ωω ωω - IIT Guwahati

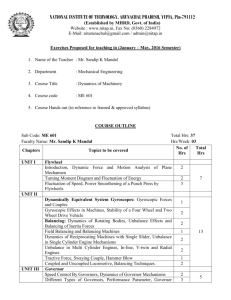

advertisement

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

CHAPTER 9

DYNAMIC BALANCING OF ROTORS

The unbalance in rotors will not only cause rotor vibrations, but also transmit rotating forces to the

bearings and to the foundation structure. The force thus transmitted may cause damage to the machine

parts and its foundation. If the transmitted force is large enough, it might affect even the neighbouring

machines and structures. Thus, it is necessary to remove the unbalance of a rotor, to as large an extend

as possible, for its smooth running. The residual unbalance estimation in rotor-bearing system is an

age-old problem. From the state of the art of the unbalance estimation, the unbalance can be obtained

with fairly good accuracy [9.1-9.5]. Now the trend in the unbalance estimation is to reduce the

number of test runs required, especially for the application of large turbogenerators where the

downtime is very expensive [9.6, 9.7].

•

Static balancing: Singe plane balancing (refer undergraduate dynamics of machinery course)

•

Dynamic balancing:

o

Two plane balancing: For rigid rotors only (ω < ω cr ) .

o

Flexible rotor balancing: If the shaft deflects, and the deflection changes with speed,

as it does in the vicinity of critical speeds (ω > ω cr ) .

9.1 Balancing of Rigid Rotor

9.1.1 Cradle balancing machine: The rotor is placed in the bearings of a cradle as shown in Fig. 9.1.

F1

I

II

+

+

F

F

F2

Figure 9.1 Craddle balancing machine

The cradle is placed on two springs and can be fulcrum about F1 or F2 to form a simple vibrating

system. Two fulcrum can be located at two chosen balance planes (i.e. I and II), where the

correction mass to be added. The rotor can be driven by a motor through a belt pulley

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

arrangement. If the spring system is such that the natural frequency of the system is in the range

of motor speed, the phase angle or the location of the mass in either plane can be determined as

follows. Fulcrum the cradle in plane I, by fixing F1 and releasing F2. Run the rotor to resonance,

observing the maximum amplitude to the right of fulcrum F2. This vibration is due to all the

unbalance in plane II, since the unbalance in plane I has no moment about F1. Use a trial mass at a

Amplitude of

vibration

chosen location and determine the amplitude of vibration.

Minimum

amplitude

Trial mass location θ

Figure 9.2 Plot of vibration amplitudes versus trial mass locations

Make a plot of this amplitude for different location of the same trial mass (see Fig. 9.2). The trial

mass for correction is added at the location where the amplitude of vibration is minimum. Increase or

decrease the trial mass at the same locations, until the desired level of balance is achived. Similar

procedure can be repeated bey Fixing F2 and releasing F1. This procedure is tedious and sometimes

may be time consuming. A procedure to determine the correction mass and location can be laid down

as follows, based on four observations of amplitude : (i) without any addition to the rotor (ii) with a

trial mass at θ = 00 (iii) with a trial mass at 1800 and (iv) with same trial mass at θ = ±900, where θ is

measured from a conveniently chosen location. This procedure has to be repeated for two cases (e.g.

when fulcruming at F1 and then for F2). Let OA is the amplitude measured with trial run (1), OB is the

amplitude measured in trial run (2) by addition of a trial mass Wt at 00 (arbitrary

chosen location on

rotor). Hence the vector AB will represent the effect of trial mass Wt. (At this stage we do not know

the location of vector OA on the rotor). OC is the vibration measured in trial run (3), with the trial

mass at 1800. So we will have AB = AC with 1800 phase difference between them (Hence AC vector

is also the effect of trial mass Wt so the magnitudes AB = AC and phase will be 1800). However we

know only OA, OB & OC from test run (1), (2) & (3) respectively & conditions AB = AC with 1800

phase. From these information we have to construct or locate points O, A, B & C on a plane.

378

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

Construction procedure

D

E’

C

A

~900 α

B

φ

E

O

Figure 9.3 A construction procedure for finding the unbalance vector

Erect a line OAD equal to 2OA. With O a center and OB & OC as radii and D as center and OC &

OB as radii draw arcs to intersect at B & C. Draw a circle with BC as diameter and A as center.

Construct the parallelogram OBDC (point B and C we will be obtained by above construction). Now

AB represent 00 position (i.e. reference line) and AC 1800 position on the rotor (AO is actual

unbalance). The angular measurement may be clockwise or CCW and is determined from the fourth

observation. The observation could be either OE or OE’ (+900 or –900). If the value observed is in the

vicinity of OE, then the angle to be measured CCW. However it will be CW if OE’ is the reading

observed in test (the fourth run also checks the validity of the linearity used in the balancing

procedure). The magnitude of trial mass Wt is proportional to AB. The unbalance OA can be obtained

accordingly in mass term. The location of unbalance is ∠OAB and the direction from figure (i.e. CW

or CCW). The test is repeated by making the cradle pivoted at FII and measurements made in plane I.

This procedure is very time consuming and also restricts the mass and size of the rotor. Modern

balancing machines use amplitude and phase measurement in two planes for balancing a rotor. The

machines are either soft support or hard support machines.

379

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

900

0

E

O

Location of fourth

90

00

0

0

270

Unbalance position at shaft

location, (ccw direction +ve)

900

0

0B

A

1800

A

0

measurement for trial mass

at 900 (ccw dir. +ve)

0B

00

φ

2700

O

Location of fourth

measurement for trial

mass at 900 (cw dir. +ve)

Unbalance position

at shaft location

(ccw dir. +ve)

900

+ve

φ

1800

A

B

00

0

measurement for trial mass

at 2700 (ccw dir. +ve)

+ve

φ

00

φ

O

Location of fourth

+ve

φ

1800

φ

E’

2700

900

900E

φ

A

0B

+ve

270

Unbalance position at shaft

location, (ccw direction +ve)

φ

O

Location of fourth

measurement for trial

mass at 2700 (cw dir.

+ve)

1800

E’

2700

00

2700

Unbalance position

at shaft location

(ccw dir. +ve)

Figure 9.4 Procedure of obtaining the sense of the unbalance mass angular position

Example 9.1 In the balancing process we make the following observations: (i) ao = amplitude of

vibration of the unbalanced rotor “as is” (ii) a1 = amplitude with an additional one-unit correction at

the location 0 deg and (iii) a2 = same as a1 but now at 180 deg.

The ideal rotor, unbalanced only with a unit unbalance (and thus not containing the residual

unbalance), will have certain amplitude, which we cannot measure. Call that amplitude x. Let the

unknown location of the original unbalance be ϕ. Solve x and ϕ in terms of a0 , a1 and a2 show that in

this answer there is an ambiguity sign. Thus four runs are necessary to solve the problem completely.

Answer: Measurements are

(i) a 0 = amplitude of vibration with residual unbalance U R ∠ϕ

(ii) a1 = amplitude with unit trial mass at an angle of 0 0

(iii) a 2 = amplitude with unit trial mass at an angle of 180 0

(iv) x = amplitude with 1 at an angle of 0 0 and without residual imbalance (i.e. U R = 0 )

OA = a 0 , AB = a1 and AC = a 2

380

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

Figure 9.5 shows variation parameters involved in the present problem. From ∆OAB , we have

cos ϕ =

a02 + OB 2 − a12

2a0 OB

(A)

and

cos (π − ϕ ) =

a02 + OC 2 − a22

2a0 OC

(B)

Since O B = O C , we have

− cos ϕ =

a02 + OB 2 − a22

2a0OB

(C)

D

C

x

x

Reference

line

0

ϕ a0

a2

B

a1

A

Figure 7.5 Geometrical constructions for

determination of unbalance

On equating equations (A) and (C), we get

2a0 OB cos ϕ = −(a02 + OB 2 − a22 ) = (a02 + OB 2 − a12 )

which gives

2a 02 + 2O B 2 − (a12 + a 22 )

(D)

O B = x , since O B (or O C ) are effect of trial mass of unit magnitude. Hence equation (D) gives

x 2 = (a12 + a 22 ) / 2 − a 02

or

x=±

381

1

2

(a12 + a22 ) − a02

(E)

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

Equations (A) and (C) gives (noting that O C = O B = x ),

x 2 = 2a 0 x cos ϕ − a 02 + a12

(F)

x 2 = −2a 0 x cos ϕ − a 02 + a 22

(G)

and

On equating equations (F) and (G), we get

cos ϕ = (− a12 + a 22 ) / 2a 0 x

(H)

Equation (E) gives the magnitude of the unbalance and equation (H) gives the magnitude of the phase

angle, the direction or sense of the phase cannot be obtained from only above measurements.

Example 9.2. A short rotor or flywheel has to be balanced. Observations of the vibration at one of the

bearings are made in four runs as follows:

amplitude 6.0 µm

amplitude 5.0 µm

amplitude 10.0 µm

amplitude 10.5 µm

Run 1; rotor “as is”

Run 2; with 5gm. at 0 deg.

Run 3; with 5 gm. at 180 deg.

Run 4; with 5gm. at 90 deg.

Find the weight and location of the correction. Take the trial and balancing masses at the same radius.

Answer:

E

D

C

A

line B

nce

e

r

e

Ref

O

OA = AD = 6 cm

DB =10 cm

OB = 5 cm

OE = 10.5 cm

AB = 6.3 cm

Imbalance position

= angle BAO

= 71 deg. CCW

71°

Figure 9.6 Geometrical constructions

382

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

Figure 9.6 shows the geometrical construction of the present problem with lengths of various arcs.

From this the net effect of the imbalance is given as

AB = 6.3 cm ≡ 5 gm

Hence, the residual imbalance is given as

OA = AD = 6 cm ≡ 4.762 gm

AB is the reference line. The fourth observation is intersecting at E, hence angle to be measured in the

CW direction (i.e. ∠BAE ). Hence, the unbalance position is given as ∠BA0 = 710 CCW direction.

The unbalance magnitude and phase can be also obtained from equations (E) and (H), we have

x=±

1

2

(a12 + a22 ) − a02 = ? kg

and

cos ϕ = ( − a12 + a 22 ) / 2a 0 x = ? degree

Exercise 9.1 A rotor is being balanced in the cradle-balancing machine by pivoting rotor about a

fulcrum (e.g. F1). The following amplitudes of vibrations are observed at the critical speed: (i) 14 µm

for the rotor without additional weights, (ii) 10 µm with 5 gm placed in location 0 deg, (iii) 22 µm

with 5 gm placed in location 90 deg and (iv) 22 µm with 5 gm placed in location 180 deg. Find the

amount and angular location of the necessary correction mass.

Exercise 9.2 A rotor is being balanced in the cradle-balancing machine by pivoting rotor about a

fulcrum (e.g. F1). The following amplitudes of vibrations are observed at the critical speed:

1. 14 µm for the rotor without additional weights

2. 10 µm with 5 gm placed in location 0 deg.

3. 22 µm with 5 gm placed in location 90 deg

4. 22 µm with 5 gm placed in location 180 deg

Find the amount and angular location of the necessary correction mass.

383

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

9.1.2 The Influence Coefficient Method

Definition of Influence coefficients: Figure 9.7(a) shows that when a force F1 is applied at station 1

and due to this force the beam deflections at stations 1 and 2 are given as

y11 = displacement at station 1 due to force F1 at station 1 = α 11 F1

and

y21 = displacement at station 2 due to force F1 at station1 = α 21 F1

where α is the influence coefficient and its first subscript represents the displacement station and

second represents the force station. Similarly for Figure 9.7(b), we have

y12 = α 12 F2

1

y22 = α 22 F2

and

F1

y11

F2

1

2

y22

y12

(i) Only force F1

2

y22

(ii) Only force F2

F1

F2

y1

y2

(iii) When both F1 and F2 are present

Figure 9.7 Definition of influence coefficients

In Figure 9.7(c), we have

y1 = y12 + y12 = α11 F1 + α12 F2

⇒

y2 = y21 + y22 = α 21 F1 + α 22 F2

y1 α11 α12 F1

=

y2 α 21 α 22 F2

Influence coefficients can be obtained by experimentation or by strength of formulae i.e.

α11 =

y11

y

, α 21 = 21 etc.

F1

F1

384

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

In soft support machines, the resonant frequency of the rotor support system is low and the rotor runs

at a speed above the resonance of the support system. Vibratory amplitudes are measured, which are

then converetd to forces. In hard support system, the support natural frequency is very high and they

measure the rotor unbalance forces directly, independent of rotor mass and configuration. The

balancing procedure is based on influence coefficient measurement. We choose two convenient planes

L and R for trial mass and two measurement planes a and b (can be chosen as bearing locations) as

shown in Figure 9.7. Let L1 and R1 be the initial readings of vibration levels (displacement, velocity

or acceleration) measured with phase angle γ 1 and δ 1 respectively.

L

L1

a

γ1

L1

R

b

No trial mass

αaR

R1

L2

γ2 Trial mass TR

δ2

L1

R3

Trial mass TL

αbR

R2

αbL

γ3

R1

δ1

δ3

R1

αaL

L3

Figure 7.7 Bearing measurements and influence

coefficients for a rigid rotor

The phase angles are measured with the same reference during the test and their relative locations

with respect to rotor is initially known. In the second run, place a trial mass TR at a convenient

location in plane R and let the observations be L2 and R2 with phase γ 2 and δ 2 respectively in the a

& b planes. The difference between R2 and R1 will be the effect of trial mass in right plane R on the

measurement made in plane b. We can denote this as an influence coefficient α bR .

α bR = ( R2 − R1 ) / TR

(9.1)

where " →" represent vector since displacement has magnitude and phase information. Similarly

385

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

α aR = ( L2 − L1 ) / TR

(9.2)

We remove the trial mass from plane R and place TL in plane L and repeat the test to obtain the

measured values

α bL = ( R3 − R1 ) / TL

α aL = ( L3 − L1 ) / TL

and

(9.3, 9.4)

With the help of equations (9.1) to (9.4), we can obtain influence coefficient experimentally. Let the

correct balance masses be W R and W L . Since the original unbalance response is R1 and L1 as

measured in right and left planes, we can write

− R1 = WRα bR + WLα bL

and − L1 = WRα aR + WLα aL

(9.5)

Correction masses will produce vibration equal and opposite to the vibration due to unbalance masses.

Hence,

R1

α bR

= − α aR

L1

α bL WR

α aL WL

(9.6)

These can be calculated either by a graphical method or analytical method of vectors (complex

algebra) i.e.

a b

c d

which gives

−1

=

1 d − b

∆ − c a

where ∆ = (ad − cb)

L1 .α bL − R1 .α aL

WR = α bR .α aL − α aR .α bL

and

386

R1 .α aR − L1 .α bR

WL = α bR .α aL − α aR .α bL

(9.7)

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

Phase mark

on shaft

Accelerometer

Measurement

Plane ‘a’

Accelerometer

(or proximity

probes on the

shaft near to the

bearing)

R

L

Photo electric

Probe

Measurement

Plane ‘b’

θ

Charge

Amplifier

Phase

meter

Oscilloscope

θ

Maximum

displacement

location

Vibration

meter

Photo sensitive

mark

Hardware or virtual instrumentation

Photo electric probe

Figure 9.8 Experimental set-up for the influence coefficient method of balancing

Signal from station a shaft

t2

T

Spike due to

notch in the

shaft surface

reference signal

Phase lag = 0 with respect to the

notch

t1

2πt1

radians and

T

2πt 2

Phase lag =

radians

T

Phase lead =

Figure 9.9 A procedure of experimental phase measurement with the help of oscilloscope

387

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

Example 9.3 A rigid rotor machine is exhibiting vibration problems caused by imbalance. The

machine is symmetric about its center-line. A trial balance mass of 0.3 kg is sited at end 1 at an angle

of 300 relative to some reference position; this causes changes in vibration vectors of 50 µm at 610 at

end 1 and 42 µm at 1300 at end 2. Determine the influence coefficients for use in balancing the

machine, and calculate the balance mass required at each end of the machine if the measured

imbalance vibrations are –30 µm at 2300 at end 1 and –70 µm at 3300 at end 2.

Solution: Given data are

Trial mass in plane 1: TR = 0.3 kg at 300 phase , which can be written as

1

TR1 = 0.3(cos30 + j sin 30) = ( 0.2598 + j 0.15 ) kg

Displacement in plane 1: R2 = 50 µm at 610 phase , which can be written as

R2 = ( 24.2404 + j 43.73) µm

Displacement in plane 2: L2 = 42 µm at 1300 phase , which can be written as

L2 = ( −26.997 + j 32.173) µm

Measured responses due to residual imbalances are

In plane 1: R1 = −30µm at 2300 phase ≡ R1 = (19.2836 + j 22.98 ) µm

In plane 2: L1 = −70µm at 3300 phase ≡ L1 = ( −60.621 + j 35 ) µm

We have, influence coefficients as

α11 = α bR =

R2 - R1

= (48.8919 + j 51.63766) × 10−6 µm/kg

TR1

α12 = α aR =

L2 - L1

= (92.3559 − j 69.1995) × 10−6 µm/kg

TR1

and

388

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

It is given that machine is symmetric about centreline.

α 21 = α12 and α 22 = α11

Measurements, influence coefficients and correction mass are related as

− R1 α11 α12 wR

=

− L1 α 21 α 22 wL

which can be simplified as

wR =

1

1

{L1α12 − R1α 22 } and wL = {R1α 21 − L1α11}

∆

∆

with

2

2

∆ = α11α12 − α12 α 22 = α11

− α12

= ( −468.066 + j 16907.73 × 10−6 ) (µm/kg)2

which gives the balancing mass and its angular position as

wR = −3.3519 × 10 −3 + j 7.123 × 10−3 ≡ 7.893 × 10-3 kg at 2950

and

wL = 3.90356 × 10−3 − j 2.7136 × 10−3 ≡ 4.7541 × 10-3 kg at ???0

Exercise 9.3 Obtain the correction masses in the right and left planes for a rigid rotor by using the

influence coefficients balancing method for the following observations: (i) The original unbalance

vectors as measured for a turbine rotor are: L1 = 9.144×10-3 mm peak to peak at 900 and R1 = 10.16

×10-3 mm peak to peak at 450 (ii) The trial mass in right plane TR = 6.8 gm at 22.50: L2 = 5.08 ×10-3

mm peak to peak at 270 and R2 = 6.35 ×10-3 mm peak to peak at 990 (iii) The trial mass in left plane TL

= 6.8 gm at 360: L3 = 9.40×10-3 mm peak to peak at 00 and R3 = 30.5 ×10-3 mm peak to peak at 990.

Exercise 9.4 For finding unbalance in the rotor the following measurements were made in the right

and left balancing plane (i). Without trial mass: L1 = 0.0015 mm ∠ 1500 ; R1 = 0.0007 mm ∠ 1620 (ii)

Trial mass at left plane TL = 29 gm ∠00 : L2 = 0.0015 mm ∠1100 ; R2 = 0.0015 mm < 1700 (iii) Trial

389

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

mass at right plane TR = 29 gm ∠00 : L3 = 0.0025 ∠ 2000; R3 = 0.0015 ∠ 1700. Obtain the influence

coefficient and correction masses in the right and left balancing planes.

Exercise 9.5 For the dynamic balancing of a rotor by using influence coefficients method, if the

uncertainty in the measurement of the vibration amplitude and phase are 2 and 5 percent, respectively.

Calculate the uncertainty of the magnitude and the phase of influence coefficients and correction

masses. Give all the intermediate formulations

9.2 Balancing of Flexible Rotors

As long as the rotor experiences no deformations i.e. it remains as a rigid rotor, the balancing

procedure discussed earlier is effective. Once the rotor bends while approaching a critical speed, the

bend center line whirls around and additional centrifugal forces are set-up and the rigid rotor

balancing becomes ineffective. (sometimes rigid rotor balancing worsens bending mode whirl

amplitude). Two different techniques are generally employed (i) Modal balancing technique. Bishop,

Gladwell & Parkinson and (ii) Influence coefficient method. Tessarrik, Badgley and Rieger.

9.2.1 Modal Balancing Method

A practical procedure to balance the rotor by model correction, masses equal in number to the flexible

mode shapes, N, known as N-plane method. Run the rotor in a suitable hard bearing-balancing

machine, to a safe speed approaching the first critical speed and record the bearing vibrations or

forces. Choose an appropriate location for the trial mass. For first critical speed, this should be

roughly in the middle for a symmetrical rotor in its axial distribution of mass. Record the readings at

the same speed as before.

(a) Rigid body modes

1

(b) First flexible mode

2

(c) Second flexible mode

Figure 9.10 Typical rigid and flexible modes of rotor-bearing systems

390

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

Using the above two readings, the correct mass and location can be determined. (single plane

balancing). With this correction mass, it should be possible to run the rotor through the first critical

speed without appreciable vibration. Next, run the rotor to a safe speed approaching the second

critical speed, if the operating speed is near the second critical or above the second critical speed.

Note the readings. Add a pair of trial masses 1800 apart in two planes without a affecting the first

mode (in fact if we try to balance one particular mode it will not affect balancing of other modes).

Note the readings at the same speed near the second critical speed. Two readings can be used to

determined the correction mass required. Similarly higher modes can be balanced i.e. upto Nth mode

can be balanced by N balancing planes. Instead of N plane correction, Kellenberger suggested that the

rotor should be corrected in N+2 planes, so as not to disturb the rigid body balancing.

z

x

bearing axis

y

Figure 7.11 Rotor-brearing axis system

Assume that all unbalance is distributed only in the x-y plane (Figure 9.11). Let the rotor speed be ω

and the deflection of the rotor be y(x). The deflection y(x) can be written in terms of summation of

mode shapes as

y ( x) = ∑ φiYi ( x)

(9.8)

where Yi ( x) is the mode shape in the ith mode and φ i is an unknown constant. The deflection y(x) can

be measured experimentally. For example, for simply supported end conditions, mode shapes are

πx

I - mode

y1 ( x) = sin

II - mode

y2 ( x) = sin

2π x

l

ith - mode

yi ( x) = sin

iπ x

l

l

391

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

For other end conditions mode shapes can be obtained by the free vibration analysis. Modal series for

eccentricity can also be written as

a( x) = ∑ α iYi ( x )

(9.9)

i

It can be written in terms of mode summation since the y(x) is the result of a(x). The main objective is

to find out α i for the eccentricity distribution to be known. Multiplying (9.8) by the mass per unit

length m(x) and the mode shape Y j ( x) would shape and integrate from 0 to l.

∫0 m( x) y( x)Y j ( x) = ∫0 m( x) ∑i φiYi ( x)Y j ( x)dx

l

l

(9.10)

Noting the orthogonality condition of mode shapes, we have

l

∫ m( x)Y ( x)Y ( x)dx = 0 for all i ≠

i

j

j

(9.11)

0

Equation (9.10) gives

l

l

l

∫ m( x) y( x)Y j ( x)dx = ∫ m( x)φ jY j ( x)dx =φ j ∫ m( x)Y j ( x)dx

2

0

2

0

(9.12)

0

which can be written as

l

φj =

1

m( x) y ( x )Y j ( x)dx

M j ∫0

(9.13)

with

l

M i = ∫ m( x)Y j2 ( x)dx

0

where M j is the generalized mass in jth mode and it can be obtained by knowing m( x) and Y j ( x) .

The m( x) can be obtained by free vibration analysis and y ( x) theoretically speaking can be found by

experiment. Governing equation for the shaft motion is given as

392

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

d2

{EI ( x) y′′( x)} = ω 2 m( x){ y ( x) + a( x)}

dx 2

(9.14)

where ω is the rotor speed. On substituting for y(x) and a(x) from equations (9.8) and (9.9)

respectively, we get

d2

EI ( x ) ∑ φiYi ′′( x) = ω 2 m( x ) ∑ φiYi ( x ) + {∑ α iYi ( x )}

2

dx

i

i

(9.15)

Noting the orthoganality condition and multiply both sides by Y j ( x) and integrate over the length of

shaft, the left hand side of equation (9.15) gives

l

d2

EI ( x ) ∑ φiYi″ ( x ) Y j ( x)dx

2

i

∫ dx

0

On performing integration by parts, we get

Y j ( x)

l

l

d

d

EI ( x ) {∑ φiYi ′′( x)} − ∫ EI ( x) ∑ φiYi ′′( x) Y j′′( x)dx

0

dx

i

0 dx

First term vanishes (since it is zero for all boundary conditions), on taking integration by parts, we get

[

− Y j′ ( x) EI ( x)

{∑φ Y ′′( x)}] + ∫ EI ( x)∑φ Y ′′( x)Y ′′( x)dx

l

i i

l

i i

0

0

j

i

First term again vanishes for all boundary conditions. On noting the orthogonality condition equation

(9.11), we get

l

[

∫

]

= φ j EI ( x) Y j′′( x) 2 dx = φ j K j

(9.16)

0

where the generalized stiffness in jth mode is defined as

l

Kj =

∫ EI ( x)[Y ′′( x)] dx

2

j

0

393

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

From right hand side of equation (9.15), noting equation (9.8) and (9.9), we have

ω 2 (φ j + α j )M j

(9.17)

Therefore from (9.15), noting equations (9.16) and (9.17), we have

φ j K j = ω 2 (φ j + α j )M j

which can be rearranged as

αj =

K j / M j −ω2

ω2

φj

(9.18)

where α j is an known, then distribution of eccentricity a (x) can be found from equation (9.9). The

equation (9.18) requires m(x), y(x), Y j ( x) and p j = K j / M j . The m(x) can be accurately found out,

y(x) is difficult to obtained, Y j ( x) is obtained by the eigen analysis and p j ( x) is natural frequency in

ith mode = K j / M j which can be obtained by the eigen analysis.

9.7.2 Influence Coefficient Methods

Figure 9.12 shows the effect of deflection of the shaft on influence coefficients. It can be seen that

they depend upon shaft speeds (especially near critical speeds).

F1

(a)

2

1

α 21

α11

ω << p1

2

1

′

α 21

′

α11

ω ≈ p1

(b)

(c)

2

′′

α 21

ω = p2

Figure 7.12 Effect of mode shapes on influence coefficients

394

F1

′′

α11

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

p

x

q

z

Figure 9.13 Measurement locations (q) and balancing planes (p)

Choose p number of balancing planes (where mass can be added or chip-off) where p>2, q number is

measuring planes; generally it is two i.e. at bearing planes. Let the unbalance ( me ) in each of the

balancing planes be U 1 , U 2 , … , U p

v1 α11 α12

v α

2 21 α 22

=

vq α q1 α q 2

… α1 p U 1

… α 2 p U 2

α qp U p

(9.19)

where v is the vibration measurement at the measuring plane. Measurements are taken at number of

speeds. On writing equation (9.19) for each of the speeds, we get

{ν } = [α ]{U }

(9.20)

with

395

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

1

α11

1

α 21

1

α q1

α 2

11

[α ] = α 2

q1

n

α11

α 21n

α n

q1

v11

1

v2

1

vq

v 2

1

{v} = 2 ;

vq

n

v1

v n

1

v n

q

α121 … α11p

1

α 22

… α 21 p

1

1

α q 2 … α qp

α122 … α12p

;

α q22 … α qp2

α12n … α1np

α 22n α 2n p

α qn2 … α qpn

U1

U2

[U ] = U 3

U p

Once the influence coefficients [α ] are known for all speeds equation (9.20) can be used to obtained

unbalances :

(

)

−1

{U } = [α ]T [α ] {v}

(9.21)

Influence coefficient matrix can be obtained by attaching trial mass and measuring displacement, from

equation (9.19), we get for a particular speed

1

1

v111 α 11 α 12

1

1 1

v21 α 21 α 22

=

1

vq11 1

α q1 α q 2

… α 1 U + T

1p

1

R

1

… α U2

2p

1 U p

… α qp

(9.22)

On subtracting equation (9.22) from first q equation in equation (9.19), we get

α 1 α 1

v111 − v11 11

12

1 1 α1 α1

v21 − v2

21

22

=

vq11 − vq1 α1 α1

q1

q2

… α1 1 p T

1 R

… α 0

2p

… α 1 0

qp

Equation (9.23) gives

396

(9.23)

Dr R Tiwari, Associate Professor, Dept. of Mechanical Engg., IIT Guwahati, (rtiwari@iitg.ernet.in)

vq11 − vq1

1

v111 − v11 1 v211 − v21

α 11 =

, α 21 =

,… , α =

q1

TR

TR

TR

1

(9.24)

Similarly by attaching a trial mass on plane 2 we get second column of the influence coefficient

matrix in equation (9.24), the above analysis should be done at a constant speed. Similarly we can

find the influence coefficient-matrix for different speeds.

Exercise 9.6 Justify your answer for the following cases: a) For the dynamic balancing of a flexible

rotor at one particular speed how many minimum numbers of balancing-planes are required? b) For

the dynamic balancing of a flexible rotor, in general, how many minimum balancing-planes are

required? c) For flexible shaft whether imbalance changes with the shaft speed? d) Apart from

balancing the rotor what are the other methods by which the amplitude of the synchronous whirl can

be reduced?

REFERENCES

[1] W. Kellenburger 1972 Transactions of the American Society of Mechanical Engineers, Journal of

Engineering for Industry 94, 584-560. Should a flexible rotor be balanced in N or N+2

planes?

[2] J. Drechsler 1980 Institution of Mechanical Engineers Conference on Vibrations in Rotating

Machinery, Cambridge, UK, 65-70. Processing surplus information in computer aided

balancing of large flexible rotors.

[3] P. Gnilka 1983 Journal of Vibration 90, 157-172. Modal balancing of flexible rotors without test

runs: an experimental investigation.

[4] J.M. Krodkiewski, J. Ding and N. Zhang 1994 Journal of Vibration 169, 685-698. Identification of

unbalance change using a non-linear mathematical model for rotor bearing systems.

[5] M.S. Darlow 1989, Balancing of High-Speed Machinery, Springer-Verlag.

[6] S. Edwards, A.W. Lees and M.I. Friswell 2000 Journal of Sound and Vibration, 232(5),

963-992. Experimental Identification of Excitation and Support Parameters of a

Flexible Rotor-Bearings-Foundation System from a Single Run-Down.

[7] R. Tiwari, 2005, Mechanical System and Signal Processing, Conditioning of Regression Matrices

for Simultaneous Estimation of the Residual Unbalance and Bearing Dynamic Parameters (in

press).

[8] IS 5172 : 1969 Specification for Balancing Bench,

[9] IS 13274 : 1992/ISO 1925 : 1990 Mechanical vibration - Balancing – Vocabulary.

[10] IS 13275 : 1992/ISO 2371 : 1974 Description and evaluation of field balancing equipment.

[11] IS 13277 : 1992/ISO 2953 : 1985 Balancing machine - Description and evaluation.

[12] IS 13278 : 1999 /ISO 3719 : 1994 Mechanical Vibration - Symbols for Balancing Machines and

Associated Instrumentation.

[13] IS 13280 : 1992/ISO 5406 : 1980 Mechanical balancing of flexible rotors.

[14] IS 14280 : 1995/ISO 8821 : 1989 Mechanical vibration - Balancing - Shaft and fitment key

convention.

[15] IS 14734 : 1999 /ISO 7475 : 1984 Balancing Machines - Enclosures and Other Safety Measures.

[16] IS 14918 : 2001 Mechanical Vibration - Methods and Criteria for the Mechanical Balancing of

Flexible Rotors

397