The Effect of Solution Heat Treatment on a Single-Crystal Ni

advertisement

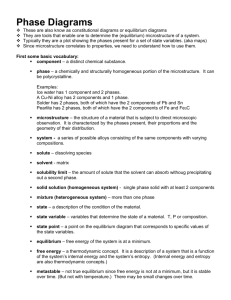

Research Summary High-Temperature Alloys The Effect of Solution Heat Treatment on a Single-Crystal Ni-Based Superalloy B.C. Wilson, J.A. Hickman, and G.E. Fuchs Understanding of the solution heat treatment response of a second generation, single-crystal nickel-based superalloy, CMSX-4, is necessary before the process can be shortened in an effort to save money. The current solution heat treatment used for CMSX-4 involves high temperatures for long durations and can be quite expensive. This investigation helps to characterize the heat-treatment process for this alloy. The achieved microstructure is described for both the as-cast and fully solution-annealed conditions. In addition, an alternate, less expensive heat treatment was selected for its lower temperatures and shorter overall duration. Microstructures and differential thermal analysis are presented for all three conditions. INTRODUCTION Single-crystal nickel-based superalloys are known for their high strength and creep resistance at high temperatures. These alloys are used extensively in the aerospace industry for turbine blades and vanes in the “hot section” of today’s gas turbine engines.1 While these properties depend largely on the alloy composition, they also rely on proper heat treatments to bring out these exceptional properties.2 Traditionally, two heat treatments are used for nickelbased superalloys. First is the solution heat treatment, designed to homogenize the microstructure and reduce the effects of elemental segregation.3 The second is one or more aging heat treatments, designed to develop a cuboidal γ/γ′ microstructure. This investigation focuses on the effects of solution heat treatments on a nickel-based superalloy at lower temperatures for a shorter duration, which may reduce costs. The material used for this study is CMSX-4, a second-generation, single-crystal 2003 March • JOM nickel-based superalloy. CMSX-4, widely used in the aerospace industry, is considered a secondgeneration superalloy because it contains approximately 3 wt.% Re.4 The solution heat treatment for this alloy is long and expensive, requiring almost a full day at elevated temperatures between 1,277°C and 1,318°C. Following this treatment, the material must be aged for an additional 26 hours. As furnace time is costly, any reduction in temperature or duration of heating will reduce costs significantly. This is especially true for high-output operations with thousands of parts requiring heat treatments. The goal of this investigation is to determine how this alloy will react to a modified solution heat treatment. The modified heat treatment chosen for this study is the standard PWA 1480 solution heat treatment, which runs at a significantly lower temperature and a much shorter duration. It has only three steps with slow ramp rates between hold temperatures, and requires about half the time of the standard heat treatment. If the modified heat treatment proves to be close a 300 µm to satisfactory, then the possibility exists of altering the solution heat treatment and, ultimately, saving money. To fully evaluate the feasibility of altering the solution heat treatment, three test groups were created. For the as-cast group no heat treatments were applied. The second group received the standard solution and aging heat treatments. The third group received the modified heat treatment and the standard aging heat treatment. The same aging heat treatment was used for both groups that received solution heat treatments in order to prevent differences due to the aging process. Experimental observation was gained through metallography, microprobe analysis, differential thermal analysis, and creep testing. See sidebar for experimental procedures. RESULTS Microstructure As-cast CMSX-4 has a two-phase γ/γ′ microstructure. The microstructure is cored, or segregated, with a dendrite pat- b 50 µm Figure 1. Photomicrographs of as-cast CMSX-4. (a) Optical micrograph of dendrites with secondary and tertiary arms extending from the primary dendrite, as well as γ/γ′ eutectic areas in between. (b) Scanning-electron micrograph of coarsening γ/γ′ morphology approaching the eutectic region in the center. A dendrite core can be seen to the left of the image. 35 EXPERIMENTAL PROCEDURE Material a 5 µm This investigation focuses on a second-generation, single-crystal nickel-based superalloy, CMSX-4. The material composition is given in Table A. The CMSX-4 master alloy was produced by Canon-Muskegon (Muskegon, OH). The single-crystal test bars were produced by PCC Airfoils (Minerva, OH) through an investment casting directional solidification process that yielded 24 test bars, 20 cm long, and of varying diameter. The test bar diameter distribution is as follows: 12 1.3-cm bars, 6 1.6-cm bars, 4 1.9-cm bars, and 2 2.5-cm bars. All of the single crystals were grown in the <001> direction and were inspected by Laue back-reflection. Test bars were also visually inspected to ensure the absence of any grain defects such as high and low angle boundaries and freckles. Once the bars were made and inspected, three test groups were established, one for each of the three heat treat conditions. Four bars were assigned for each group (two 1.3-cm bars and two 1.6-cm bars). Heat Treatments b 5 µm Figure 2. Scanning-electron micrographs of CMSX-4 following the standard solution heat treatment. (a) Prior to aging, γ′ is irregular in size and shape. (b) Following aging, γ′ has coarsened and become more regular. The three solution-heat-treatment conditions used for this research are as-cast, the standard solution heat treatment for CMSX-4, and a modified lower temperature, shorter duration, solution heat treatment. As already mentioned, the modified heat treatment needed to be of lower temperature and shorter duration. For this investigation, the PWA 1480 solution heat treatment, developed by Pratt & Whitney (East Hartford, CT), was chosen as the alternate heat treatment. PCC Airfoils performed the PWA 1480 heat treatment and the standard CMSX-4 solution heat treatment. After the solution heat treatments were completed, both groups underwent the same aging heat treatments. The standard and modified heat treatment schedules as well as the aging heat treatment schedules are given in Table B. The 1.6-cm diameter bars from all three groups were then exposed to one final long-term, high-temperature heat treatment to test the long-term stability of the microstructure. These six bars were placed in an air furnace and held at 1,000°C for 1,000 hours (approximately six weeks). During the exposure, the temperature was verified with two Type K thermocouples in addition to the furnace control thermocouple. At the end of the exposure, the bars were air-cooled. Specimen Preparation for Metallography tern and γ/γ′ eutectic regions throughout the microstructure (Figure 1a). Scanning electron microscopy reveals a relatively fine γ′ distributed within the dendrite cores that becomes coarse near the eutectic regions (Figure 1b). The cored microstructure is due to compositional gradients throughout the material that formed upon solidification. The dendrite cores are enriched in tungsten and rhenium while the eutectic regions are depleted of these two elements. The eutectic regions, however, are enriched in tantalum, titanium, and aluminum while the dendrites are depleted of them.5,6 This behavior is seen in the partitioning coefficients. The partitioning coefficients and average concentrations of selected elements for the three zones within the microstructure are given in Table C. A value of one indicates no deviation from the average composition of the alloy and, hence, no significant segregation. A value greater than one corresponds to an element that partitions, or segregates, to the dendrite core, while a value lower than one corresponds to an 36 Samples were prepared for metallographic examination from each of the heat-treated conditions discussed previously, including before and after the long-term exposure to temperature. Disks approximately 0.4-cm thick were cut from the bars that were to be observed metallographically. These disks were mounted and polished prior to etching. The etch selected for this investigation was Pratt &Whitney etch #17 (100 mL H2O + 100 mL HNO3 + 100 mL HCl + 3 g MoO3). This etch is a γ′ etch that selectively dissolves the γ′ in the microstructure. Scanning electron microscopy and light-optical microscopy were used to observe the microstructure. Differential Thermal Analysis Differential thermal analysis (DTA) was also performed for all six conditions. Again, 0.9-cm thick disks were cut from the single crystal test bars and sent to Dirats Laboratories (Westfield, MA) for analysis. Data was gathered upon heating in a DuPont (Philadelphia, PA) 9000 series differential thermal analyzer. The liquidus, solidus, and γ′ solvus temperatures were then determined and reported. The DTA unit was calibrated prior to testing with high-purity nickel at a scan rate of 20°C/min. A purged high-purity argon atmosphere with a flow rate of approximately 50 cm3/min. was used in all tests. Samples were contained in high-purity alumina crucibles during testing. Specimen Preparation for Creep Testing Two creep tests were performed on specimens of each of the six different conditions. Each sample was low-stress ground to make a creep rupture specimen with gauge diameter element that partitions to the eutectic region. From these values it can be seen that tungsten and rhenium heavily partition to the dendrite, and tantalum, titanium, and aluminum heavily partition to the eutectic. The three elements nickel, cobalt, and chromium do not heavily partition to either the dendrite or the eutectic. This behavior can be easily observed because of the relatively small compositional changes among the three regions of the microstructure. Solution heat treatments, though long and expensive, are required to achieve a desirable microstructure. Following the standard solution heat treatment, the microstructure becomes very uniform. The γ/γ′ eutectics have been dissolved and a fine γ′ (approx. 0.3–0.5 µm) is apparent throughout the microstructure (Figure 2a).7 Once the solution heat treatment is completed, the aging heat JOM • March 2003 of 0.5 cm and a gauge length of 2.6 cm. The tests were performed on Satec creep frames at a constant load to produce an initial stress of 310 MPa (45 ksi) and at a temperature of 950°C. The specimens were attached to an extensometer that was connected to an LVDT to measure displacement. Three type-K thermocouples were attached along the gauge section to monitor and maintain a constant temperature. Microprobe Analysis As-cast CMSX-4 is highly segregated, which is a large contributor to the need for a solution heat treatment.5,6 One method to analyze the degree of segregation is microprobe analysis. The analysis was conducted on an as-cast metallography sample. This sample was observed in the polished, but unetched condition. Three types of microstructural regions were examined to determine local concentrations of alloying elements: dendrite cores, eutectic regions, and the interdendritic region. Five different representative sites for each of the three regions were selected for analysis. From the composition data, partitioning coefficients of the alloying elements can be determined. The partitioning coefficient, k′ = (dendritic composition)/(interdendritic composition), indicates how strongly a given element segregates to either the dendrite or the eutectic regions. The higher the partitioning coefficient is, the higher the concentration of a given element in the dendrite core region. Conversely, the lower the partitioning coefficient is, the lower the concentration of a given element in the dendritic region with respect to the interdendritic region. For example, the weight percentage of W in a dendrite of as-cast CMSX-4 is 1.69 times as great as the weight percentage of W in the interdendritc region (Table C). a b 20 µm 10 µm Table A. Composition of CMSX-4 (Heat 6V0051) in Weight Percent Ni Cr Co Mo W Ta Re Al Ti Hf Bal. 6.4 9.6 0.6 6.4 6.6 2.9 5.64 1.03 0.1 Table B. Heat Treatment Schedules Heat Treatment c Standard 1,277°C/4 h → 1,287°C/2 h → 1,296°C/3 h → 1,304°C/3 h → 1,313°C/2 h → 1,316°C/2 h → 1,318°C/2 h/GFC* Modified 1,210°C/2 h → ramp 16.7°C/h → 1,285°C/2 h → ramp 1.67°C/h → 1,287°C/0.5 h/GFC* Aging HT 1,140°C/6 h/AC** → 871°C/20 h/AC** * Gas furnace quench ** Air cooled Table C. Average Compositions of CMSX-4 Dendritic Pattern and Partitioning Coefficients (in wt.%) Average Composition Dendrite Core Interdendritic Area Eutectic Area Partitioning Coefficient Ni W Re Al Ti Ta Co Cr 61.42 60.06 61.94 61.64 0.97 6.40 7.91 5.86 4.67 1.69 2.90 5.82 3.63 2.87 2.03 5.64 4.94 5.71 5.61 0.88 1.03 0.59 0.92 1.18 0.50 6.60 4.23 6.23 6.93 0.61 9.60 10.34 9.79 10.07 1.03 6.40 6.10 5.94 7.03 0.87 treatment is performed. Aging serves to slightly coarsen the γ′ to 0.5 µm in size and to form the very uniform, cuboidal structure often associated with γ′ (Figure 2b). The modified heat treatment is the PWA 1480 heat treatment developed by Pratt & Whitney. The PWA 1480 treatment utilizes lower temperatures and a shorter duration. The microstructure obtained by the modified heat treat2003 March • JOM ment is considerably different from the standard solution heat treatment. The eutectic γ/γ′ regions are not fully dissolved and large regions of extremely coarse γ′ are present throughout the material (Figure 3a). In addition, a high degree of segregation is still evident following the modified heat treatment. The aging heat treatment does manage to form the proper γ′ structure within the dendritic regions, however, due to the 10 µm Figure 3. Scanning-electron micrographs following PWA 1480 solution heat treatment. (a) Partially dissolved γ/γ′ eutectic region with coarse γ′ at boundaries. (b) Coarse structure at dendrite/eutectic boundary. (c) Following aging, γ′ in dendrite is the proper size and shape, however, a distinct boundary is present between the dendrite and the eutectic. large undissolved eutectic regions, a fine γ′ structure is not formed throughout the microstructure (Figure 3b). Furthermore, distinct boundaries are present and are observed between the dendrites and the eutectic areas. Here, a rapid change from fine γ′ to exceedingly coarse γ′ is readily noticeable (Figure 3c). The samples then undergo longterm, high-temperature exposure to test microstructural stability. Following the long-term exposure, metallography was performed on the test bars. The as-cast material was found to have significant coarsening and topologically close packed (TCP) formation. Some of the eutectic regions were dissolved to form a 37 a 20 µm b 20 µm Figure 4. Scanning-electron micrographs topologically close packed (TCP) phases in as-cast CMSX-4. (a) Following the 1,000 hour exposure, the γ′ coarsened, the γ/γ′ eutectic partially dissolved, and some TCP phases formed along the dendrite/eutectic border (light gray, top of micrograph). (b) TCP phase enveloped in γ′ surrounded by an overly coarsened γ/γ′ matrix. microstructure similar to that formed by the PWA 1480 heat treatment yielding the highly coarse structure that was present at the borders between the dendrites and the eutectic areas. The TCP phases primarily formed in regions near these dendrite/eutectic borders (Figure 4a). They were also typically enveloped in γ′, meaning the continuous matrix is interrupted by long γ′ structures with TCP phases inside (Figure 4b). The material with the PWA 1480 heat treatment produced similar results. The γ/γ′ matrix coarsened significantly during the long high-temperature exposure. In addition, the residual eutectic areas continued to dissolve into the microstructure (Figure 5a), possibly due to the high degree of segregation that remained in the microstructure following the solution heat treatment. Furthermore, TCP phases were frequently observed throughout the microstructure, though not to the degree as that observed in the as-cast microstructure (Figure 5b). The standard solution heat treatment produced results considerably different. There was still γ′ coarsening evident (Figure 6a). The difference, however, is in eutectic dissolution and TCP resistance. First, since there were no residual eutectics to be dissolved, this type of behavior was not observed in the material with the standard solution heat treatment. Second, the amount of TCP observed was greatly reduced. TCP formations were still present, but to a much smaller scale (Figure 6b). The uniform microstructure associated with the standard heat treatment appears to be much more TCP resistant. 38 DIFFERENTIAL THERMAL ANALYSIS Differential thermal analysis was performed on the materials in all six conditions [before and after long-term, high temperature exposure (Table I)]. Prior to exposure, both the standard and modified heat-treated materials exhibit almost identical liquidus and solidus temperatures, the only difference being the γ′ solvus temperatures. The as-cast material exhibits a thermal response very different from either of the two heat-treated conditions. Although there is a rather large difference in the microstructures, only a small difference appears upon differential thermal analysis prior to the long-term exposure test. Following the exposure, the modified and standard heat treatments exhibited very different DTA responses. While the liquidus temperatures are the a 50 µm same, the solidus temperature of the material with the PWA 1480 solution heat treatment dropped slightly. The γ′ solvus temperatures, though higher, maintained the same difference as before. The solidus temperatures, however, behaved differently. Long-term, hightemperature exposure slightly decreased the solidus of the modified alloy, while the solidus of the standard material experienced an increase. These differences, though, are small and may be within experimental scatter. The uniform structure produced during the standard solution and aging heat treatments appears to be more stable with only small changes in the liquidus, solidus, and solvus temperatures. The irregular structure observed due to the modified heat treatment still exhibits significant segregation, which results in some amount of diffusion during the longterm heat treatment and a drop in the solidus temperature. CREEP TESTING As seen in Table II, the samples with the standard solution heat treatment outperformed the other treatments in all aspects of creep testing. These samples exhibited creep lives of 380 hours and 568 hours, which exceeded all other specimens by at least 83 hours. In addition, although the aging of 1,000°C for 1,000 hours proved to degrade properties in each of the sets of heat treatments, the standard treatment samples exhibited longer creep lives than the other aged specimens. The samples with the modified solution heat treatment surpassed the as-cast b 20 µm Figure 5. Scanning-electron micrographs of long-term, high-temperature exposure effects on CMSX-4 with the PWA 1480 solution heat treatment. (a) Continued dissolution of γ/γ′ eutectic along with γ′ coarsening within the dendrites. (b) TCP phases in the material with the modified solution heat treatment. JOM • March 2003 a 10 µm b produced by this heat treatment, however, retained some segregation from the as-cast stage in its production. This heat treatment was not able to dissolve the γ/γ′eutectics and as a result, produced a very coarse microstructure. Differential thermal analysis (DTA) of the two heat-treated conditions, however, produced similar results. The solidus, liquidus, and γ′ solvus temperatures were approximately the same for the two heat treatments. Following the solution and aging heat treatments, the test bars received a long-term, high-temperature exposure. The purpose of this exposure is to reveal the reaction of the material to a simulated operating environment over an extended period of time. During this exposure, typically two responses will occur. First, the γ′ structure will continue to coarsen. Rafting of the γ′ is another response associated with coarsening for long periods of time. The second possible response is the formation of TCP phases. Though the effect of TCP phases on a single crystal component is not fully understood, two possibilities do arise. First, though many morphologies are possible, the needle or plate-like morphology is common, which can act as a stress raiser with the microstructure. Second, TCP phases also remove the solid-solution strengtheners tungsten and rhenium from the 10 µm Figure 6. Scanning-electron micrographs of long-term, high-temperature exposure effects on CMSX-4 with the standard solution heat treatment. (a) Coarsening of γ′ is exhibited in this alloy, but to a lesser degree. (b) TCP formations were present in the microstructure; however, they are fewer and smaller in size when compared to the as-cast and PWA 1480 heat-treated conditions. structure in rupture life even after being heated for 1,000 hours at 1,000°C. Therefore, although the PWA 1480 heat treatment does not produce a CMSX-4 alloy with creep life equivalent to material with the standard heat treatment, it does improve its properties. The solution heat treatment also affected the percent creep at rupture. The as-cast samples exhibited 21% and 30% creep. For the PWA 1480 solution heat treatment samples, the as-heattreated condition produced 24% and 28% creep while the standard heat treatment produced 27% and 28% creep. Following the exposure heat treatment, the PWA 1480 heat-treated samples proved to have the most total plastic strain of the two solution heat treatments. Following the exposure, the PWA 1480 heat treatment samples exhibited 35% and 36% creep while the standard solution heat treatment actually produced lower elongation values than it recorded before the long-term exposure. One of the as-cast samples, after the long-term exposure, produced the greatest percent creep with a value of 44%. leads to the preferred microstructure for CMSX-4. To get this microstructure, however, the material spent almost two full days in a furnace at high temperature. A reduction in the temperature or time required for heat treatment, therefore, could save money.8 However, it is not desirable to alter the heat treatment process in such a way that degrades the material’s performance. As a result of the need for a more cost-effective heat treatment, a different solution heat treatment was selected. The PWA 1480 solution heat treatment is a commercial heat treatment that utilizes lower temperatures and a shorter overall duration. The microstructure Table I. DTA Results of CMSX-4 (Temperatures in °C) Before Long-Term Exposure Liquidus Solidus γ Solvus As-Cast PWA 1480 Standard As-Cast PWA 1480 Standard 1,383 1,322 N/A 1,386 1,340 1,276 1,386 1,341 1,286 1,384 1,327 N/A 1,385 1,338 1,280 1,386 1,344 1,290 Table II. Creep Results for CMSX-4 DISCUSSION As-cast CMSX-4 has a highly segregated, two-phase γ/γ′ microstructure. It is this chemical segregation, or compositional gradient, that causes the material to require a solution heat treatment.2 By solution heat treating CMSX-4, the effects of segregation can be drastically reduced. In addition to the solution heat treatment, one or more aging heat treatments are utilized to fully strengthen the material. This step 2003 March • JOM After Long-Term Exposure Sample ID PWA 1480 HT/aging HT PWA 1480 HT/aging HT/ 1,000°C for 1,000 h STD soln HT/aging HT STD soln HT/aging HT/ 1,000°C for 1,000 h As Cast As cast/ 1,000°C for 1,000 h 302-1 302-2 308-1 308-2 316-1 316-2 320-1 320-2 305-1 305-2 309-1 309-2 Time to Rupture Time to 1% Total % Creep (h) Creep Elongation (h) Elongation 204 251 154 212 568 380 297 200 182 170 141 133 74.50 104.38 49.00 84.19 81.08 170.45 100.18 89.43 53.50 62.05 30.18 35.11 23.95 28.32 36.53 34.78 27.33 28.65 26.68 15.82 30.09 21.26 26.90 44.33 39 surrounding matrix. These two effects together within the microstructure raise concerns about the possibility of premature failure. As a result, TCP phases are typically considered undesirable.9–11 The long-term exposure affected the as-cast material by producing a coarse microstructure and TCP phases throughout the material. Topologically close-packed phases were prevalent in the as-cast microstructure. The standard solution heat treatment, however, produced different results. The uniform microstructure that was produced after aging was only slightly coarsened with a few small TCP formations present. The PWA 1480 solution heat treatment, however, resembled the as-cast material more than the standard solution heat treatment. The large γ/γ′ eutectic regions that were still present following the aging heat treatment were surrounded by a very coarse microstructure. The TCP formations were very prevalent within this microstructure as well. The retained segregation was still evident, even after the long-term, hightemperature exposure. Creep testing is critical in understanding how a material will behave when subjected to a high-stress, hightemperature environment. This is especially the case for turbine blade materials like CMSX-4. Again, as with microstructure, creep behavior is directly impacted by the applied heat treatments. All six conditions were tested to determine any differences in the two solution heat treatments and any differences in the rate at which creep properties degrade. Of the three heat-treated conditions, the standard heat treatment produced the longest creep life. The PWA 1480 solution heat treatment produced a definite increase in creep life over the as-cast material; however, it was still 40 much lower than the standard solution heat treatment. The same trend can be seen in the time required to reach 1% creep. The percent creep at rupture was similar for the three conditions prior to the exposure heat treatment. Following the exposure, however, the as-cast and PWA 1480 conditions experienced significant increases in percent creep at rupture. The standard solution heat treatment, however, actually experienced a slight decrease. CONCLUSIONS The modified heat treatment proved to be insufficient to produce an acceptable homogeneous microstructure in CMSX-4. A high degree of retained segregation persists after the PWA 1480 heat treatment of CMSX-4. Upon exposure to 1,000°C for 1,000 hours, the modified samples resembled the as-cast microstructure more than the microstructure produced by the standard solution heat treatment. Creep testing produced similar results. The creep properties of the sample with standard heat treatments were superior to those of the as-cast and modified heat treatment specimens. Long-term exposures resulted in the formation of significant amounts of γ′ coarsening and TCP phases in the as-cast and modified heat treatment samples, which further degraded the creep properties of these samples. Only a limited amount of γ′ coarsening and TCP phases were observed in samples with the standard heat treatments, which resulted in a limited decrease in creep strength. The modified heat treatment produced an improvement over the as-cast material; however, it is not as good as the standard solution heat treatment, therefore, the modified heat treatment examined in this study does not appear to be an acceptable alternative to the standard solution heat treatment. ACKNOWLEDGEMENTS The authors would like to acknowledge the support of the National Science Foundation (award number 0072671) and Tom VanVranken at PCC Airfoils for supplying the heat treatments of the samples. References 1.“Metallurgy, Processing and Properties of Superalloys,” Heat Resistant Materials-ASM Specialty Handbook, ed. J.R. Davis (Materials Park, OH: ASM International, 1997), pp. 221–254. 2. “Directionally Solidified and Single Crystal Superalloys,” Heat Resistant Materials-ASM Specialty Handbook, ed. J.R. Davis (Materials Park, OH: ASM International, 1997), pp. 255–271. 3. D.N. Duhl, Superalloys II, ed. C.T. Sims, N.S. Stoloff, and W.C. Hagel (New York: Wiley and Sons, 1987), pp. 198–200. 4. G.L. Erickson, Materials Science and Engineering (Warrendale, PA: TMS, 1995), p. 36. 5. M. Durand-Charee, The Microstructure of Superalloys (New York: Gordon and Breach Science Publishers, 1997), p. 60. 6. F.J. Fela (Master’s Thesis, University of Florida, Gainesville, FL, 2000). 7. G.E. Fuchs, “Solution Heat Treatment Response of a Third Generation Single Crystal Ni-base Superalloy,” Mater. Sci. Eng., A300 (2001), pp. 52–60. 8. T. Khan and P. Caron, “Advanced Single Crystal Ni-base Superalloys,” Advances in High Temperature Structural Materials and Protective Coatings, ed. A.K. Koul et al. (Ottawa, Canada: NRC of Canada, 1994). 9. W.S. Walston, J.C. Shaeffer, and W.H. Murphy, “A New Type of Microstructural Instability in Superalloys-SRZ,” Superalloys 1996, ed. R.D. Kissinger et al. (Warrendale, PA: TMS, 1992), pp. 9–18. 10. E.W. Ross and K.S. O’Hara, “René N4: A First Generation Single Crystal Turbine Airfoil with Improved Oxidation Resistance, Low Angle Boundary Strength and Superior Long Time Rupture Strength,” Superalloys 1996, R.D. Kissinger et al. (Warrendale, PA: TMS, 1992), pp. 19–25. 11. S.T. Wlodek, “The Stability of Superalloys,” Long Term Stability of High Temperature Materials, ed. G.E. Fuchs, K.A. Dannemann, and T.C. Deragon (Warrendale, PA: TMS, 1996), pp. 3–40. B.C. Wilson, J.A. Hickman, and G.E. Fuchs are with the Department of Materials Science and Engineering at the University of Florida. For more information, contact G.E. Fuchs, University of Florida, Department of Materials Science and Engineering, P.O. Box 116400, Gainesville, FL 32611-6400. JOM • March 2003