Evaluation of CHWW_Fresh Alkaline Noodles

advertisement

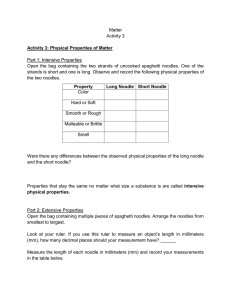

B. X. Fu, E. Assefaw, and L. Malcolmson Canadian International Grains Institute, 1000-303 Main Street, Winnipeg, Manitoba, Canada R3C 3G7 Evaluation of Canada Hard White Wheats for Fresh Alkaline Noodle Processing Fig 1. Noodle Processing and Quality Evaluation Process INTRODUCTION Alkaline noodles are important wheat flour based products in Asia. High quality alkaline noodles should have a bright, clear appearance with few specks, and have a firm and smooth texture. White wheats have an advantage over red wheats in terms of end product appearance especially when they are processed into noodles.The development of hard white wheat in Canada was undertaken to meet market needs, primarily for noodle processing in Asia. In this study, two Canada hard white spring wheat varieties (Kanata and Snowbird) were compared with a composite Canada Western Red Spring (CWRS) wheat for noodle quality in terms of processing properties, dough sheet colour and colour retention properties, and cooked noodle texture. MATERIALS & METHODS Milling A No. 1 CWRS (13.9% protein) composite sample and samples of Canada hard white wheat Kanata (14.5% protein) and Snowbird (14.2% protein) were milled in the CIGI pilot mill to generate straight grade flours and short patent flours of 40% extraction. Noodle Processing The noodle processing and quality evaluation process is shown in Fig. 1. The flours were processed into fresh alkaline noodles using an Ohtake laboratory noodle machine. Salt (NaCl) and alkaline salts (K2CO3:Na2CO3 = 6:4, w/w) dissolved in water were added to flour, with an amount of 1% and 1.3% (based on flour weight), respectively. Constant water absorption of 34% (14% Table 1a: Flour Flour Results Kanata 1 CWRS Protein (%) straight grade 40% extraction Ash content (%) straight grade 40% extraction Grade colour straight grade 40% extraction Snowbird 13.45 12.42 0.450 0.331 -1.2 -3.3 14.12 13.23 0.448 0.334 -0.4 -2.6 13.83 12.65 0.450 0.346 -0.3 -3.1 mb, mass balanced) was used for all flours. Mixing was carried out at 100 rpm for 10 min followed by 15 min of dough resting.The mixture was sheeted with an initial gap setting of 3.5 mm.The resulting dough sheet was folded and sheeted again with the same gap setting. After resting for 30 min, the dough sheet was subjected to four reduction passes (2.5, 1.8, 1.3, and 1.0 mm). A 100 cm long section was cut from the noodle sheet for colour and speck evaluation.The remaining dough was sheeted one more time before cutting.The final gap setting was adjusted for each sample to ensure the resulting noodle strands had a thickness of 1.4 mm. Noodle strands were cut using a No. 10 or No. 20 cutter to produce noodles with a width of 3.0 or 1.5 mm, respectively. Noodle Processing Properties, Appearance and Textural Analysis The size and hand-feel properties of the dough crumb were evaluated after mixing. During the sheeting process, uniformity of hydration, surface smoothness and stickiness of the dough sheet were assessed. A Minolta Chroma Meter CR-310 equipped with a C illuminant using the L*, a*, and b* colour scale was used to measure the colour of the noodle dough sheet.The dough sheet was folded into six layers and stored in a covered container at room temperature (22±1oC) over a 48-hr examination period. Measurements were made at five spots on the dough sheet surface at 3, 24, and 48 hr after mixing was started. The dough sheet was also assessed for brightness and clearness of the background using sensory evaluation. Specks were counted under a magnifier lamp.The size and darkness of the specks were visually evaluated. Noodle strands prepared with the No. 10 cutter were assessed for maximum cutting stress using TA-XT2 Table 2a: Minolta Dough Sheet Colour (lightness) Straight Grade Flour 1 CWRS L* (3h) Table 1b: Farinograph Results* Parameters Absorption (%) Development time (min) Mixing tolerance (B.U.) Stability (min) * Based on straight grade flour 1 CWRS Kanata (24h) 68.0 67.2 6.0 7.5 7.0 9.4 30 13.3 Snowbird 30 11.5 RESULTS Flour Properties Similar protein and ash contents were found among the three wheat samples (Table 1a). Dough strength was also similar, although the flours from the two white wheat cultivars were slightly stronger (Table 1b).These results indicate that this set of samples was comparable for evaluating their noodle processing properties. Noodle Processing Properties Flours milled from 1CWRS, Kanata, and Snowbird all produced a dough crumb with the desired size and hand-feel properties. All noodle sheets had a smooth surface, and showed uniform hydration with little stickiness. However the dough crumbs from the 40% extraction flours were smaller and more uniform in size than from the straight grade flours. Noodle Sheet Appearance Noodle sheets prepared from Snowbird were lighter than the noodle sheets made from CWRS.The noodle sheets made from Kanata were in between the two other samples (Table 2a). Snowbird and CWRS produced noodle sheets that had more yellow colour than Kanata (Table 2b). Noodle dough sheets made Table 3: Sensory Dough Sheet Appearance (background) Straight Grade Flour 1 CWRS Brightness (3h) s. dull (24h) m. dull 1 CWRS Kanata Snowbird 70.17 72.94 74.13 78.76 78.85 79.93 62.21 64.56 67.81 73.89 74.35 76.52 Clearness (3h) s. cloudy (24h) m. cloudy b* (3h) (24h) 40% Extraction Flour 1 CWRS Kanata Snowbird 1 CWRS 27.05 24.60 27.10 26.73 24.48 22.37 25.53 Kanata Snowbird 1 CWRS Kanata Snowbird s. bright m. bright m. bright m. bright v. bright s. dull s. bright s. bright s. bright m. bright 26.46 Kanata 24.20 24.15 Snowbird 26.70 27.13 s. clear m. clear m. clear m. clear v. clear s. cloudy s. clear s. clear s. clear m. clear Table 4: Sensory Dough Sheet Appearance (specks) 40% Extraction Flour Straight Grade Flour Table 2b: Minolta Dough Sheet Colour (yellowness) Straight Grade Flour 40% Extraction Flour from Snowbird straight grade flour maintained their brightness even after 24 hrs of storage at room temperature, while those made from CWRS straight grade flour were dull and cloudy (Table 3).The dough sheets made from the white wheats had fewer, lighter and smaller specks than those made from CWRS (Table 4). As expected, dough sheets made from the 40% extraction flours showed better noodle sheet appearance than from the straight grade flours. Cooked Noodle Texture Noodles made from the two white wheat samples were slightly firmer than noodles prepared from CWRS (Table 5). Sensory results indicated that noodles made from Snowbird were more elastic and smoother than noodles made from CWRS and Kanata, and all flour samples produced noodles with a firmer texture than the commercial noodle flour sample (Table 6). CONCLUSIONS Canada hard white wheat and CWRS samples produced noodle sheets with very smooth surface, uniform hydration, and little stickiness. Noodles made from Snowbird were brighter and clearer in appearance than noodles made with CWRS, especially when straight grade flour was used. Kanata, Snowbird, and CWRS all produced noodles that were firm and chewy. Noodles made from Snowbird were smoother and more elastic than noodles made from Kanata and CWRS. Acknowledgements We would like to acknowledge the Canadian Wheat Board for providing the wheat samples, the assistance of CIGI's Milling Technology and Quality Control group for milling of the wheat and analysis of flour samples.Thanks also to CIGI's Communication group for poster preparation. Table 5: Cooked Noodle Texture (TA - XT2) Max. cutting stress (g/mm2) 40% Extraction Flour Snowbird 68.7 40 Kanata texture analyzer. Noodle samples were evaluated after cooking for 3.5 and 7.0 min. Noodles prepared with the No. 20 cutter were cooked for 2.5 min, and assessed by sensory for firmness, springiness, smoothness, and chewiness using 10 point intensity scales. A commercial alkaline noodle flour from Japan was used as a control sample. 1 CWRS Kanata Snowbird 1 CWRS Kanata Snowbird (3h) 14 2 1 6 1 0 (24h) 44 35 23 19 14 5 (3h) s. small m. small v. small m. small v. small (24h) s. large s. small s. small s. small s. small Darkness (3h) s. light v. light v. light m. light v. light (24h) m. dark s. light s. light s. light s. light Number (cm2) Size m. small m. light Straight Grade Flour 40% Extraction Flour 1 CWRS Kanata Snowbird 1 CWRS 3.5 min 36.0 47.0 39.9 36.4 40.3 37.0 7.0 min 22.2 28.0 25.2 22.7 26.0 24.1 Kanata Snowbird Table 6: Sensory Evaluation of Cooked Noodles Control 1CWRS Kanata Snowbird Firmness Springiness Smoothness 7 9 9 8 7 6 6 7 7 6 6 7 Chewiness 7 8 9 8