ASM Handbook,Volume 7: Powder Metal Technologies and Applications

P.W. Lee, Y. Trudel, R. Iacocca, R.M. German, B.L. Ferguson, W.B. Eisen, K. Moyer,

D. Madan, and H. Sanderow, editors, p 376-381

Copyright © 1998 ASM International®

All rights reserved.

www.asminternational.org

Warm Compaction

Francis G. Hanejko,

Hoeganaes

Corporation

THE FERROUS P/M INDUSTRY continues

to grow because of developments in raw materials and part production processes enabling the

manufacture of components with greater complexity and higher levels of performance. Advances in raw materials include higher compressibility iron powders, molybdenum prealloyed

steels, diffusion-alloyed powders, and the use of

binder-treated iron powders. These new powders

and premix technologies offer P/M users greater

flexibility in mechanical properties at traditional

part densities, typically less than 7.1 g/cm 3.

However, end users of P/M parts are demanding

still higher levels of mechanical properties available solely through higher part densities. Traditional methods used to achieve higher densities

include the use of copper infiltration, doublepressing/double-sintering (DP/DS), and powder

forging. Because these techniques involve the

use of secondary processing, significant cost

penalties are encountered, often negating the potential cost savings realized by powder metallurgy. Warm-compaction process is a technique

to achieve DP/DS densities and mechanical

properties utilizing a single compaction process.

The process incorporates the use of heated powder and heated tooling in standard compacting

presses to achieve higher green and sintered densities.

Temperatures above room temperature and below the hot-forging range are used extensively in

wrought steels to lower forging loads and minimize distortion. Work at MeriSinter AG in the

mid-1980s found certain advantages to be present when ferrous, bulk lubricated powders were

heated in the vicinity of 100 °C. It was of particular interest that compressibility improved

with heating as compared to the some powders

in an unheated condition (Ref 1). The practical

Powder l

prem,x

I

1 -I

Press ready

binder-treated

premix

Fig. 1 Warm-compaction process

Powder I

he=or

EITemp

Abbott heater

Slotheater

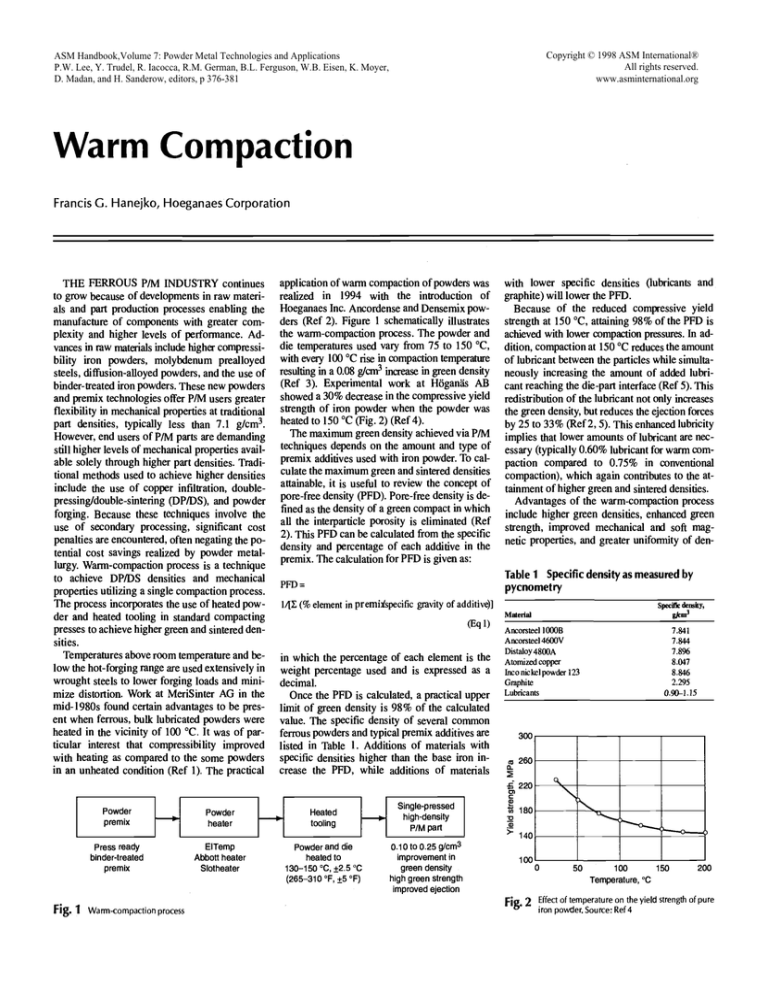

application of warm compaction of powders was

realized in 1994 with the introduction of

Hoeganaes Inc. Ancordense and Densemix powders (Ref 2). Figure 1 schematically illustrates

the warm-compaction process. The powder and

die temperatures used vary from 75 to 150 °C,

with every 100 °C rise in compaction temperature

resulting in a 0.08 g/crn3 increase in green density

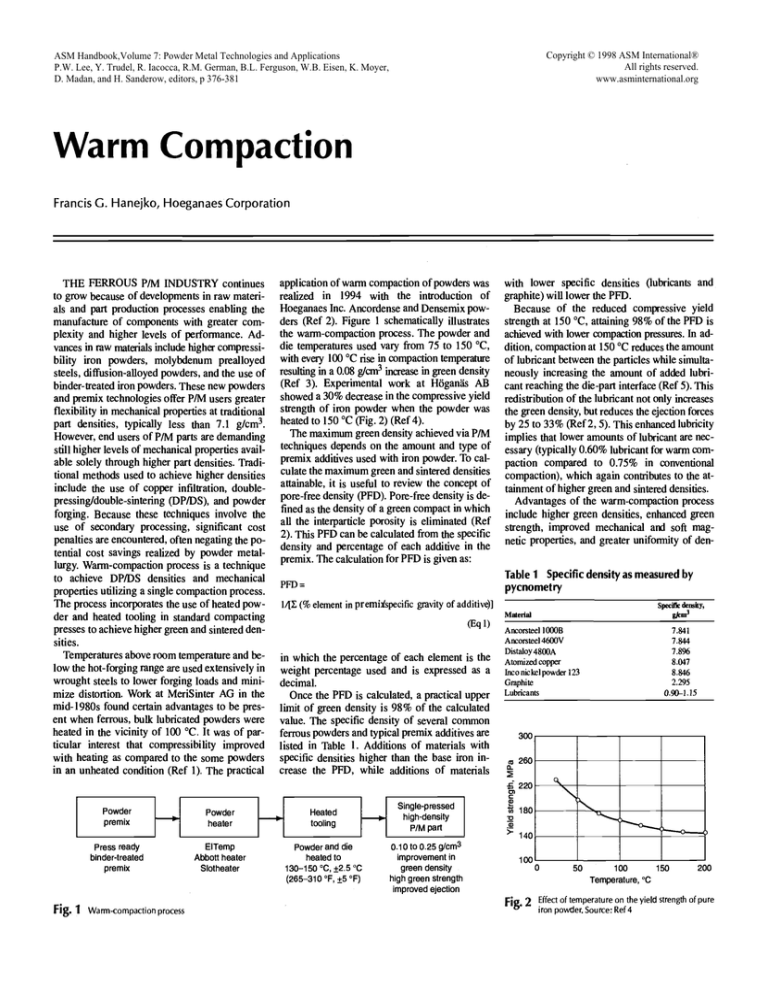

(Ref 3). Experimental work at H6gantis AB

showed a 30% decrease in the compressive yield

strength of iron powder when the powder was

heated to 150 °C (Fig. 2) (Ref 4).

The maximum green density achieved via P/M

techniques depends on the amount and type of

premix additives used with iron powder. To calculate the maximum green and sintered densities

attainable, it is useful to review the concept of

pore-free density (PFD). Pore-free density is defined as the density of a green compact in which

all the interparticle porosity is eliminated (Ref

2). This PFD can he calculated from the specific

density and percentage of each additive in the

premix. The calculation for PFD is given as:

Table I Specific density as measured by

pycnometry

PFD =

l/[E (% element in premb/specific gravity of additive)]

(Eq 1)

in which the percentage of each element is the

weight percentage used and is expressed as a

decimal.

Once the PFD is calculated, a practical upper

limit of green density is 98% of the calculated

value. The specific density of several common

ferrous powders and typical premix additives are

listed in Table 1. Additions of materials with

specific densities higher than the base iron increase the PFD, while additions of materials

~

I

I- I

with lower specific densities (lubricants and

graphite) will lower the PFD.

Because of the reduced compressive yield

strength at 150 °C, attaining 98% of the PFD is

achieved with lower compaction pressures. In addition, compaction at 150 °C reduces the amount

of lubricant between the particles while simultaneously increasing the amount of added lubricant reaching the die-part interface (Ref 5). This

redistribution of the lubricant not only increases

the green density, but reduces the ejection forces

by 25 to 33% (Ref 2, 5). This enhanced lubricity

implies that lower amounts of lubricant are necessary (typically 0.60% lubricant for warm compaction compared to 0.75% in conventional

compaction), which again contributes to the attainment of higher green and sintered densities.

Advantages of the warm-compaction process

include higher green densities, enhanced green

strength, improved mechanical and soft magnetic properties, and greater uniformity of den-

Heated

tooling

I

I1

Powder and die

heated to

130-150 °C, +2.5 °C

(265-310 °F, _+5°F)

=

Single'pressed

high-density

P/M part

0.10 to 0.25 g/cm 3

improvement in

green density

high green strength

improved ejection

Specific density,

g]cm3

Material

Ancorstee11000B

Ancorstee14600V

Distaloy4800A

Atomizedcopper

Inconickelpowder123

Graphite

Lubricants

7.841

7.844

7.896

8.047

8.846

2.295

0.90-1.15

300

to 260

g 220

.¢

180

~ 140

lOO

Fig. 2

o

50

1oo

150

Temperature, °C

200

Effectof temperature on the yield strength of pure

iron powder. Source: Ref4

Warm Compaction / 377

sity throughout the as-sintered part. The balance

of this article details the process and the improved properties resulting from warm compaction.

Effects on Green

and Sintered Properties

Warm compaction results in a 0.10 to 0.25

g/cm3 increase in the green and sintered densities of P/M parts (Ref 2). Figure 3 shows the

improved green and sintered densities achieved

with a diffusion-alloyed powder premixed with

0.6% graphite. At lower compacting pressures,

the beneficial effect of warm compaction is

greater than the improvement observed at higher

compaction pressures. Figure 4 summarizes the

transverse rupture strength results of the diffusionbonded material compacted by both conventional and warm-compaction techniques under

compaction conditions of 410 to 690 MPa.

Table 2 summarizes the as-sintered mechanical properties of various warm-compacted premix compositions (Ref 6). This processing is

applicable to all iron and low-alloy powder compositions. The magnitude of the increase in sintered density depends on the material system and

subsequent part processing. Premixes containing

copper additions exhibit growth during the sintering process; this growth negates the beneficial

effects of the warm-compaction processing. Con-

415

7.5

I

Compaction pressure, MPa

550

690

I

I

I

.~i I

P'~

p,¢~,_

.(9

c~ 7 . 1

,~,,~ -

6.9

~

r

Table 2 As-sintered tensile properties of warm-compacted P/M materials, sintered at

1120 °C (2050 °F)

Sinlered

density,

g/cm3

Composition(a)

FL-4405 with0.6% graphite

FLN 2-4405 with 2% Ni and 0.6%

graphite

FL-4205 with 0.6% graphite

Ancorstee1150Mo (b) with 2% Ni

and 0.6% graphite

FDr0405 with 0.6% graphite

Iron plus 0.45% phosphorus

FN 0250 with 0.6% graphite

0.2 % offset

yield strength

MPa

ksi

Ten.~le strength

MPa

ksi

7.37

7.44

273

444

40

65

471

628

69

92

3.5

2.8

77

87

7.24

7.40

417

533

61

78

506

718

74

105

1.7

1.3

81

93

7.25

7.39

7.37

425

267

267

62

39

39

117

422

452

800

62

66

2.6

25.2

3.52

97

67

79

Sintered

Green [

Conventional

Material

Simering

tempermure

*C

OF

Heat

treat

Dendty,

g/tin a

7.23

7.40

7.33

7.50

7.07

7.17

7.19

7.32

7.26

7.37

7.20

7.32

7.18

7.34

7.21

7.37

7.31

7.35

7.20

7.16

7.27

7.16

7.28

7.23

7.17

7.30

7.19

7.29

2050

No

Fe-0.45 wt% P

1260

2300

No

Fig. 3 Compressibility of diffusion-bonded 4% Ni, 1£%

FC-0208

1120

2050

No

lubricant

FD-4805

1120

2050

No

FD-4805

1260

2300

No

FD-4805

1120

2050

Yes

A150HP, 2% Ni

and0.6 Gr

A 150HP, 2% Ni

and 0.6 (Jr

FLN2-4405

FLN2-4405

FLN2-4405

A41AB

1120

2050

No

1260

2300

No

1120

1260

1290

1290

2050

2300

2350

2350

No

No

No

No

A41AB

1290

2350

Yes

FN0250

FL-4405

1120

1120

2050

2050

Yes

Yes

FD-0205

1120

2050

Yes

(9

35

40

45

50

Compaction pressure, tsi

55

60

Cu, and 0.5% Mo with 0.6% graphite and 0.6%

•~ 260

.¢=

30

240

r

r

t

I

Warm compacted at 150 °C

~'o

t , ~ °~

1800 ~.

1700 ~

16oo

220

1500 rn

200

1400

(9

~nventional

o 180

~- 1613

6.8

Fig. 4

1 3 0 0 (9

12oo >=

oo

6.9

~rn~t

laardaes~ BRB

Table 3 Fatigue data of warm-compacted ferrous materials

1120

25

Elongation,

%

"~;"" ~Green

Fe-0.45 wt% P

6.7

formed by Donaldson and others, warm-compacted P/M parts were presintered at 870 °C

(1600 °F) and subsequently re-pressed at up to

690 MPa (50 tsi) at room temperature (Ref 1012). Following re-pressing, the part was then sintered at either 1120 °C or 1260 °C, resulting in

sintered densities ranging from 7.5 to 7.6 g/cm3.

Figures 5 and 6 present data on transverse rupture strength and impact energy from this study.

These higher densities of the doublepressed/double-sintered (DP/DS) warm compacted materials produced an approximately

15% improvement in the transverse rupture

strengths (Fig. 5), but more importantly resulted

in a 50 to 80% improvement in the impact energy (Fig. 6) when compared to the 7.4 g/cm3

density level (Ref 10). This study demonstrated

the potential for significantly improved mechanical properties of P/M materials via DP/DS

of a warm-compacted component. The resultant

(a) MPIF designations, based on MPIF Standard 35, 1997 edition. (b) Hoeganaes Corporation prealloyed powder with nominal

1.5% Mo

Siniered

Warm compacted at 150 °C

I

I

I

1~

7.3

sequently, copper-containing premixes are not

considered ideal candidates for warm compaction (Ref7).

Rotating bending fatigue testing was performed on a variety of warm-compacted materials in both the as-sintered and heat-treated conditions; Table 3 summarizes the available data

(Ref 8, 9). As expected, increasing the density

increased the fatigue endurance limit; however,

higher-temperature sintering did not consistently

improve the fatigue endurance limit. Reviewing

Table 3, it is observed that no generalized correlation exists between the fatigue endurance limit

and the tensile strength of P/M materials. It is

recommended that designers use available data

when specifying the fatigue endurance limit of

P/M components.

Double pressing of conventionally compacted

parts results in improved part densities and mechanical properties. In experimental work per-

7

7.1 7.2 7.3

Sintered density, g/cm3

1100 ~

7.4

Sintered transverse rupture strength of diffusionbonded 4% Ni, 1.5% Cu, and 0.5% Mo with

0.6% pmrnixed graphite

50% fatigue

endurance Ihnit

MPa

ksi

99% fatigue

endurance limit

MPa

kd

MI~

k.4

207

225

216

260

234

243

230

242

217

227

399

409

233

262

207

256

253

247

239

242

270

403

449

316

330

336

368

374

185

197

210

234

175

193

181

192

172

185

317

332

189

241

165

201

222

219

227

210

234

353

410

276

283

279

315

316

365

403

403

476

596

621

710

798

814

925

249

1327

64|

693

652

710

632

672

621

856

917

1211

1349

1193

1131

1151

1192

1303

53

58

59

69

86

90

103

115

118

134

18t

193

30

32.7

31.4

37.7

33.9

35.3

33.3

35.3

31.5

32.9

57.9

59.3

33.8

38.0

30.0

37.1

36.7

35.8

34.6

35.1

39.2

58.5

65.1

45.8

47.9

48.8

53.4

54.2

26.8

28.6

29.7

34

25.4

28.0

26.3

27.8

24.9

26.9

46.0

48.1

27.4

35.0

24.0

29.2

32.2

31.7

32.9

30.4

34.0

51,2

59.4

40.1

41.1

40.4

45.7

45.9

Temne

93

101

95

103

91

98

90

124

133

176

196

176

164

167

173

189

378 / Shaping and Consolidation Technologies

mechanical properties of such parts are equivalent to the properties of ductile cast irons and

machined carbon steel forgings.

Green Strength Enhancement. Warmcompaction processing provides improved green

strength of the as-compacted component. This

increase in the green strength results from the

synergy of greater powder particle deformation

with enhanced particle welding during compaction, plus the presence of the unique binder and

lubricant utilized in the ANCORDENSE material (Ref 2, 5). The improved green strengths are

realized at densities significantly below the porefree density (Fig. 7). These data imply the potential of warm compaction being used in lowerdensity applications where the enhanced green

strength reduces part breakage or part chipping

of fragile features.

A consequence of the enhanced green strength

via warm compaction is the ability to green machine the as-compacted part. This concept has

been used in a commercial application of a P/M

safety locker part (Ref 13). After compaction,

the component was milled in the green condition, thus reducing the overall part cost. A machinability study utilizing a drilling test was conducted on a molybdenum prealloyed material

premixed with 2% Ni, 0.5% graphite, and 0.6%

lubricant (Ref 14). This study concluded that

satisfactory surface finishes are achieved with

machining conditions using high speeds and

high feed rates. Additionally, modifications of

the standard drill bit geometry from a standard

38o

34O

2300 °i= (1260 °C'), DPDS

e 320

&--'f

2160

I

3oo - - 2300 OF(1260 °C), SP

~. 280

I~

2452 ~

2316 ~

2044

1908 ~.

L ~ 5 0 1 1 * F (1120 °C), DPDS 1772 ~

m 260

/

>m 240 2050 °Fl(1120 °C),I S P - ~

1636

220

1500

7.4

7.45

7.5

7.55

7.6

IDensity, g/cm 3

~

I

Fig. 5

Transverse rupture strength of diffusion-bonded

4% Ni, 1.5% Cu, and 0.5% Mo prernixed with

0.3% graphite subsequently carburized and tempered

90 ° chisel bit to a 135 split-point drill bit en-

hanced the as-machined surface finish. Prior to

establishing green-machining parameters, it is

recommended that testing be conducted to examine the effects of tool-bit geometry, machining feed rate, and machining speed. Green machining of P/M parts in combination with sinter

hardening offer the part designer greater flexibility in part design and material selection.

M a g n e t i c Applications

The use of warm compaction of P/M magnetic

alloys effects higher sintered densities with corresponding higher saturation induction levels

and higher permeabilities with no change in the

coercive force (Ref 15). Sintered densities in excess of 7.4 g/cm3 are possible using warm compaedon of iron-phosphorus alloys. At this density

level, the magnetic and mechanical performances of this family of materials are equal to

the properties of a low-carbon steel forging. Table 4 summarizes the mechanical and magnetic

property data for a 0.45% P/M phosphorus steel

processed to 7.4 g/cm 3 and an AISI 1008 steel

forging. From these data, the P/M material is a

suitable replacement for the wrought steel.

Warm-compaction processing enables the introduction of a new class of P/M materials for

use in alternating current (ac) magnetic applications (Ref 15-17). These materials utilize a

high-strength polymer and warm-compaction

processing to produce components that do not

require sintering. The polymer acts to both electrically insulate the powder particles and provide

strength without the need for sintering. As-compacted green densities in excess of 7.2 g/cm 3 are

possible. Manufacturing flexibility can produce

a variety of material options with unique magnetic performance. Applications for these materials include automotive ignition coils and stators for high-speed eleclric motors.

5O

¢= 40

63.6

- 2300 °F (1260 °C) sinter 7

cm 30

Table 4 Magnetic and mechanical

properties of a warm-compacted

iron-phosphorus steel versus AISI 1008

Property

Fe-0.45wt% P

Density, g/cm3

Sintering temperature,

7.35

1120 (2050)

N/A

N/A

0.2% yield strength,

MPa (ksi)

Tensile strength,

MPa(ksi)

Elongation, %

Maximum permeability

Coercive force, Oe

Saturation at 15 Oe, G

285 (42)

285 (42)

405 (59)

383 (56)

12

2700

1.9

15,000

37

1900

3.0

14,400

oC(°F)

N/A, not applicable

AIS11008

~. 2o

g

10

7.4

DPDS

/

s. ~ ' _ . 2 "°s

o!,,1oo0,isn.

7.45

7.5

7.55

Sintered density, g/cm 3

Table 5 summarizes these ac magnetic materials and their magnetic performance. These materials are ideally suited for applications with operating frequencies above 400 Hz. Optimizing

the amount and type of insulation produces components that can operate at frequencies up to

50,000 Hz. The unique three-dimensional structure of these materials can be used to carry magnetic flux in any direction. The strength of these

materials in the as-compacted condition is approximately 103 MPa (15 ksi) transverse rupture

strength. Employing a 315 °C (600 °F) thermal

treatment to the as-compacted part raises the

transverse rupture strength to approximately 240

MPa (35 ksi).

C o m m e r c i a l Powder Heating

and Delivery Systems

Successful utilization of the warm-compaction

process necessitates that the powder, powder

shuttle, and compaction tooling be heated to the

proper temperature. Recommended temperature

control of the heated powder and tooling is _+2.5

°C. It is imperative that the ~mperature of the

powder not exceed 170 °C (320 °F); above this

temperature the lubricant and binder degrade,

resulting in diminished powder flow. Heating of

the tooling is accomplished using cartridge heaters embedded in the stress ring of the die. Typically, eight to twelve 500 W cartridge heaters are

required to heat the tooling to 150 °C (300 °F) in

approximately 30 min. Heating of the powder

shuttle is necessary to maintain the powder temperature during the transfer of the powder into

the die cavity. Top-punch heating is recommended to eliminate the possibility of a tool

binding between the top punch and core rod(s).

Heating the core rod and lower punches is not

necessary; where practical, incorporating a car-

135

7.2

53.6 .~"

~6.8

8884

23.6 g

13.6

7.6

Fig.

6 Impact energy for diffusion-bonded 4% Ni, 1.5%

Cu, and 0.5% Mo premixed with 0.3% graphite

subsequently carburized and tempered

J

7.0

43.6 =~

33.6 ~

Compacting pressure, MPa

205

275

345

- Green density I \

/

f

~"

3000

v

"~

(27.5) ~,

(20.5)

2oo0

g 6.2

m

(13.75)

O 6.0

5"810

Fig. 7

415

4000

15

20

25

Compacting pressure, tsi

.~

10oo o

3~(7"0)

Green density and green strength of warm-compacted FN0205 at low compacting pressures

Table 5 Magnetic performance of insulated iron p o w d e r s

Material

Iron powder with 0.6% plastic

Iron powder with 0.75% plastic

Iron powder with oxide coating and 0.75% plastic

Initial

permeability

120

100

80

Ma.~mum

permeability

425

400

210

Coercive

farce,Oe

4.7

4.7

4.7

Induction

40 Oe, G

11,200

10,900

7,700

Warm Compaction / 379

tridge heater in the core rod will provide greater

temperature uniformity.

Currently, three commercial powder heating

and delivery systems are available. Each system

is capable of delivering heated powder at the

proper temperature. Additionally, each has the

capability of heating and controlling temperatures in the die, the punches, and the powder

shuttle system. The three systems are:

• Cincinnati Inc. El Temp System

• Abbott Furnace Company Thermal Powder

Processor

• Slotheater

The Cincinnati Incorporated E1 Temp system

utilizes an auger to both heat and transport the

powder from the powder feed hopper to the

heated shuttle (Ref 18). The auger operates

within a resistively heated shell; additionally, the

auger is hollowed, allowing preheated air to provide for additional heating capability. The

amount of powder heated is determined by the

part weight and press speed. Production systems

are available that heat up to a maximum of 9

kg/min (20 lb/min). A unique feature of the E1

Temp system is its direct interface with the Cincinnati computer operating system of the press,

allowing for control of all press and heating

functions from a single touch screen.

The Abbott Furnace Company Thermal Powder Processor, TPP 300 (patent pending) uses a

low-pressure fluidizing air 35 kPa (5 psi) to heat

the powder within a sealed reactor. Heating of

the powder is accomplished in a stream of air

that passes across resistively heated elements. As

powder is withdrawn from the bed into the delivery system, additional powder is drawn into the

reactor. This system uses a stand-alone programmable logic controller (PLC) controller to heat

the powder, die, and powder shuttle. Units are

available that can deliver powder up to 3.5

kg/min (8 lb/min) and 3.5 to 9 kg/min (8 to 20

lb/min). The TPP 300 is portable and can be

adapted to any press. These units have no moving parts, thus minimizing maintenance.

The Slotheater uses the principle of direct contact of the powder with the heated surfaces of an

oil-filled slotted heat exchanger (Ref 4). The

powder flows via gravity from the press feeder

hopper into the slot heater where it is heated and

then flows into the powder delivery system. The

temperature of the heated oil is controlled to a

temperature approximately 4 °C (7 °F) hotter

than the desired temperature of the powder. To

achieve uniform temperature of the powder, the

residence time of the powder in the heater must

be at least 5 min. Commercial units are available

that can deliver 3.5 kg/min (8 lb/min) of hot

powder. However, the design is scalable to

achieve up to 9 kg/min (20 lb/min).

Considerable attention has been given to the

actual mechanism of heating the powder; however, attention must also be given to the powder

shuttle system. Although no commercial systems

exist, it is a relatively easy task to design and

build a hot powder feed shoe. Heating of the

feed shoe is accomplished by embedding car-

tridge heaters and a thermocouple in the aluminum feed shoe. Temperature control of the feed

shoe is necessary to prevent any heat loss during

the residence time of the powder in the shoe.

Both a closed shoe and an open shoe have been

successfully used. Unlike conventional powder

shoes, the amount of powder in the feed shoe is

critical. Excessive amounts of powder in the feed

result in a long residence time within the feed

shoe, possibly resulting in a temperature drop

causing excessive part-to-part weight variations.

~

~/

i

0.3

02

i

t~

--

0

-0.2

-03

Conventional

~

6.8

_ _ Sintered dimensional change _

6.9

7.0

I

7.1

I

7.2

I

7.3

7.4

Density, g/cm 3

Tooling Design for

Warm Compaction

[::|o.R

V

Green expansion and sintered dimensional

change of warm-compacted material relative to

conventional compaction techniques

~n~

The tooling design for warm compaction is

essentially the same as for regular compaction

with typical radial tooling clearance of 0.01 to

0.02 mm (0.0004 to 0.0008 in.). The choice of

carbide inserts or tool steel inserts is not critical.

Carbide inserts have proven to be successful;

however, the designer is cautioned that additional interference fits are required to compensate for the differential thermal expansion of the

carbide insert compared to the steel stress ring.

One word of caution in the design of tooling is

the stress involved during the compaction to

near-pore-free densities. As the density increases, the tooling loads increase rapidly. This

increase in tooling pressure necessitates that

thicker stress rings be used and the allowances

made for the greater tool deflections. Shown in

Fig. 8 is the green expansion as a function of the

green density Of powder compacts compacted

using both conventional room-temperature compaction in addition to warm-compaction conditions. Note that the green expansion at equivalent density is lower for the warm-compacted

material. The rationale for the lower green expansion for the warm compacted material is explained by the fact that lower compacting pressure was required to achieve this same density;

thus the tooling load was decreased. However, as

the green density increases to near-pore-free

density, the green expansion increases dramatically. With this increased density, the tooling

loads increase, resulting in greater expansion of

the part.

This increased green expansion can cause microlaminations in the compacted part. These microlaminations are serious problems because

they reduce the structural integrity of the sintered component. In multilevel parts, these microlaminations usually occur at the transition

from one level to another. Incorporating toppunch hold-down during the ejection cycle often

prevents these cracks from occurring. However,

even top-ptmch hold-down is not sufficient to

prevent microcracking if the density of the part

exceeds 98% of the theoretical density.

part variability of the warm-compaction process

is equivalent to conventional compaction (Ref

10, 19, 20). Equal press speeds were achieved

with the warm-compaction process compared to

conventional compaction. The limiting feature in

part production is the rated capacity of the powder heating system and the part weight. Although conventional compacting presses are

used, attention must be given to prevent the heat

generated in the tooling from reaching critical

bearing components. Cincinnati Inc. recommends that stainless steel adapter plates be used

to minimize the flow of heat to the critical components (Ref 18). Additionally, incorporating an

air gap between the die body and die pot within

the press minimizes the transfer of heat.

Part Processing Considerations

Because warm compaction is a single-press

and single-sinter process, the process is ideal for

complex multilevel P/M parts that require high

mechanical properties that cannot be obtained at

Studies conducted by Hoeganaes, Presmet,

QMP, and others demonstrated that the part-to-

Effects of Prolonged Time at Temperature

and Regrinding of Green Parts. Laboratory

testing performed by Hoeganaes demonstrated

that binder-treated powder can be reheated to

warm-compaction temperatures a maximum of 4

cycles with minimal loss of powder flow and

compressibility (Ref 4). Additionally, the powder can be held at temperature up to 4 h with no

degradation of the apparent density, flow, green

density, and green strength.

Although powder metallurgy is considered a

low-scrap manufacturing process, nonusable

parts are generated during the setup stage. To

address this issue of potential green scrap, laboratory work was initiated at Hoeganaes Corporation to study the effects of adding reground

warm-compacted powder into new premixes.

This work demonstrated that additions up to 5%

regrind can be successfully compacted without

any degradation in the strength or flow characteristics of the premix. Although it is not recommended that regrind additions be made to critical

components, this work demonstrated that additions can be made without any loss in powder or

sintered properties.

Potential Applications

of Warm Compaction

380 / Shaping and Consolidation Technologies

REFERENCES

Table 6 Density and processcomparison between warm and cold compaction

Base

powder

Graphite

Distaloy AE(a)

0.5%

Distaloy DC(b)

0.5%

DistaloyAE

0.8%

Lubricant

0.7% Kenolube

0.6% Densmix

0.6% Kenolube

0.6% Densmix

0.6% Kenolube

0.6% Densmix

0.6%Kenolube

0.6% Densmix

Compaction

Sintered

density, g/cm3

Simermg

600 MPa cold compaction

600MPa warm compaction

650 MPa cold compaction

500 MPa warm compaction

650 MPa cold compaction

500 MPa warm compaction

600+500MPacoldcompacdon

(DPDS)(c)

700 MPa warm compaction

1120 °C, 30 rain, Endogas

1120 °C, 30 min, Endogas

1120 °C, 30 rain, 90% N2/10% H2

1120 °C, 30 min, N2/10% H2

1120 °C, 30 rain, 90% N2/10% H2

1120 °C, 30 min, 90% N2/10% H2

750+1120°C,20+30min,

90% N2/10% 1-12

1120 °C, 30 rain, 90% N2/10% H2

7.07

7.31

7.1

7.1

7.1

7.1

7.3

7.3

(a) Distaloy AE is a diffusion bonded powder utilizing pure iron with 4.0% Ni, 1.5% Cu, and 0.5% Mo. (b) Distaloy DC is a diffusion bonded powder utilizing a prealloy 1.50% Mo powder with 2.0% Ni. (c) DPDS, double-press double sinter. Source: Ref

21

Table 7 Comparisonof warm-compacted materials to selectedwrought and cast alloys

Material

Ylekl

areagth

....MPa

AIS11020

AIS11050

AIS18620

AIS18620 Heat treat

Ductile iron 120-90-02

Powder forged F-0005

Powder forged FL-4605

FLN-4205 at 7.39 g/cm3

FIMM05 at 733 g/cm 3

7.80

7.60

345

427

358

1390

860

765

1172

1220

938

~

MPa

50

62

52

202

125

111

170

177

136

440

745

635

1482

965

827

1455

1503

1248

Warm comp~ed turbinehub

7.40

7.20

~b 7 00 -

::t

6.00 '

0

Conventionallycompactedturbine hub

'

'

10

'

20

Y,

30

'

40

'

50

Distance along spllnefrom bottom,mm

60

Fig. 9

Variation in sintered density and dimensional

change of turbine hub processed by conventional

P/M and warm compaction

conventional compaction densities. Higher density (or equivalent density at lower compaction

pressures) can be achieved with warm compaction as compared with cold compaction (Table

6).

Recent articles have demonstrated the usefulness of the warm-compaction process in the fabrication of an automotive turbine hub for highperformance engines (part weight 1100 g), the

manufacture of helical gears with gear densities

in excess of 7.3 g/cm,3 lock components (part

weight 27 g), and gearing with complex gear

forms or spiral gears requiring high gear densities (Ref 22-24). The current production parts

made by warm compaction are parts with a complex shape that are not adaptable for double

pressing and double sintering. Warm compaction

offers a simplified manufacturing process with

Tensile

strength

I~

64

108

92

215

140

120

211

218

181

Eiongatiaa,

%

35

20

26

10

2

10

9.5

1.9

1.7

hardness

77 HRB

96 HRB

90 HRB

45 HRC

36 HRC

27 HRC

47 HRC

42 HRC

41 HRC

resulting mechanical properties that met or surpassed the part specification.

Mechanical properties of warm-compacted steel

powders were compared to selected wrought and

forged alloys (see Table 7). Note that the yield

and tensile strengths of the warm-compacted alloys were equivalent to those of wrought alloys.

Thus it would seem that components made from

these alloys are suitable candidates for the

warm-compaction process. It must be noted that

the elongation of the P/M materials is significantly lower than the wrought alloys chosen (except for the heat-treated ductile iron). Thus,

proper application of the warm-compaction

process must consider the reduced elongation

and impact energy of the P/M part.

One significant advantage of the warm-compaction process is the increased density uniformity achieved in the compacted part (Ref 22, 23).

Quantitative metallographic techniques demonslrated this feature in both a helical gear and an

automotive turbine hub. Figure 9 demonstrates the

greater uniformity of sintered density achieved

with a turbine hub compared to a conventionally

compacted part. This enhanced density uniformity results in increased load-carrying capacity

with reduced dimensional variations because of

the uniform density.

Future applications of the warm-compaction

process will exploit the ability to achieve higher

green densities at lower compaction pressures,

thus minimizing the tooling stresses. Additionally, with the increased interest in the sinterhardening process, warm compaction offers the

potential to green machine these components

prior to sintering and subsequent hardening.

1. G.E Bocchini, The Warm Compaction Process: Basics, Advantages, and Limitations, Society of Automotive Engineers, 1998

2. H.G. Rutz and EG. Hanejko, High Density

Processing of High Performance Ferrous Materials, Advances in Powder Metallurgy and

Particulate Materials--1994, Vol 5, Metal

Powder Industries Federation, 1994, p 117133

3. E Chagnon and Y. Tmdel, Effect of Compaction Temperature on the Sintered Properties of

High Density P/M Materials, Advances in

Powder Metallurgy and Particulate Materials-1995, Vol 2, Part 5, Metal Powders Industries Federation, 1995, p 106-126

4. U. Engstrom, B. Johansson, H. Rutz, F. Hanejko, and S. Luk, High Density Materials for

Future Applications, Advances in Powder Metallurgy and Particulate Materials--1995, Vol

3, Part 11, Metal Powders Industries Federation, 1995, p 106--126

5. M. Gagne, "Behavior of Powder Mix Constituents During Cold and Warm Compaction"

presented at the 1997 International Conference

on Powder Metallurgy & Particulate Materials,

29 June to 2 July 1997, Chicago, IL

6. H.G. Rutz and T.M. Cimino, Advanced Properties of High Density Ferrous Powder Metallurgy Materials, A d v a n c e s in Powder

Metallurgy and Particulate Materials--1995,

Vol 3, Part 10, Metal Powders Induslries Federation, 1995, p 97-117

7. S. Luk, H. Rutz, and M. Lutz, Properties of

High Density Ferrous P/M Materials--A

Study of Various Processes, Advances in Powder Metallurgy and Particulate Materials-1994, Vol 5, Metal Powder Industries

Federation, 1994, p 135-155

8. H.G. Rutz, T. Murphy, and T. Cimino, The

Effect of Microstructure on Fatigue Properties

of High Density Ferrous P/M Materials, Advances in Powder Metallurgy and Particulate

Materials--1996, Vol 13, Metal Powder Industries Federation, 1996, p 375-390

9. R. O'Bfien, "Fatigue Prolxxfies of P/M Materials" Technical Data, Hoeganaes Corporation,

1988

10. I. Donaldson and E Hanejko, An Investigation

into the Effects of Processing Methods on the

Mechanical Characteristics of High Performance Ferrous P/M Materials, Advances in

Powder Metallurgy and Particulate Materials-1995, Vol 5, Metal Powder Industries

Federation, 1995, p 51-69

11. S.R. Sun and K. Couchman, Repressing of

Warm Compacted Materials, Advances in

Powder Metallurgy and Particulate Materials-1996, Vol 5, Metal Powder Induslries

Federation, 1996, p 109-125

12. I. Donaldson, An Evaluation of High Performance Materials Processed Using Warm Compaction Technology, Advances in Powder

Metallurgy and Particulate Materials--1996,

Vol 5, Metal Powder Industries Federation,

1996, p 235-246

Warm Compaction / 381

13. U. Engstrom, B. Johansson, and O. Jacobson,

"Properties and Tolerances of Warm Compacted PM Materials" presented at Euro '95

(Birmingham), Oct 1995

14. T. Cimino and S.H. Luk, Machinability Evaluation of Selected High Green Strength P/M

Materials, Advances in Powder Metallurgy and

Particulate Materials 1995, Vol 2, Part 8,

Metal Powders Industries Federation, 1995, p

129-149

15. C.G. Oliver and H.G. Rutz, Powder Metallurgy

in Electromagnetic Applications, Advances in

Powder Metallurgy and Particulate Materials-1995, Vol 3, Part 11, Metal Powders Industries Federation, 1995, p 87-106

16. S. Pelletier, L.P. Lefebvre, and C. Gelinas,

Resin Impregnation of Soft Magnetic Materials for Low Frequency Applications, presented

at the 1997 International Conference on Powder Metallurgy and Particulate Materials (Chicago, IL), 29 June to 2 July 1997

17. D.E. Gay, Higher Performance Microencapsulated Powders for Various P/M Applications,

Advances in Powder Metallurgy and Particulate Materials--1995, Vol 3, Part 11, Metal

Powders Industries Federation, 1995, p 103117

18. R. Unkel, Additional Applications of Cincinnati EL-TempTM,Advances in Powder Metallurgy and Particulate Materials--1995, Vol 2,

Metal Powders Industries Federation, 1995, p

3-11

19. S. St.-Laurent and F. Chagnon, "Designing

Robust Powders Mixes for Warm Compaction," presented at the 1997 International

Conference on Powder Metallurgy and Particulate Materials (Chicago, IL), 29 June to 2

July 1997

20. E Hanejko, H.G. Rutz, U. Engstrom, and B.

Johansson, Properties of Diffusion Bonded Alloys Processed to High Densities, Advances in

Powder Metallurgy and Particulate Materi-

21.

22.

23.

24.

als--1995, Vol 3, Part 10, Metal Powders Industries Federation, 1995, p 77-97

O. Mars and U. Engstrfrn, Warm Compaction

and Its Influence on the Dynamic Properties of

Sintered Steels, Powder Metallurgy in Automotive Applications, P. Ramarlaishnan, Ed., Science Publishers Inc., 1998, p 147-155

J. Chemlar, B. Nelson, H. Rutz, M. Lutz, and

J. Porter, An Evaluation of the ANCORDENSE Single Compaction Process and

HPP Processing Technique on Fine Pitched

Spur and Helical Gears, Advances in Powder

Metallurgy and Particulate Materials-1994, Vol 5, Metal Powder Industries Federation, 1994, p 73-89

T. Miller and E Hanejko, "Development of a

Warm Compacted Automatic Transmission

Torque Converter Hub" Paper 970428, Society of Automotive Engineers

Advertising Literature on W~a'rn Compaction,

Porite Taiwan Company, LTD