Bus bar isolators / -supports

advertisement

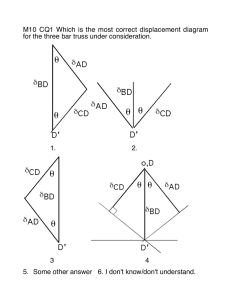

Bus bar isolators / -supports We make energy measurable and take care of your future www.mbs-ag.com MBS AG MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Page 2 Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com MBS AG Spacing isolator Type DB/P Made of Polyglas-polyester material, reinforced with fiberglass, colour red, selfextinguishing. The isolators of type DB are unbreakable and have excellent electrical and mechanical characteristics and can be used under extreme working conditions such as high room temperatures, also when in contact with corrosive substances, vibrations, etc. The hexagon, arranged middle layer with two facing sides, facilitates the connection and locking in place the isolator. Isolator without threaded bolt (Art.no. XXXXX; e.g. 90015): Upon request, the isolators can be supplied as follows: - The isolator can be equipped with a thread which is not standard - The isolator can be supplied with one or two threaded bolts „GB“ Operating temperature: -40 °C up to +130 °C Fire resistance class: UL94-V0 Art.no. Isolator with one threaded bolt (Art.no. XXXXX-1; e.g. 90015-1): Isolator with two threaded bolts (Art.no. XXXXX-2; e.g. 90015-2): Type 90015 DB/P 12 90018 DB/P 12 90022 DB/P 16 90025 DB/P 20 90026 DB/P 20 90028 DB/P 25 90029 DB/P 25 90030 DB/P 25 90033 DB/P 30 90034 DB/P 30 90035 DB/P 34 90036 DB/P 34 90037 DB/P 34 90038 DB/P 35 90039 DB/P 35 90040 DB/P 35 90438 DB/P 40 90439 DB/P 40 90440 DB/P 40 90041 DB/P 45 90042 DB/P 45 90043 DB/P 45 90044 DB/P 45 90046 DB/P 50 90047 DB/P 50 90048 DB/P 50 90441 DB/P 60 90442 DB/P 60 90443 DB/P 60 90050 DB/P 65 90051 DB/P 65 90052 DB/P 65 90053 DB/P 75 90054 DB/P 75 90055 DB/P 75 90057 DB/P 750 90058 DB/P 750 * sw = wrench width H [mm] sw* [mm] D1 [mm] UM [mm] M A [mm] Colour 12 12 16 20 20 25 25 25 30 30 35 35 35 35 35 35 40 40 40 45 45 45 45 50 50 50 60 60 60 63.5 63.5 63.5 76 76 76 75 75 11 11 14 17 17 19 19 19 30 30 32 32 32 41 41 41 40 40 40 41 41 41 41 36 36 36 55 55 55 41 41 41 50 50 50 65 65 10 10 13 15 15 15 15 15 26 26 28 28 28 35 35 35 30 30 30 35 35 35 35 29 29 29 40 40 40 35 35 35 36 36 36 52 52 220 220 380 500 500 600 600 600 600 600 1000 1000 1000 1000 1000 1000 1000 1000 1000 1500 1500 1500 1500 2000 2000 2000 2000 2000 2000 3000 3000 3000 5000 5000 5000 5000 5000 M3 M4 M4 M4 M6 M6 M5 M6 M6 M8 M6 M8 M10 M6 M8 M10 M8 M10 M12 M6 M8 M10 M12 M8 M10 M12 M8 M10 M12 M8 M10 M12 M8 M10 M12 M12 M16 3 3 4 6 6 7 7 7 8 7 9 10 10 9 9 10 11 12 10 12 12 12 12 12 12 13 20 21 20 17 19 19 19 19 19 18 23 black red red red red black red red red red red red red red red red red red red red red red red red red red red red red red red red red red red red red Packaging unit [pcs.] 100 100 100 100 100 250 250 250 80 80 64 64 64 36 36 36 100 100 100 27 27 27 27 36 36 36 25 25 25 22 22 22 12 12 12 8 8 MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com Page 3 MBS AG Type Thread Ripple current resistance [kV] DB/P 16 DB/P 20 DB/P 20 DB/P 25 DB/P 25 DB/P 30 DB/P 30 DB/P 34 DB/P 34 DB/P 34 DB/P 35 DB/P 35 DB/P 45 DB/P 45 DB/P 45 DB/P 45 DB/P 50 DB/P 50 DB/P 50 DB/P 65 DB/P 65 DB/P 65 DB/P 75 DB/P 75 DB/P 75 DB/P 750 DB/P 750 M4 M4 M6 M5 M6 M6 M8 M6 M8 M10 M6 M8 M6 M8 M10 M12 M8 M10 M12 M8 M10 M12 M8 M10 M12 M12 M16 3 4 4 7 7 8 8 10 10 10 10 10 12 12 12 12 12 12 12 15 15 15 25 25 25 25 25 Discharge voltage [kV] Max. tensile load [kN] Max. bending load [kN] 8 15 15 20 20 23 23 30 30 30 30 30 40 40 40 40 40 40 40 40 40 40 50 50 50 50 50 1 1.5 1.5 3 3 5 5 8 8 8 11 11 12 12 12 12 8.5 8.5 8.5 15 15 15 23 23 23 28 28 0.5 0.6 0.6 1.8 1.8 2.5 2.5 4.5 4.5 4.5 8 8 8 8 8 8 4.5 4.5 4.5 7 7 7 9 9 9 15 15 Max. compression load [kN] 5 6 6 21 21 44 44 65 65 65 80 80 80 80 80 80 68 68 68 83 83 83 100 100 100 150 150 Max. starting torque [Nm] 2.8 2.8 8.9 5.1 8.9 8.9 21.5 8.9 21.5 43.0 8.9 21.5 8.9 21.5 43.0 85.0 21.5 43.0 85.0 21.5 43.0 85.0 21.5 43.0 85.0 85.0 180.4 The spacing isolator type DB/P has been tested for isolating material (discharge voltage, discharge strength and arking) according to the regulations covering VDE 0303-21 03/1999 / DIN EN 60243-1 03/1999. Appraisal of the discharge voltage or arking between two unequal electrodes (diameter 25 mm or 75 mm). The test was made for the norm climate 23/50, ambient temperature (23 ±2) °C and (50 ±5) % relative humidity. MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Page 4 Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com MBS AG Short-circuiting resistance of the isolators Type DB/P MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com Page 5 MBS AG Spacing isolator Type CO/P Made of Polyglas-polyester material, reinforced with fiberglass, colour red, selfextinguishing. Upon request the isolators type CO/P, can be supplied with 1 or 2 threaded bolts “GB”, fitted and secured with Loctite. Operating temperature: -40 °C up to +130 °C Fire resistance class: UL94-V0 Art.no. Type H [mm] Sw* [mm] D1 [mm] UM [mm] M A [mm] 16 16 16 16 20 20 20 25 25 25 30 30 30 35 40 40 45 45 50 50 60 60 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 21 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 220 220 220 220 400 400 400 500 500 500 600 600 600 600 600 600 750 750 750 750 750 750 M4 M5 M6 M8 M5 M6 M8 M5 M6 M8 M5 M6 M8 M6 M6 M8 M6 M8 M6 M8 M6 M8 4 4 4 4 5 5 5 6 6 6 7 7 7 7 9 10 9 10 10 10 9 9 90061 CO/P 16 90062 CO/P 16 90063 CO/P 16 90064 CO/P 16 90065 CO/P 20 90066 CO/P 20 90067 CO/P 20 90068 CO/P 25 90069 CO/P 25 90070 CO/P 25 90071 CO/P 30 90072 CO/P 30 90073 CO/P 30 90075 CO/P 35 90077 CO/P 40 90078 CO/P 40 90079 CO/P 45 90080 CO/P 45 90081 CO/P 50 90082 CO/P 50 90083 CO/P 60 90084 CO/P 60 * sw = wrench width Type Ripple current resistance [kV] Discharge voltage [kV] Max. tensile load [kN] Max. bending load [kN] CO/P 30 CO/P 40 CO/P 50 CO/P 60 5 8 10 10 15 20 25 30 4 4 4 4 2 1.5 1 1 Max. compression load [kN] 21 21 21 21 Packaging unit [pcs.] 200 200 100 150 200 100 200 150 150 150 140 140 140 120 110 110 100 100 80 80 70 70 Max. starting torque [Nm] 5.9 (M5) … 21.5 (M8) 8.9 (M6) … 21.5 (M8) 8.9 (M6) … 21.5 (M8) 8.9 (M6) … 21.5 (M8) The spacing isolator type CO/P has been tested for isolating material (discharge voltage, discharge strength and arking) according to the regulations covering VDE 0303-21 03/1999 / DIN EN 60243-1 03/1999. Appraisal of the discharge voltage or arking between two unequal electrodes (diameter 25 mm or 75 mm). The test was made for the norm climate 23/50, ambient temperature (23 ±2) °C and (50 ±5) % relative humidity. MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Page 6 Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com MBS AG Spacing isolator Type CS/P Made of Polyglas-polyester material, reinforced with fiberglass, colour red, selfextinguishing. Operating temperature: -40 °C up to +130 °C Fire resistance class: UL94-V0 Art.no. Type H [mm] sw* [mm] D1 [mm] UM [mm] M A [mm] 30 30 30 35 35 35 40 40 40 45 45 45 50 50 50 55 55 60 60 60 65 70 70 70 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 750 750 750 1000 1000 1000 1000 1000 1000 1000 1000 1000 1500 1500 1500 1500 1500 1500 1500 1500 1500 1500 1500 1500 M6 M8 M10 M6 M8 M10 M6 M8 M10 M6 M8 M10 M6 M8 M10 M6 M8 M6 M8 M10 M8 M6 M8 M10 9 9 9 9 9 9 12 12 12 12 12 13 12 13 12 12 11 12 16 20 18 14 18 18 90087 CS/P 30 90088 CS/P 30 90089 CS/P 30 90090 CS/P 35 90091 CS/P 35 90092 CS/P 35 90093 CS/P 40 90094 CS/P 40 90095 CS/P 40 90096 CS/P 45 90097 CS/P 45 90098 CS/P 45 90099 CS/P 50 90100 CS/P 50 90101 CS/P 50 90102 CS/P 55 90103 CS/P 55 90105 CS/P 60 90106 CS/P 60 90107 CS/P 60 90109 CS/P 65 90111 CS/P 70 90112 CS/P 70 90113 CS/P 70 * sw = wrench width Type Ripple current resistance [kV] Discharge voltage [kV] Max. tensile load [kN] Max. bending load [kN] CS/P 30 CS/P 40 CS/P 50 CS/P 60 8 8 10 15 20 25 35 35 9 9 9 9 4.5 3 2 1.5 Max. compression load [kN] 40 40 40 40 Packaging unit [pcs.] 80 80 80 64 64 64 60 60 60 48 48 48 48 48 48 40 40 40 40 40 32 32 32 32 Max. starting torque [Nm] 8.9 (M6) … 43 (M10) 8.9 (M6) … 43 (M10) 8.9 (M6) … 43 (M10) 8.9 (M6) … 43 (M10) The spacing isolator type CS/P has been tested for isolating material (discharge voltage, discharge strength and arking) according to the regulations covering VDE 0303-21 03/1999 / DIN EN 60243-1 03/1999. Appraisal of the discharge voltage or arking between two unequal electrodes (diameter 25 mm or 75 mm). The test was made for the norm climate 23/50, ambient temperature (23 ±2) °C and (50 ±5) % relative humidity. MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com Page 7 MBS AG Spacing isolator Type CT/P Made of Polyglas-polyester material, reinforced with fiberglass, colour red, selfextinguishing. Operating temperature: -40 °C up to +130 °C Fire resistance class: UL94-V0 Art.-no. Typ 90118 CT/P 30 90119 CT/P 30 90120 CT/P 35 90121 CT/P 35 90122 CT/P 40 90123 CT/P 40 90123M12 CT/P 40 90124 CT/P 45 90125 CT/P 45 90126 CT/P 50 90127 CT/P 50 90127M12 CT/P 50 90129 CT/P 55 90130 CT/P 60 90131 CT/P 60 90131M12 CT/P 60 90133 CT/P 65 90134 CT/P 70 90135 CT/P 70 * sw = wrench width Type Thread Ripple current resistance [kV] CT/P 30 CT/P 30 CT/P 40 CT/P 40 CT/P 40 CT/P 50 CT/P 50 CT/P 50 CT/P 60 CT/P 60 CT/P 60 M8 M10 M8 M10 M12 M8 M10 M12 M8 M10 M12 8 8 10 10 10 10 10 10 10 10 10 H [mm] sw* [mm] D1 [mm] UM [mm] M A [mm] 30 30 35 35 40 40 40 45 45 50 50 50 55 60 60 60 65 70 70 41 41 41 41 41 41 41 41 41 41 41 41 41 41 41 41 41 41 41 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 40 750 750 750 750 1000 1000 1000 1000 1000 1500 1500 1500 1500 1500 1500 1500 1500 1500 1500 M8 M10 M8 M10 M8 M10 M12 M8 M10 M8 M10 M12 M10 M8 M10 M12 M10 M8 M10 8 9 9 9 12 12 12 13 12 12 13 11 12 18 18 18 18 18 18 Discharge voltage [kV] Max. tensile load [kN] Max. bending load [kN] 20 20 25 25 25 35 35 35 35 35 35 10 10 10 10 10 10 10 10 10 10 10 7.5 7.5 7 7 7 5 5 5 3.7 3.7 3.7 Max. compression load [kN] 80 80 80 80 80 80 80 80 80 80 80 Packaging unit [pcs.] 45 45 36 36 27 27 27 27 27 27 27 27 18 18 18 18 18 18 18 Max. starting torque [Nm] 21.5 43.0 21.5 43.0 73.8 21.5 43.0 73.8 21.5 43.0 73.8 The spacing isolator type CT/P has been tested for isolating material (discharge voltage, discharge strength and arking) according to the regulations covering VDE 0303-21 03/1999 / DIN EN 60243-1 03/1999. Appraisal of the discharge voltage or arking between two unequal electrodes (diameter 25 mm or 75 mm). The test was made for the norm climate 23/50, ambient temperature (23 ±2) °C and (50 ±5) % relative humidity. MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Page 8 Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com MBS AG Spacing isolator Type CPE Made of Polyglas-polyester material, reinforced with fiberglass, colour red, selfextinguishing. Operating temperature: -40 °C < T < +130 °C Fire resistance class: UL94-V0 Art.no. Type 90140 CPE 40 90141 CPE 40 90142 CPE 40 90143 CPE 60 90144 CPE 60 90145 CPE 60 90146 CPE 80 90147 CPE 80 90148 CPE 80 90149 CPE 100 90150 CPE 100 90151 CPE 100 * sw = wrench width Type CPE 40 CPE 60 CPE 80 CPE 100 Ripple current resistance [kV] 10 20 25 30 Discharge voltage [kV] 25 50 50 50 Max. tensile load [kN] 11 15 23 30 H [mm] sw* [mm] D1 [mm] UM [mm] M A [mm] 40 40 40 60 60 60 80 80 80 100 100 100 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 60 1500 1500 1500 3000 3000 3000 5000 5000 5000 8000 8000 8000 M10 M12 M16 M10 M12 M16 M10 M12 M16 M10 M12 M16 11 11 12 18 18 19 19 19 23 19 19 23 Max. bending load [kN] 7 5 9 15 Max. compression load [kN] 100 100 120 150 Packaging unit [pcs.] 12 12 12 10 10 10 8 8 8 5 5 5 Max. starting torque [Nm] 43 (M10) … 180.4 (M16) 43 (M10) … 180.4 (M16) 43 (M10) … 180.4 (M16) 43 (M10) … 180.4 (M16) The spacing isolator type CPE has been tested for isolating material (discharge voltage, discharge strength and arking) according to the regulations covering VDE 0303-21 03/1999 / DIN EN 60243-1 03/1999. Appraisal of the discharge voltage or arking between two unequal electrodes (diameter 25 mm or 75 mm). The test was made for the norm climate 23/50, ambient temperature (23 ±2) °C and (50 ±5) % relative humidity. MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com Page 9 MBS AG Passing isolator Vertical bus bar support Type PI/P Type PSB Polyester material, red Panel bore Art.no. 90166 90167 90168 90169 90170 90171 90172 Art.no. 90166 90167 90168 90169 90170 90171 90172 Type PI/P 4 PI/P 6 PI/P 8 PI/P 10 PI/P 12 PI/P 16 PI/P 20 Type PI/P 4 PI/P 6 PI/P 8 PI/P 10 PI/P 12 PI/P 16 PI/P 20 L [mm] 50 65 80 95 105 135 155 ØD [mm] 15 22 25 30 35 43 54 UM [mm] 600 1000 1000 1000 1000 2000 2000 Ø1 [mm] 2.0 3.0 3.0 4.0 4.5 5.0 5.5 Ø2 [mm] 8.5 12.0 15.0 17.0 20.0 25.0 31.0 Cmax [mm] 2.0 3.0 4.0 4.0 4.0 8.0 10.0 M M4 M6 M8 M10 M12 M16 M20 Pack. [pcs.] 60 40 25 20 15 8 4 Easy to assemble vertical bus bar support in polyester material with reinforced fibre glass, red, suitable for bus bars with dimensions between 40 x 60 mm and 120 x 10 mm. Due to its construction characteristics this bus bar support is suitable for special isolating and mechanical resistance requirements. For the mounting of a bus bar support the following parts are required: 1 or 2 lateral supports, two mounting screws and the necessary block number to clamp into place the required bus bars. MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Page 10 Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com MBS AG PSB/1 – Horizontal / lateral support PSB/6 - Block for 6 mm bus bar PSB/2 - Horizontal / lateral support PSB/8 - Block for 8 mm bus bar PSB/120 - Horizontal / lateral support PSB/10 - Block for 10 mm bus bar Lateral support PSB/1 PSB/2 PSB/120 Blocks PSB 6 PSB 8 PSB 10 PSB 6 PSB 8 PSB 10 PSB 6 PSB 8 PSB 10 Art.no. Bus bars 60 x 6 60 x 8 60 x 10 40 x 6 40 x 8 40 x 10 120 x 6 120 x 8 120 x 10 80 x 6 80 x 8 80 x 10 50 x 6 50 x 8 50 x 10 100 x 6 100 x 8 100 x 10 90175* Elastic deviation of the teeth with signs of rupture PSB/6 kg 950 PSB/8 kg 1130 PSB/10 kg 1375 * = storage parts Pack. [pcs.] 36 30 24 Art.-no. 90178* 90179* 90180* 90176* 90177* Operating voltage Operating temperature Fire resistance 1000 V -40 °C ≤ q ≤ +130 °C class: UL94-V0 Resistance of short-circuiting of the bus bar support type PSB Type Mounting acc. illustration Bus bar per phase 3 x 100 mm x 10 mm 3 x 100 mm x 10 mm 3 x 100 mm x 10 mm Distance between phases [mm] 185 185 120 Supporting width [mm] 400 300 300 Rated surge current Ipk [kA] 143 154 220 Rated short-time current [kA / 1 sec.] 65 70 100 PSB/1 PSB/1 PSB/1 PSB/1 plus PSB/120 PSB/1 plus PSB/120 1B 1B 5 1B 3 x 120 mm x 10 mm 185 300 176 80 5 3 x 120 mm x 10 mm 185 300 264 120 MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com Page 11 MBS AG Vertical bus bar support Type PSB Illustration 1 Example of an unipolar bus bar support with 3 parallel bus bar support holders A = Number of blocks B = Bus bar thickness C = Length of mounting screw L = External space requirement H = Height M = Module Illustrations 1 – 2 – 3 – 4 – 5 – 6 show some of the possible variations. Illustrations up to max. 10 x 100 mm ill. 1B ill. 1A ill. 2 ill. 3 ill. 4 ill. 5 ill. 6 H. With lateral support M. With block PSB/1 PSB/2 = = 177 mm 127 mm PSB/6 PSB/8 PSB/10 = = = 36 mm 48 mm 60 mm Art.no. 90175 90176 90177 Pack. [pcs.] 96 144 244 Article group PSB/1 PSB/2 PSB/120 H [mm] 177 127 177 B [mm] 46 46 35 UM [V] 1000 1000 1000 90178 90179 90180 36 30 24 PSB/6 PSB/8 PSB/10 37 38 38 36 48 60 1000 1000 1000 M10 M10 M10 M10 M10 M10 Art.Article H L UM For B ill. no. group [mm] [mm] [V] thread [mm] 90187 PSB 1A 177 1000 M10 6 90188 PSB 1A 177 1000 M10 8 90189 PSB 1A 177 1000 M10 10 90190 PSB 1B 177 162 1000 M10 6 90191 PSB 1B 177 174 1000 M10 8 90192 PSB 1B 177 186 1000 M10 10 90193 PSB 2 177 198 1000 M10 6 90194 PSB 2 177 222 1000 M10 8 90195 PSB 2 177 246 1000 M10 10 90196 PSB 3 177 234 1000 M10 6 90197 PSB 3 177 270 1000 M10 8 90198 PSB 3 177 306 1000 M10 10 90199 PSB 4 177 270 1000 M10 6 90200 PSB 4 177 318 1000 M10 8 90201 PSB 4 177 366 1000 M10 10 90202 PSB 5 177 306 1000 M10 6 90203 PSB 5 177 366 1000 M10 8 90204 PSB 5 177 426 1000 M10 10 90205 PSB 5 177 342 1000 M10 6 90206 PSB 5 177 414 1000 M10 8 90207 PSB 5 177 486 1000 M10 10 90211 PSB 1A 127 1000 M10 6 90212 PSB 1A 127 1000 M10 8 90213 PSB 1A 127 1000 M10 10 90214 PSB 1B 127 152 1000 M10 6 90215 PSB 1B 127 164 1000 M10 8 90216 PSB 1B 127 176 1000 M10 10 90217 PSB 2 127 188 1000 M10 6 90218 PSB 2 127 212 1000 M10 8 90219 PSB 2 127 236 1000 M10 10 90220 PSB 3 127 224 1000 M10 6 90221 PSB 3 127 260 1000 M10 8 90222 PSB 3 127 296 1000 M10 10 90223 PSB 4 127 260 1000 M10 6 90224 PSB 4 127 308 1000 M10 8 90225 PSB 4 127 356 1000 M10 10 90226 PSB 5 127 296 1000 M10 6 90227 PSB 5 127 356 1000 M10 8 90228 PSB 5 127 416 1000 M10 10 90229 PSB 6 127 332 1000 M10 6 90230 PSB 6 127 404 1000 M10 8 90231 PSB 6 127 476 1000 M10 10 The above mentioned data are only for information purposes and are without a guarantee. The customer is required to check from time to time if the product is suitable for the required application. Upon request milled bus bar supports and other from GPO-3 extracted details can be supplied. In this instance drawings are to be submitted. Type-tested according to IEC 61439-2:2011-08, EN 61439-2:2012-06 with practically relevant fixing points and supporting widths. MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Page 12 For thread Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com MBS AG Mounting material / Threaded bolts GB Threaded bolt Hexagon screw M10 with nut and washer Threaded bolt M10 complete with nut and washer Art.no. 90270 90271 90272 90273 90274 90275 90276 90277 90278 90279 90280 90281 90282 90283 90284 90285 90286 90287 90288 90289 90290 90291 90292 90293 90294 90295 90296 90297 90298 90299 90300 90301 90326 90327 Pack. [pcs.] 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 Article group GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB GB Art.no. 90309 90310 90311 90312 90313 90314 90315 90316 90317 Pack. [pcs.] 100 100 100 100 100 100 100 100 100 Article group SKS SKS SKS SKS SKS SKS SKS SKS SKS Art.no. 90318 90319 90320 90321 90322 90323 90324 90325 Pack. [pcs.] 100 100 100 100 100 100 100 100 Article group GB GB GB GB GB GB GB GB Thread M3 M3 M4 M4 M4 M4 M5 M5 M5 M5 M6 M6 M6 M6 M6 M6 M8 M8 M8 M8 M8 M8 M8 M8 M10 M10 M10 M10 M10 M10 M12 M12 M16 M16 Thread M10 M10 M10 M10 M10 M10 M10 M10 M10 Thread M10 M10 M10 M10 M10 M10 M10 M10 Hexagon spacer in brass Length L [mm] 12 15 15 16 18 20 20 22 27 30 18 20 25 27 33 35 20 23 25 30 33 35 38 50 30 35 38 40 45 50 30 50 40 60 SK Length L [mm] 60 80 70 90 100 110 140 150 160 Art.no. 90330 90331 90332 90333 90334 90335 90336 90337 90338 90339 90340 90341 90342 90343 90344 90345 90346 90347 90348 90349 90350 90351 90352 90353 90354 90355 90356 90357 Pack. [pcs.] 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 Thread M4 M4 M4 M4 M4 M4 M5 M5 M5 M5 M5 M5 M5 M5 M6 M6 M6 M6 M6 M6 M6 M8 M8 M8 M8 M8 M8 M8 Height H [mm] 15 20 25 30 50 70 90 15 20 25 30 50 70 90 15 20 25 30 50 70 90 15 20 25 30 50 70 90 sw* [mm] 7 7 7 7 7 7 7 8 8 8 8 8 8 8 10 10 10 10 10 10 10 13 13 13 13 13 13 13 *sw = wrench width Length L [mm] 194 230 242 270 290 350 410 1000 MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com Page 13 MBS AG Bus bar support L Support L185/1 Art.-no. 90392 Support L185/2 (2 x M10 each phase) Art.-no. 90395 Bus bar supports in general Characteristics of the raw material (GFK-profile, hot hardened) - Temperature range - Operating AC voltage - Continuous current - Phase clearance - Form stability - Natural density - Fire resistance - Discharge resistance - Resistance voltage tracking - Specific flow resistance -40 °C to +130 °C 1000 V L/Z 280 mm 2500 A L/Z 500 mm 4000 A L/Z 280 mm 100 mm L/Z 500 mm 185 mm DIN 53462 °C > 200 DIN 53479 gr/cm² approx. 1.7 UL 94 HB DIN 53481 kV/cm 10 DIN IEC 112 CTI 600 DIN 53482 Ohm x cm 1012 All bus bars are type tested acc. to VDE 0660, part 500 - Torque for M10: approx. 4.5 Nm - Copper bus bar 10 mm thick made of copper F30 not nickel-plated Type-tested according IEC 61439-2:2011-08, EN 61439-2:2012-06 with practically relevant fixing points and supporting widths. Support L100 Type L100 L185/1 L185/2 Art.no. 90391 90392 90395 Art.-no. 90391 Pack. [pcs.] 1 1 1 Article group L L L Length [mm] 280 500 500 Profile [mm] 50/50 50/50 50/50 Bore [mm] 7 7 7 Thread Color M8 M10 M10 grey grey grey MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Page 14 Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com MBS AG Bus bar support Z Support Z185/1 Art.-no. 90382 Support Z185/2 (2 x M10 each phase) Art.-no. 90385 Bus bar supports in general Support Z100 Art.-no. 90381 Characteristics of the raw material (GFK-profile, hot hardened) - Temperature range - Operating AC voltage - Continuous current - Phase clearance - Form stability - Natural density - Fire resistance - Discharge resistance - Resistance voltage tracking - Specific flow resistance -40 °C to +130 °C 1000 V L/Z 280 mm 2500 A L/Z 500 mm 4000 A L/Z 280 mm 100 mm L/Z 500 mm 185 mm DIN 53462 °C > 200 DIN 53479 gr/cm² approx. 1.7 UL 94 HB DIN 53481 kV/cm 10 DIN IEC 112 CTI 600 DIN 53482 Ohm x cm 1012 All bus bars are type tested acc. to VDE 0660, part 500 - Torque for M10: approx. 4.5 Nm - Copper bus bar 10 mm thick made of copper F30 not nickel-plated Type-tested according IEC 61439-2:2011-08, EN 61439-2:2012-06 with practically relevant fixing points and supporting widths. Type Z100 Z185/1 Z185/2 Art.no. 90381 90382 90385 Pack. [pcs.] 1 1 1 Article group Z Z Z Length [mm] 280 500 500 Profile [mm] 30/40/30 30/40/30 30/40/30 Bore [mm] 7 7 7 Thread Color M8 M10 M10 grey grey grey Short-circuiting resistance of the lateral bus bar support type L100 and Z185/2 Type Mounting acc. illustration Bus bar per phase L100 / 1x M8 Z185/2 / 2 x M10 Art.-no. 90391 Art.-no. 90382 1 x 30 mm x 10 mm 1 x 100 mm x 10 mm Distance between phases [mm] 100 185 Supporting width [mm] 300 400 Rated surge current Ipk [kA] 105 176 Rated short-time current [kA / 1 sec.] 50 60 MBS AG Eisbachstraße 51 ∙ 74429 Sulzbach-Laufen Germany Telefon: +49 7976 9851-0 ∙ Telefax: +49 7976 9851-90 E-Mail: info@mbs-ag.com ∙ Web: www.mbs-ag.com Page 15 Current transformers for industry Current transformers for tariff Accessories for current transformers Medium-voltage CTs Bus bar insulators / -supports Shunts Voltage transformers All current sensors Measuring transducers Energy meters with or without MID approval Accessories for energy meters Panel board heaters, filter fans, roof MBS AG Eisbachstraße 51 • 74429 Sulzbach-Laufen • Germany Telefon: +49 7976 9851-0 • Telefax: +49 7976 9851-90 info@mbs-ag.com • www.mbs-ag.com www.mbs-ag.com MBS IDNR 8.1.0145/1000/02-2014 fans and control units