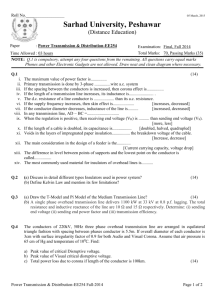

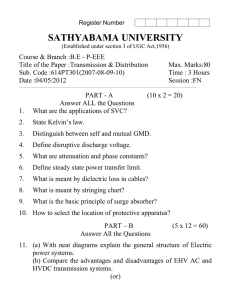

Evaluation Scheme - Roorkee College of Engineering

advertisement