Dolphon XL

advertisement

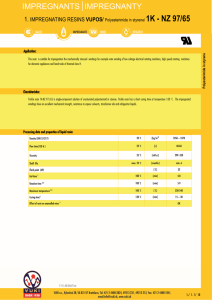

IMPREGNANTS 1K Resin Dolphon® XL-2102 OPT ® Description Dolphon XL-2102 OPT is a transparent, low emission, 1K resin based on polyester. Properties Dolphon XL -2102 OPT is characterised by the following properties when in a liquid state: ® - low viscosity - high reactivity - low odour, low emissions - no MAK value - good storage stability - very short curing time at 150 °C - excellent penetration in the winding Cured Dolphon® XL-2102 OPT is a material with the following exceptional properties: - very good bond strength combined with flexibility - high dynamic load capacity Application Dolphon® XL-2102 OPT is a trickle resin which due to its storage stability can also be used as a fast curing dip resin. It is a proven product for the trickle impregnation of sophisticated electric motor rotors and stators, as well as larger objects, such as large-scale coils. It also provides numerous advantages when impregnating small transformers during full capacity production. Standards UL approved class H (180 °C), file no. E 51047 UL system approved from 130 °C - 220 °C RoHS compliant according to 2002/95 EC UL approved: With enamelled Cu wire: MW 35: 180 Temperature class according to UL 1446 Twisted pair ASTM D2307 Electrical insulation systems according to UL 1446 E 247773 class 130, 155, 180 Dolphon® is a registered trademark of John C. Dolph Company The information on this data sheet is based on the information provided by our supplier. It is offered for service purposes and addressed to experts who use it at their own discretion and at their own risk. We do not guarantee results, or accept liability for the indicated specifications or for results obtained based on the specifications. Updated 02/08 IMPREGNANTS 1K Resin Dolphon® XL-2102 OPT Processing ® Due to its low viscosity, low emission Dolphon XL-2102 OPT can be processed in existing trickle plants without heated pipes and, in general, without process changes. Exemplary impregnating process suggestion: 1. Pre-heat the object to approx. 120 °C. 2. Trickle impregnate the rotating, inclined object for 4 min. 3. Cure at 150 °C for 0.5 to 1 hour (measured once the object temperature has been reached) in the closed oven. 4. Optional slightly forced cooling in the exhaust air flow Vacuum (pressure) impregnating is possible. Curing Curing occurs via the Joule heat or in the closed oven. During curing processes in the drying oven, the fresh air supply should be reduced to the lowest possible level for safety reasons. The curing time commences once the object temperature has been reached. Typical curing times: at 150 °C at 140 °C at 130 °C Cleaning the tools 0.5 - 1 h 1-2h 2-4h Since the cured trickle and dip resin is practically insoluble, the tools have to be cleaned as soon as possible with a suitable solvent. Maintenance and care of impregnating plants, especially cleaning, must be carried out according to operational requirements. Always refer to the user manual of the plant. Dolphon® is a registered trademark of John C. Dolph Company The information on this data sheet is based on the information provided by our supplier. It is offered for service purposes and addressed to experts who use it at their own discretion and at their own risk. We do not guarantee results, or accept liability for the indicated specifications or for results obtained based on the specifications. Updated 02/08 IMPREGNANTS 1K Resin Dolphon® XL-2102 OPT Storage ® Dolphon XL -2102 OPT can be stored for 12 months at room temperature in a sealed container (max. 30 °C). The trickle and dip resin must be stored in a suitable place and protected against direct sunlight, UV radiation and sources of heat. Always observe general rules and regulations. The storage life of the dip resin can be extended indefinitely by adding fresh resin during processing. Protective measures Cured Dolphon® XL -2102 OPT is biologically inactive and safe to health. Always refer to the safety data sheet and implement protective measures when processing the liquid trickle and dip resin. Delivery format Dolphon® XL-2102 OPT is delivered in 25 kg disposable containers or in 230 kg barrels. Dolphon® is a registered trademark of John C. Dolph Company The information on this data sheet is based on the information provided by our supplier. It is offered for service purposes and addressed to experts who use it at their own discretion and at their own risk. We do not guarantee results, or accept liability for the indicated specifications or for results obtained based on the specifications. Updated 02/08 IMPREGNANTS 1K Resin Dolphon® XL-2102 OPT Technical data Mechanical Conditions Values Specific density at 25 °C Viscosity Ford Cup 8 at 25 °C 120 - 180 s Gel time at 100 °C 8 - 20 min Weight loss (1 h at 150 °C) Bond strength Helical coil method ASTM D-2519 at 25 °C Helical coil method ASTM D-2519 at 150 °C 1.150 ± 50 g/l < 3.5 % 18 kg 3 kg Electrical Dielectric strength ASTM D - 115 > 3200 V/mm 0.025 Thermal Flashpoint > 130 °C Chemical Reaction with: Copper Copper alloys Natural rubber yes yes yes Dolphon® is a registered trademark of John C. Dolph Company The information on this data sheet is based on the information provided by our supplier. It is offered for service purposes and addressed to experts who use it at their own discretion and at their own risk. We do not guarantee results, or accept liability for the indicated specifications or for results obtained based on the specifications. Updated 02/08