Thermocouple General Specifications

Thermocouple

General Specifications

Seebeck Effect

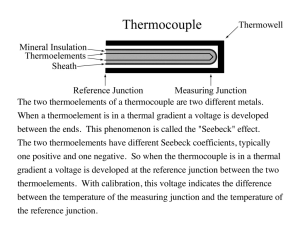

Thermocouples were discovered in 1821 when Thomas J. Seebeck observed the phenomenon of thermoelectricity - the Seebeck Effect. When two dissimilar metals are joined creating two junctions and those "sensing junctions" are at different temperatures - an electric current flows through the created circuit. The emf is proportional to the temperature difference and is measured in mV.

Thermocouple measurements are deduced from the millivolt reading and the known reference junction temperature. A signal converter must make the millivolt reading and compare the millivolt value of the reference junction at a known temperature to be able to make the temperature measurement.

Hot or

Hot or

Measuring

Junction

Cold or

Cold or

Reference

Junction

Selection of a Thermocouple

Factors to consider when selecting a thermocouple:

· Temperature Range

· Media

· Required Response Time

· Accuracy

· Measurement System Installation

· Cold Junction Compensation

· Leadwire Compatibility

Standard Thermocouples

Any combination of dissimilar metals will create the

Seebeck Effect; however eight wire combinations are predominately used in thermocouples in the

United States. They are types: J, K, T, E, R, S, B

& N.

Refer to the chart on the following page for characteristics of each type.

Thermocouples are designated by capital letters that refer to their composition according to the American National Standards

Institute (ANSI). They have been chosen for stability of EMF, ability to be replicated, mechanical and chemical properties, and costs.

Rev 0204 43

Standard Thermocouple Characteristics

Type Wire Materials

J Iron (+)

Constantan (-)

Wire Insulation Recommended

Coloring Atmosphere

White

Red

Vacuum, Inert,

Oxidizing or Reducing

K

T

E

N

R

S

B

Chromel (+)

Alumel (-)

Copper (+)

Constantan (-)

Chromel (+)

Constantan (-)

Nicrosil (+)

Nisil (-)

Platinum-13%/

Rhodium (+)

Platinum-10%/

Rhodium (+)

Platinum (-)

Platinum-30%/

Rhodium (+)

Platinum (-)

Yellow

Red

Blue

Red

Purple

Red

Orange

Red

Black

Red

Black

Red

Grey

Red

Features

Inert or Oxidizing

Vacuum, Inert,

Oxidizing or Reducing

Inert, Oxidizing or

Reducing

Inert or Oxidizing

Inert or Oxidizing

Inert or Oxidizing

Inert or Oxidizing

Most commonly used. Iron wire may rust or become brittle at sub-zero temperatures. If unprotected, iron wire may be attacked by ammonia, nitrogen and hydrogen atmospheres.

Type J should not be used in sufurous atmospheres about 540°C.

Generally used to measure high temperatures to

2300°F. Should not be used for accurate measurement to below 900°F or after prolonged exposure above 1400°F. Short life in alternately oxidizing and reducing atmospheres.

Commonly used for sub-zero to 700°F temperature. Superior corrosion resistance.

Preferred to type J for sub-zero applications due to copper’s higher moisture resistance, as compared to iron.

Highest EMF output of any standard metallic thermocouple. Wires are not subject to corrosion at sub-zero temperatures.

Developed for oxidation resistance and EMF stability superior to those of type K thermocou ples at elevated temperatures. Popular in

Europe.

Good linearity at high temperatures. Should always be protected from contamination insulation should be silica free.

Widely used in laboratories as a standard for calibration of base metal thermocouples and other temperature sensing instruments.

For use between 1000 and 3175°F. As with other platinum thermocouples, protection from contamination with silica-free insulation is required.

Typical Response Time for MgO Constructed Thermocouples

Thermocouple O.D. (inch) Measuring Junction Typical Response (seconds)

1/50

1/50

1/25

1/25

1/16

1/16

1/8

1/8

3/16

3/16

1/4

1/4

1/4

Grounded 0.05

Ungrounded 0.15

Grounded 0.1

Ungrounded 0.3

Grounded 0.2

Ungrounded

Grounded

Ungrounded

Grounded

Ungrounded

0.5

0.7

1.3

1.1

2.2

Grounded

Ungrounded

Exposed

2.0

4.5

0.1

44 Rev 0204

Junction Type/Description

Ungrounded Junction

Thermocouple junction is insulated from sheath and ground.

Provides better performance under noisy conditions. Slower response time than grounded junction thermocouples.

Grounded Junction

Thermocouple junction is an integral part of the sheath. Provides fast response time and is least expensive construction. Susceptible to ground loops and noise interference.

Exposed Junction

Thermocouple junction extends beyond sheath. Provides fastest response. Not suitable for pressurized or corrosive environments.

Moisture will affect performance.

Initial Thermocouple Tolerances

Thermocouple

N

R

S

B

J

K

T

E

Range

32 to 1400°F

-328 to 2300°F

-328 to 700°F

-328 to 1600°F

-454 to 2372°F

32 to 2700°F

32 to 2700°F

32 to 3100°F

ANSI Standard Limits of Error ANSI Special Limits of Error

(Whichever is greater) (Whichever is greater)

Weed Standard

±4.0°F or 0.75%

±4.0°F or 0.75%

±1.8°F or 0.75%

±3.0°F or 0.50%

±4.0°F or 0.75%

±2.7°F or 0.25%

±2.7°F or 0.25%

±0.50%

±2.0°F or 0.40%

±2.0°F or 0.40%

±0.9°F or 0.40%

±1.8°F or 0.40%

±2.0°F or 0.40%

±1.1°F or 0.10%

±1.1°F or 0.10%

±0.25%

Weed Instrument Company uses only ANSI Special Limits of Error in its manufacturing of thermocouples.

Rev 0204 45