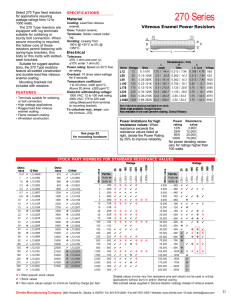

OX/OY Series

advertisement

OX/OY Series Ceramic Composition 10% Tolerance F e at u r e s The OX/OY Series of fixed ceramic resistors are ideal for circuitry associated with surges, high peak power or high energy. They offer enhanced performance in high voltage power supplies, R-C snubber circuits, and inrush limiters. The OX/ OY resistors can often replace carbon composition resistors which can be difficult to source. •Replaces 1 and 2 watt carbon composition resistors •Meets high energy density demands •High peak power •10% Tolerance S ER I E S S P E C I F I C AT I O N S Series OX OY Watts max.* 1 2 * at 70°C. **For a single impulse. Resistance range 3.3Ω-100K 3.3Ω-1M Joules max.** 50 80 Max. working volts 300 400 c h a r a c t e r i t ics Terminals Pb-free solder-coated axial Test Condition Coating Silicone ceramic Life Test MIL-STD-202, Method 108 Derating Linear from 100% @ +70°C to 0% @ +200°C Resistance to 700V Max Overload Voltage 600V 800V Max Pulse Voltage1 14KV 20KV 0.80% 0.40% 1 Kohm 0.20% 100 ohms 0.00% figures 0 0.80% 1 sec. on / 1 sec. off 1000 pF 100 1,000 Cycles 14KV and 20KV values used in circuit as shown; full voltage R.U.T. not applied directly to resistor. 10,000 20,000 DC 14KV see circuit for test conditions OX Series 0.60% �R/R 10 kohm Max. Pulse Voltage ±5% 10 Kohms Pulse Tolerance, 1240V @ 52µF, 1640V @ 52µF, 70J/35 sec. 100 pulses 40J/ 35 sec. 1See ±(2% ±0.05Ω) DC 20KV see circuit for test conditions OY Series 0.60% �R/R Dielectric Strength 500V ±5% Resistance to Pulse OY 400V ±(2% +0.05Ω) 20,000 cycles. See circuit for test conditions Moisture Resistance 1000 hrs @ 40°C, 90 - 95% RH Power Rating Based on 70°C free air rating Max Working Voltage 300V Pulse1 Thermal Shock MIL-STD-202, Method 107 Tolerance ±10% standard Temperature -1300 ±300ppm/°C. Coefficient ±5% Short Time Overload 2x rated V, 5 sec ON @ 70°C Operating Temp. -40°C to +220°C Range OX Maximum ∆R 10 Kohms 0.40% 0.20% 0.00% 1 Kohm 100 ohms 0 100 1,000 Cycles 10,000 20,000 (continued) 56 1-866-9-OHMITE • Int’l 1-847-258-0300 • Fax 1-847-574-7522 • www.ohmite.com • info@ohmite.com OX/OY Series Ceramic Composition 10% Tolerance D I ME N S I O N S in./mm 1.50" ±.118 38.0mm ±3* L *approx. 27mm for taped & reeled units 13" 6.2mm ±.5 63mm ±1 3" 2.88" Length C max. 0.65 / 16.5 OY 2.5mm max. C Length L Series ±.039 (±1.0) OX Tape and Reel Dimensions 0.031" nom. (0.8mm) D 0.748 / 19.0 Diameter D ±.039 (±1.0) 0.748 / 19.0 0.217 / 5.5 0.886 / 22.5 0.276 / 7.0 Qty. per reel 10.16mm ±.80 1000 0.80mm max. 500 L1 ø 1.13" L2 L1 – L2 = 1mm max. o r d e r in g info r m a t ion RoHS Compliant Packaging TR = tape & reel B = bulk O X 8 2 G K E -TR Size Tolerance Ohm Value OX = 1W Example: K = 10% Standard OY = 2W 33G = 3.3 Ohms 330 = 33 Ohms 331 = 330 Ohms 1-866-9-OHMITE • Int’l 1-847-258-0300 • Fax 1-847-574-7522 • www.ohmite.com • info@ohmite.com 57 2 OY– 120000 150000 180000 220000 270000 330000 390000 470000 560000 680000 820000 1 MEG Wattage 1 Part No. Prefix Suffix OX– Ohmic value 2 ––153KE ––183KE ––223KE ––273KE ––333KE ––393KE ––473KE ––563KE ––683KE ––823KE ––104KE 1 15000 18000 22000 27000 33000 39000 47000 56000 68000 82000 100000 Wattage OY– Part No. Prefix Suffix OX– Ohmic value ––182KE ––222KE ––272KE ––332KE ––392KE ––472KE ––562KE ––682KE ––822KE ––103KE ––123KE 2 1800 2200 2700 3300 3900 4700 5600 6800 8200 10000 12000 OY– 1 OX– Ohmic value ––221KE ––271KE ––331KE ––391KE ––471KE ––561KE ––681KE ––821KE ––102KE ––122KE ––152KE 2 220 270 330 390 470 560 680 820 1000 1200 1500 1 OY– OX– 2 Ohmic value 1 Ohmic value OY– 2 OY– ––270KE ––330KE ––390KE ––470KE ––560KE ––680KE ––820KE ––101KE ––121KE ––151KE ––181KE OX– 1 OX– 27 33 39 47 56 68 82 100 120 150 180 Wattage ––124KE ––154KE ––184KE ––224KE ––274KE ––334KE ––394KE ––474KE ––564KE ––684KE ––824KE ––105KE Part No. Prefix Suffix Wattage Part No. Prefix Suffix ––33GKE ––39GKE ––47GKE ––56GKE ––68GKE ––82GKE ––100KE ––120KE ––150KE ––180KE ––220KE Wattage 3.3 3.9 4.7 5.6 6.8 8.2 10 12 15 18 22 Part No. Prefix Suffix Wattage Part No. Prefix Suffix Ohmic value Standard part numbers for OX/OY Series