titan fci model: bv 60-bz

advertisement

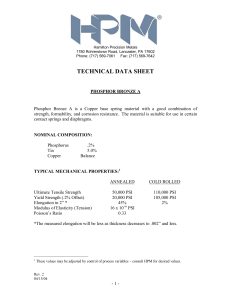

BV60-0809 BLOW-OFF DRAIN VALVE TITAN ® TITAN FLOW CONTROL, INC. WOG 600 MODEL: BRONZE f f f TWO-PIECE BALL VALVE MALE x FEMALE THREADED ENDS BV 60-BZ ( c as t b ro nze ) F SIZ E RANGE: 1/4" ~ 2" FE ATURES s f u l l p o rt f l ow f ull p o rt d esign o f f ers c o mple t e an d rapi d c leaning o f s t rainer s c reen w i t h minimal pressure d ro p . s simple o p e r at i o n q ui c k q uart er t urn o pens o r c l o ses valv e . direct T l o c k ing h an d le is als o availa b le . s TECHNICAL c o n n e c t i o n to s t r a i n e r male t h rea d e d en d s m o un t d ire c t ly in to s t rainer b l o w - o f f c o nne c t i o n f o r c o n v enien t b l o w d o w n c leaning . s fa c to ry PRESSURE/ TEMPERATURE RATING BRONZE ASTM B62 i n s ta l l at i o n a s b l ow - o f f va lv e WOG (Non-shock): 600 PSI @ 100 °F Max Liquid: 80 PSI @ 400 °F Saturated Steam: 150 PSI @ 366 °F b all valv e c an b e pro f essi o nally ins talle d to a t i tan s t rainer at o ur fa c to ry , ensuring q uali t y an d SEAT MATERIAL TEMPERATURE RANGE re d u c ing s h ipping an d la b o r c o s t s . s rugged, R-PTFE: -100 °F - 400 °F h i g h q ua l i t y d e s i g n t h e b v 60 f eat ures a c h ro mium plat e d b all , rein f o r c e d - p t f e seat , 1. The above listed temperatures are theoretical and may vary during actual operating conditions. an d b l o w - o u t pro o f s t em d esign . can be professionally installed at the titan factory ! APPLICATIONS A screen cleaning: d uring n o rmal use , t h e s t rainer s c reen w ill b e c o me c l o gge d w i t h f o reign mat t er c ausing t h e d i f f eren t ial pressure to in c rease . o n c e t h e d i f f eren t ial pressure h as una c c ep ta b le value , b l o w - d o w n c leaning is re c o mmen d e d . rea c h e d an i t is n ot a dv isa b le to all o w t h e d i f f eren t ial pressure to in c rease b y 2 0 psi as t h is may c ause t h e s c reen to fail an d p o ssi b ly damage d o w ns t ream e q uipmen t . i f t h e d i f f eren t ial pressure is n ot res to re d to n o rmal parame t ers a f t er b l o w - d o w n c leaning t h en t h e s c reen mus t b e rem o v e d an d c leane d o r repla c e d . The above data represents common market and ser vice a p p l i c a t i o n s . N o re p re s e n t a t i o n o r g u a ra n t e e , e x p re s s e d o r i m p l i e d , i s g i v e n d u e t o t h e n u m e ro u s v a r i a t i o n s of concentrati o ns , te mpe rature s and fl ow co nditio ns that m ay o c c ur dur i ng ac t ual se r v i c e . TITAN FLOW CONTROL, INC. YOUR PIPELINE TO THE FUTURE! Tel: 910-735-0000 s Fax: 910-738-3848 s titan@titanfci.com s www.titanfci.com 290 Corporate Drive s PO Box 7408 s Lumberton, NC 28358 BLOW-OFF DRAIN VALVE ● BALL VALVE TYPE TITAN FLOW CONTROL, Inc. TITAN ® 290 Corporate Drive Lumberton, NC 28358 Tel: 910.735.0000 BV 60-BZ (Cast Bronze) E-mail: titan@titanfci.com Web: www.titanfci.com Fax: 910.738.3848 Male x Female Ends ● Two-Piece Design Illustrations are for representational purposes only. Please ask for certified drawings when required. BILL OF MATERIALS (1) No. PART BV 60-BZ 1 Body Bronze, ASTM B62 2 Cap Bronze, ASTM B62 3 Ball Brass, Chrome Plated 4 Ball Seat (2) 5 Joint Gasket 6 Stem 7 Thrust Washer 8 Stem Packing (2) PTFE 9 Gland Nut Brass 10 Handle T-304 SS 11 Spring Washer T-304 SS 12 Stem Nut T-304 SS 13 Plastic Cover Plastic D 12 9 6 11 8 R-PTFE, 15% Glass Filled PTFE (2) Working Pressure: 600 PSI 5 Brass 10 7 13 C +BV60-0809 2 ØB PTFE (2) A 1. Equivalent or better materials may be substituted at the manufacturer's discretion. 2. Denotes recommended spare parts. 3 APPROXIMATE WEIGHT in mm in mm in mm in mm in mm lb kg Flow Coefficient Cv SIZE t h rea d e d en d s A DIMENSION FACE TO FACE (2) ØB DIMENSION INSIDE DIAMETER C DIMENSION HORIZONTAL CENTER LINE TO TOP OF HANDLE D DIMENSION VERTICAL CENTER LINE TO END OF HANDLE strainer's blow off connection 1 DIMENSIONS AND PERFORMANCE DATA (1) male x f emale male end mounts directly in the 4 1/4 8 1.75 44 0.38 10 1.7 43 3.43 87 < 0.5 < 0.23 18 3/8 10 1.75 44 0.48 12 1.7 43 3.43 87 < 0.5 < 0.23 18 1/2 15 2.17 55 0.63 16 1.7 43 3.43 87 0.5 0.23 18 3/4 20 2.64 67 0.88 22 2.12 54 4.5 114 0.5 0.23 42 1 25 3.15 80 1.13 29 2.25 57 4.5 114 1 0.45 74 1 1/4 32 C/F C/F C/F C/F C/F C/F C/F C/F C/F C/F 130 1 1/2 40 4.32 110 1.49 38 2.825 72 5.5 140 2.5 1.13 210 2 50 4.78 121 2.04 52 3.25 83 5.5 140 3.5 1.59 380 1. Dimensions and weights are for reference only. When required, request certified drawings. 2. Face to face values have a tolerance of ±0.06 in (±2.0 mm) for sizes 10" and lower and a tolerance of ±0.12 in (±3.0 mm) for sizes 12" and larger. PRESSURE - TEMPERATURE RATINGS (1) REFERENCED STANDARDS & CODES Cast Bronze, ASTM B62 Bronze not recommended for prolonged use above 400 °F 700 600 CODE DESCRIPTION ASME/ANSI B16.15 Cast Bronze Threaded Fittings Pressure (PSI) 500 PRESSURE - TEMPERATURE RATING 400 Operating Conditions Range WOG (Non-shock): 600 PSI @ 100 °F 200 Saturated Steam: 150 PSI @ 366 °F 100 Max Liquid: 80 PSI @ 400 °F 300 0 -100 0 100 200 Temperature (°F) 300 400 500 1. This chart displays the pressure versus temperature ratings for the valve's body. SEAT TEMPERATURE RATING Seat Material Range Reinforced-PTFE -100 °F - 400 °F Titan FCI makes every effort to ensure the information presented on our literature accurately reflects exact product specifications. However, as product changes occur, there may be short-term differences between actual product specifications and the information contained within our literature. Titan FCI reserves the right to make design and specification changes to improve our products without prior notification. When required, request certified drawings.