T300 DATA SHEET - Toray Carbon Fibers America

advertisement

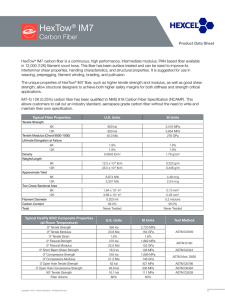

TECHNICAL DATA SHEET No. CFA-001 ® T300 DATA SHEET Baseline carbon fiber used in aerospace applications. Has 30 year production history a n d i s k n o w n f o r i t s b a l a n c e d c o m p o s i t e p r o p e r t i e s , h i g h q u a l i t y, c o n s i s t e n cy, r e l i a b i l i t y a n d s u p p l y a b i l i t y. F I B E R P R O P E R T I E S English Tensile Strength Tensile Modulus Strain Density Filament Diameter Yield 512 33.4 1.5 0.064 2.8E-04 1K 3K 6K 12K Sizing Type & Amount 22,568 7,523 3,761 1,862 Metric ksi Msi % lbs/in 3 in. 3,530 230 1.5 1.76 7 ft/lbs ft/lbs ft/lbs ft/lbs 40A, 40B 40D 50A, 50B 66 198 396 800 TY-030B-01 TY-030B-01 TY-030B-01 TY-030B-02 g/1000m g/1000m g/1000m g/1000m TY-030B-03 TY-030B-03 TY-030B-03 TY-030B-03 TY-030B-05 TY-030B-05 TY-030B-05 Twisted, Untwisted, or Never twisted F U N C T I O N A L P R O P E R T I E S CTE Specific Heat Thermal Conductivity Electric Resistivity Chemical Composition: Carbon Na + K C O M P O S I T E MPa GPa % g/cm 3 µm 1.0 % 0.7 % 1.0 % Twist Test Method -0.41 0.19 0.025 1.7 93 <50 α⋅10 -6 /˚C Cal/g⋅˚C Cal/cm⋅s⋅˚C x 10 -3 Ω⋅cm % ppm P R O P E R T I E S * Tensile Strength Tensile Modulus Tensile Strain 270 ksi 20.0 Msi 1.3 % 1,860 MPa 135 GPa 1.3 % ASTM D-3039 ASTM D-3039 ASTM D-3039 Compressive Strength Flexural Strength Flexural Modulus 215 ksi 260 ksi 18.0 Msi 1,470 MPa 1,810 MPa 125 GPa ASTM D-695 ASTM D-790 ASTM D-790 ILSS 90˚ Tensile Strength 14 ksi 11.0 ksi 10 kgf/mm 2 76 MPa ASTM D-2344 ASTM D-3039 * To r a y 2 5 0 ˚ F E p o x y R e s i n . N o r m a l i z e d t o 6 0 % f i b e r v o l u m e . TORAY CARBON FIBERS AMERICA, INC. T300 C O M P O S I T E P R O P E R T I E S * * Tensile Strength Tensile Modulus Tensile Strain 255 ksi 19.5 Msi 1.3 % 1,760 MPa 130 GPa 1.3 % ASTM D-3039 ASTM D-3039 ASTM D-3039 Compressive Strength Compressive Modulus 230 ksi 18.5 Msi 1,570 MPa 125 GPa ASTM D-695 ASTM D-695 In-Plane Shear Strength ILSS 90˚ Tensile Strength 14 ksi 15.5 ksi 11.5 ksi 98 MPa 11 kgf/mm 2 80 MPa ASTM D-3518 ASTM D-2344 ASTM D-3039 ** Toray Semi-Toughened 350˚F Epoxy Resin. Normalized to 60% fiber volume. See Section 4 for Safety & Handling information. The above properties do not constitute any warranty or guarantee of values. These values are for material selection purposes only. For applications requiring guaranteed values, contact our sales and technical team to establish a material specification document. P A C K A G I N G The table below summarizes the tow sizes, twists, sizing types, and packaging available for standard material. Other bobbin sizes may be available on a limited basis. Tow Sizes Twist1 Sizing Bobbin Net Weight Bobbin Type2 (kg) 1K 3K 6K 12K a b c d e Spools per Case Bobbin Size (mm) Case Net Weight (kg) A 40A, 50A 1.0 I 94 99 320 135 260 15 15 A 40A, 50A 1.0 II 76 82 192 132 156 16 16 B 50B 1.0 II 76 82 192 132 156 16 16 A 40A, 50A 2.0 II 76 82 192 157 156 12 24 B 40B, 50B 2.0 II 76 82 192 157 156 12 24 A 40D, 50A 2.0 II 76 82 192 157 156 12 24 B 40D, 50B 2.0 II 76 82 192 157 156 12 24 A 50A 4.0 II 76 82 192 204 156 6 24 B 50B 4.0 II 76 82 192 204 156 6 24 1 Twist A: Twisted yarn B: Untwisted yarn made from a twisted yarn through an untwisting process 2 Bobbin Type See Diagram below T Y P E TORAY I CARBON T Y P E II FIBERS T Y P E III AMERICA, INC. 6 H u t t o n C e n t r e D r i v e , S u i t e # 1 2 7 0 , S a n t a A n a , C A 9 2 7 0 7 T E L : ( 7 1 4 ) 4 3 1 - 2 3 2 0 FA X : ( 7 1 4 ) 4 2 4 - 0 7 5 0 S a l e s @ To r a y c f a . c o m Te c h n i c a l @ To r a y c f a . c o m w w w . t o r a y u s a . c o m