CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 46 (2014) 124–133

Contents lists available at ScienceDirect

CALPHAD: Computer Coupling of Phase Diagrams and

Thermochemistry

journal homepage: www.elsevier.com/locate/calphad

Solution-based thermodynamic modeling of the Ni–Al–Mo system

using first-principles calculations

S.H. Zhou a,b,n, Y. Wang a, L.-Q. Chen a, Z.-K. Liu a, R.E. Napolitano b,c

a

Department of Materials Science and Engineering, The Pennsylvania State University, University Park, PA 16802, USA

Materials & Engineering Physics Program, Ames Laboratory, USDOE, USA

c

Department of Materials Science and Engineering, Iowa State University, Ames, IA 50011, USA

b

art ic l e i nf o

a b s t r a c t

Article history:

Received 31 October 2013

Received in revised form

9 January 2014

Accepted 6 March 2014

Available online 22 March 2014

A solution-based thermodynamic description of the ternary Ni–Al–Mo system is developed here,

incorporating first-principles calculations and reported modeling of the binary Ni–Al, Ni–Mo and

Al–Mo systems. To search for the configurations with the lowest energies of the N phase, the Alloy Theoretic

Automated Toolkit (ATAT) was employed and combined with VASP. The liquid, bcc and γ-fcc phases are

modeled as random atomic solutions, and the γʹ-Ni3Al phase is modeled by describing the ordering

within the fcc structure using two sublattices, summarized as (Al,Mo,Ni)0.75(Al,Mo,Ni)0.25. Thus, γ-fcc

and γʹ-Ni3Al are modeled with a single Gibbs free energy function with appropriate treatment of the

chemical ordering contribution. In addition, notable improvements are the following: first, the ternary

effects of Mo and Al in the B2-NiAl and D0a-Ni3Mo phases, respectively, are considered; second, the

N-NiAl8Mo3 phase is described as a solid solution using a three-sublattice model; third, the X-Ni14Al75Mo11

phase is treated as a stoichiometric compound. Model parameters are evaluated using first-principles

calculations of zero-Kelvin formation enthalpies and reported experimental data. In comparison with the

enthalpies of formation for the compounds ψ-AlMo, θ-Al8Mo3 and B2-NiAl, the first-principles results

indicate that the N-NiAl8Mo3 phase, which is stable at high temperatures, decomposes into other phases

at low temperature. Resulting phase equilibria are summarized in the form of isothermal sections and

liquidus projections. To clearly identify the relationship between the γ-fcc and γʹ-Ni3Al phases in the

ternary Ni–Al–Mo system, the specific γ-fcc and γʹ-Ni3Al phase fields are plotted in x(Al)–x(Mo)–T space

for a temperature range 1200–1800 K.

& 2014 Elsevier Ltd. All rights reserved.

Keywords:

CALPHAD

First-principles calculation

Ni–Al–Mo phase diagram

ATAT

1. Introduction

The high temperature performance of superalloys based on the

Ni–Al binary system is a critical factor in current and future power

generation and transportation technologies. Moreover, the refractory metal Mo is well established as a key contributor to the high

temperature stability of many multicomponent Ni-base superalloys [1–6]. Despite its widespread use, quantitative guidelines

for future alloy development and processing design call for more

complete descriptions of the effects of Mo additions on the phase

stability and phase transformation in the Ni–Al–Mo system. This is

the focus of the present work.

Thermodynamic modeling for the ternary Ni–Al–Mo system

was first performed by Kaufman and Nesor [7], in which all

compounds were described as stoichiometric compounds. Subsequent to treatments of the Ni–Al [8], Al–Mo [9], and Ni–Mo [10]

systems, Lu et al. [11] reassessed the ternary Ni–Al–Mo system

n

Corresponding author.

http://dx.doi.org/10.1016/j.calphad.2014.03.002

0364-5916/& 2014 Elsevier Ltd. All rights reserved.

which represented a great improvement over the modeling by

Kaufman and Nesor [7], and, despite several limitations, has been

used with reasonable success for quite some time. As increased

demands for high temperature materials drive the exploration of

new multicomponent alloy regimes, however, these limitations

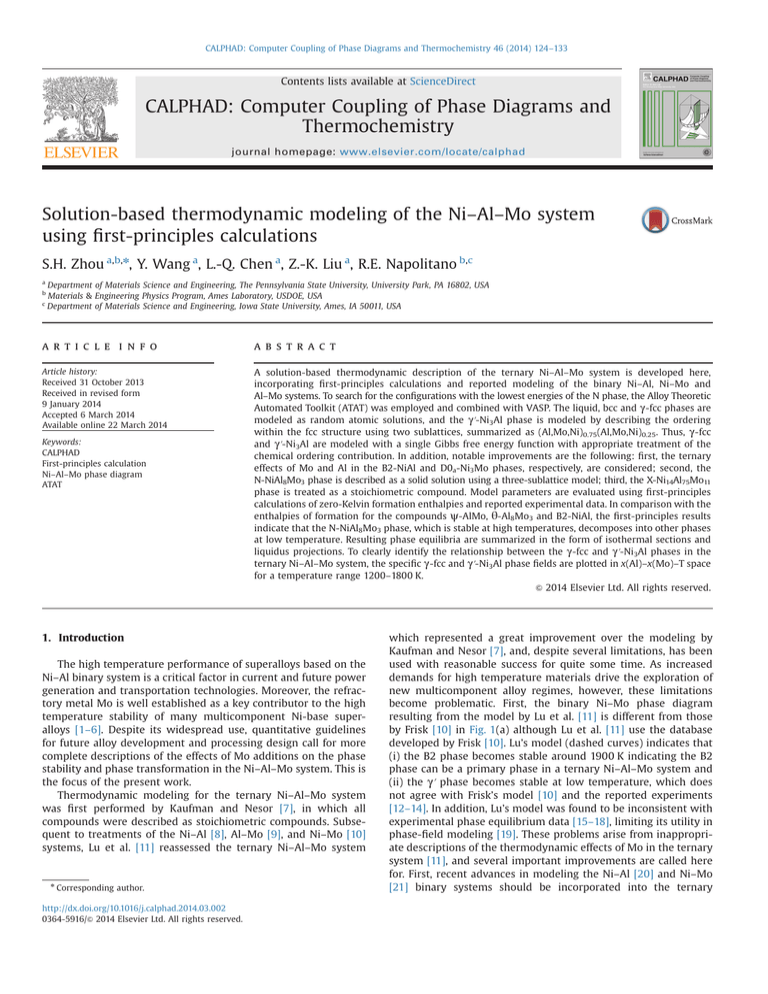

become problematic. First, the binary Ni–Mo phase diagram

resulting from the model by Lu et al. [11] is different from those

by Frisk [10] in Fig. 1(a) although Lu et al. [11] use the database

developed by Frisk [10]. Lu’s model (dashed curves) indicates that

(i) the B2 phase becomes stable around 1900 K indicating the B2

phase can be a primary phase in a ternary Ni–Al–Mo system and

(ii) the γʹ phase becomes stable at low temperature, which does

not agree with Frisk’s model [10] and the reported experiments

[12–14]. In addition, Lu’s model was found to be inconsistent with

experimental phase equilibrium data [15–18], limiting its utility in

phase-field modeling [19]. These problems arise from inappropriate descriptions of the thermodynamic effects of Mo in the ternary

system [11], and several important improvements are called here

for. First, recent advances in modeling the Ni–Al [20] and Ni–Mo

[21] binary systems should be incorporated into the ternary

S.H. Zhou et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 46 (2014) 124–133

125

Fig. 1. The binary phase diagrams of the (a) Ni–Mo system calculated using the parameters by Frist [10] in solid-line and Lu et al. [11] in dash-line; (b) Ni–Mo system

calculated using the parameters by Zhou et al. [21] in solid-line and Lu et al. [11] in dash-line; (c) Al–Mo system [9] and (d) Al–Ni system [8,20].

Table 1

A listing of phases modeled in the current treatment.

Formula unit

Sym.

Phases extending from the

Ni, Ta, Mo

–

Ni

γ

Al

γ

Mo

–

Phases extending from the

Al3Ni

–

Al3Ni2

–

AlNi

–

Al3Ni5

ε

AlNi3

γ’

Phases extending from the

NiMo

δ

Ni2Mo

ρ

Ni3Mo

–

Ni4Mo

–

Ni8Mo

ζ

Phases extending from the

Al12Mo

ϕ

Al5Mo

η

Al4Mo

φ

Al8Mo3

s

Al63Mo37

τ

AlMo

ψ

AlMo3

–

Ternary compounds

NiAl8Mo3

N

Ni14Al75Mo11

X

Lattice

pure component states:

–

Cub

Cub

Cub

Ni–Al binary system:

Ort

Tri

Cub

Ort

Cub

Ni–Mo binary system:

Orth

Tet

Tet

Tet

Tet

Al–Mo binary system:

Cub

Hex

Mon

Mon

–

Cub

Cub

Tet

–

Struk. des.

Prototype

–

A1

A1

A2

Liquid

fcc

fcc

bcc

D011

D513

B2

–

L12

Fe3C

Al3Ni2

ClCs

Ga5Pt3

AuCu3

–

–

D0a

D1a

–

NiMo

Pt2Mo

Cu3Ti

Ni4Mo

Ni8Nb

–

–

–

–

–

A2

A15

Al12W

Al5W

Al4W

Al8W3

–

W

Cr3Si

D022

–

Al3Ti

–

description. Second, the ternary N and X phases listed in Table 1,

which were not described in previous reports [7,11], should be

considered.

In the present work, the thermodynamic descriptions of the binary

Ni–Al [8,20], Al–Mo [9], and Ni–Mo [21] systems with the associated

phase diagrams shown in Fig. 1(b–d) are employed within a general

solution-based approach, using first-principles calculations and experimental data [11,15–18,22–39], which are appropriate to determine the

ternary model parameters. The ternary N and X phases are included

and the full Ni–Al–Mo phase diagram is computed. The equilibrium

phase diagram is presented with a series of isothermal sections and a

3D plot for the γ and γʹ phase fields. The resulting phase diagrams of

the ternary Ni–Al–Mo system are compared with the experimental

data [11,15–18,22–39] and the prior report by Lu [11].

2. First-principles calculations

To determinate the Gibbs free energy of formation for the intermediate phases, the zero-Kelvin energies of the N phases and the

unstable end-members (described in Section 3) for the B2 and D0aNi3Mo phases as well as fcc-Al, fcc-Ni, bcc-Mo were calculated by

means of VASP [40] employing Vanderbilt ultrasoft pseudopotential

[41] and the generalized gradient approximation (GGA) [42] with the

high precision choice. Monkhost 15 15 15 k points were used for

the pure elements Ni, Al and Mo, 11 11 11 k points for the

compounds B2 and D0a-Ni3Mo, and 6 6 6 k points for the compound N. For the stable structures, we fully relaxed the volume, the

126

S.H. Zhou et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 46 (2014) 124–133

cell shape, and the internal atomic coordinates while for the unstable

structures of the end-members we only relaxed the cell volume to

maintain the unit cell structures to their stable phases.

The enthalpy of formation, ΔH Φ

f , for a given compound

Φ is

calculated as the difference between the energy EΦ

TOT of the

compound and the linear combination of the pure element

reference state energies, EfAlcc , EfNicc and Ebcc

Mo

Φ

Φ f cc

Φ f cc

Φ bcc

ΔH Φ

f ¼ ETOT xNi ENi xAl EAl xMo E Mo

ð1Þ

where xΦ

i is the mole fraction of component i in Φ. The calculated

enthalpies of formation of the compounds are listed in Table 2a.

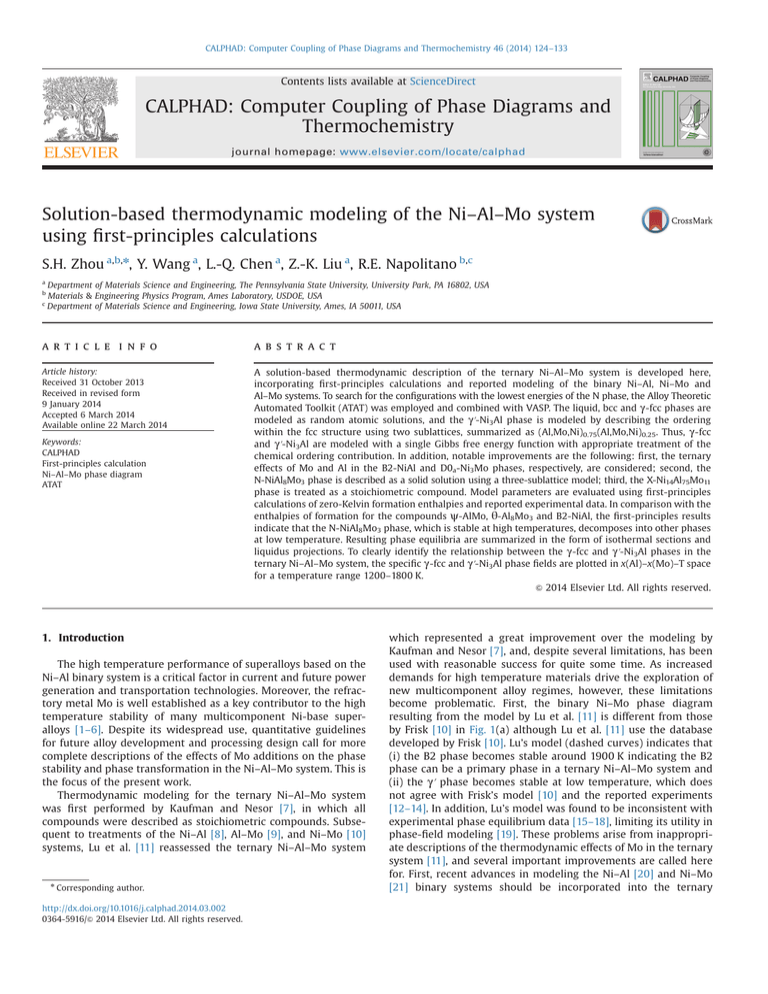

The compositions of the N phase were reported as

Ni12.5Al62.5Mo25 by Raman and Schubert [23,24] and as

Ni3Al72Mo25 by Markiv et al. [22] as the dashed-lines in Fig. 2,

respectively. To search for the configurations with the lowest

energies, ATAT developed by van de Walle [43] was employed

and combined with VASP. The starting geometry was limited to

the D022 structure with the fixed composition (25 at% Mo) and Mo

atom positions. Gamma centered k points were used and more

than 65 configurations were studied. The calculated enthalpies of

formation for some of the structures found by ATAT are plotted in

Fig. 2 indicating that the structure at the lowest point along the

concave curve is at composition NiAl8Mo3 and gives a formation

energy of 38.17 kJ/mol, which is lower than the those values at

both Ni12.5Al62.5Mo25 and Ni3Al72Mo25 by Raman and Schubert

[23,24] and Markiv et al. [22], respectively. This ternary compound

is a tripled superstructure of that of DO22 along b direction,

resulting in a body centered orthorhombic structure with the

lattice parameters being a ¼3.6904 Å, b¼11.1050 Å, and

Table 2a

A summary of results from the first-principles calculations.

Phase

Ni

Al

Mo

Symbol

Formula

ΔH, kJ/mol of atoms

Ni

Al

Mo

NiMo

AlMo

Ni3Al

Ni3Mo

Al2NiMo

Al8NiMo3

Al3Mo

0

0

0

27.84

5.88

38.12

6.15

28.01

38.17

27.19

A2

NiAl

B2

CsCl

Ni3Mo

D0a

Cu3Ti

NiAl8Mo3

N

Al3Ti

Position type

Atomic position

Al1

Al1

Al2

Mo

Ni1

Ni1

Ni2

Ni2

Ni3

Ni3

Ni4

Ni5

0

0.5

0

0.5

0

0.5

0

0.5

0

0.5

0

0.5

0.9938

0.4938

0.0194

0.7525

0.4821

0.9821

0.2486

0.7486

0.7503

0.2503

0.5210

0.2575

0.3284

0.1716

0

0

0.3399

0.1601

0.1704

0.3296

0.1518

0.3482

0

0

c¼8.5710 Å. The primitive unit cell of this ternary compound

contains 12 atoms which are arranged in the symmetry. The

atomic positions of this ternary compound are listed in Table 2b.

In this work, we designated this ternary compound as N-NiAl8Mo3

and describe it as a solution phase with small homogeneous

composition by considering the experimental observations by

Raman and Schubert [23,24] and Markiv et al. [22].

As listed in Table 2a, the first-principles calculated enthalpy of

formation for the N-NiAl8Mo3 phase is 38.17 kJ/mol, which is

less negative than the enthalpy of mixing, i.e. 40.19 kJ/mol, for

the ψ-AlMo, θ- and B2-NiAl phases from the binary systems,

indicating that the N phase decomposes into other phases at low

temperature. Due to the lack of structural information, the firstprinciples calculation was not performed for the compound X.

3. Thermodynamic models

Prototype

fcc

fcc

bcc

γ

Table 2b

The crystal structure of the lowest energy structure at composition NiAl8Mo3.

The thermodynamic properties of pure Al, Mo, and Ni in

various structures were computed using the parameters from

the SGTE database [44] as listed in Table 3. In addition to the

compounds in the Ni–Al [8,20], Al–Mo [9] and Ni–Mo [21]

systems, the liquid, bcc, γ-fcc, B2-NiAl, γʹ-Ni3Al, D0a-Ni3Mo, and

N were modeled as ternary solution phases and X phase as a

stoichiometric compound. The associated Gibbs free energy functions are defined in Table 4, where the total Gibbs free energy for

the phase, Φ, is generally given by the sum of three contributions:

ref Φ

xs Φ

Gm þ id GΦ

GΦ

m ¼

m þ Gm ;

ð2Þ

where the subscript m denotes that all terms are molar quantities.

The first term in Eq. (2) is the sum of occupancy-weighted

sublattice end-member contributions. The second and third terms

are the ideal and excess parts of the Gibbs free energy of mixing,

respectively. The excess Gibbs free energy in all Gibbs free energy

equations is expressed in terms of the Redlich–Kister polynomial

[45]. The specific treatment of each phase is discussed briefly here.

The liquid, bcc and γ-fcc are described using the model given in

Table 4, where 1GΦ

i is the molar Gibbs free energy of the pure

element i with the structure Φ (Φ ¼ liquid, bcc or γ-fcc) as listed in

Table 3 and xi is the mole fraction of the indicated component

Φ

i. j LΦ

i;k is the binary interaction parameter, and LAl;Mo;Ni is a composition dependent ternary interaction parameter evaluated with the

experimental data. Magnetic property of the Ni is considered for

its fcc structure. mg GΦ

m is the magnetic contribution [46] to Gibbs

free energy in solution phases, and expressed as the following:

mg

Fig. 2. Enthalpy of formation for the N phase calculated using ATAT and VASP with

the fixed Mo atomic positions xMo ¼ 0.25 and current thermodynamic parameters in

Tables 6 and 7. Reference states: fcc-Ni, fcc-Al and bcc-Mo.

Φ

Φ

GΦ

m ¼ RT lnðβ þ1Þf ðτ Þ;

Φ

ð3Þ

where β is the quantity related to the total magnetic entropy and

is set equal to the Bohr magnetic moment per mole of atom. τΦ is

S.H. Zhou et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 46 (2014) 124–133

127

Table 3

Thermodynamic parameters for pure elements [44].

Al phases

0

Gliq

Al

0

GfAlcc

0

Gbcc

Al

Tmin, K

Tmax, K

298

933

933

6000

298

700

700

933

933

6000

298

3200

0

0 f cc

GAl

11,005.029

11.841867

–

–

–

–

7.934 10 20

–

0 f cc

GAl

10,482.282

11.253974

–

–

–

–

–

1.231 1028

–

–

–

7976.15

137.093038

24.3671976

1.884662 10 3

74,092

8.77664 10 7

–

–

11,276.24

223.048446

38.5844296

0.018531982

74,092

5.764227 10 6

–

–

11,278.378

188.684153

31.748192

0 f cc

GAl

10,083

4.813

–

–

–

–

–

–

GREF

A

B

C

D

E

F

G

H

1.234 1028

Mo phases

0

Gliq

Mo

0

cc

GfMo

Tmin

Tmax

298

2896

2896

6000

298

6000

0

0

0

0 bcc

GMo

15,200

0.63

–

–

–

–

–

–

–

Gbcc

Mo

41,831.347

14.694912

–

–

–

–

4.24519 10 22

–

–

GREF

A

B

C

D

E

F

G

H

I

Gbcc

Mo

34,095.373

11.890046

–

–

–

–

4.849315 1033

–

–

0

Gbcc

Mo

298

2896

0

7746.302

131.9197

23.56414

3.443396 10 3

65,812

5.66283 10 7

–

–

1.30927 10 10

2896

3000

0

30,556.41

283.559746

42.63829

–

–

–

–

4.849315 1033

–

Ni phases

0

Gliq

Ni

0

Gbcc

Ni

0

GfNicc

Tmin

Tmax

298

1728

1728

6000

298

6000

298

1728

1728

3000

0

GREF

A

B

C

D

E

F

G

H

Tc

β

0 f cc

GNi

16,414.686

9.397

–

–

–

–

3.82318 10 21

–

–

–

0 f cc

GNi

18,290.88

10.537

–

–

–

–

–

1.12754 1031

–

–

0 f cc

GNi

8715.084

3.556

–

–

–

–

–

–

575

0.85

0

0

5179.159

117.854

22.096

4.8407 10 3

–

–

–

–

633

0.52

27,840.655

279.135

43.1

–

–

–

–

1.12754 1031

–

–

Note: O Gθi ¼ O GRef þ a þ bT þ cT ln T þ dT 2 þ eT 1 þ f T 3 þ gT 7 þ hT 9 þ iT 4 (J/mol) and Tc (K) is the Curie temperature and β is the average magnetic monent per atom (Bohr

magnetons).

Φ

defined as T=T Φ

c and T c is the Curie temperature. For the solution

Φ

phase, T c and β

Φ

are described as the following:

n

0 Φ

j Φ

0 Φ

j

TΦ

c ¼ xA T cA þ xB T cB þ xA xB ∑ LTðA;BÞ ðxA xB Þ

j¼0

n

j Φ

j

0 Φ

βΦ ¼ xA 0 βΦ

A þ xB β B þ xA xB ∑ Lβ ðA;BÞ ðxA xB Þ

j¼0

Φ

0 Φ

T ci and 0 i are from the pure

j Φ

j Φ

3. LTðA;BÞ and LβðA;BÞ are the magnetic

where

Table

β

ð4Þ

ð5Þ

et al. [20] in the thermodynamic evaluation of the Ni–Al, and Ni–Al–Cr

systems with a special emphasis on the relationship among the

parameters for the ordered γʹ phase. The γʹ phase in the binary

Ni–Al system was modeled with the two-sublattice model (Al,Ni)0.75

(Al,Ni)0.25 [8]. Considering the thermodynamic effect of the component

Mo, the two-sublattice model for γʹ was modified as (Al,Mo,Ni)0.75

(Al,Mo,Ni)0.25. Adopting the descriptions by Ansara et al. [8,47] and

'

Dupin et al. [20], the Gibbs free energy, Gγm , for γʹ is expressed as the

following:

element i as listed in

ðaÞ

interaction parameters

Gγm' ¼ Gγm ðxi Þ þ ΔGord

m ði : jÞ;

ðbÞ

ord

ord

ΔGord

m ði : jÞ ¼ Gm ði : jÞyIi ;yIIi Gm ði : jÞxi ¼ yIi ¼ yIIi ;

between the elements A and B. In this work, the magnetic

parameters from the binary Al–Ni system [8] are employed as

listed in Table 7.

The thermodynamic modeling of the ordered γʹ-Ni3Al and disordered γ-fcc phases was discussed by Ansara et al. [8,47] and Dupin

ð6Þ

where Gγm ðxi Þ is the Gibbs free energy of the disordered γ-fcc phase as

described in Table 4. ΔGord

m ði; jÞ in Eq. (6) corresponds to the ordering

energy, being described with Eq. (6b) [20,48]. Gord

m ði : jÞ in Eq. (6b) is

128

S.H. Zhou et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 46 (2014) 124–133

Table 4

ref Φ

xs Φ 0 ref

0 f cc

Gm þ id GΦ

¼ 0 GfAlcc , 0 Gbcc

Summary of the thermodynamic models used for the Al–Mo-Ni ternary system with the total Gibbs free energy GΦ

m ¼

m þ Gm ( Gi

Mo or GNi ).

Phase

Formulation

Model

Liquid

γ-fcc

Bcc

(Al,Mo,Ni)1

ref

GΦ

m ¼

id

xs

GΦ

m

xi 1GΦ

i

∑

i ¼ Al;Mo;Ni

¼ RT

∑

xi ln xi

i ¼ Al;Mo;Ni

n

n

j¼0

j¼0

j Φ

j Φ

j

j

GΦ

m ¼ xAl xMo ∑ LAl;Mo ðxAl xMo Þ þ xAl xNi ∑ LAl;Ni ðxAl xNi Þ

n

Φ

j

þ xMo xNi ∑ j LΦ

Mo;Ni ðxMo xNi Þ þ xAl xMo xNi LAl;Mo;Ni ;

j¼0

2 Φ

0 Φ

1 Φ

LΦ

Al;Mo;Ni ¼ xAl LAl;Mo;Ni þ xMo LAl;Mo;Ni þ xNi LAl;Mo;Ni

ψ-AlMo

B2-NiAl

D0a-Ni3Mo

(Al,Mo)1(Al,Mo)1

(Al,Mo,Ni)1(Al,Mo,Ni,Va)1

(Al,Mo,Ni)0.75(Al,Mo,Ni)0.25

ref

D0a

D0a

a

GD0

Al:Al ¼ GAl:Mo ¼ GAl:Ni ¼ 0

GΦ

m ¼

∑

yIi

∑

yIIj 1GΦ

i:j

i ¼ Al;Mo;Ni j ¼ Al;Mo;Ni

ref

ref

Φ

1GΦ

¼

p1G

þ

q1G

þ

ΔG

¼

p1Gref

i:j

i:j

i

j

i

id

GΦ

m

¼

xs

GΦ

m

I

I k

¼ ∑ ∑ yIi yIl ∑ ∑ k LΦ

i;l:j ðyi yl Þ

i l4i

j k¼0

RT

∑

ðpyIi

i ¼ Al;Mo;Ni

ln

yIi þ qyIIi

Φ

Φ

þ q1Gref

j þ ai:j þ bi:j T

ln

yIIi Þ

II

II k

þ ∑ ∑ ∑ yIIi yIIl ∑ k LΦ

j:i;l ðyi yl Þ

i l4i

j

k¼0

(p and q are the subscript numbers of sublattices, respectively)

γ’-Ni3Al

(Al,Mo,Ni)0.75(Al,Mo,Ni)0.25

0

0 ord

1

Gord

i:j ¼ Gj:i ¼ 3uij

0 ord

Li;j:i

1

¼ 0 Lord

i;j:j ¼ 6uij

1 ord

Li;j:i

4

¼ 1 Lord

i;j:j ¼ 3uij

1 ord

Li:i;j

4

¼ 1 Lord

j:i;j ¼ uij

0 ord

Li;j:k

¼ 6u1ij þ ðuiijk þ ujijk Þ3=2

1 ord

Li;j:k

¼ 3u4ij þ ðuiijk ujijk Þ=2

0 ord

Li;j;k:i

N

(Al,Ni)2(Al,Ni)1(Mo)1

D513-Al3Ni2

δ-NiMo

GN

Ni:Al:Mo ¼ 0

(Al)3(Al,Ni)2(Ni,Va)1

(Ni)24(Mo,Ni)20(Mo)12

ref

¼ 6uiijk 3ujijk =2 3ukijk =2

N

I

II

III

GΦ

m ¼ ∑ yi ∑ yj ∑ yk 1Gi:j:k

i

j

k

ref

ref

ref

N

1GΦ

i:j:k ¼ p1Gi þ q1Gj þ r1Gk þ ΔGi:j:k

id

I

I

II

II

III

III

GΦ

m ¼ RT∑ðpyi ln yi þ qyi ln yi þ ryi ln yi Þ

xs

n Φ

n Φ

I I

I

I n

II II

II

II n

GΦ

m ¼ ∑ ∑ yi yl ∑ ∑ Li;l:j:k ðyi yl Þ þ ∑ ∑ ∑ yi yl ∑ Lj:i;l:k ðyi yl Þ

i

i l4i

j n¼0

j

i l4i

n¼0

n Φ

III

III

III n

þ ∑ ∑ ∑ yIII

i yl ∑ Lk:j:i;l ðyi yl Þ

j

n¼0

i l4i

ϕ-Al12Mo

φ-Al4Mo

η-Al5Mo

τ-Al63Mo37

θ-Al8Mo3

A15–AlMo3

D011-Al3Ni

ε-Al3Ni5

D1a-Ni4Mo

ρ-Ni2Mo

ζ-Ni8Mo

(Al)12(Mo)1

(Al)4(Mo)1

(Al)5(Mo)1

(Al)63(Mo)37

(Al)8(Mo)3

(Al)0.75(Mo)0.25

(Al)0.75(Ni)0.25

(Al)0.375(Ni)0.625

(Ni)0.8(Mo)0.2

(Ni)0.67(Mo)0.33

(Ni)0.89(Mo)0.11

ref

ref

Φ

GΦ

m ¼ ΔGi:j þ p1Gi þ q1Gj

X

(Al)0.75(Mo)0.11(Ni)0.14

0 f cc

X

GXm ¼ 0:750 GfAlcc þ 0:110 Gbcc

Mo þ 0:14 GNi þ a þ b T

Φ

ref

¼ aΦ þ b T þ p1Gref

i þ q1Gj

(p and q represent subscript values in formulation, respectively.)

X

the Gibbs free energy contribution due to ordering with

xi ¼ 3yIi =4 þ yIIi =4 as described by the two-sublattice model in

Table 4 where yIi and yIIi are sit-fraction in first and second sublattices,

respectively. It has three terms as shown in Eq. (2) and in Table 4 and

contains implicitly a contribution to the disordered state also. When

yIi ¼ yIIi ¼ xi , Gord

m ði : jÞ represents the extraneous excess energy contribution to the disorder state. Thus ΔGord

m ði; jÞ is described as the

Gord

m ði

Gord

m ði

temperature and composition ranges, Gγm' should always have an

extremum when yIi ¼ yIIi ¼ xi . When the disordered phase is stable,

this extremum is a minimum. Hence, the following equation [8,47]

has to be fulfilled:

!

∂Gγm'

γ'

ðdGm Þxi ¼ ∑ ∑

dyðsÞ

ð7Þ

i ¼0

yðsÞ

i s

i

x

i

: jÞxi ¼ yI ¼ yII in Eq. (6b) and

k ord

k ord

From this equation, the parameters 0 Gord

i:j , Li;j:l , and Li:j;l can be

k ord

k ord

must be zero when the phase is disordered. 0 Gord

i:j , Li;j:l , and Li:j;l

expressed with the parameters u1ij , u4ij , uiijk , ujijk , and ukijk (i, j, or

listed in Table 4 are the parameters for Gord

m ði : jÞ.

As described in reports [8,20,47,49], in order to favor the

stability of the ordered phase to disorder transit in certain

k¼ Al, Mo, or Ni) as shown in Table 4. The detail descriptions of the

difference between

: jÞyI ;yII and

i

i

i

i

parameter derivation for the ordered γʹ-Ni3Al phase can be found

in Refs. [20,49].

S.H. Zhou et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 46 (2014) 124–133

129

Table 5

Symbols and related references used in Figs. 2–4.

Figure

Figs. 3 and 5(b)

Boundary

Single phase

Symbol

Ref.

▽γ

●bcc

△ γʹ

◇δ

þγ

*

γʹ

[26]

Symbol

Two-phase

Ref.

Fig. 5(d) and (f)

Fig. 5(e) and (g)

Symbol

Ref.

Symbol

Ref.

◆ γ þγʹ

[27]

▼γ þδ þ bcc

□γ þγʹ þbcc

▲γ þγʹ þbcc

[26]

△fccþ bcc þliq

[37]

γ þγʹ þbcc

◆ bcc þ B2 þγʹ

▲ γ þ bcc þδ

B2þ bcc þ l12

fccþ l12 þbcc

[15]

✖ γ þγʹþ δ

* bcc þ δ þγʹ

◆ bcc þ B2 þ γʹ

D0a þ γʹ þδ

γ þ γʹþ D0a

✡ B2 þAlMo3 þN

[15]

⊖ γ þ γʹþ δ

*

bcc þ δþ γʹ

✶liqþ Al3Moþ N

liq þ Al3Ni2 þX

N þAl3Ni2 þ X

◆γ þγʹ þ D0a

✖ γ þγʹþ δ

[31]

▲ bcc þliq

○ bcc þliq

■ fcc þ liq

◆ bccþ liq

◇ fccþ liq

▼ Nþ liq

▽γ

△ γʹ

□ B2

δ

þ bcc

γ

✧γʹ

◯γ

◇γʹ

B2

▽γ

△ γʹ

□ B2

δ

γ

✧γʹ

B2

δ

○γ

◇γʹ

B2

▽γ

△ γʹ

○D0a

□ B2

γ

✧γʹ

δ

D0a

Y γʹ

✚γ

[25]

[27]

Fig. 4

Fig. 5(a) and (c)

Three-phase

[15]

✖N

●γ

N

[22]

[15]

[23,24]

[25]

[34]

[38]

[22]

■ γ þγʹ

δ þγ

▼ bcc þγʹ

*

bcc þ B2

[15]

■ γ þγʹ

▲ γʹþ δ

δþ γ

▼ bcc þγʹ

✰γʹþ D0a

∅δ þD0a

⊖γ þ D0a

[15]

◇ δþ γ

✰δ þ γʹ

∅ bcc þ γʹ

▲Al3Niþ X

@

▼ γ þ γʹ

[31]

[29]

[29]

[22]

[35]

[15]

[11]

[24]

[35]

[22]

● γʹ

N

■X

[28]

[22]

[32]

[36]

[18]

[36]

[32]

[35]

@γ þ γʹ two-phase field at 1048 K.

The N-NiAl8Mo3 phase has the D022 structure with the space

group I4/mmm [22,24]. Their atoms distribute in three-sublattices.

According to the first-principles data in Table 2a and experimental

data [22,24] discussed in Section 2, the N-NiAl8Mo3 phase is

described with the three-sublattice model, (Al,Ni)2(Al,Ni)1(Mo)1, with

the Gibbs free energy given in Table 4, where yI and yII are the site

fractions in the first and second sublattices, respectively. The Gibbs

free energy of formation ΔGN

i:j:Mo of the end-member i:j:Mo is

N

xs N

expressed as aN

þ

b

T.

G

m is the excess Gibbs free energy

i:j:Mo

i:j:Mo

1 N

with the interaction parameters 0 LN

Al:Al;Ni:Mo and LAli:Al;Ni:Mo being

N

assumed as a constant. Both of them as well as aN

i:j:Mo and bi:j:Mo are

evaluated with the experimental and first-principles data.

The thermodynamic models of B2-NiAl and D0a-Ni3Mo phases

were described in detail in Refs. [8,21], respectively. The experimental data [11,15,35] revealed a small solubility of Mo in B2-NiAl

and Al in D0a-Ni3Mo. The non-stoichiometric B2-NiAl and D0aNi3Mo phases were modified here with the model shown in

Table 4. Here we only consider the unstable end-members with

B2

the Gibbs free energy of formationsΔGB2

Al:Mo and ΔGMo:Ni for B2D0a

NiAl and ΔGNi:Al for D0a-Ni3Mo.

The X phase was treated as stochiometric compounds with the

X

Gibbs free energy functions as shown in Table 4, where aX and b

are the model parameters to be evaluated.

4. Determination of the thermodynamic model parameters

The parameters described in the preceding section for the

ternary Ni–Al–Mo system were determined in the order of γ-fcc

and γʹ-Ni3Al phases, B2-NiAl, D0a-Ni3Mo, liquid, N and X phases

using the available experimental data in Table 5 and first-principles

data in Table 2a. The evaluated parameters as well as those of the

binary Ni–Al [8,20], Al–Mo [9] and Ni–Mo [21] systems are listed in

Tables 6 and 7. In the present section, the methodology used for

the determination of the parameters is discussed.

In both binary Ni–Al and Ni–Mo systems, Al and Mo dissolve in

γ-fcc(Ni). The isothermal section at 1533 K is calculated only using

the parameters of the three binary systems in Tables 6 and 7 and

shown in Fig. 3, where the calculated γ and γʹ two-phase region

deviates far from the experimental data [25–27] indicating that the

130

S.H. Zhou et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 46 (2014) 124–133

Table 6

Gibbs free energy of formation for end-member reference states (per mole of formula unit).

Phase

Parameters

Value, J/mol of atoms

D011-Al3Ni

11

ΔGD0

Al:Ni

48,483.73þ 12.299T

13

ΔGD5

Al:Al:Ni

39,465.978þ 7.895T

D513-Al3Ni2a

ε-Al3Ni5

B2-NiAl

γʹ-Ni3Al

13

ΔGD5

Al:Ni:Ni

427,191.9þ 79.217T

13

ΔGD5

Al:Al:Va

30,000 3T

13

ΔGD5

Al:Ni:Va

357,725.92 þ 68.322T

ΔGεAl:Ni

55,507.7594 þ7.265T

0

a

ΔGB2

Al:Al

B2 a

ΔGB2

Al:Ni , ΔGNi:Al

152,397.3 þ 26.406T

a

ΔGB2

Al:Va

1000 T

a

ΔGB2

Ni:Ni

0

a

ΔGB2

Ni:Va

162,397.3 27.406T

ΔGB2

Mo:Va

150,000

ΔGB2

Mo:Mo

150,000

B2

ΔGB2

Al:Mo , ΔGMo:Al

5876

B2

ΔGB2

Mo:Ni , ΔGNi:Mo

27,844

u1AlNi

u4AlNi

u1MoNi

ϕ-Al12Mo

φ-Al4Mo

η-Al5Mo

τ-Al63Mo37

θ-Al8Mo3

ψ-AlMo

A15–AlMo3

δ-NiMo

ρ-Ni2Mo

D0a-Ni3Mo

D1a-Ni4Mo

ζ-Ni8Mo

N

X

a

[9]

This work

13,415.515 þ 2.082T

[8]

341 3.515T

This work

u4MoNi

3621.1 þ3.411T

u1AlMo

0

u4AlMo

0

uNi

AlMoNi

20,375 12.033T

ΔGφAl:Mo

ΔGϕAl:Mo

ΔGηAl:Mo

ΔGτAl:Mo

ΔGθAl:Mo

ΔGψAl:Al

ΔGψMo:Al

ΔGψMo:Mo

ΔGA15

Al:Mo

ΔGδNi:Mo:Mo

ΔGδNi:Ni:Mo

ΔGρNi:Mo

139,100 þ 26.975T

[9]

137,570 þ29.69T

139,104þ 30.156T

2,268,100 þ167.2T

412,500 þ105.05T

20,166.8 9.626aT

36,850þ 1.0T

0

89,000 þ20T 0.003T2

169,981 þ1154.981T 155.484T ln (T)

[21]

154,106þ 2855.001T 94.923T ln (T)

9421 þ 49.551T 6.231T ln (T)

a

ΔGD0

Mo:Mo

42,650

a

ΔGD0

Ni:Mo

10,131.9þ 58.132T 7.366T ln (T)

a

ΔGD0

Mo:Ni

17,060

a

ΔGD0

Ni:Ni

2840

a

ΔGD0

Ni:Al

37,910 þ5.651T

This work

a

ΔGD1

Ni:Mo

ΔGςNi:Mo

ΔGN

Ni:Ni:Mo

ΔGN

Al:Ni:Mo

ΔGN

Al:Al:Mo

ΔGXAl:Mo:Ni

9021 þ 55.004T 7.080T ln (T)

[21]

6115 þ33.258T 4.085T ln (T)

29,600þ 32.028T

[21]

This work

119,040

108,760 þ22.128T

39,464.2 þ6.521T

0

0

0

bcc

Reference state is Al-bcc and Ni-bcc, i.e. Gref

¼ Gbcc

Al or GNi .

i

[21], the thermodynamic properties of the γ and γʹ phases in the

ternary Ni–Al–Mo system are described with the ternary interacuNi

AlMoNi .

[8]

7088.7363 3.687T

binary interaction parameters for γ-fcc from both Ni–Al [8,20] and

Ni–Mo [21] systems predict a ternary γ-fcc-field that is too expansive; hence positive ternary interaction parameters here had to be

considered to reduce it. Similar behavior was also found in the

ternary Ni–Al–Cr system modeled by Dupin et al. [20], in which the

positive ternary interaction parameter for γ-fcc(Ni) was employed.

In addition to the parameters in the Al–Ni [8,20] and Ni–Mo

tion parameters

Ref.

γ

γ

0 γ

LAl;Mo;Ni , 1 LAl;Mo;Ni , 2 LAl;Mo;Ni ,

u1Mo;Ni , u4Mo;Ni and

These parameters are evaluated with the experimental

data [11,15–18,22,26–35] and listed in Tables 6 and 7. The

experimental data [11,15,22,26,35] indicate little solubility of Mo

in B2-NiAl. The model parameters ΔGB2

Mo:i (i ¼ Al,Ni), which are

considered as a constant in Table 4, were fixed with the firstprinciples data as listed in Tables 6 and 7.

Based on the thermodynamic description in Section 3, the

D0a

a

model parameters aD0

and bNi:Al

in Table 4 are used for the

Ni:Al

a

was determined with

compound D0a-Ni3Mo. The parameter aD0

Ni:Al

D0

a

was evaluated with the phase

the first-principles data, while bNi:Al

equilibrium data [15], i.e. the four-phase δ þ γ-γʹ þD0a reaction at

11637 5 K. The evaluated parameters are listed in Table 6.

According to the experimental phase equilibrium data [22–24]

and first-principles data in Fig. 2, the composition range of the

S.H. Zhou et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 46 (2014) 124–133

131

Table 7

Excess Gibbs free energy interaction parameters.

Phase

Parameters

Value, J/mol

Ref.

Liquid

0 Liq

LAl;Ni

1 Liq

LA;Ni

2 Liq

LA;Ni

3 Liq

LA;Ni

4 Liq

LA;Ni

0 liq

LAl;Mo

1 liq

LAl;Mo

0 liq

LMo;Ni

1 liq

LMo;Ni

2 liq

LMo;Ni

0 liq

LAl;Mo;Ni

1 liq

LAl;Mo;Ni

2 liq

LAl;Mo;Ni

0 bcc

LMo;Ni

1 bcc

LMo;Ni

0 bcc

LAl;Mo

0 γ

LAl;Mo

0 γ

LAl;Ni

1 γ

LAl;Ni

2 γ

LAl;Ni

3 γ

LAl;Ni

0 γ

LTðAl;NiÞ

1 γ

LTðAl;NiÞ

0 γ

LMo;Ni

1 γ

LMo;Ni

2 γ

LMo;Ni

0 γ

LAl;Mo;Ni

1 γ

LAl;Mo;Ni

2 γ

LAl;Mo;Ni

0 D513

LAl:Al;Ni:Ni

0 D513

LAl:Al:Ni;V a

0 D513

LAl:Ni:Ni;Va

0 D513

LAl:Al;Ni:V a

0 B2

LAl;Ni:Ni

0 B2

LAl:Ni;Va

0 B2

LNi:Ni;Va

0 B2

LAl;Ni:Va

0 ψ

LAl;Mo:Al

0 ψ

LAl:Al;Mo

0 ψ

LMo:Al;Mo

1 ψ

LMo:Al;Mo

0 ψ

LAl;Mo:Mo

1 ψ

LAl;Mo:Mo

0 δ

LNi:Mo;Ni:Mo

1 δ

LNi:Mo;Ni:Mo

0 D0a

LMo;Ni:Mo

0 D0a

LNi:Mo;Ni

0 N

LAl:Al;Ni:Mo

1 N

LAl:Al;Ni:Mo

207,109þ 41.315T

[8]

bcc

γ-Fcc

D513-Al3Ni2

B2-NiAl

ψ-AlMo

δ-NiMo

D0a-Ni3Mo

N

10,186þ 5.871T

81,205 31.957T

4365 2.516T

22,101.64 þ 13.163T

100,000 þ 35T

[9]

15,000 þ 6.3T

39,597þ15.935T

[21]

7373þ 4.102T

12,123þ 5.551T

50,748

This work

Fig. 3. Isothermal section of the Ni–Al–Mo phase diagram calculated at 1533 K

using the parameters of the three binary systems in Tables 6 and 7 in comparison

with experimental data with the symbols listed in Table 5.

70,748

115,748

27,691

[21]

18,792

75,000þ 25T

[9]

92,220 þ 20T

162,407.75 þ16.213T

[20]

73,417.798 34.914T

33,471.014 9.837T

30,758.01 þ10.253T

1112

[8]

1745

8916 þ3.591T

[21]

5469 0.249T

1549 2.741T

41,546 50.349T

This work

91,047

193,074 12.948T

193,484.18 þ 131.79T

[8]

22,001.7þ 7.033T

22,001.7þ 7.033T

Fig. 4. Liquidus projection of the Ni–Al–Mo system calculated in the composition

triangle using the parameters in Tables 6 and 7 indicating the primary phases and comparing with experimental data as the symbols in Table 5 and dash-line by Lu et al. [11].

193,484.18 þ 131.79T

52,440.88 þ 11.3012T

64,024.38þ 26.4949T

64,024.38þ 26.494T

52,440.88 þ 11.301T

5000

[9]

5000

25,000

10,000

25,000

10,000

829,211þ 825.923T

[21]

417,368 þ 326.504T

three binary systems and ternary parameters, 0 Lliq

, 1 Lliq

Al;Mo;Ni

Al;Mo;Ni

6710

and 2 Lliq

. Henry [25] studied the two alloys of Ni65.7Al17.6Mo16.7

Al;Mo;Ni

1198–0.401T

140,870

0 N

function of the N phase in which ΔGN

LAl:Al;Ni:Mo and

Al:Ni:Mo ,

assumed to be constant. The parameters,

and aN

Al:Al:Mo , were fixed by the first-principles

N

N

data. The parameters, bNi:Ni:Mo and bAl:Al:Mo , were evaluated with

the phase equilibrium data [22,24]. The interaction parameters,

0 N

LAl:Al;Ni:Mo and 1 LN

Al:Al;Ni:Mo , were evaluated with the first-principles

data in Fig. 2. For the X phase, due to the lack of experimental data,

the parameter aX in Table 4 had to be assumed by calculating the

enthalpy of mixing of the compounds N, D011-Al3Ni and D513X

Al3Ni2. The parameter b was evaluated with the phase equilibrium data [36].

The liquid phase was described with the parameters of the

1 N

LAl:Al;Ni:Mo were

N

aN

Ni:Ni:Mo , aAl:Ni:Mo

This work

60,570

stable N phase is estimated between Ni12.5Al62.5Mo25 and

Ni3Al72Mo25 at high temperatures. Fig. 2 shows the composition

with the minimum enthalpy of formation for the N phase being at

NiAl8Mo3. Therefore, the interaction parameters, 0 LN

Al:Al;Ni:Mo and

1 N

LAl:Al;Ni:Mo , and the Gibbs free energies of formation, ΔGN

Ni:Ni:Mo ,

ΔGNAl:Ni:Mo and ΔGNAl:Al:Mo were considered for the Gibbs free energy

and Ni65.6Al14.4Mo20 using the optical microscopy and observed

that the primary phase of the two alloys is the Mo-bcc phase

during the solidification. Svetlov et al. [34] studied the

liquid þsolids (solid¼ fcc or bcc) two-phase field at the Ni-rich

corner using DTA and optical microscopy. Yoshizawa et al. [37]

studied the eutectic reaction (liquid-bcc þ γ) using SEM and TEM.

, 1 Lliq

and 2 Lliq

, were evaluated

The parameters, 0 Lliq

Al;Mo;Ni

Al;Mo;Ni

Al;Mo;Ni

with the primary solidification phase data [25,34,37]. The para1 bcc

2 bcc

meters 0 Lbcc

Al;Mo;Ni , LAl;Mo;Ni and LAl;Mo;Ni were considered to be zero.

132

S.H. Zhou et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 46 (2014) 124–133

5. Phase equilibrium results

The Ni–Al–Mo phase diagrams computed from the Gibbs free energy functions

of individual phases described above are shown in Figs. 4 and 5. Relevant

Fig. 5. The isothermal section calculated at different temperatures in comparison

with experimental data as the symbols in Table 5 and the calculated results in

dash-line by Lu et al. [11]. (a) At 1573K, (b) at 1533K, (c1) overall composition at

1473K, (c2) Ni–rich corner at 1473K, (d1) overall composition at 1373K, (d2) Ni–

corner at 1373K and at 1273K, (e) at 1273K, (f) at 1153K and (g) at 1073K.

experimental data in Table 5 as well as the phase diagram calculated using the

parameters by Lu et al. [11] are also shown in Fig. 1(a), Figs. 4 and 5 for comparison.

The phase diagrams we propose here include several dramatic differences from

previously suggested phase diagrams as described briefly here.

Our model describes the ternary compound N and X phases using a threesublattice model and as a stoichiometric compound, respectively, which were

ignored by Lu et al. [11]. The first-principles calculated enthalpies of formation of

the N phase in Fig. 2 were used to evaluate the thermodynamic parameters of the N

phase. In addition, our first-principles data were used to determine the Gibbs

energy of the end-members of the B2-NiAl and D0a-Ni3Mo phases. This differs

greatly from the modeling by Lu et al. [11]. The other major contributor of this work

is that the recent descriptions of the binary Ni–Al [20] and Ni–Mo [21] in Fig. 1

were adopted for better description of γ and γʹ in the Ni–Al–Mo system.

The current model liquidus projection of the Ni–Al–Mo system is plotted in

Fig. 4, showing a good agreement with experimental data [22,25,34,37,38]. In

comparison with our results, the liquidus projection calculated using parameters by

Lu et al. [11] shows two significant differences in Fig. 4. In our calculation, the N

phase is a primary phase on Al rich side while the calculated primary phase by Lu

et al. [11] is the θ-Al8Mo3 phase as marked with “Al8Mo3” in gray in Fig. 4. Second, a

curve as marked “A-line” in Fig. 4 is calculated using the parameters by Lu et al.

[11]. This curve starts from the binary Ni–Mo system as shown in Fig. 1

(a) indicating that the B2 phase can be the primary phases in the liquidus

projection.

Fig. 6. γ-fcc and γʹ-Ni3Al single-phase domains plotted in 3D as computed using the

present model where symbol ϑ (ϑ ¼ liq, bcc, B2, and δ) indicates the phase

equilibrium with γ-fcc or γʹ-Ni3Al.

S.H. Zhou et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 46 (2014) 124–133

The calculated isothermal sections at 1573, 1533 and 1473 K along with the

experimental data in Table 5 are shown in Fig. 5(a–c), in which the calculated equilibrium phases are in good agreement with the experimental data

[15,22–27,29,35]. The calculated isothermal sections at 1473 and 1373 K plotted

in Fig. 5 (c and d) show the invariant reaction γ þbcc-γʹ þ δ, which occurs at

1400 K. According the experimental data, the invariant reaction γ þbcc-γʹþ δ

temperature is between 1356 and 1420 K by Miracle et al. [26], between 1300 and

1400 K by Hong et al. [30] and at 1403 K by Wakashima et al. [31]. This means that

our calculated invariant reaction γ þ bcc-γʹþ δ is in good agreement with the

experimental data [26,30,31]. Furthermore, our calculated results show an agreement with the experimental data [15] of the γ þ γʹ two-phase region in Fig. 5(c),

while the calculated results by Lu et al. [11] are in the single fcc phase region.

Fig. 5(d) and (e) shows the isothermal section calculated at 1373 and 1273 K

with experimental data [11,15,18,22,24,28,31,32,35,36]. There are two significant

differences between Fig. 5(d) and (e). First, the X phase appears in Fig. 5(e). Our

calculated results indicate that the X phase forms at 1282 K, which is in reasonable

agreement with the experimental data 1288 K measured by Grushko et al. [36].

Second, the invariant reaction, liqþ θ-Nþ φ, occurs at 1355 K. It should be noted

that the data by Grushko et al. [36] plotted in Fig. 5(e) indicate the liqþ Al3Mo þN

three phases in equilibrium at 1273 K. This is inconsistent with our calculated

liq þ φ-Al4Mo þN three-phase equilibrium. According to the thermodynamic

description for the binary Al–Mo system [9] adopted in this work with the

associated phase diagram in Fig. 1(d), the liquid, Al4Mo, Al8Mo3, AlMo3 and bcc

phases are stable at 1273 K, while the Al3Mo phase is not considered as a stable

phase. The stability of the Al3Mo phase needs to be confirmed in future work.

Fahrmann et al. [16,17] investigated the Ni79.2Al6.4Mo14.4 and Ni77.97Al12.9Mo9.13

alloys. In the Ni79.2Al6.4Mo14.4 alloy aged at 1258 K, minor amounts of the δ-NiMo

phase was observed [16,17] which is consistent with our calculated result i.e. the

mole fraction of the δ-NiMo phase in Ni79.2Al6.4Mo14.4 alloy is 0.0057 which is very

little. The volume fraction of the γʹ phase for the Ni77.97Al12.9Mo9.13 alloy calculated

at 1258 K in this work is 0.61, which is in good agreement with the experimental

data 0.60 7 0.06 [16,17], while that calculated using parameters by Lu et al. [11] is

0.54. It is clear that our model yields better agreement with experimental data

[16,17].

Fig. 5(f) and (g) shows the isothermal sections calculated at 1153 and 1073 K,

respectively, with the experimental data [15,22,24,32,35,36]. Comparing with Fig. 5

(e), the calculated four phase δ þ γ-γʹþ D0a reaction occurs at 1167 K, which is in a

good agreement with the experimental phase transformation data 1163 75 K [15].

In Fig. 5(f), the experimental data [15], which indicated the γ þ γʹ two-phase region,

are in agreement with our calculated results, but outside the calculated γ þ γʹ twophase region using the parameters by Lu et al. [11]. A similar problem is also shown

in Fig. 5(g), where our calculated results shown better agreement with the

experimental γ þ γʹ two-phase field data [18] than those by Lu et al. [11]. To

understand the stabilities of the γ and γʹ phases, we plotted the stable γ and γʹ

phase field in the related composition triangle over the temperature range 1200–

1800 K in Fig. 6, which is useful for Ni-based superalloy design by showing the

stable γ, γʹ and γ þ γʹ phase domains with related composition and temperature

dimensions.

6. Summary

By combining CALPHAD approach with the first-principles

calculations, a thermodynamic model was developed for the

ternary Ni–Al–Mo system. The present work exhibits several key

differences relative to previously reported models: (i) firstprinciples calculations were used to determine some thermodynamic parameters, (ii) both ternary compounds N and X, and the

first-principles calculations confirm that the N-compound is only

marginally stable; (iii) calculated phase diagrams exhibit improved

agreement with the experimental data.

Acknowledgment

This work was supported by the Pennsylvania State University

by the NSF Grants (DMR-9983532, DMR-0122638, and DMR0205232). First-principles calculations were carried out on the

LION clusters at the Pennsylvania State University supported in

part by the NSF Grants (DMR-9983532, DMR-0122638, and DMR0205232).

133

Appendix A. Supporting information

Supplementary data associated with this article can be found in

the online version at http://dx.doi.org/10.1016/j.calphad.2014.03.002.

References

[1] S. Miyazaki, Y. Murata, M. Morinaga, Tetsu To Hagane—J. Iron Steel Inst. Jpn. 80

(1994) 166.

[2] S. Miyazaki, Y. Kusunoki, Y. Murata, M. Morinaga, Tetsu To Hagane–J. Iron Steel

Inst. Jpn. 81 (1995) 1168.

[3] R. Hashizume, A. Yoshinari, T. Kiyono, Y. Murata, M. Morinaga, Development of

Ni-based single crystalsuperalloys for power-generation gas turbines, in:

K.A. Green, H. Harada, T.M. Pollock, T.E. Howson, R.C. Reed (Eds.), Superalloys

2004, Minerals, Metals & Materials Soc, Champion, PA, 2004, p. 53.

[4] R. Yamamoto, Y. Kadoya, H. Kawai, R. Magoshi, S. Ueta, T. Noda, S. Isobe, J. Iron

Steel Inst. Jpn. 90 (2004) 37.

[5] J.E. Gould, F.J. Ritzert, W.S. Loewenthal, Preliminary investigations of joining

technologies for attaching refractory metals to Ni-based superalloys, in:

M.S. ElGenk (Ed.), Space Technology and Applications International Forum

(STAIF 2006), Amer Inst Physics, Albuquerque, NM, 2006, p. 757.

[6] J. Lapin, J. Marecek, M. Kursa, Kov. Mater. Met. Mater. 44 (2006) 1.

[7] L. Kaufman, H. Nesor, Metall. Trans. 5 (1974) 1623.

[8] I. Ansara, N. Dupin, H.L. Lukas, B. Sundman, J. Alloy. Compd. 247 (1997) 20.

[9] N. Saunders, J. Phase Equilib. 18 (1997) 370.

[10] K. Frisk, CALPHAD 14 (1990) 311.

[11] X. Lu, Y. Cui, Z. Jin, Metall. Mater. Trans. A 30A (1999) 1785.

[12] R.E.W. Casselton, W. Hume-Rothery, J. Less-Common Met. 7 (1964) 212.

[13] G. Grube, H. Schlecht, Z. Elektrochem. 44 (1938) 413.

[14] C.P. Heijwegen, G.D. Rieck, Z. Metallkd. 64 (1973) 450.

[15] S.B. Maslenkov, N.N. Burova, V.A. Rodimkina, Russ. Metal (1988) 179.

[16] M. Fahrmann, W. Hermann, E. Fahrmann, A. Boegli, T.M. Pollock, H.G. Sockel,

Mater. Sci. Eng. A 260 (1999) 212.

[17] M. Fahrmann, E. Fahrmann, T.M. Pollock, W.C. Johnson, Metall. Mater. Trans.

A 28 (1997) 1943.

[18] M. Fahrmann, P. Fratzl, O. Paris, E. Fahrmann, W.C. Johnson, Acta Metall. Mater.

43 (1995) 1007.

[19] S.H. Zhou, Y. Wang, C. Jiang, J.Z. Zhu, R.A. MacKay, L.Q. Chen, Z.K. Liu, in: K.A.

Green, H. Harada, T.M. Pollock, T.E. Howson, R.C. Reed (Eds.), Superalloys 2004,

Champion, PA, TMS (The minerals, Metals & Materials Society 2004), 2004, p.

969.

[20] N. Dupin, I. Ansara, B. Sundman, CALPHAD 25 (2001) 279.

[21] S.H. Zhou, Y. Wang, C. Jiang, J.Z. Zhu, L.-Q. Chen, Z.-K. Liu, Mater. Sci. Eng. A 397

(2005) 288.

[22] V.Y. Markiv, V.V. Burnashova, L.I. Pryakhina, K.P. Myasnikova, Izv. Akad. Nauk

SSSR Metall 5 (1969) 180.

[23] K. Schubert, A. Raman, W. Rossteutscher, Naturwissenschaften 51 (1964) 506.

[24] A. Raman, K. Schubert, Z. Metallkd 56 (1965) 99.

[25] M.F. Henry, Scripta Metall 10 (1976) 955.

[26] D.B. Miracle, K.A. Lark, V. Srinivasan, H.A. Lipsitt, Metall. Trans. A 15A (1984)

481.

[27] S. Chakravorty, D.R.F. West, Met. Sci 18 (1984) 207.

[28] M.P. Arbuzov, I.A. Zelenkov, Fiz. Metal. Metalloved. 15 (1963) 725.

[29] P. Nash, S. Fielding, D.R.F. West, Met. Sci 17 (1983) 192.

[30] Y.M. Hong, Y. Mishima, T. Suzuki, Mater. Res. Soc. Symp. Proc 133 (1989) 429.

[31] K. Wakashima, K. Higuchi, T. Suzuki, S. Umekawa, Acta Metall. 31 (1983) 1937.

[32] S. Chakravorty, D.R.F. West, J. Mater. Sci. 19 (1984) 3574.

[33] S. Chakrovorty, D.R.F. West, Mater. Sci. Technol. 1 (1985) 61.

[34] I.L. Svetlov, A.L. Udovskii, E.V. Monastyrskaya, I.V. Oldakovskii, M.P. Nazarova,

Russ. Metal (1987) 186.

[35] C.C. Jia, K. Ishida, T. Nishizawa, Metall. Mater. Trans. A 25 (1994) 473.

[36] B. Grushko, S. Mi, J.G. Highfield, J. Alloy. Compd. 334 (2002) 187.

[37] H. Yoshizawa, K. Wakashima, S. Umekawa, T. Suzuki, Scr. Metall. 15 (1981)

1091.

[38] H. Sprenger, H. Richter, J.J. Nickl, J. Mater. Sci. 11 (1976) 2075.

[39] Y. Jin, M.C. Chaturvedi, Y.F. Han, Y.G. Zhang, Mater. Sci. Eng. A 225 (1997) 78.

[40] G. Kresse, T. Demuth and F. Mittendorfer. ⟨http://cms.mpi.univie.ac.at/vasp/⟩

vol. 2003, 2003 .

[41] D. Vanderbilt, Phys. Rev. B 41 (1990) 7892.

[42] J.P. Perdew, J.A. Chevary, S.H. Vosko, K.A. Jackson, M.R. Pederson, D.J. Singh,

C. Fiolhais, Phys. Rev. B 46 (1992) 6671.

[43] A. van de Walle, M. Asta, G. Ceder, CALPHAD 26 (2002) 539.

[44] A.T. Dinsdale, CALPHAD 15 (1991) 317.

[45] O. Redlich, A.T. Kister, Ind. Eng. Chem. 40 (1948) 345.

[46] M. Hillert, M. Jarl, CALPHAD 2 (1978) 227.

[47] I. Ansara, B. Sundman, P. Willemin, Acta Metall. 36 (1988) 977.

[48] B. Sundman, I. Ansara, M. Hillert, G. Inden, H.L. Lukas, K.C.H. Kumar, Z. Metallk.

92 (2001) 526.

[49] C.R. Li, J.C. Hu, F.M. Wang, Z.M. Du, W.J. Zhang, CALPHAD 30 (2006) 387.