Developability Assessment Supporting Drug

advertisement

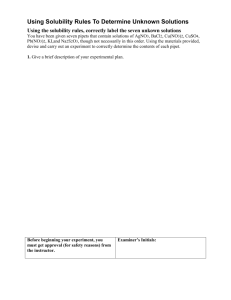

Developability Assessment Supporting Drug Candidate Selection Wei-Qin (Tony) Tong, Ph.D. Novartis Pharmaceuticals Corporation Integrated Drug Product Development Process (3 day-course), University of Utah July 17-19, 2006 Introduction n New Trends and Challenges in Drug R&D: – Business Challenges n n n n – Patent expirations Mounting cost of drug development Generic competition Price controls Scientific Challenges n n n Combinatorial chemistry and high-throughput screening result in many more hits and more development candidates Properties of NCEs become less favorable for development Success rate in clinical studies continue to be low Introduction How to Maximize efficiency and minimize risks? – To profile biopharmaceutical and pharmaceutical properties early in the discovery process so that n certain desirable properties can be incorporate into molecule design n lead compounds that are most likely to survive in the pipeline can be selected n development risks can be identified early Key Developability Criteria n Solubility – – as related to bioavailability for oral dosage form for solution formulations Stability n Solid State Properties n Biopharmaceutical Properties n Solubility n Why is solubility so important? n How do the solid state properties impact solubility? n How do we ensure quality of the solubility data supporting intended decision-making? Drug has to be in solution to be absorbed Disintegration Deaggregation Granules or aggregates Tablet or capsule Dissolution Dissolution Fine Particle Dissolution Precipitation Drug in solution Absorption Dissolution Systemic circulation – – Dissolution rate limited absorption Solubility limited absorption Fine fine particle Formulation Challenges with Poorly Soluble Compounds – Poor dissolution rate – Low and variable bioavailability – More potential for food effect – Inability to deliver high doses for tox studies – Difficulty in developing parenteral formulations Solubility Criteria: how soluble is soluble enough? – Dependent on Dose and Permeability n Dissolution Time n Maximum Absorbable Dose (MAD): S (mg/mL) x Ka (/min) x SIWV (mL) x SITT (min) – Biopharmaceutical Classification Minimum Acceptable Solubility Solubility (µ g/ml) 10000 1000 207 100 21 21 10 1 55 207 52 5 10 2 10 2100 2100 520 520 100 100 Med Pe § Low Pe 11 0.1 0.1 1 High Pe 10 Projected Dose in mg/kg Factors Causing Poor Solubility n High crystallinity/high MP – – – n Zwitterion formation Insoluble salts H-bonding networks Hydrophobicity/High LogP – – Lack of ionizable groups High molecular weight Effect of Solid State Form Amorphous vs. crystalline – n Differences could be > 1000x Polymorphs Solubility (mcg/mL) n 1200 1000 800 600 400 200 0 1 2 3 4 5 6 7 8 Equilibration Time (Days) 9 Examples n Comparison of apparent solubility of amorphous material (A) and crystalline material (C): Solute Caffeine Theophylline Morphine Hydrochlorthiazide Sulfamethoxydiazine Melting Point Solubility Ratio (A/C) (°C) 238 5 272 50 197 270 273 1.1 215 1.5 •S. Yalkowsky, Solubility and Solubilization in Aqueous Media, American Chemical Society, Washington D.C. (1999). Examples n Comparison of apparent solubility of polymorphs: Solute Acemetacin Cyclopenthiazide Mebendazole Spironolactone ∆ Melting Point (°C) 20 70 41 57 30 70 05 10 Solubility Ratio (L/H) 2.3 4.7 2 3.6 3.6 7.4 1.2 1.9 •S. Yalkowsky, Solubility and Solubilization in Aqueous Media, American Chemical Society, Washington D.C. (1999). Issues with kinetic solubility n Solubility data are time-dependent! n Dissolving material in organic solvents does not necessarily normalize the effect of crystal form. n It is difficult to predict whether significant differences are expected between non-equilibrium and equilibrium solubility data. Correlation between equilibrium solubility and kinetic solubility Compound Solubility (mcg/mL) From solid From DMSO From by HPLC soln by HPLC nephelometry Benzthiazide 11 20 27 Progesterone 6 15 20 Butylparaben 139 88 97 Betamethasone 63 > 196 > 196 Oxyphenbutanzone > 500 <1 40 Phenyl salicylate 16 <1 > 107 Propylparaben 273 89 > 89 •C. Bevan and R. Lloyd, Anal. Chem. 72:1781-1787 (2000). Structure-Solubility Correlations n Only equilibrium solubility is considered as the intrinsic property of a particular molecule. n Both intrinsic solubility of the unionized form and pKa should be considered. n Building correlation within the same structure series Structure-Bioavailability Correlations n n Bioavailability is formulation dependent! Formulation strategies for better structurebioavailability correlation – – n pH adjusted solution (in situ salt) Lipid based formulation Dissolution rate vs. equilibrium solubility: – equilibrium solubility is still important Solubility Study Strategies n Formulation development for discovery compounds: – – n Lead Optimization: – – – n Visual observation method is typically sufficient In vitro dilution studies can be very useful Computational alert/in silico profiling Identify if solubility is a contributor to poor absorption through carefully designed PK studies Equilibrium solubility determination of representative lead compounds with significant structure changes: e.g. MW and pKa changes Candidate Evaluation/Selection: – Miniaturized preformulation studies including salt screening Throughput Considerations n Can equilibrium solubility determination be high throughput? – – – – n Time required for equilibration Automation possibility and challenges Importance of checking residual solid of solubility samples Do we need automation or high throughput? Does high throughput really add value? – – – Careful studying of representative lead compounds vs. massive screening Experimental measurement vs. solubility prediction Most compounds with MW>500 and without any ionizable group or with ionizable group but have poor solubility Stability How do the solid state properties impact stability? n How does solution stability impact solid dosage form development? n How do we ensure quality of the stability data supporting intended decision-making? n Impact on Chemical Stability n n n n Amorphous material is typically less stable than crystalline material Higher melting point typically results in better stability Hygroscopicity also plays an important role Example: – – NCEX: 2 forms (160ºC and 140ºC) % degradation observed after 4 weeks at 40ºC/75%RH n n n Form 1: 0.3% Form 2: 6% Amorphous: 20% Physical Stability n Amorphous Material/Solid Dispersion n n n n Tg and mobility Effect of moisture on Tg Solid solubility Hydrates/solvates n n Effect of processing Impact on chemical stability and bioavailability Stability Screening Strategies n Formulation development for discovery compounds: – n Lead optimization: – – – – n Need for stability data depends on stages Structure analysis Stability in SGF and SIF Stability screening of key lead compounds in each structure series Identify the degradation mechanism and define the screening method Candidate evaluation and selection – Miniaturized preformulation studies including salt screening Solid State Properties Bioavailability (solubility/dissolution rate) n Stability (physical and chemical) n Processing Factors n n n n n Hygroscopicity Bulk, mechanical, and rheological properties Ease of isolation, filtration, and drying Degree of purification Risk Assessment Related to Crystal Form Issues n The Fundamental Question: – What will be the consequence should a new thermodynamically more stable form is discovered? n n High risk if this could lead to significant delay in the overall project timeline or product failure Low risk if impact on timeline and resources are minimum High Risk Compounds n n Poorly soluble compounds as defined by the FDA biopharmaceutical classification system Compounds that would require one of the non-equilibrium methods or semi-solid/liquid formulations to enhance dissolution rate/ bioavailability n n n n n amorphous meta-stable polymorphs solid dispersion lipid based formulations Compounds with parenteral formulations formulated close to equilibrium solubilities at given temperature Phase Appropriate Screening n Lead Optimization Stage – Monitor solid state form by microscopic examination (and DSC if possible) – Small scale limited crystal form screening as needed – In situ salt screening as needed – Potential impact n pharmacokinetics (PK) results n in vivo efficacy studies n solubility results Phase Appropriate Screening n Candidate Evaluation/Selection Stage – Risk assessment for crystal form issue – Continue monitoring the key properties of new batches of drug substance – Preliminary screening followed by comprehensive screenings for salt and polymorphs – Identify or finalize the “most” desirable salt and form for further development prior to GLP tox High Throughput Salt and Crystal Form Screening n Automation of manual steps and enhancement in data handling ability: – – – n n n not a solution for all Still require intellectual input Broader crystallization space but not possible to cover all What about time for crystallization and combination of various methods? Analytical methods consideration Drug substance requirement: quantity and purity Conclusion n n n n Solid state properties have profound impact on solubility and stability. This impact should be taken into account in designing solubility and stability experiments and assessing developability of drug candidates. Phase appropriate characterization strategies to address solid state related issues should balance the need of speed and throughput with the quality of data. Careful planning and a clear decision making process are key for ensuring doing the right work at the right time for ensuring developability. Case Study 1: Solubility in Lead Optimization n Compound A: – R''' Structures: ''R N R'''' 'R – – – – n N Amorphous material: solubility in the range of 0.5-1 mg/mL Poor metabolic stability Moderate permeability poor bioavailability (from aqueous solution) Key Question: should we improve solubility as part of the chemistry effort to improve PK? Case Study 1 -Continued n Strategy: – – Structure analysis: Benzimidazole plane type structure can result in high crystallinity, so will the crystalline material have low solubility? Crystalline material n n – High melting Solubility in SIF (fasted): ~ 0.001 mg/mL Recommendation: Improving solubility as well as metabolic stability n n Addition of ionizable group (improving pKa) Disruption of the plane structure Case Study 1 -Continued n Strategy: – – – n Monitor solid state form and conduct micro-scale screening Using in-situly prepared salt to maximize exposure in the efficacy studies Determine equilibrium solubility of crystalline material and only use equilibrium solubility together with DSC results for structuresolubility correlation Result: Bioavailability in rat improved from 2-5% to 40% Case Study 2: Impact of Formulation on Bioavailability n Compound B: – Basic properties: n n n – Solubility: n n n n – Weak acid with pKa ~ 4.0 Melting point of form 1: ~ 170ºC Permeability: moderate Phosphate buffer (pH 7.4): < 0.001 mg/mL SGF (pH 1.2): < 0.001 mg/mL Ph 6.4-6.8 FaSSiF: ~ 0.03 mg/mL Estimated clinical dose: 1-10 mg/mL Bioavailability in rat: n n Suspension of free acid (micronized form 1): ~ 15% Solution in NaOH (in situ Na salt): ~ 85% Case Study 3: Candidate Evaluation and Selection Phase – Salt and Crystal Form Screening n Compound C: – – – n n Containing a group that can undergo acid catalyzed hydrolysis T1/2 in 0.1 M HCl: < 30 min Solubility in 0.1M HCl: < 0.001 mg/mL Key Question: Strategies: – Small scale crystal form screening n n – – – – n should we improve stability as part of the chemistry effort? Form I: very fine needle with MP of 160C (Form I) Form II: MP of 140C Stability (40/75%RH for 4 weeks) Amorphous 20% degradation Form I: 0.3% Form II: 6% Decision: Include stability enhancement as part of lead optimization whenever possible n Results: candidate with significantly enhanced stability identified. ACKNOWLEDGMENT n Johnson and Johnson: – n GlaxoSmithkline: – – – – n Om Dhingra Graham Whitesell Richard Winnike Joel Sutton University of Iowa – n Lian F. Huang Keith Guillory Novartis: – – – – Abu Serajuddin Madhu Pudipuddi Yatindra Joshi Alan Royce