COMMERCIAL & INDUSTRIAL

M A N U FA C T U R I N G

Energy-Saving Solutions

for Manufacturing Companies

Creating More Goods

with Less Energy

SDG&E understands

the heavy energy load

that general and large

manufacturing companies

carry in their daily

operations, which is

why our energy-efficient

rebates, programs and

incentives work overtime

to save you energy

and money.

SDG&E® offers manufacturing companies

financial incentives, design assistance,

performance audits and training to build

greater energy-efficiency into their operations. Whether it’s making upgrades when

you buy new equipment or reducing usage

during periods of peak demand, SDG&E’s

energy management initiatives provide a

wide range of customized solutions to help

lower your electricity and natural gas costs

and solidify your bottom line.

Key Equipment Installations

to Reduce Energy Usage

Variable-Speed Drives — Installing

variable-speed drives on pumps, fans and

other equipment electronically controls

motor speed and can yield substantial

energy savings. For example, reducing fan

speed by 20% can reduce energy use by

up to 50%.

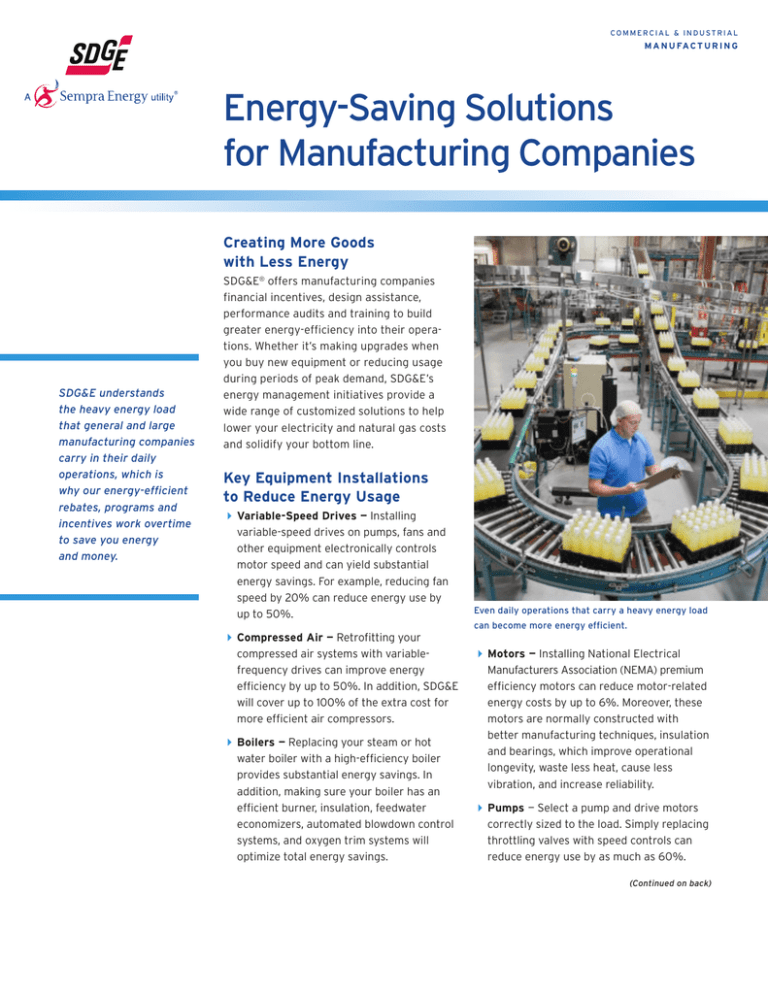

Even daily operations that carry a heavy energy load

can become more energy efficient.

Compressed Air — Retrofitting your

compressed air systems with variablefrequency drives can improve energy

efficiency by up to 50%. In addition, SDG&E

will cover up to 100% of the extra cost for

more efficient air compressors.

Boilers — Replacing your steam or hot

water boiler with a high-efficiency boiler

provides substantial energy savings. In

addition, making sure your boiler has an

efficient burner, insulation, feedwater

economizers, automated blowdown control

systems, and oxygen trim systems will

optimize total energy savings.

Motors — Installing National Electrical

Manufacturers Association (NEMA) premium

efficiency motors can reduce motor-related

energy costs by up to 6%. Moreover, these

motors are normally constructed with

better manufacturing techniques, insulation

and bearings, which improve operational

longevity, waste less heat, cause less

vibration, and increase reliability.

Pumps — Select a pump and drive motors

correctly sized to the load. Simply replacing

throttling valves with speed controls can

reduce energy use by as much as 60%.

(Continued on back)

COMMERCIAL & INDUSTRIAL

M A N U FA C T U R I N G

Solutions that Save Energy

on the Production Floor

Rebates — Rebates are the easiest way for you to earn

money on your energy-efficient purchases. For example,

qualifying variable frequency drives for HVAC fans, energyefficient lights, and storage heaters offer cash back for

upgrades. To get detailed information on eligible rebate

products, visit sdge.com/manufacturing or contact the

Energy Information Center at 1-800-644-6133

for an application.

Incentives — Our technology incentive payments help

offset the costs of energy-saving upgrades, whether that’s

the installation of new high-efficiency equipment or

systems, or the retrofit of existing infrastructure. Incentives

are based on the amount of energy saved. Be sure to

contact SDG&E early in the design process — or before you

start your project — to schedule the required pre-inspection

of your existing equipment and optional technical support.

Demand Response — Demand-response initiatives help

reduce electricity demand at peak times to prevent strain

on our system. For example, manufacturers can receive

financial incentives for reducing their energy use on hot

summer days.

Benchmarking — Benchmarking with the Environmental

Protection Agency’s ENERGY STAR® Portfolio Manager

allows you to track and assess energy performance across

your entire portfolio of buildings in a secure online environment. A Portfolio Manager will rate your facility’s energy

performance on a scale of 1 to 100 relative to similar

buildings nationwide. Additional information on energy

planning is available through our Continuous Energy

Improvements program at sdge.com.

Note: Beginning January 1, 2010 benchmarking will be

required for all commercial customers who participate in

energy-efficiency programs.

Upgrading your equipment with energy efficiency in mind can help

reduce your energy use and costs.

Audits — Our Technical Audit and Technology Incentives

provide on-site facility evaluations for customers using

20 kilowatts (kW) or more of electricity. These audits range

from simple site assessments to comprehensive engineering

studies and are designed to determine load reduction poten­tial while also identifying energy-efficiency opportunities.

Our energy-efficiency and demand-response initiatives plus

relevant equipment are designed to help reduce your energy

usage, lower your operating costs and generate real savings.

For more details on how our energy management solutions

can help you save money, contact your Account Executive

today or call our Energy Information Center at

1-800-644-6133.

1-800-411-SDGE (7343)

sdge.com

©2010 San Diego Gas & Electric Company.

All copyright and trademark rights reserved. 0980223 1209 XXM