsum

or Composite Boards with HRK

(half-rounded edge) or HRAK (halfrounded tapered edge) without

joint tape (except cut edge).

Packaging:

25 kg/bag

42 bags/pallet

Trias is a gypsum compound

that is used for filling joints of

drywall systems and is applied

by hand. It is adjusted to the

colour of the Gypsum Boards

and has a reduced absorption

after hardening. TRIAS shows

extremely low shrinkage when

drying. This special gypsum-

based, synthetic-tempered,

powdery material contains

additives for easy application.

It is used for hand filling of

Gypsum Boards or Composite

Boards with HRK (half-rounded

edge) or HRAK (half-rounded

tapered edge) without joint tape

on paper covered edges.

Packaging:

25 kg bag

42 bags/pallet

This gypsum-based powdery

material is used for filling joints

of drywall systems and is applied

by hand. It contains suspending

agents and mineral fillers for

application range. It is used for

hand filling of Knauf Boards with

joint tape on paper covered

edges, preferably Joint Tape Kurt.

Packaging:

25 kg bag

40 bags/pallet

Trias

Fugenfüller leicht

12 _ 13

Product range

Readygips

Readygips consists of synthetic

dispersion as binder and an

exactly set up combination of

particle-sized mineral calcium

sulphate extenders and

suspending agent. It is used for

indoor skimming of Gypsum

Boards. READYGIPS is very easy

to sand and produces a very

fine surface after drying. For

hand filling or machine filling in

combination with Joint Tape Kurt.

Packaging:

Pail:

20 kg pail

24 pails/pallet

Bag:

25 kg bag

12 bags/pallet

JOINTFILLER SUPER is used for

joint filling in combination with

Joint Tape KURT and for

full-surface skim coating also in

combination with UNIFLOTT. It

contains organic binders and a

balanced combination of

suspending agents and mineral

fillers and experiences very little

shrinkage when drying.

JOINTFILLER SUPER can be

applied by hand or by machine.

Packaging:

20 kg bag

42 bags/pallet

MULTI-FINISH is a synthetic

modified, gypsum-based filling

compound and thin plaster. It is

suitable for interior applications

such as efficient filling of uneven

and coarse surfaces, holes and

slots. MULTI-FINISH is particularly

suitable for the creation of

surfaces which comply with

surface quality level Q4. In

addition, MULTI-FINISH is

suitable for the creation of

premium interior coloured

decorative surface design.

PFT RITMO powercoat.

Easyputz decorative plaster is

a pure mineral plaster which can

be used to create a structural

finish for indoor rooms on top of

Gypsum Board. It is ready-made,

solvent-free, free of preservatives

and perfectly mixed for optimal

processing characteristics.

Easyputz is available with 0.5

mm and with 1 mm grain and

can be applied by pump or by

hand. Many colour variants are

possible as it can be pigmented

with COMPACT-COLOR.

JOINTFILLER SUPER

Multi-Finish/Multi-Finish M

Packaging:

25 kg bag

42 bags/pallet

MULTI-FINISH M is a machineapplied filling compound and

is exclusively applied using the

Easyputz

Packaging:

20 kg pail

24 pails/pallet

Joint Tape KURT

Joint Tape Kurt is a 50 mm wide

strip of special paper which is

used to reinforce the joint filling

and edges of Gypsum Boards

and Gypsum Fibre Boards.

Particulary resistant to tearing.

Width: 50 mm

Length: 25 m/roll, 75 m/roll

Flächendicht

FLÄCHENDICHT is a liquid

sealant comprising synthetic

latex and mineral fillers. As it

dries, it forms a waterproof,

elastic seam.

Flächendichtband

FLÄCHENDICHTBAND is a

12 cm-wide, stretchy polyester

fabric with an integrated

7 cm-wide, elastic, grained,

blue central strip providing a

waterproof coating.

14 _ 15

Product range

Interior walls + Interior ceilings

Priming of Gypsum Board

Tiefengrund

Tiefengrund is a smooth

water-based dispersion of

synthetic resins which is used to

improve adhesion of finishing

layers such as paint, plaster or

tile adhesive for tiling. It is the

standard primer for regular

absorbent substrates.

Packaging:

15 l pail

24 pails/pallet

Spezialgrund is a mineralfilled, white pigmented synthetic

dispersion which is used to

improve adhesion of finishing

layers such as paint, plaster or tile

adhesive for tiling. It is formulated

for smooth and porous surfaces

(i.e. non absorbent and strongly

absorbent substrates. When

smoothed, it creates a surface

finishing without visible pores.

Putzgrund is a synthetic resin

dispersion filled with fine quartz

sand, white pigmented and

alkali-resistant. It is used for

interior priming on Gypsum

Boards before plastering and

pre-treatment of absorbent and

non-absorbent substrates.

Packaging:

20 l pail

24 pails/pallet

Spezialgrund

Putzgrund

Packaging:

20 l pail

24 pails/pallet

Product range

Metal profiles – walls

Corrosion-resistant metal profiles and accessories

Knauf Wetroom Solutions with AQUAPANEL® Technology Inside are

constructed with a corrosion-resistant metal framework. Knauf offers

a full range of profiles and geometries to suit all applications. Knauf

metal profiles are precision-engineered, high-quality steel sections.

For standard applications, profiles from 0.6 mm to 1 mm

thickness are sufficient

Profiles of 1 mm or higher thickness should be used for

higher demands

C and CW profiles

For vertical placement between UW profile rails of substructures

for Knauf Wetroom Solutions

Corrosion-resistant

Can also be used for exterior constructions.

UW profiles

Horizontal profile rails for floor and ceiling to place C and CW

profiles of substructures for Knauf Wetroom Solutions

Corrosion-resistant

Can also be used for exterior constructions.

UA profiles and angle connections

Higher thickness profiles

For vertical placement between UW profile rails of substructures

for Knauf Wetroom Solutions

For higher statics and loading requirements

Corrosion-resistant

Can also be used for exterior constructions.

16 _ 17

Product range

Metal profiles – walls

Hat profiles

For direct application on existing surface

For renovation projects

For constructions with limited space requirements.

Illustrator grid gebruiken

1 omhoog = 2 naar rechts

Additional profiles

To reinforce corners

For curved wall applications;

for interior use.

Decoupling Tape

Self-adhesive tape for decoupling

UW and CW profiles that are

connected to other building

elements (walls, columns,

ceilings) so that sound and

thermal bridges can be reduced.

Thickness: 3.2 mm

Width: 30/50/70/95 cm

Roll length: 30 m

Product range

Metal profiles – ceilings

Profiles

CD

60/27

Ceiling substructure as support and basic profile

For interior and exterior ceilings

Corrosion resistant

Connected with cross connectors

UA profiles and angle connections

as base section

Suspensions

a. Nonious Stirrup

b. Nonious Hanger Bottom

c. Direct suspension (Direktabhänger)

a.

b.

c.

Connector

Cross connectors

For connection of basic and bearing profiles

18 _ 19

Product range

Insulation

Glass mineral wool

Knauf Insulation glass mineral wool with ECOSE® Technology meets

the highest demands for thermal and sound insulation in buildings.

Insulating materials are made from naturally occurring and / or

recycled materials and bound with ECOSE® Technology, a binding

agent, free of formaldehyde, phenol and acrylic. They are noncombustible, diffusion-open and resistant to aging. Thanks to their

compaction and low weight they are easy to lift and transport. Knauf

Insulation glass wool conforms to EN 13162 standard.

Knauf Insulation Partition Wall

Slab TP 115: MW EN 13162

T4-WS-WL(P)-AFr5

Knauf Insulation Partition Wall

Slab TW: MW EN 13162

T4-WS-WL(P)-AF10

Knauf Insulation Partition Wall

Roll TI 140 T: MW EN 13162

T2-AF5

Covered with black-coloured

glass mat on one side.

Covered with light-coloured

glass mat on one side.

Stone mineral wool

Knauf Insulation stone mineral wool insulation materials meet the

highest demands for thermal, sound and fire protection in buildings.

Insulating materials are non-combustible and resistant to deformation

and aging. Stone wool insulation materials are heavier than glass

wool insulation products due to the higher dry density. Knauf

Insulation mineral wool conforms to EN 13162 standard.

KD 035 Core insulating board:

MW EN 13162 T4-WL(P)

DPF 50 Fire insulating board:

MW EN 13162 T4-AF5

KP 035 Clamping board:

MW EN 13162 T4-AF5

FPL 035 Fire insulating board:

MW EN 13162 T4-AF5

Processing/handling

Transportation and storage

Boards

Profiles

Always carry the boards upright,

or use board rollers. Handle with

fork lift or crane as palletted

goods. Take care not to damage

corners and edges when setting

the boards down! Place boards

down on their long edge before

laying them flat.

Protect profiles from moisture

and weathering before they are

installed. Products should not be

left permanently exposed to the

elements.

Use a pallet to support the

boards when using mechanical

handling equipment. Ensure that

the base is strong enough to

support the boards.

Protect boards from moisture

and weathering before they are

installed. Boards which have

become damp must be dried on

both sides on a flat surface prior

to fitting.

Before installing, condition

the boards to the ambient

temperature and humidity. The

ambient air and component

temperatures may not be below

+5°C. Do not apply joint fillers,

basecoat or finishing materials

in temperatures less than +5°C.

insulation

Insulation materials are supplied

enclosed in polythene which is

designed for short term protection

only. For longer term protection

on site, the product should be

stored either indoors, or under

cover and off the ground.

Installation instructions are on

every pack. Products should not

be left permanently exposed to

the elements.

health and safety

Observe the recommendations regarding the handling and storage of

materials given earlier in this section. Consult the appropriate product

data sheets and material safety data sheets. In addition the following

notes are offered for guidance:

Avoid unnecessary dust on job site when using electrical saw.

Keep sanding and other dust generation to a minimum. Maintain

adequate ventilation and/or wear suitable protection.

Exercise care when using power tools and take all necessary

precautions.

Follow instructions on packaging when applying system accessories.

When using powdered products, mix with water in well-ventilated

conditions. Avoid contact with eyes and skin. In the event of contact

with the eyes, irrigate with plenty of clean water immediately.

When handling insulation or cutting boards which contain

glass-fibre, wear suitable protection including face mask and

gloves. Wear protective glasses when working overhead.

Follow national health and safety regulations at all times.

A full range of product and safety information sheets are available

upon request.

20 _ 21

Processing/handling

Formatting/cut-outs

Boards

Profiles

Mark the desired shape or

opening on the board with pencil

and ruler. Use a knife to score the

board on one side along the line

so that the mesh or thick paper is

cut. Snap the scored edge and cut

the mesh/paper on the rear side.

Cut profiles up to 0.7 mm

thickness using manual or

electrical scissors or use an

electrical circular saw with special

metal blade. When cutting

corrosion-resistant profiles, make

sure the cut edges are recoated

with appropriate material.

For sharp-edged cuts, for

example, exterior edges, use a

hand-held circular saw with a

dust extractor or a pendulum

jigsaw. Use of a carbide or

diamond-tipped saw blade is

recommended.

To make cut-outs for wiring and

pipes, use a jigsaw or keyhole

saw. The diameter of the opening

should be approximately 10 mm

greater than the diameter of the

pipe. The remaining gap can be

closed with a cuff, suitable

sealant or sealing strip.

Metal thicknesses bigger than

0.7 mm cannot be cut by scissors.

Electric separating tools need to

be used. The tool has to be

selected according to the coating

system. This is especially important

for lacquers and other organic

coatings, which are damaged by

the influence of temperature and

flying sparks. The use of a band

saw is highly recommended.

For special cut-outs e.g. for

pipes, services, only use special

pre-fabricated slots as available

in the profiles.

Insulation

Insulation materials are easy

to handle and install, being

lightweight and easily cut to

size, where necessary using an

appropriate knife on flat surface

to cut. To minimise thermal

bridges insulation should fill

the complete stud spaces. Do

not use small pieces.

installation of Knauf Wetroom Solutions with

AQUAPANEL® technology inside

Installation of Interior Walls

1. create substructure

1.1 AQUAPANEL® Cement

Board Indoor can be mounted

on a wall framework made from

either metal or wooden profiles.

1.2 The connection profile on

either side must be coated with

partition wall putty or sealing

tape. Rotary pin dowels or other

fasteners are used to secure the

profiles to the walls.

Screw spacing ≤ 250 mm.

Spacing from edge ≥ 15 mm.

Screws should not be

overtightened.

Note: Please observe a gap of

3 – 5 mm between the boards.

1.3 Mark out the path of the

AQUAPANEL® Cement Board

Indoor wall. All runners are

fastened to the floor and ceiling.

Profiles are cut to length and then

spaced 62.5 (60) cm apart. Set

and align these profiles with the

floor and ceiling profiles. Connect

the wall connection studs to the

end walls on either side.

2. Align the board

Align the first AQUAPANEL®

Cement Board Indoor panel

along the profiles. Ensure that

the board is aligned correctly

horizontally and vertically using

3. fastening with screws

Fasten AQUAPANEL Cement

Board Indoor to the framework

with AQUAPANEL® Maxi Screws.

First fasten the screws into the

centre of the cement boards; then

work towards the ends and the

edges. During installation, make

sure the cement boards are

resting on the framework.

®

≥15 mm

≤250 mm

4. clean the edge of the board

In order to ensure a good

connection with AQUAPANEL®

Joint Adhesive (PU), clean the

edges of the board using, for

example, a wet brush.

5. Apply the joint adhesive

5.1 Apply AQUAPANEL® Joint

Adhesive (PU).

22 _ 23

installation of Knauf Wetroom Solutions with

AQUAPANEL® technology inside

Installation of Interior Walls

This must be done before the

next board is placed.

5.2 Insert AQUAPANEL® Cement

Board Indoor into the bed of

adhesive. Screw panel to the

framework. Joint reinforcement of

AQUAPANEL® Cement Board

Indoor panel is achieved by

means of the adhesion technique.

There is no need for the timeconsuming process of filling and

inserting joint tape.

5.3 AQUAPANEL® Joint

Adhesive (PU) must be applied

as a continuous bead along the

edges of the boards. Before

applying the adhesive, ensure that

the edges are cleaned using, for

example, a wet brush. It takes

approximately 50ml/m2 (40ml/m).

The tube contains enough

adhesive for approximately 6,5 m2.

7. Scraping off

Leave the adhesive to harden after

which the excess AQUAPANEL®

Joint Adhesive (PU) can be

scraped off (usually the next day).

8. completed wall

The joints between the walls,

ceiling and floor require

permanent elastic sealing in

dry areas. Expansion joints

should be at a minimum of

7.5 (7.2) m intervals.

6. Place next board

Install the next AQUAPANEL®

Cement Board Indoor panel and

ensure that the boards are

correctly aligned horizontally

and vertically. Screw panel to

the framework.

9. Priming

AQUAPANEL® Cement Board

Indoor must be primed before

tiling or finishing using

AQUAPANEL® Board Primer.

Surface finishing

Tiling

Boards

Finishing

For ceramic tile coverings, (tile

dimensions ≤ 300 x 300 mm),

use a flexible adhesive when

placing tiles. The tile adhesive

must – as a minimum – meet the

requirements of class C2

according to EN 12004.

For a smooth finish, apply a thin

layer of AQUAPANEL® Joint

Filler & Skim Coating – white.

When dry, the surface can be

painted.

Note: Where single-layer

panels are required in tiling

applications, AQUAPANEL®

Cement Board Indoor is the

best tile backing board!

Finishing

Skim coating

AQUAPANEL® Cement Board

Indoor can be prepared for

painting by coating it fully with

AQUAPANEL® Joint Filler &

Skim Coating – white (minimum

coating depth 4 mm).

Reinforcing

Apply AQUAPANEL® Reinforcing

Mesh and embed it in the skim

coat with a trowel.

Painting

The majority of common

painting systems can be used.

These include water-based

emulsions, matt enamels,

polymer resin colours, and

epoxy-based enamels.

Alkyd enamels are not

compatible with the product.

For confirmation of usage,

please refer to the paint

manufacturers’ instructions.

A test coat is recommended.

For surface finishes up to Q4,

apply AQUAPANEL® Q4 Finish

over the entire pre-prepared

(filled and reinforced) surface.

After drying, do any re-finishing

with an electric orbital sander

(grade 120 or finer).

24 _ 25

Surface finishing

Coating above the tiled section up to Q4 quality

For fine finishing to a Q4 surface quality,

use AQUAPANEL® Q4 Finish ready-to-use skim coat.

Embedding glass fibre joint cover strips

Using a 15 cm wide stainless

steel finishing trowel, apply

AQUAPANEL® Q4 Finish to the

visible joints which have been

bonded with AQUAPANEL® Joint

Adhesive (PU). Embed the glass

fibre joint cover strips (e.g.

GLASS FIBRE JOINT COVER

STRIPS) into the centre of the

paste so that they overlap the

joints. Apply a thin layer of

AQUAPANEL® Q4 Finish to the

cover strips. Remove excess

material.

Note: AQUAPANEL® Cement

Board Indoor is already glued

using AQUAPANEL® Joint

Adhesive (PU).

Embed fastener heads

Fill all screw heads. If necessary,

after drying, use a hand sander

to remove irregularities from the

screw holes.

Smoothing over joints and fasteners

Sand away all surface

unevenness. Apply AQUAPANEL®

Q4 Finish to a width of at least 20

cm (5 cm beyond the edge of the

first layer). Embed fastener heads

and sand down any uneven areas.

full surface skim coating

Apply AQUAPANEL® Q4 Finish

to completely cover the untiled

areas using a 20 cm wide

finishing trowel. Apply the filler

solidly to fill in uneven areas in

the joints and smooth the surface

texture. If necessary, sand down

with paper. If a Q4 surface

quality is required, apply a

further layer of AQUAPANEL®

Q4 Finish. After approx. 24

hours drying, sand with abrasive

paper (grade 120 or finer). For

particularly smooth surfaces,

sand down with, for example,

an electric orbital sander.

Coating

Depending on the intended use

and requirements, water emulsion

paints, emulsion silicate paints or

latex paints can be used.

Note: The tiled section of the wall

should be > 50% of the total

height of the wall.

Not suitable for areas subject to

water spray!

Finishing options

General

Surface finishing and quality levels

Gypsum Boards can be used with every conceivable surface

finishing but the quality of the finishing depends on the decorative

finish required as part of the contract and the skills of the dryliner.

When closing the joints on the plaster boards, it is possible to

achieve four quality levels.

Level of finishing

Q1

Q2 (Standard)

Q3

Q4

Jointed surface

Smooth surface for normal optical

requirements

Smooth surface for higher visual

requirements

Smooth surface for high visual

requirements

Aesthetic requirements

None

Normal

Enhanced. Few marks and traces

under direct light. Shading is still

possible under shallow light angles

High end. Minimised appearance

of any marks or traces. Shading

caused by shallow light angles

will be avoided to a large extent.

Application requirements

Joints and screw heads filled with

joint compound

Joints and screw heads filled,

finished to achieve a continuous

transition to the board surface,

sanded if necessary

Joints and screw heads filled,

finished (Q2), plus wide finish

trowelling and a sharp trowelled

full cover of the plaster board surface

(filling the paper pores), sanded if

necessary.

Joints and screw heads filled,

finished (Q2) plus a complete

surface covering skim coat of min

1 mm thickness, sanded if

necessary.

Finished surface suitability

Only suitable for functional

applications such as stability, fire

resistance and sound insulation.

E.g. filing joints of the first board

layer which is under tile coverings or

thick layered plasters.

Medium and coarse-structured wall

coverings, matt filling, medium

and coarse-structured paint coatings/

coats, top coats (particle size/

largest particle over 1 mm).

Fine-structured wall coverings, matt,

fine-structured paint coatings/coats,

top coats (largest particle size less

than 1 mm).

Smooth or glossy wall coverings,

e.g. metal-based or vinyl wallpapers,

scumbles, paints or coats up to

medium gloss, stucco marble or

similar specialist decorative finishes.

Flatness requirements

Refer to National standards

Note: Priming the surface will depend on the selected interior finishing option. Quality level of surface finishing depends on the skills of the dryliner.

Quality classification according to leaflet no 2 “Skimming of Plaster

Boards – Surface Qualities” of the Plasterboard Industry Group

Association, which provides for four levels of quality.

26 _ 27

Interior finishing

Dry applications

Joint treatment: Gypsum Boards

In order to close the joints and to prepare the surface for the finishing

options the following materials can be used:

Uniflott: “The original”

for Q1– Q2 surface quality

tested and approved standard product

for manual use

Trias: “The efficient”

for Q1– Q2 surface quality

joints don‘t show due to carton-grey colour

good absorption behaviour

extremely low shrinkage when drying

tested and approved standard product

for manual use

Readygips: “The quickstarter”

ideal for Q1– Q4 quality

ready to use from the bucket and processing-friendly

full-surface joint compound to be used with Joint Tape Kurt

very easy to sand

very fine surface after drying

for manual and machine use

Multi-Finish / Multi-Finish M: “The noble”

ideal for Q4 quality

suitable for almost all subsurfaces

use for filling of uneven and rough surfaces

for manual and machine use

Joint Tape KURT

Joint Tape Kurt is a 50 mm wide strip of special

paper which is used to reinforce the joint filling

and edges of Gypsum Boards and Gypsum Fibre

Boards. Particulary resistant to tearing.

PUTZGRUND

Putzgrund is a synthetic resin dispersion filled with fine

quartz sand, white pigmented and alkali-resistant.

It is used for interior priming on Gypsum Boards

before plastering and pre-treatment of absorbent

and non-absorbent substrates.

28 _ 29

Interior finishing

Dry applications

HRAK – semi-circular flattened longitudinal edge

Cut edge and develled/mixed joint

HRK – semi-circular longitudinal edge

TRIAS / Uniflott / Uniflott impregnated

AFK – long side panel edge

TRIAS / Uniflott / Uniflott impregnated

The technically required surface – without optical requirements

TRIAS / Uniflott /

Uniflott impregnated

TRIAS / Uniflott /

Uniflott impregnated

+ Joint Tape KURT

For surfaces with conventional optical requirements

TRIAS / Uniflott /

Uniflott impregnated

TRIAS / Uniflott /

Uniflott impregnated

+ Joint Tape KURT

For surfaces with higher optical requirements

TRIAS / Uniflott /

Uniflott impregnated

Readygips

TRIAS / Uniflott /

Uniflott impregnated

+ Joint Tape KURT

Readygips

For surfaces with highest optical requirements

TRIAS / Uniflott /

Uniflott impregnated

Readygips or Putzgrund

and Multi-Finish /

Multi-Finish M

TRIAS / Uniflott /

Uniflott impregnated

+ Joint Tape KURT

Readygips or Putzgrund

and Multi-Finish /

Multi-Finish M

Installation of Knauf Wetroom Solutions

Installation of Gypsum Boards

1. Studs to be installed first

2. Place insulation material

Use the right product for the job

depending on whether thermal

insulation, acoustic insulation or

fire protection is required. Cut

insulation to width /length with a

sharp long bladed knife.

3. Apply vapour barrier (if necessary)

Make sure all electrical installation

has been completed. To ensure air

tightness of building construction,

apply vapour barrier to the inside

if specified in building physical

calculation.

Fill joints (e.g. standard Gypsum

Board application with HRAK

edge). Use trowel to fill joints

with suitable joint filler (Uniflott).

For double layer system, the

joints of the first layer of board

must also be filled before placing

the second layer of boards.

Run the trowel progressively down

the joint applying sufficient

pressure to squeeze out entrapped

air. Allow the joint filler to set for

approx. 1 hour. If required, sand

lightly to remove any high spots.

Remove surface dust.

Apply an additional thinner

layer of joint filler and remove

any surplus filler. Feather out

application beyond the joints

– approximately 100 to 200 mm.

Where the wall construction

includes a double layer of

Gypsum Board, the vapour barrier

can be placed between the two

layers for fast easy installation.

The vapour barrier must overlap

where more than 1 layer is

placed. It must also overlap when

applied at connections to other

building elements. Use suitable

glue and tapes.

5. Joint treatment (dry applications only)

Allow the joint filler to set for

approx. 1 hour. If required, sand

lightly to remove any high spots.

Remove surface dust.

Where services penetrate the

building elements, ensure that the

penetrations are sealed in order to

obtain optimum air tightness.

Note on interior finishing

(dry applications only)

4. Install Gypsum Board (dry applications only)

Screw Gypsum Boards to

substructure using Drywall

Screws (TN3.5/35).

Once joints have been filled and after drying, if finishing is not satisfactory,

use trowel to apply a tight coat of Uniflott joint filler. Feather out beyond

previous application of material. Allow the joint treatment to set. Lightly

sand to remove any minor imperfections and create a smooth surface.

If required, apply a final coat of Finish-pastös and feather out beyond

previous application. Lightly sand to remove minor imperfections.

Remove surface dust.

Note: Priming the surface will depend on the selected interior

finishing option.

See section Interior finishing for more details.

30 _ 31

Interior finishing options

Choose the perfect surface finishing

Ceramic tiles Q1

1. AQUAPANEL® Cement Board Indoor

2. AQUAPANEL® Maxi Screw

3. AQUAPANEL® Joint Adhesive (PU)

4. AQUAPANEL® Board Primer

5. Knauf Tile Adhesive

6. Ceramic tiles

Ç

Ö

Ñ

É Ä

Å

Decorative plaster finish

Q2

1. Knauf Gypsum Board with HRAK edge

2. Knauf Drywall Screws

3. Knauf Uniflott

4. Knauf Tiefengrund

5. Knauf Easyputz

Ñ

É

Ç

Ä

Å

Wallpaper finish Q3

1. Knauf Gypsum Board with HRAK edge

2. Knauf Drywall Screws

3. Knauf Uniflott

4. Knauf Tiefengrund

5. Wallpaper

Ñ

É

Ç

Ä

Å

Paint finish Q4

Ñ

1. AQUAPANEL® Cement Board Indoor

2. AQUAPANEL® Maxi Screw

3. AQUAPANEL® Joint Adhesive (PU)

4. AQUAPANEL® Board Primer

5. Glassfibre Joint Covering Strip

6. AQUAPANEL® Q4 Finish

Ç

Ö

É

Ö

Level of finishing

Ä

Å

Ö

Q1

Q2 (Standard)

Q3

Q4

Jointed surface

Smooth surface for normal optical

requirements.

Smooth surface for higher visual

requirements.

Smooth surface for high visual

requirements.

32 _ 33

Installation details

Curved interior walls

Gypsum Boards

Gypsum Board may be used to form almost any cylindrically curved

surface. To prevent flat spots on the curved surface, profiles must be

spaced more closely together than required for typical flat wall or

ceiling surfaces.

Gypsum Board should be bent wet. Evenly spray water on the surface

so that the water is allowed to soak into the core before application.

The board must be dried within 24 hours of wetting to prevent the

development of mould. Fans and mechanical dehumidifiers should

be used to accelerate drying when conditions are not conducive to

natural drying. When the Gypsum Board dries thoroughly, its original

hardness is regained.

AQUAPANEL® Cement Board Indoor

For applications such as arches

AQUAPANEL® Cement Board

Indoor can be curved. Using

metal shears, cut the UW-profile.

Fit the UW-profile to the desired

radius. Crimp the CW-profile to

the perforated UW-profile.

Before installation, bend the

cement board panel. The fine

cracks that occur on the board

surface will not cause any loss

of performance.

Board size: 1200/2400/1250/

2500 x 900 mm

Minimum bending radius ≥ 3 m

Strip size: 1200/2400/1250/

2500 x 300 mm

Minimum bending radius ≥ 1 m

Max. stud spacing: ≤ 300/312.5

mm (external radius)

_ 3m

r: >

Knauf Metal Stud Partitions

W11

Partitions

withconstruction

Bent Knauf Boards and UW Runners 75x40x0.6 Pre-punched at Web

CurvedBent

interior

wall

Inside Arch - Concave

Outside Arch - Convex

Board

thickness

Knauf Metal Stud Partitions

Bending radius r

Length of layout L

W11

ed

ss

sid

ed

ed

e

ss

sid

e

e

ed

ss

sid

sid

ss

e

dry

wet

angle

90° r of Gypsum Boards

Board thickness

Bending

radius

d

d

bending

bending

r.

L= 2

mm

mm

mm

Bent Partitionsbwith

75x40x0.6

at Web

d mm Pre-punched Dry

bending mm

Wet bending mm

e c om Bent Knauf Boards and UW Runners

6.5 (Mold Board) � 1000

� 300

angle

180°

t o c e s i pr e

.

r

f a r de

6.5

≥

1000

≥ 300

L

=

9.5 Bending radius

� 2000 r � 500

Inside Arch - Concave Outside Arch - Convex

Length of layoutr L

to

r e Board

b e c o m p thickness12.5

� 2750

� 1000

all

angles

up

to

180°

9.5

≥ 2000

≥ 500

dry

wet

. r.

angle

90°

f a

c e ds i d e d

d

bendingbending

bending

r . L = 180

longitudinal

only

L

=

mm

mm

mm

12.5

≥ 2750

≥ 1000

2

b e c om p r

6.5 (Mold Board) � 1000

� 300

angleonly 180°

t oBiegeanleitung

e

s

e

Longitudinal

bending

i

c

d

Inside arch f–a concave,

outside arch – convex

r

L = r.

9.5

� 2000

� 500

r e

to

re

b e c omp

Wet

bending� 1000

12.5

� 2750

all angles up to 180°

. r.

f a

c e s i de

d

L =Lon a grid

1.

Put

the

cut-to-length

Knauf

Boards

made of

longitudinal bending only Length of layout

180

channels or similar with the side to be compressed on top and

α the

= 90°

180°

excessing theAngle

grid on

perimeters (so excessAngle

waterα

can= drip

off).

batten

to fix the

board

batten to

fix the

board

Wet bending

a few minutes.

Repeaton

process

water drains.

1. Put the cut-to-length

Knauf Boards

a grid until

madeexcessive

of

channels4.or similar

withon

theprecast

side to

bePcompressed

onwith

top and

Lay board

device,

fix

tape Gypsum

1.molding

ut the

cut-to-length

excessing theand

gridletonit dry.

the perimeters (so excess water can drip off).

Boards on a grid made of channels

or similar with the side to be compressed on top and excessing

2. Perforate the board laterally and longitudinally with Spike Roller.

the grid on the perimeters (so excess water can drip off).

3. Wet the board by spraying or with lambskin roller and let it settle for

2. excessive

Perforate

the

board laterally and longitudinally with spike roller.

a few minutes. Repeat process until

water

drains.

4. Lay board on precast molding device,

fixet

withthe

tapeboard by spraying or with lambskin roller and let it settle

3. W

and let it dry.

for a few minutes. Repeat process until excessive water drains.

Bending device

deviceon precast moulding device, fix with tape and

4. molding

L ay board

angle or CD Channel

let it dry.

to support boards

length of layout

longitudinal direction

length of layout

longitudinal direction

Wet bending

3. Wet the board by spraying or with lambskin roller and let it settle for

wet bending

batten

to fix the

board

Knauf Board strip

to support

cut board

molding deviceAngle or CD profile

Detail scale 1:5

device

Inside arch –molding

concave,

outside

to support boards

Knauf Board strip

cut board

arch – convex

d � 12.5 mm

UW Runner

75x40x0.6

Dry bending

1. Bend Knauf Boards over metal grid or frame.

Dry bending

the board

d � 12.5 mm

Board strips; cutted

Boardangle

thickness

12.5 mm

or CD≥Channel

Detail scale 1:5

All angles up to α = 180°

2. Perforate the board laterally and longitudinally with Spike Roller.

length of layout

longitudinal direction

Biegeanleitung

wet bending

2. Fix with Drywall

Screws

following the bending continuously.

molding

device

Dry bending

1. Bend Gypsum Boards over metal grid or frame.

2. Fix with Drywall Screws following the bending continuously.

1. Bend Knauf

Boards over metal grid or frame.

Assembly

2. Fix with Drywall

Screws flange

following

the bending

1. cut outside

at web

punchescontinuously.

2. bend UW Runners to required radius

Knauf

CW Stud

75x50x0.6

3. connect Knauf CW Studs to pre-punched UW Runners by crimping

Assembly4.

cladding lateral

Assembly

spacing

CW Studs:

� 312.5 mm (outside radius)

1. cut outside

flange atKnauf

web punches

Plug:

� 300

mm punches.

1. Cutradius

outside flange

at web

2. bend UWspacing

Runners toNailable

required

Knauf

UW profile

UW

Runner

75x40x0.6 UW Runner 75x40x0.6

pre-punched at web

Knauf

(Mat. no. 00003387)

CW Stud

75x50x0.6

2.toBpre-punched

end UW UW

profiles

3. connect Knauf CW Studs

Runnerstobyrequired

crimping

radius.

3. Connect CW profiles to pre-punched UW profiles by crimping.

Drywall Screw TN

4. Cladding

lateral.

spacing Knauf CW Studs:

� 312.5

mm (outside radius)

Knauf

sinus flexible

UW

Runner

75x40x0.6

U-connection profile

spacing Nailable Plug:Spacing CW

� 300profiles:

mm

pre-punched at web

≤ 312.5 mm (outside radius)

e.g. Knauf Mold Boards

(Mat. no. 00003387)

Spacing anchor: ≤ 300 mm

2x 6.5 mm

4. cladding lateral

Nailable Plug

Knauf Drywall

Drywall

Screw Screw

TN

UW Runner

75x40x0.6

Knauf Uniflott +

Joint Tape

e.g. Knauf

Knauf Gypsum

Board

e.g.

Mold Boards

2x 6.5 mm

Nailable Plug

W111-SO1

Bent Partition

UW Runner

Knauf

UW profile

75x40x0.6

KnaufUNIFLOTT

Uniflott ++

Knauf

Knauf JointJoint

Tape Tape

KURT

21

W111-SO1

Bent Partition

Inside arch – concave, outside arch – convex

21

34 _ 35

spachtel - grau geschlossen und

das AQUAPANEL® Fugenband in

die Spachtelmasse eingearbeitet.

Die Schraubenköpfe werden

ebenfalls verspachtelt.

Installation of ceilings

Nach Erhärtung wird die Fläche

mit AQUAPANEL® Grundierung

– innen grundiert (Grundierung /

Wasser 1:2).

Montage

Montage von

von Decken

Decken

Variant 1 1

Variante

Variante

Variante 1

1

The following

minimum spacings

Bei

Bei der

der Unterkonstruktion

Unterkonstruktion

Bei

der

Unterkonstruktion

are

required

for

the framework:

Bei

der

Unterkonstruktion

werden mindestens

werden

mindestens folgende

folgende

werden

mindestens

folgende

Hanger

werden

mindestens

folgende

Abstände vorausgesetzt:

vorausgesetzt:

Abstände

Abstände

vorausgesetzt:

a

=

750

mm

Abstände

vorausgesetzt:

Abhänger

Abhänger

Abhänger

section CD 60/27/06

Abhänger

aaSupport

=

= 750

750 mm

mm

aaTragprofil

b=

450mm

mm 60/27/06

==750

750

mm

Tragprofil CD

CD 60/27/06

Tragprofil

CD

60/27/06

Base

section

60/27/06

Tragprofil

CDCD

60/27/06

b

b=

= 450

450 mm

mm

c

=

1000

mm

b

=

450

mm

b

=

450

mm

Grundprofil

Grundprofil CD

CD 60/27/06

60/27/06

Grundprofil

CD

Grundprofil

CD 60/27/06

60/27/06

cc =

1000

mm

= 1000 mm

cc =

= 1000

1000 mm

mm

Align the Platte

first cement entlang

board

Die

Die erste

erste Platte wird

wird entlang der

der

panel

carefully

along

the lath,der

Die

erste

Platte

wird

entlang

Die

erste Platte wird

entlang

der

Traglattung

Traglattung (quer

(quer zur

zur GrundGrundperpendicular

to the

batten.

Traglattung

(quer

zur

GrundTraglattung

(quer

zur

Grundlattung)

sorgfältig

ausgerichtet.

lattung)

sorgfältig ausgerichtet.

®

Using AQUAPANEL

Maxi

lattung)

sorgfältig

lattung)

sorgfältig ausgerichtet.

ausgerichtet.

Mit

den

AQUAPANEL®

Maxi

Mit

den

AQUAPANEL®

Maxi ®

screws,

screw

the

AQUAPANEL

Mit

den

AQUAPANEL®

Maxi

Mit den AQUAPANEL®

Maxi

Schrauben

werden

die

Schrauben

werden

die

Cement

Board

Indoor

panel

Schrauben

werden

die

Schrauben

werden

die Boardto

AQUAPANEL®

Cement

AQUAPANEL®

Cement

Boardof

the framework,Cement

with spacing

AQUAPANEL®

Board

AQUAPANEL®

Cement

Board

Indoor

in

einem

Abstand

von

a

Indoor

in

einem

Abstand

von

2

a

=

170

mm

(22

pieces/m

). a

Indoor

in

einem

Abstand

von

aa

2

Indoor

in einem

Abstand

von

=

170

mm

(22

Stück/m

die

2) an

= 170 mm (22 Stück/m22) an die

=

170

mm

(22

Stück/m

)

an

die

=

170 mm (22 Stück/m ) an die

Unterkonstruktion

Unterkonstruktion geschraubt.

geschraubt.

Unterkonstruktion

Unterkonstruktion geschraubt.

geschraubt.

Die

folgenden

Platten

werden

Die

folgenden

Leave

a gap ofPlatten

at least werden

3-4 mm

Die

folgenden

Platten

werden

Die

folgenden

Platten

werden

mit

ca.

3

–

4

mm

Fuge

im Vermit

ca. 3 joints

– 4 mm

Verbetween

andFuge

makeim

all

mit

ca.

3

–

4

mm

Fuge

Vermit

ca.montiert,

3 – 4 mmKreuzfugen

Fuge im

imsure

Verbund

sind

bund

montiert,

Kreuzfugen

joints montiert,

are staggered.

After sind

bund

Kreuzfugen

sind

bund

montiert,Die

Kreuzfugen

sind

nicht

zulässig.

Fugen

werden

nicht

zulässig.

Dieshould

Fugenbe

werden

installation,

joints

filled

nicht

zulässig.

Die

werden

nicht

zulässig.

Die Fugen

FugenFugenwerden

mit

dem

AQUAPANEL®

mit

demAQUAPANEL

AQUAPANEL®

Fugen®

in with

Joint

Filler

mit

dem

Fugenmit

dem AQUAPANEL®

AQUAPANEL®

Fugenspachtel

-- grau

geschlossen

und

spachtel

grau

geschlossen

und

®

– grey with

AQUAPANEL

Tape

spachtel

grau

geschlossen

und

spachtel

- grau geschlossen

und

das

AQUAPANEL®

Fugenband

in

das

AQUAPANEL®

Fugenband

embedded

into

the

filler.

Also

fillin

das

AQUAPANEL®

in

das

AQUAPANEL® Fugenband

Fugenband

in

die

Spachtelmasse

einge

arbeitet.

die

Spachtelmasse

arbeitet.

all screw

heads. einge

die

Spachtelmasse

einge

arbeitet.

die

Spachtelmasse

einge

arbeitet.

Die

Schraubenköpfe

werden

Die Schraubenköpfe werden

Die

Schraubenköpfe

Die

Schraubenköpfe werden

werden

ebenfalls

ebenfalls verspachtelt.

verspachtelt.

ebenfalls

ebenfalls verspachtelt.

verspachtelt.

Nach

Erhärtung

die

Nach

Erhärtung wird

wird

dietheFläche

Fläche

After hardening,

prime

Nach

Erhärtung

wird

die

Nach

Erhärtung

wird

die Fläche

Fläche®

mit AQUAPANEL®

AQUAPANEL® Grundierung

Grundierung

mit

surface

over using AQUAPANEL

mit

AQUAPANEL®

Grundierung

mit

AQUAPANEL®

Grundierung

innen grundiert

grundiert (Grundierung

(Grundierung //

––Board

innen

Primer (primer/water

1.2)

––Wasser

innen

(Grundierung

innen grundiert

grundiert

(Grundierung //

1:2).

Wasser 1:2).

Wasser

Wasser 1:2).

1:2).

AQUAPANEL®

AQUAPANEL® Q4

Q4 –– Finish

Finish

AQUAPANEL®

Q4

AQUAPANEL®

Q4 –– Finish

Finish

kann

nun

nach

kann nun nach Trocknung

Trocknung der

der

kann

nun

nach

Trocknung

der

kann

nun nach Trocknung

der

Grundierung

Grundierung vollflächig

vollflächig und

und ohne

ohne

Grundierung

vollflächig

und

Grundierung

vollflächig

und ohne

ohne

Gewebearmierung

aufgetragen

Gewebearmierung aufgetragen

Gewebearmierung

aufgetragen

Gewebearmierung

aufgetragen

werden.

Der

Auftrag

in

einem

werden. Der Auftrag in einem

werden.

Der

werden.

Der Auftrag

Auftrag in

in einem

einem

Arbeitsgang

Arbeitsgang beträgt

beträgt max.

max. 2

2 mm.

mm.

Arbeitsgang

beträgt

max.

2

Arbeitsgang

beträgt max.

2 mm.

mm.

Nach

der

Trocknung

ist

die

Nach der Trocknung ist die OberOberNach

Trocknung

ist

Nach der

der

Trocknung(Schleifpapier

ist die

die OberOberfläche

zu

schleifen

fläche zu schleifen (Schleifpapier

fläche

zu

fläche

zu schleifen

schleifen (Schleifpapier

(Schleifpapier

120

120 oder

oder feiner).

feiner). Ggf.

Ggf. ist

ist ein

ein zweizwei120

oder

feiner).

ist

120

oder feiner). Ggf.

Ggf.erforderlich.

ist ein

ein zweizweiter

Spachtelvorgang

ter Spachtelvorgang erforderlich.

ter

Spachtelvorgang

erforderlich.

ter

Spachtelvorgang

erforderlich.

Mit

AQUAPANEL®

Q4

–

Finish

Mit AQUAPANEL® Q4 – Finish

Mit

Mit AQUAPANEL®

AQUAPANEL® Q4

Q4 –– Finish

Finish

Once the primer has dried,

Alternativ:

Alternativ: ® Q4 – Finish

AQUAPANEL®

Alternativ:

AQUAPANEL

Q4 FinishArbeitscan

Alternativ:

Über

die

beschriebene

Übernun

die nach

beschriebene

Arbeitskann

Trocknung

der

Über

die

beschriebene

Arbeitsbe

applied

to

the

entire

surface

Über

die

beschriebene

Arbeitsweise

ist

weise hinaus

hinausvollflächig

ist ein

ein Verkleben

Verkleben

Grundierung

und

ohne

weise

hinaus

ist ein

eininVerkleben

Verkleben

without

any reinforcing.

No more

weise

hinaus

ist

der

der Plattenkanten

Plattenkantenaufgetragen

in der

der DeckenDeckenGewebearmierung

der

Plattenkanten

inisder

der

Deckenthan

2mm of coating

applied

der

Plattenkanten

in

Deckenanwendung

möglich.

Unteranwendung

möglich.inDie

Die

Unterwerden.

Der Auftrag

einem

anwendung

möglich.

Die

Unterinanwendung

a

single

step.

Once

the

finish

möglich.

Die

Unterkonstruktion

und

Plattenrichtung

konstruktion

und Plattenrichtung

Arbeitsgang

beträgt

max. 2 mm.

konstruktion

und

Plattenrichtung

has

dried,

sand

the

surface

(using

konstruktion

und

Plattenrichtung

ist

Variante

auszuführen.

ist wie

wie

inTrocknung

Variante 11 ist

auszuführen.

Nach

derin

die Oberist

wie

insandpaper

Variante

auszuführen.

120-grit

finer).

ist

wie

in

Variante

11orauszuführen.

Die

Montage

ist

wie

im

Die Montage

ist wie

im WandWandfläche

zu

schleifen

(Schleifpapier

ADie

second

coat ist

of finish

may

be

Montage

wie

WandDie

Montage

ist

wie im

im

Wandbereich

vorzunehmen.

Dehnfugen

bereich

vorzunehmen.

Dehnfugen

120

oder

feiner).

Ggf.

ist

® ein zweirequired.

AQUAPANEL

Q4

bereich

vorzunehmen.

Dehnfugen

bereich

vorzunehmen.

Dehnfugen

sind

alle

sind

alle 7,5

7,5 m

m anzuordnen.

anzuordnen.

ter

Spachtelvorgang

erforderlich.

Finish

achieves

finish of up to

sind

alle

7,5 m

m aanzuordnen.

anzuordnen.

sind

alle

7,5

Mit

AQUAPANEL®

Q4

– Finish

Q4

surfaceInnenwände

quality. Please see

the

Montage

Montage

Innenwände s.

s. S.

S. 9

9 ff.

ff.

kann

eine

Oberflächenqualität

specific

instructions

on

page

15.

Montage

Innenwände

s.

S.

9

Montage Innenwände s. S. 9 ff.

ff.

bis Q4 erreicht werden.

Bitte beachten Sie die besonderen

Hinweise auf Seite 15.

14

Alternative

AQUAPANEL1 Cement Board Indoor

As an alternative to the method

described here, the edges of the

board panel can be glued into

the ceiling application. The

framework and boards should be

arranged and positioned as

shown in Variant 1. To assemble,

proceed as for a wall installation.

Expansion joints should be

installed at 7.5 m intervals.

Variant 2

Align the first AQUAPANEL®

Cement Board Indoor panel

carefully, perpendicular to the

supporting profile. Screw the

panel to the framework using

AQUAPANEL® Maxi Screws

(material requirement 25 pcs/

m2). The centre space between

the supporting profiles is

300/312.5 mm.

Leave a gap between joints of

at least 3-4 mm. Make sure all

joints are staggered. After

installation, joints should be

filled in with AQUAPANEL® Joint

Filler – grey with the 10 cm

wide AQUAPANEL® Tape

embedded into the filler. Fill

all screw heads.

Prime the surface over using

AQUAPANEL® Board Primer

(primer/water 1.2).

Special notes

In rooms with continuous high

humidity levels such as commercial

kitchens, swimming pools, saunas

or chemical laboratories, it is

necessary to provide improved

corrosion protection for the

metal framework.

When cutting AQUAPANEL®

Cement Board Indoor, the

distance of the screws from the

board edge must be ≥ 15 mm.

The distance between screws

must be ≤ 250 mm.

Fasten the hanger of the

framework with suitable, building

authority approved ceiling pins

e.g. Type KDM Kunkel ceiling pin

or MKT anchor bolt B6 material

1.4529.

We recommend that expansion

joints are included at maximum

15 m intervals. Align with

the expansion joints in the

background if practical.

Use AQUAPANEL® Joint Filler &

Skim Coating – white to coat the

panels to at least 4 mm depth

all-over, and embed the

AQUAPANEL® Reinforcing Mesh.

For fine finishing up to Q4

surface quality, use

AQUAPANEL® Q4 Finish on

AQUAPANEL® Joint Filler &

Skim Coating – white.

36 _ 37

Permitted console loads

Permitted console loads

Light partition walls built with AQUAPANEL® Cement Board ­Indoor

can accept console loads of different sizes. Should loads be inserted

in double-layer walls, the stud rows must be connected together using

consoles to ensure tensile strength. The size and geometry of the load

must be monitored for all walls. A deciding size is the “load height“,

i.e. the distance of the load outer edge from the wall or the height of

a hanging shelf or hanging cabinet. The following cases can be

distinguished depending on the size and height of the load:

Light console loads up to 40 kg/metre wall length

Light console loads can be arranged on any position of the wall or

facing panel. If the load is attached to the panel, the distance of the

fastening points from each other must be at least 75 mm. Loads of up to

40 kg per metre wall length at a load height of 60 cm are considered

light console loads. Loads can be increased if the load height is low.

Maximum size “light console loads” as a function of load depth b

Load depth (cm)

10

20

30

40

50

60

Permissible console load P

(kg/metre wall length)

78

71

63

55

48

40

Other console loads of 40 to 70 kg/metre wall length

Other console loads can be attached in any position on a ­single or

double stud installation with double-layer panelling of AQUAPANEL®

Cement Board Indoor. With double stud walls, the stud rows must be

fixed with consoles to ensure tensile strength. Loads of between 40

and 70 kg per metre wall length at a load height of 60 cm are

considered medium console loads. Loads can be increased if the

load height is low.

Light console loads

Maximum size “other console loads” as a function of load depth b

Load depth (cm)

10

20

30

40

50

60

Permissible console load P

(kg/metre wall length)

107

100

93

85

78

70

Heavy console loads of 70 to 150 kg/metre wall length

Heavy console loads must be attached to special construction parts

such as cross beams, console frames or cross member ­bracing. Cross

beams and cross member bracings are directly linked to the framework

so that the loads can be securely taken into the framework. Supporting

frames are fastened to the ­framework depending on the type of

construction but are generally anchored directly to the original floor.

Other console loads

Construction details

Wall hooks

5 kg

10 kg

15 kg

Hooks for light, flat objects up to 15 kg/m

Plastic cavity wall plugs

Metal cavity wall plugs

Light and other bracket loads up to 70kg/m

Wall hooks

Flat loads

Loads up to 15 kg can be secured using simple hooks. Flat loads

up to 50 kg are fastened using metal or plastic cavity wall plugs.

Light and other bracket loads

Light and other bracket loads are secured using at least two

plastic or metal cavity wall plugs. Plugs should be spaced more

than 75 mm apart. See table.

Plug load-bearing capacity (kg) under pull and shear

Panel thickness (mm)

Plastic cavity wall plugs

Ø8

Ø 10 mm

Metal cavity wall plug

M5 or M6 screw

Knauf

Hartmut

1 x 12.5

30 kg

40 kg

30 kg

60 kg

2 x 12.5

40 kg

70 kg

50 kg

110 kg

Ceiling hooks

Tilting ceiling hooks

Spring toggle ceiling hooks

Securing loads to suspended ceilings

Light loads, which do not exceed the load-bearing capacity of a light

suspended ceiling, may be fastened to the panel. Heavier loads must

be secured separately to the original ceiling. Tilting ceiling hooks or

spring toggle ceiling hooks should be used to fix these.

The maximum possible load capacity depends on the individual ceiling

construction. The maximum load-bearing capacity of the ceiling hooks

is 20 kg in single-layer panelling and 25 kg in double-layer panelling.

38 _ 39

AQUAPANEL® special fittings

AQUAPANEL® Traverse

I. Attach using crimping pliers

M type traverse

MH type traverse

II. Stud profile

AQUAPANEL® Traverse: installation

AQUAPANEL® Traverse

Sanitary mounts

To ensure light console loads are borne securely, AQUAPANEL® Traverses

Standard sanitary mounts are used to bear greater loads. Various types

of mount are available for the various sanitary objects. Sanitary mounts

are secured using either side U-bracing profiles or are anchored directly

into the original flooring. Manufacturer guidelines should be followed

when assembling.

are attached between the C-wall profiles. The cross panels should be

secured twice on each side using crimping pliers. Alternatively, the cross

panels can be secured with self-tapping screws.

For single layer panelling, the following maximum loads apply:

M type: up to 0.7kN/m

MH type: up to 1.5kN/m

For single layer panelling with tiled AQUAPANEL® Cement Board

Indoor or double layer panelling, the following maximum loads apply:

M type and MH type: up to 1.5kN/m

AQUAPANEL® Traverse

AQUAPANEL® Traverse: arrangement and loading

Axis frame dimensions

600/625 mm

Height