New Screening Process for Manufacturing Color Picture Tubes

advertisement

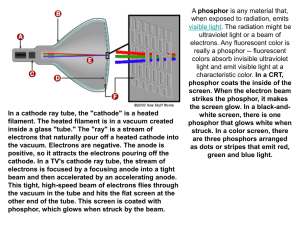

New Screening Process for Manufacturing Color Picture Tubes Istvan Gorog Thomson Consumer Electronics A new process uses electrophotographic techniques in manufacturing color picture tubes. It is less expensive, reduces energy and water consumption, and produces little waste. regions of the world, the need for CRTs increases. CRT plants are typically organized as “lines.” A plant’s production line receives incoming components, principally glass, metal parts, electron guns, and deflection yokes, and produces finished tubes. Phosphor screening is a key operation in the line process. Practically all picture tube manufacturers worldwide use a slurry-based process, wherein mixtures of the phosphor powders and a photosensitive material are applied as thin layers onto the glass, are optically exposed, and subsequently developed by washing away the unexposed regions. Glass +Ill> Phosphors or Rlack Matrix DEVELOP ElectroPhotographic Screening Process Introduction More than 150 million color television picture tubes, also called color cathode ray tubes (CRTs), are produced worldwide annually. Color tubes are the principal display components in virtually all TV sets and in most personal computers. Manufacturing CRTs is an industry that is still growing, particularly as consumer demand rises in the developing economies of South America, China, and the former Soviet Union. Also, as new information age applications emerge in the more developed Concept Description Thomson Consumer Electronics has developed an alternative screening process to the slurry-based process, ElectroPhotographic Screening (EPS). EPS uses electrophotographic techniques requiring less capital investment, reducing energy and water consumption, and producing practically no waste. The EPS process sequentially deposits three kinds of cathodoluniinescent materials, phosphors, in precisely controlled, interleaved patterns onto the inside surface of the front glass or faceplate of the picture tube. In the first step, the inside of the faceplate is coated with a conductive layer. In the next step, a photoconductive layer is coated over the conductive layer (see figure la). The surface of the photoconductor is subsequently charged uniformly with a corona charger, and the charged surface is then exposed. The shadow mask (shown in figure 1 a) serves as the optical exposure mask, the same as in the conventional slurry process. In a finished CRT, the shadow mask serves to selectively constrain the scanning electron beams so that they strike only the appropriate phosphor elements. During phosphor screening, the shadow mask is placed in its precisely predetermined position with respect to the glass faceplate and is appropriately illuminated. The optical system is arranged so that the illuminating light rays accurately mimic the electron trajectories of the scanning beams during normal tube operation. Optical elements provide a projected light source arrangement that produces the required illumination (see figure la). As a result of the exposure, the photoconductor discharges the surface in the illuminated regions, while it retains the surface charge in regions shadowed by the mask. The next step is phosphor development (see figure lb). Here, the developer housing and developer grid comprise a suitable process developer unit, on top of which the exposed glass plate is placed face down, i.e., with its charged surface facing inside the developer unit. In the developer unit, electrically charged phosphor is blown against the charged plate. As shown in figure lb, the surface charge is positive, causing positively charged phosphor particles to be repelled by the surface charge to accumulate only in the previously illuminated and discharged regions. The charge, expose, and develop steps are repeated in sequence three times, with the light source arrangement in the exposure step appropriately moved each time to produce the desired interleaved red, green, and blue phosphor patterns. In the final step, the phosphor particles are fixed in position by exposure to intense infrared radiation that softens the photoconductor. Fixing ensures that the phosphor particles do not move during subsequent phases of tube manufacturing. Economics and Market Potential Studies have shown an estimated energy savings of 4 kWh per tube produced with the EPS process over the conventional slurry phosphor screening of CRTs. Further, phosphor use is expected to be significantly reduced. For example, in the conventional process about 75% of the phosphor applied to the faceplate is removed during development of the CRTs. Some of the phosphor wasted during application and development is lost; some of it is captured and recovered in a complex chemical process that has its own waste stream. In the EPS process all phosphor that is applied and not attached to the faceplate during development is captured and can be reused after a simple sieving operati on. The potential market for the EPS phosphor screening process is substantial with more than 150 million color tubes produced worldwide each year. If the useful life of a screening machine is 15 years, then even in the absence of market growth, 10 million tubes must be replaced each year. Key Experimental Results All process segments and required materials for the EPS process have now been completely developed. Some patents have been obtained and others are pending. In the laboratory, many commercial-quality phosphor screens have been produced and fabricated into functioning picture tubes. A pilot manufacturing facility designed to produce one screened faceplate per minute is nearing completion at Thomson's plant in Marion, Indiana. This pilot facility will establish process capabilities in a higher-volume manufacturing environment. To evaluate the benefits of the EPS process, accurate quantitative monitoring of all materials and energy consumption will be completed as part of the pilot project. Future Development Needs The advantages of EPS have been proven in the laboratory, but it now needs to be refined and proven in production. An area with obvious economic and environmental importance that requires additional research and development is solvent recovery. While the EPS process requires only minor amounts of solvents to coat a faceplate, in mass production this adds up to substantial volumes. Current plans are to incinerate the exhausted solvents. Given the available technologies today, the EPS solvent stream is too dilute and too small for economical recovery. Nevertheless, developing a suitable recovery technology could produce economic benefits and reduce waste heat. With solvent recovery EPS could become a completely closed system, where all input materials are either shipped out as part of the finished product, or are recycled intemall y. For more information, contact Istvan Gorog Thomson Consumer Electronics 1002 New Holland Avenue Lancaster, PA 17601 Phone: (7 17) 295-6938 Fax: (7 17) 295-6489 Compiled by Pacific Northwest Laboratory for the U.S. Department of Energy, Innovative Concepts Program 590240. This flier was printed on